Card to Bundle in One Pass

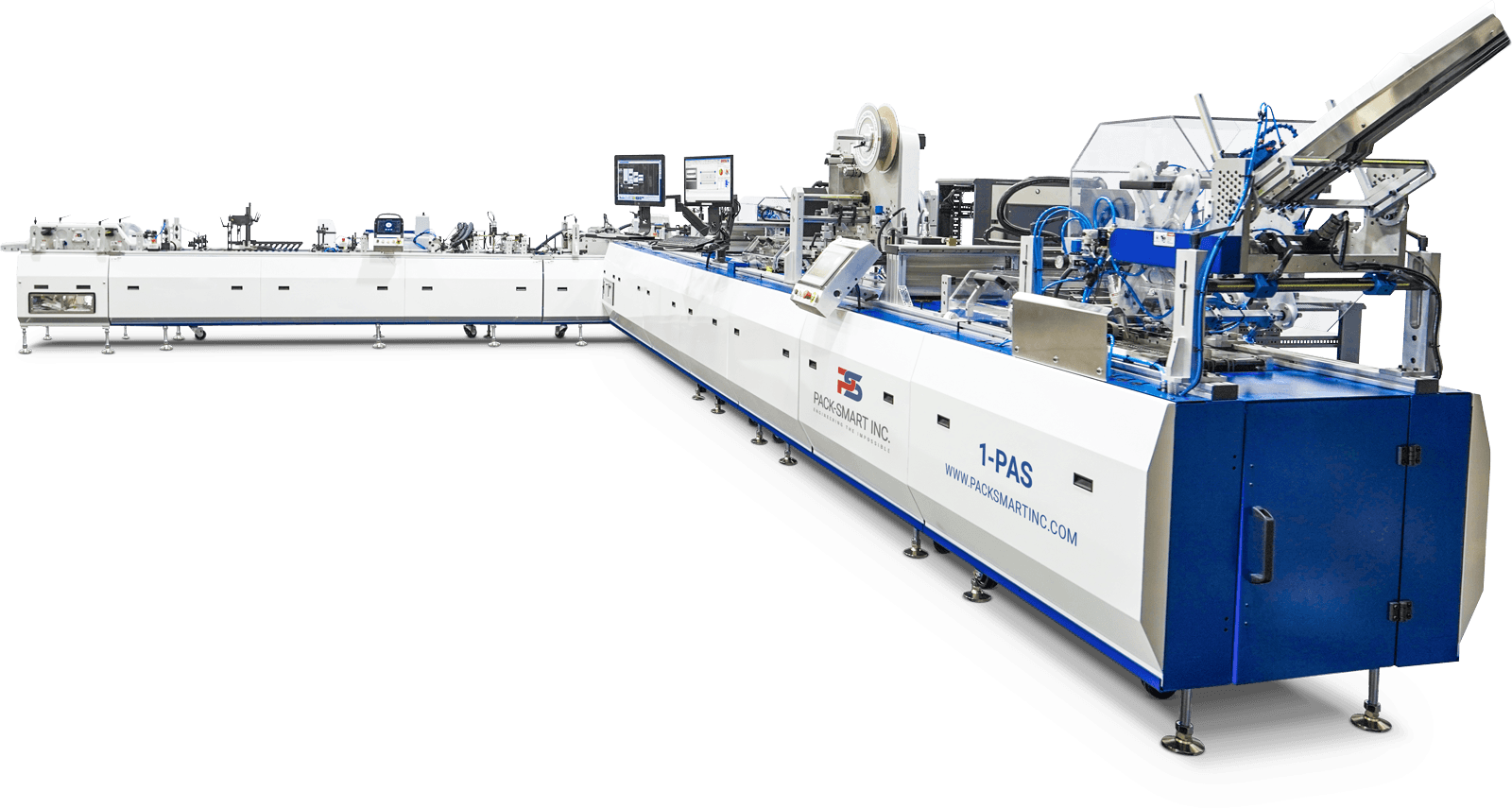

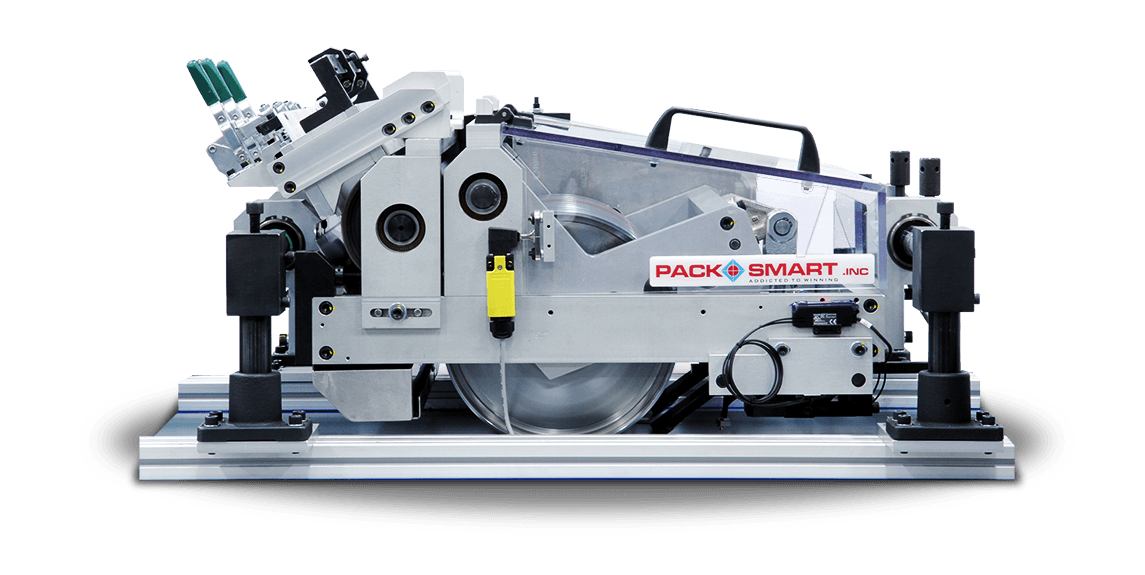

World’s first inline solution for high volume personalization, affixing, packaging and pack-out of secure open and closed loop cards at 20,000 PPH.

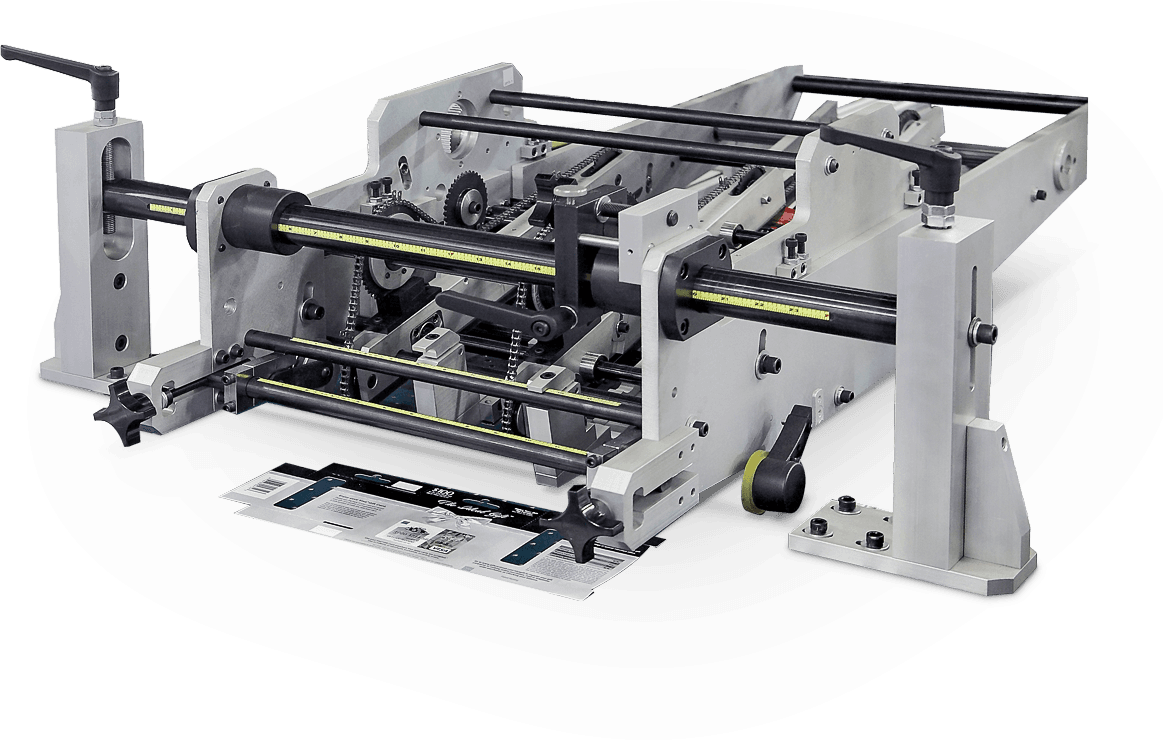

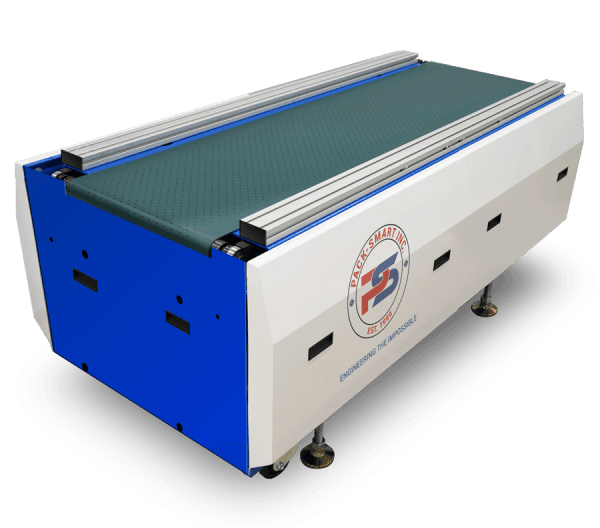

Enhance your production line with the ABM Automatic Product Alignment Module, designed to ensure precise alignment and placement of products with minimal changeover time.

The ABM Automatic Product Alignment Module is engineered to optimize the precision of product placement in high-speed production lines.

This module ensures accurate registration of affixed items, improving the overall efficiency and reliability of the production process.

Designed for continuous operation, the ABM module features modern servo motor technology and robust construction, making it ideal for various applications, including feeding plastic cards, labels, and product samples.

The ABM — Automatic Product Alignment is a precision-engineered technology designed for seamless integration and unparalleled accuracy. This system operates as a singular, optimized solution with no variations, ensuring consistent performance and reliability across all applications. Its simplicity and efficiency make it the ideal choice for environments requiring flawless product alignment without the complexity of customization.

This technology is used in the following automated systems.

World’s first inline solution for high volume personalization, affixing, packaging and pack-out of secure open and closed loop cards at 20,000 PPH.

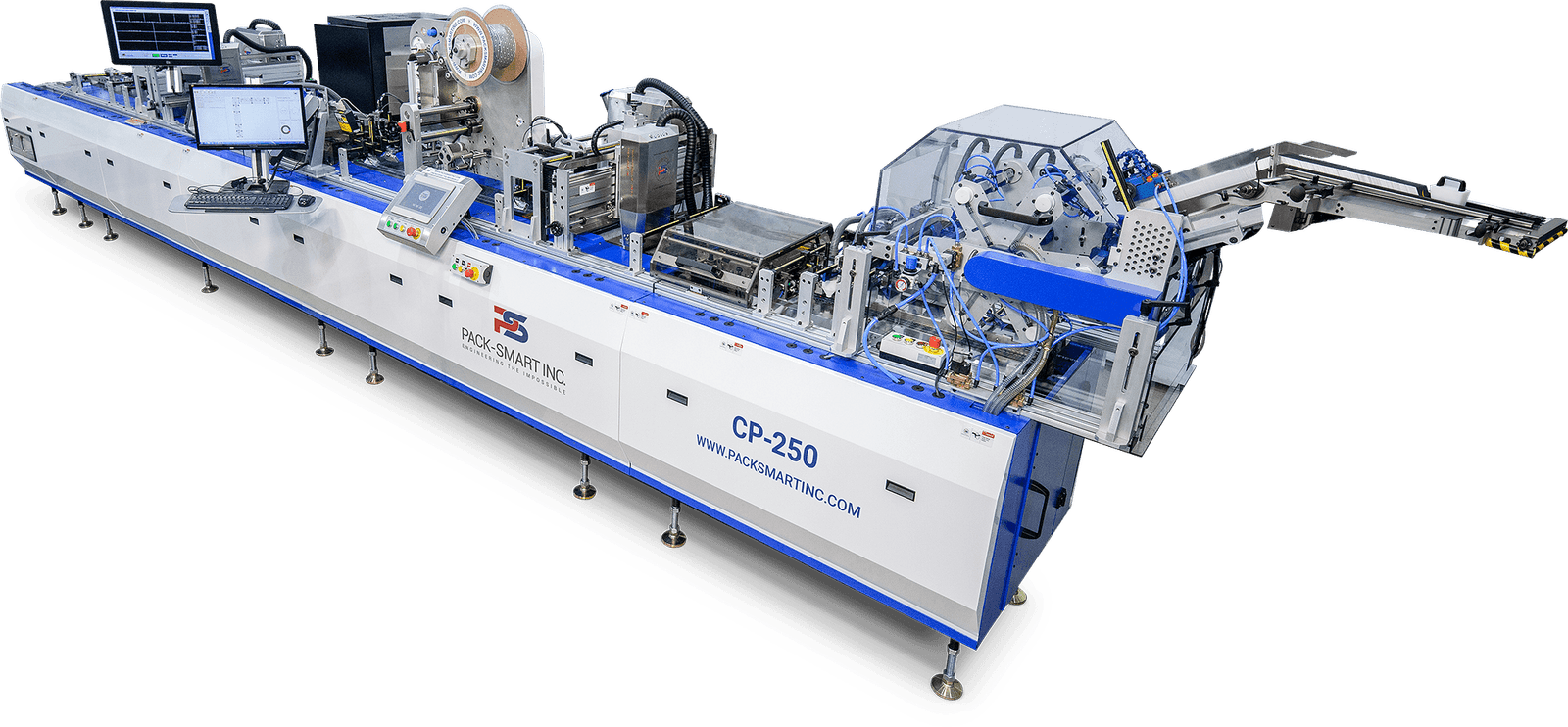

With speeds up to 30,000 PPH, it is ideal for all your closed, secure, and open loop needs.

The CC-500 delivers unparalleled defect detection for cartons by integrating advanced imaging and processing technology to inspect a variety of materials at speeds up to 150 m/min.

Inline card to carrier affixing, booklet tipping, 4-corner secure folding/gluing, and DOD personalization.

This system is equipped with sophisticated sensors and control systems that adjust parameters in real-time to suit varying material specifications and environmental conditions.

Explore the FG-500 Folding and Gluing System for high-precision carton packaging. With ±0.4 mm accuracy, 600 DPI printing, and real-time quality assurance, achieve flawless packaging outcomes.

Related modules are available for inline applications.

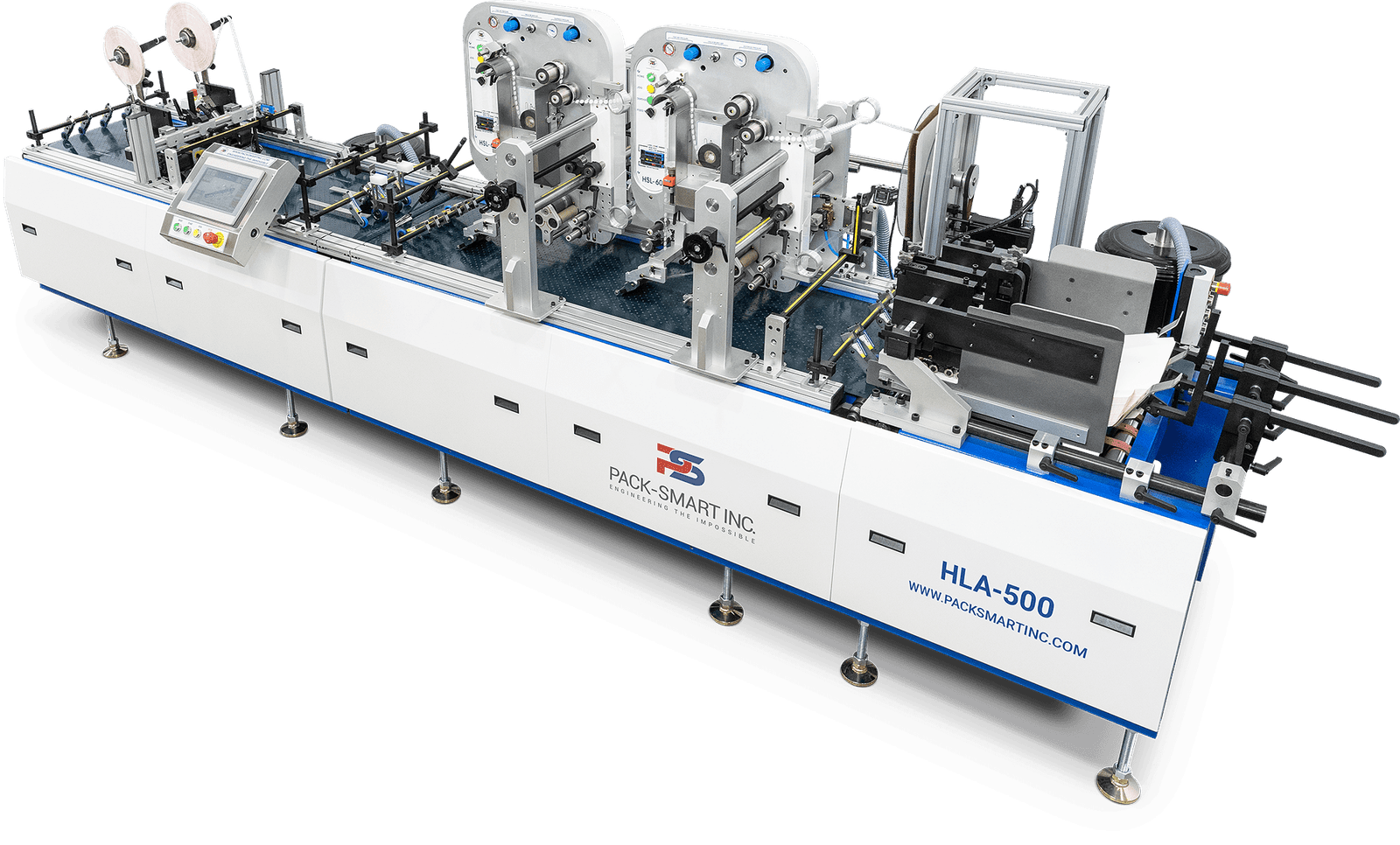

Consistently feed, insert, attach, and batch delicate materials and oddly shaped products at 30,000 PPH, with vacuum pick & place motion and ±0.02″ placement accuracy.

Revolutionize your production with the HM-10 Hot Melt Glue System, offering precision application for a wide range of adhesive needs.

High torque servo driven vacuum transport conveys products at accurate speeds and controls product placement with 8 selectable vacuum zones.

Elevate your production capabilities with the PG-900 Flexo Pattern Glue Module, designed for precise and flexible adhesive applications.

The CEG-1 Cold Glue System is engineered for high-precision, tamper-proof adhesive applications.

Smart Jet uses industry leading head technology to deliver UV Cured 600 DPI DOD Ink onto any surface.

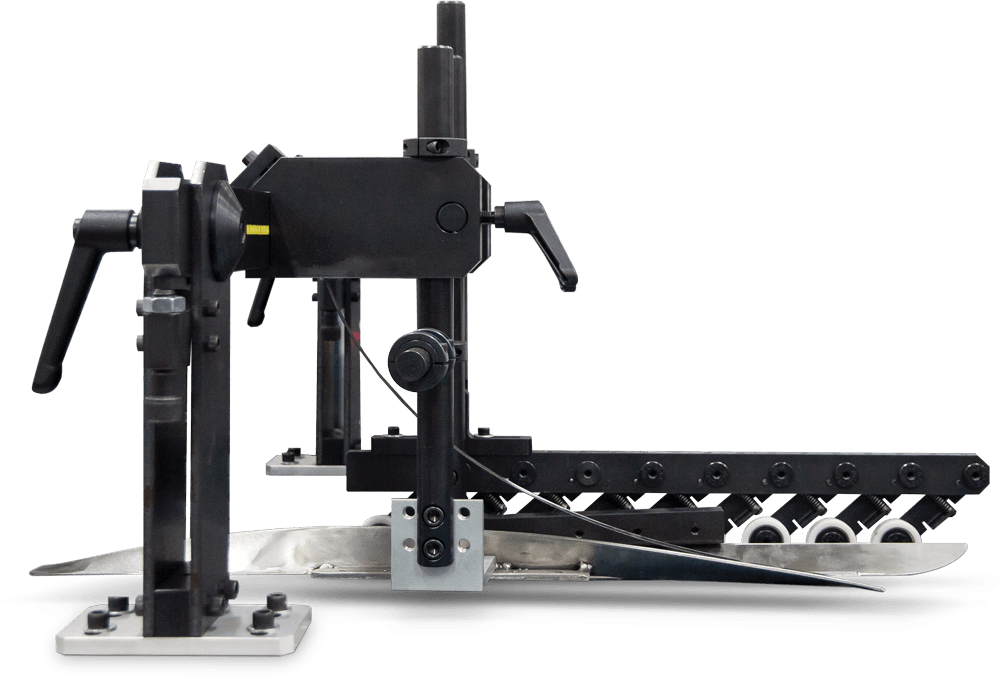

The PF50-90 Plow Fold Module integrates seamlessly into production lines, offering both left and right folding configurations.