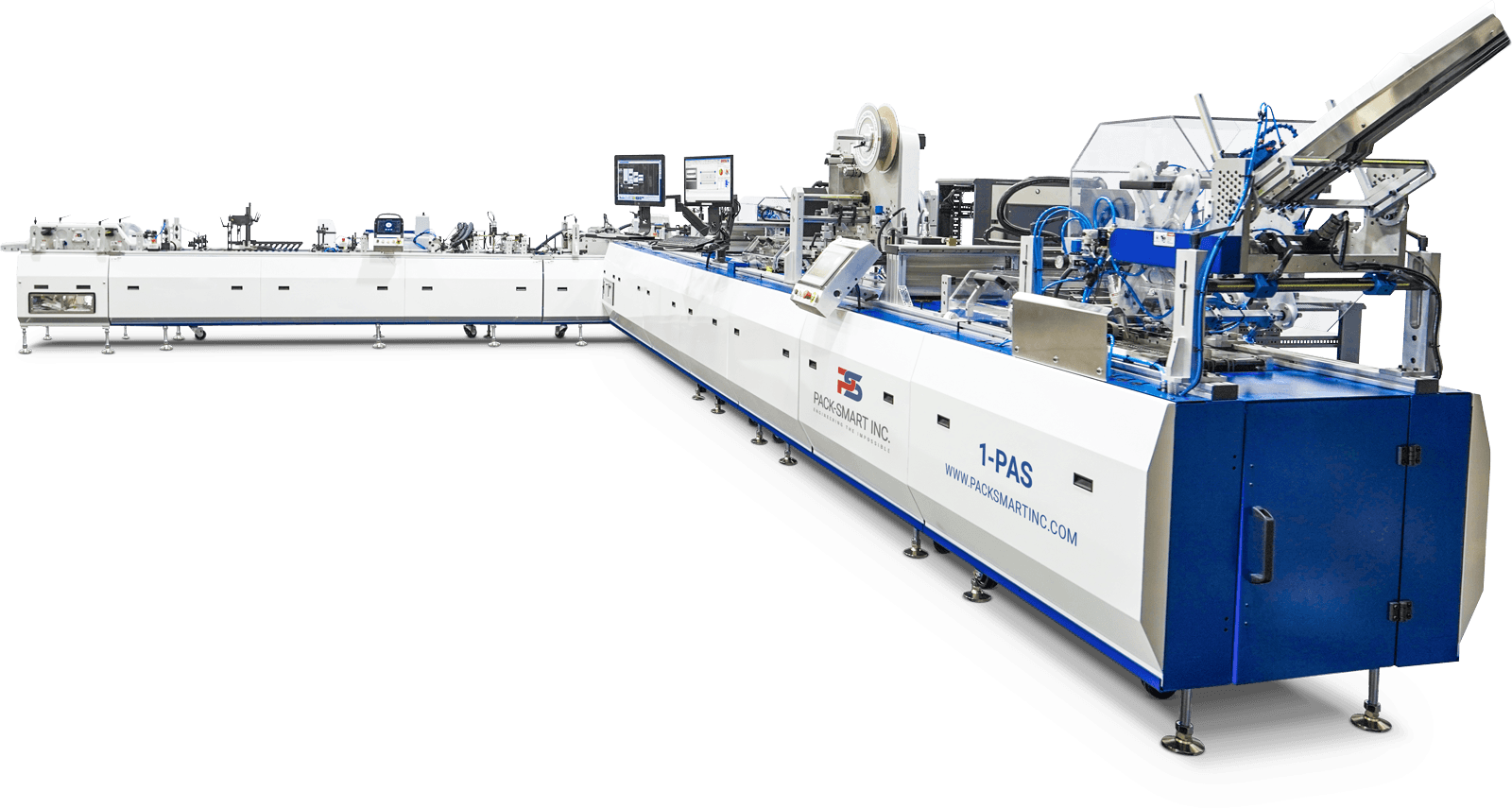

Card to Bundle in One Pass

World’s first inline solution for high volume personalization, affixing, packaging and pack-out of secure open and closed loop cards at 20,000 PPH.

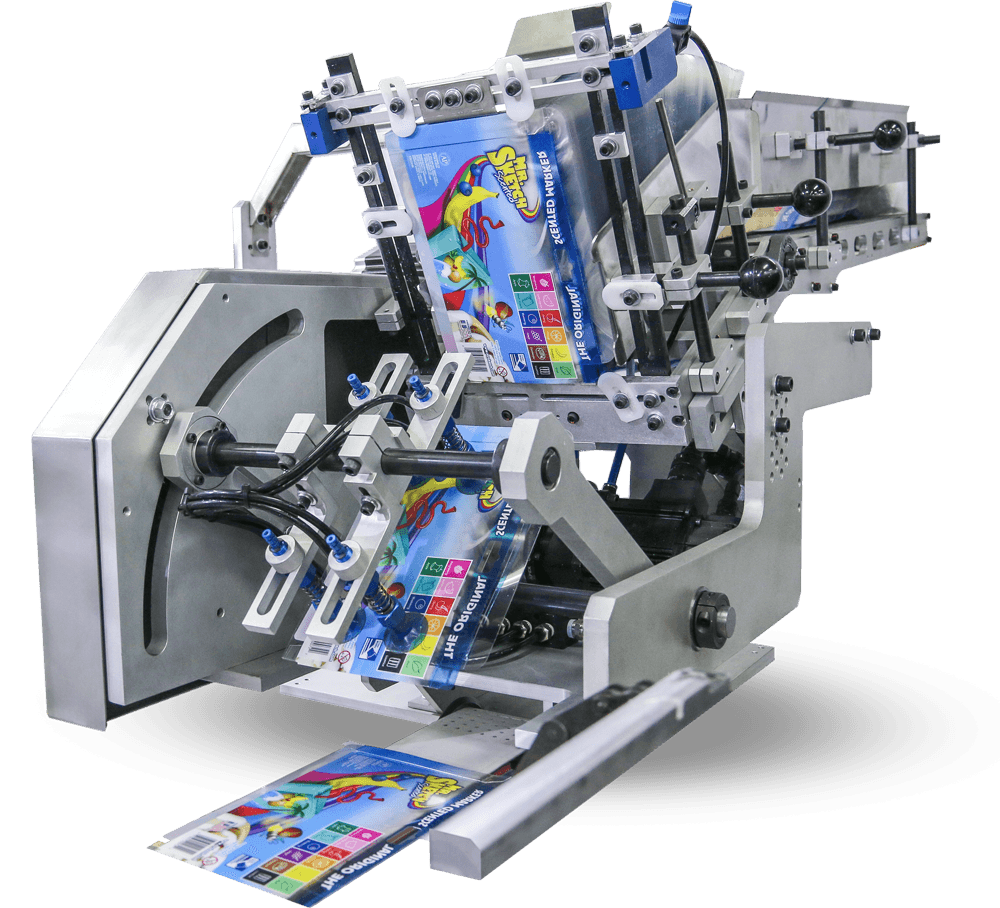

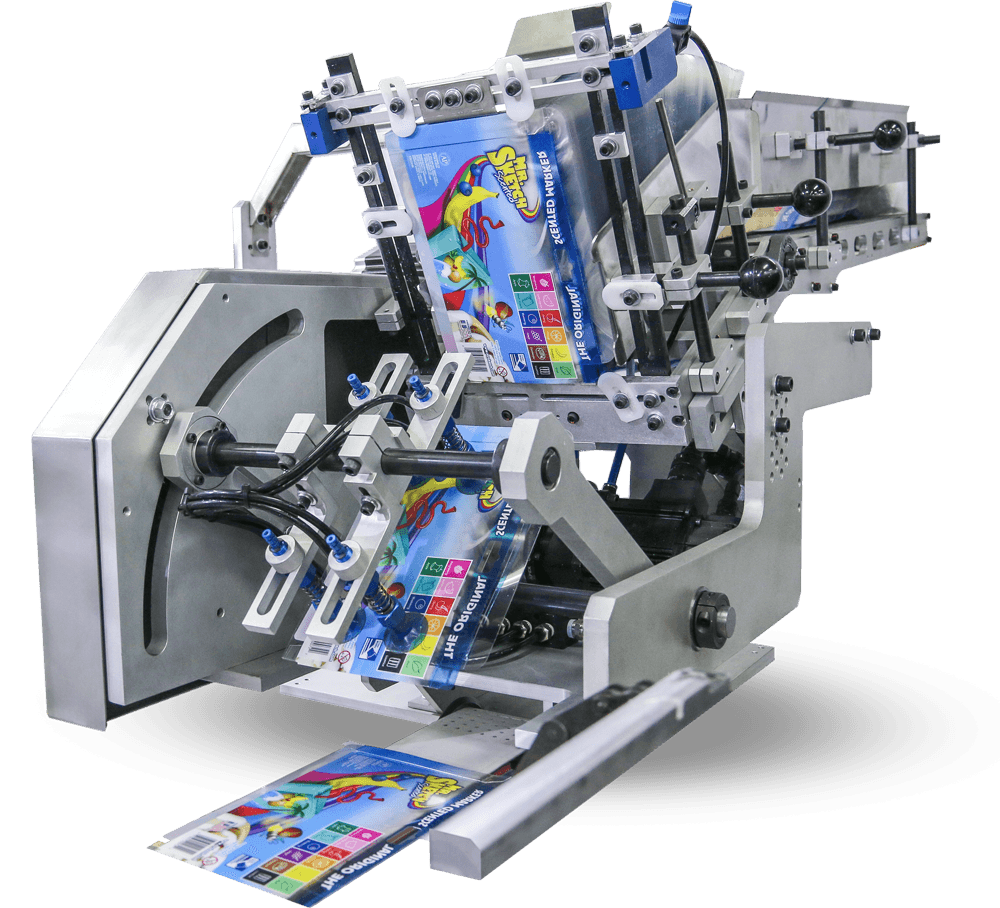

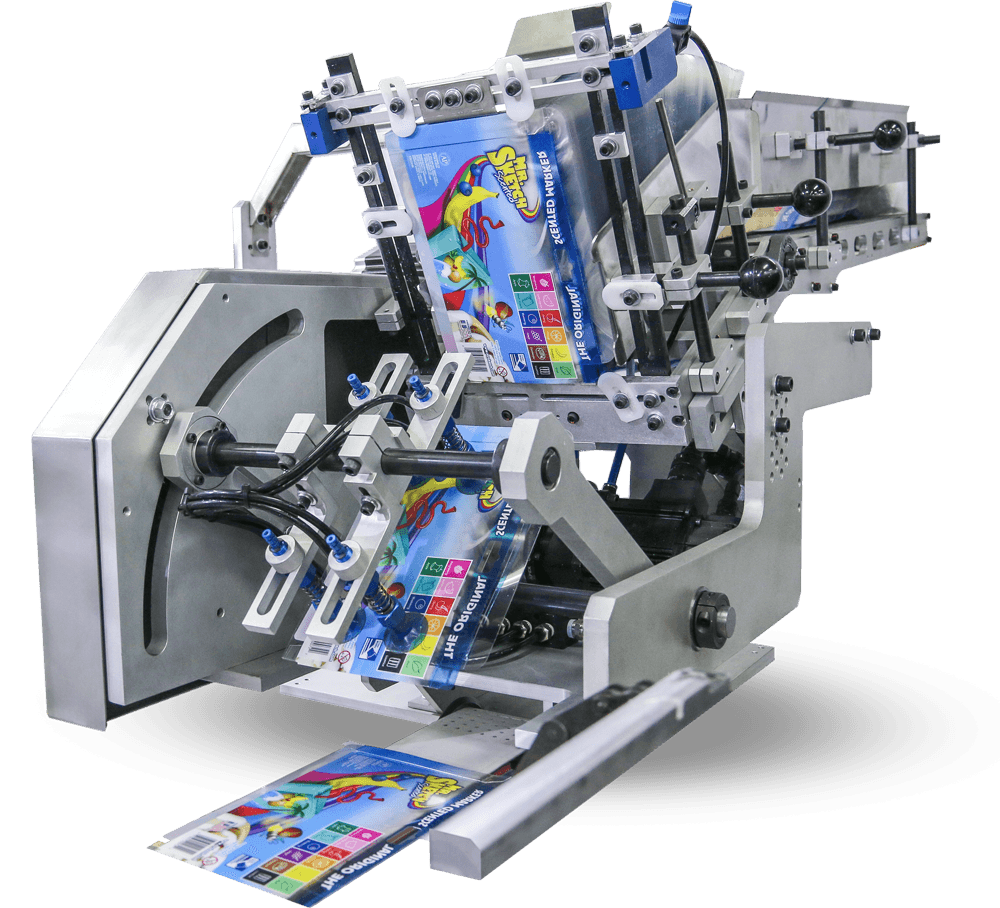

Maximize your production efficiency with the RPP Series Reciprocating Pick and Place, designed for high-speed, accurate handling of delicate materials and uniquely shaped products.

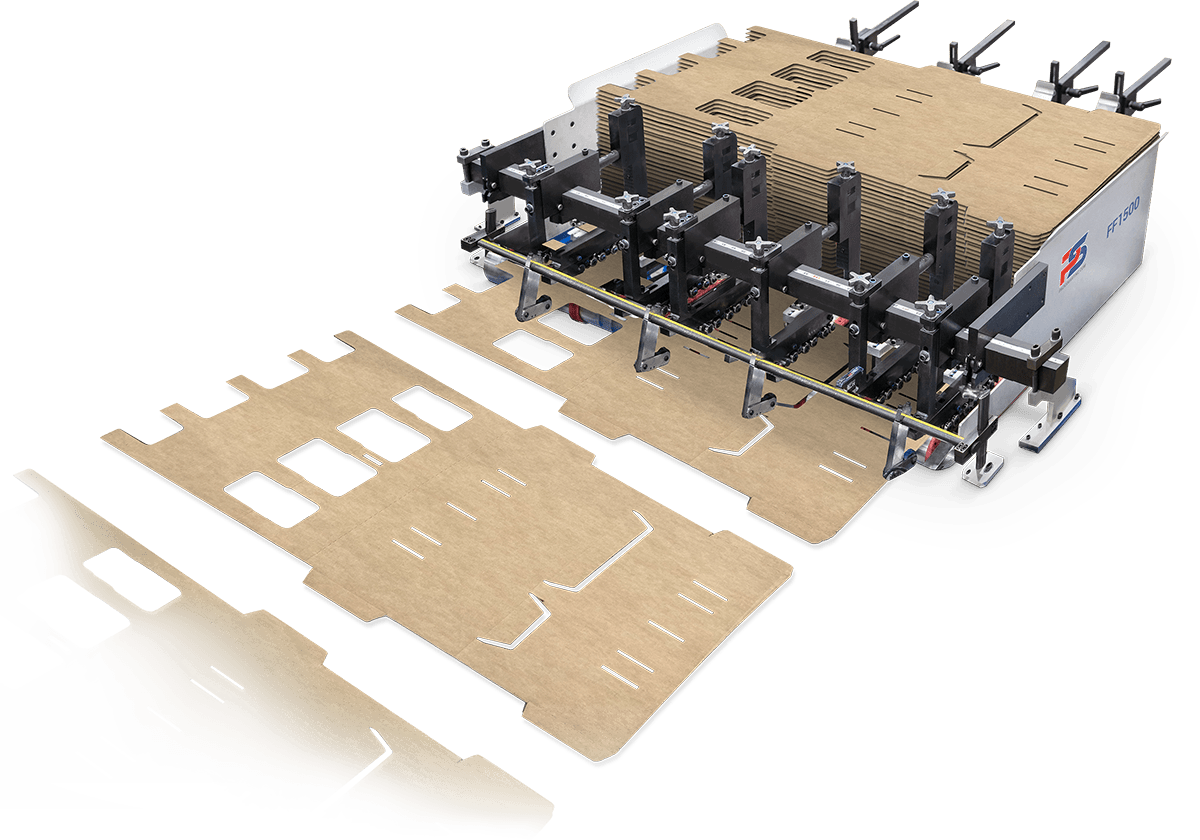

The RPP Series — Reciprocating Pick and Place Feeder is designed to handle a wide array of materials, from plastic cards to corrugated boards, with the capability to feed, insert, attach, and batch products efficiently.

Its robust design features a vacuum pick and place system that ensures gentle handling of delicate materials, reducing waste and improving product quality.

The system’s modular design allows for easy integration into existing production lines, making it a versatile solution for industries ranging from pharmaceuticals to consumer goods.

Membership & Loyalty

eCommerce

Retail

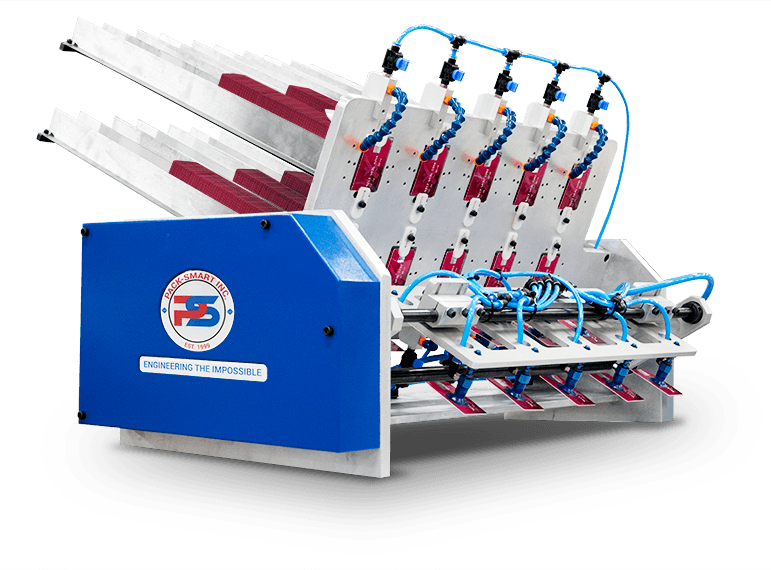

For the RPP Series Reciprocating Pick and Place Feeders, Pack-Smart offers tailored solutions to accommodate a range of industrial needs, ensuring flexibility across various applications. The design variations within the RPP Series are detailed below.

RPP-300

Integrated solution for easily feeding

products up to 300 mm in width

RPP-500

Larger format handling for products

up to 500 mm in width

RPP-1100

Multi-product handling with capabilities

to feed five different products simultaneously

This technology is used in the following automated systems.

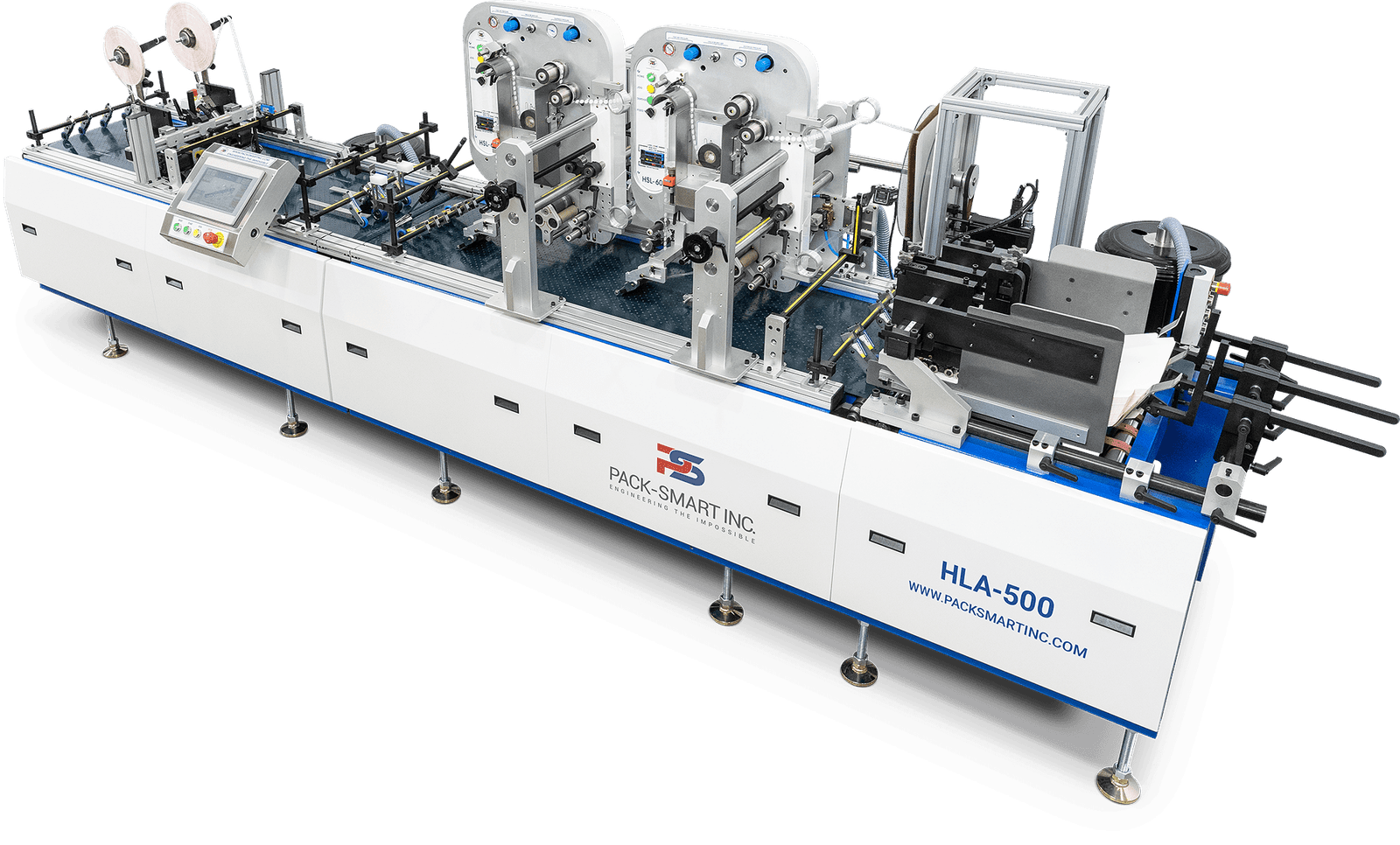

World’s first inline solution for high volume personalization, affixing, packaging and pack-out of secure open and closed loop cards at 20,000 PPH.

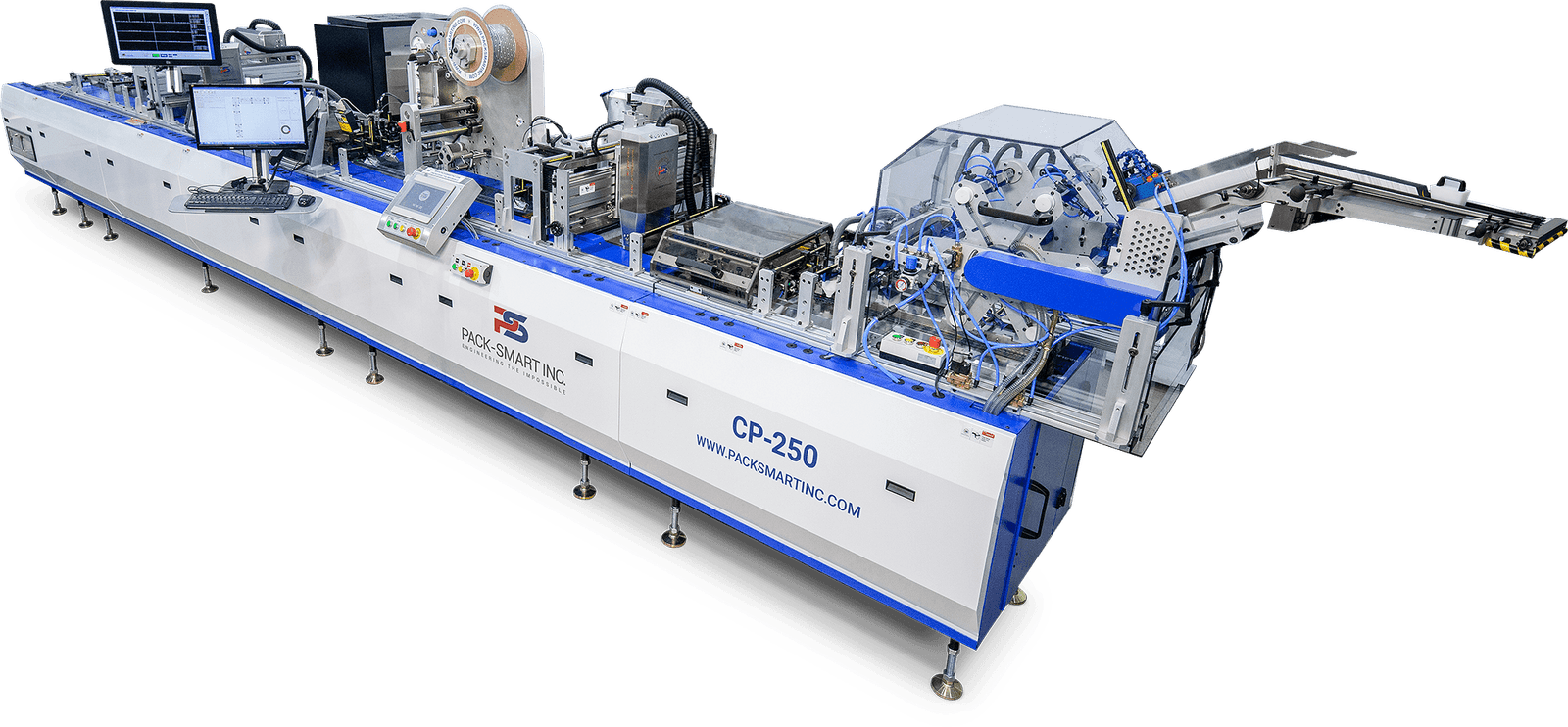

With speeds up to 30,000 PPH, it is ideal for all your closed, secure, and open loop needs.

Engineered to meet the rigorous demands of EMV chip card encoding, this system combines advanced encoding capabilities with high-speed processing to deliver unparalleled efficiency.

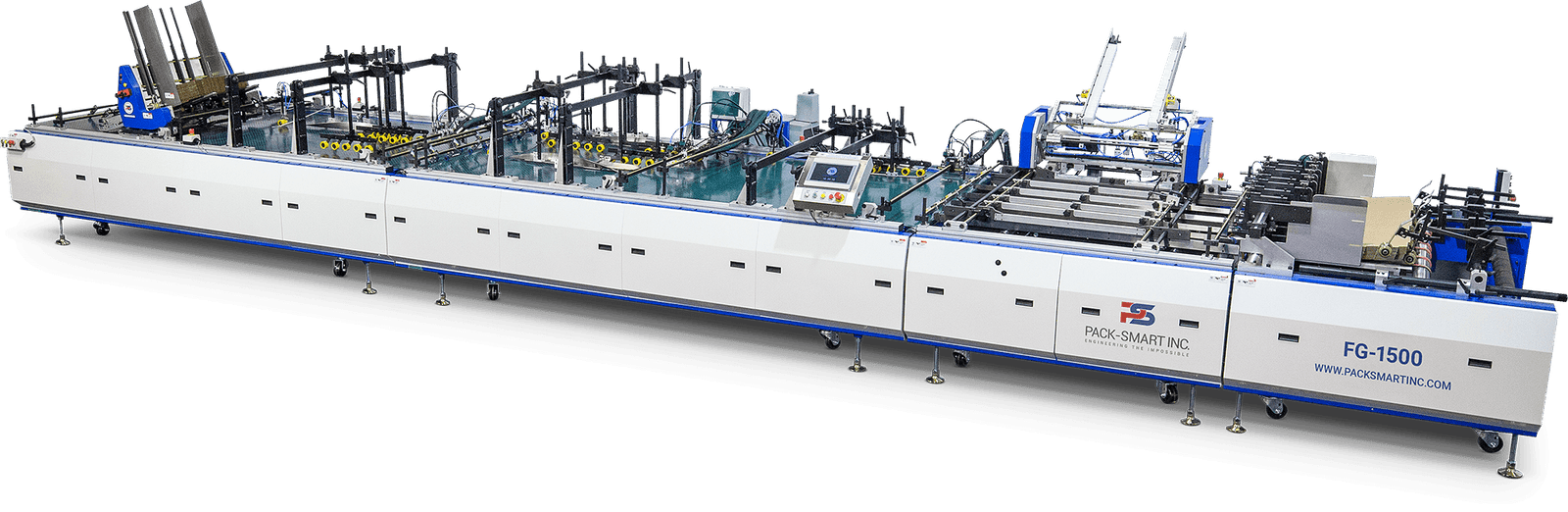

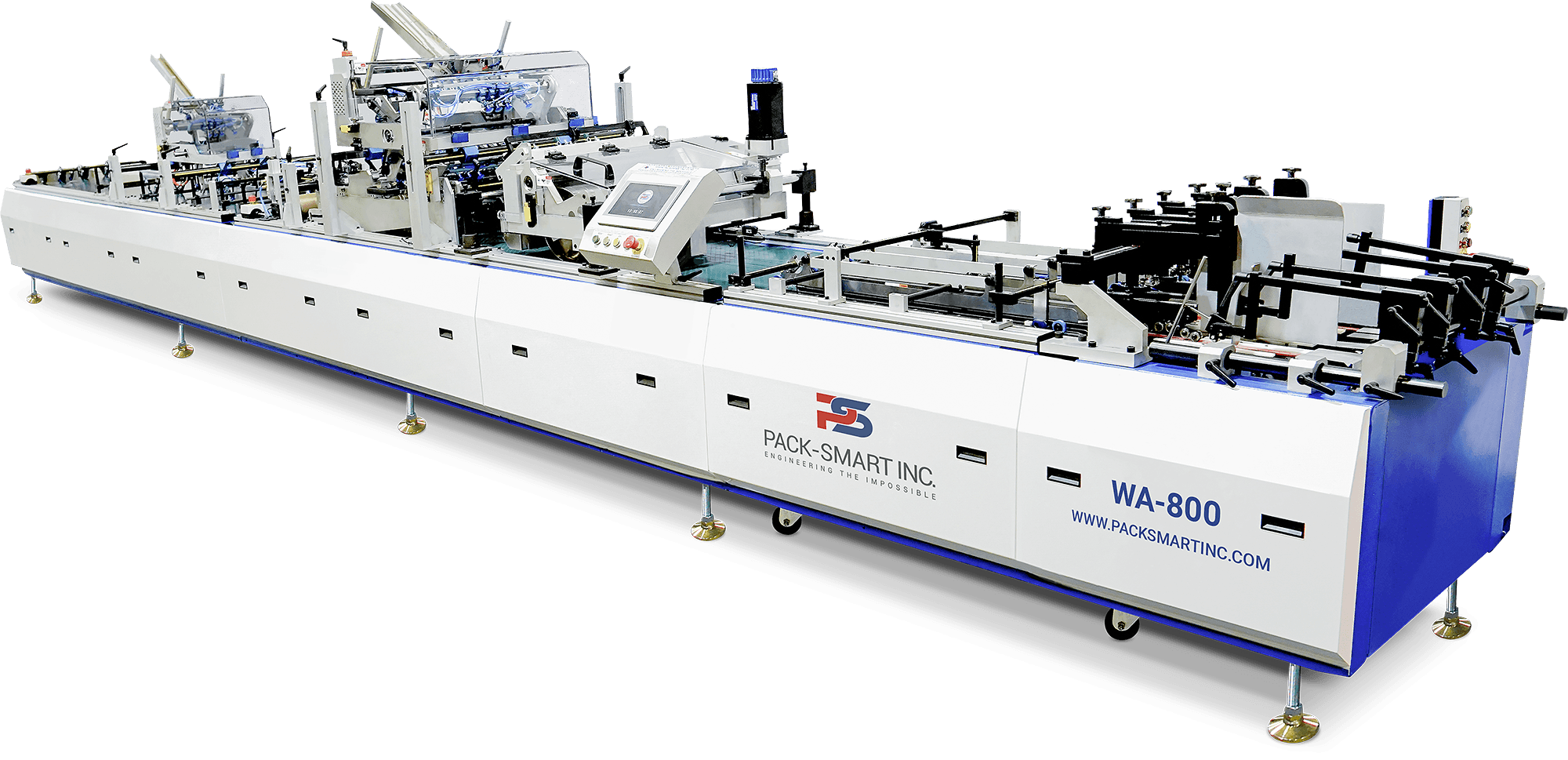

Specialty 60″ Corrugated Folder Gluer with Plastics Clips and Reinforcements for POP Displays.

Combine folding, gluing, affixing, personalization, and sorting in a single pass.

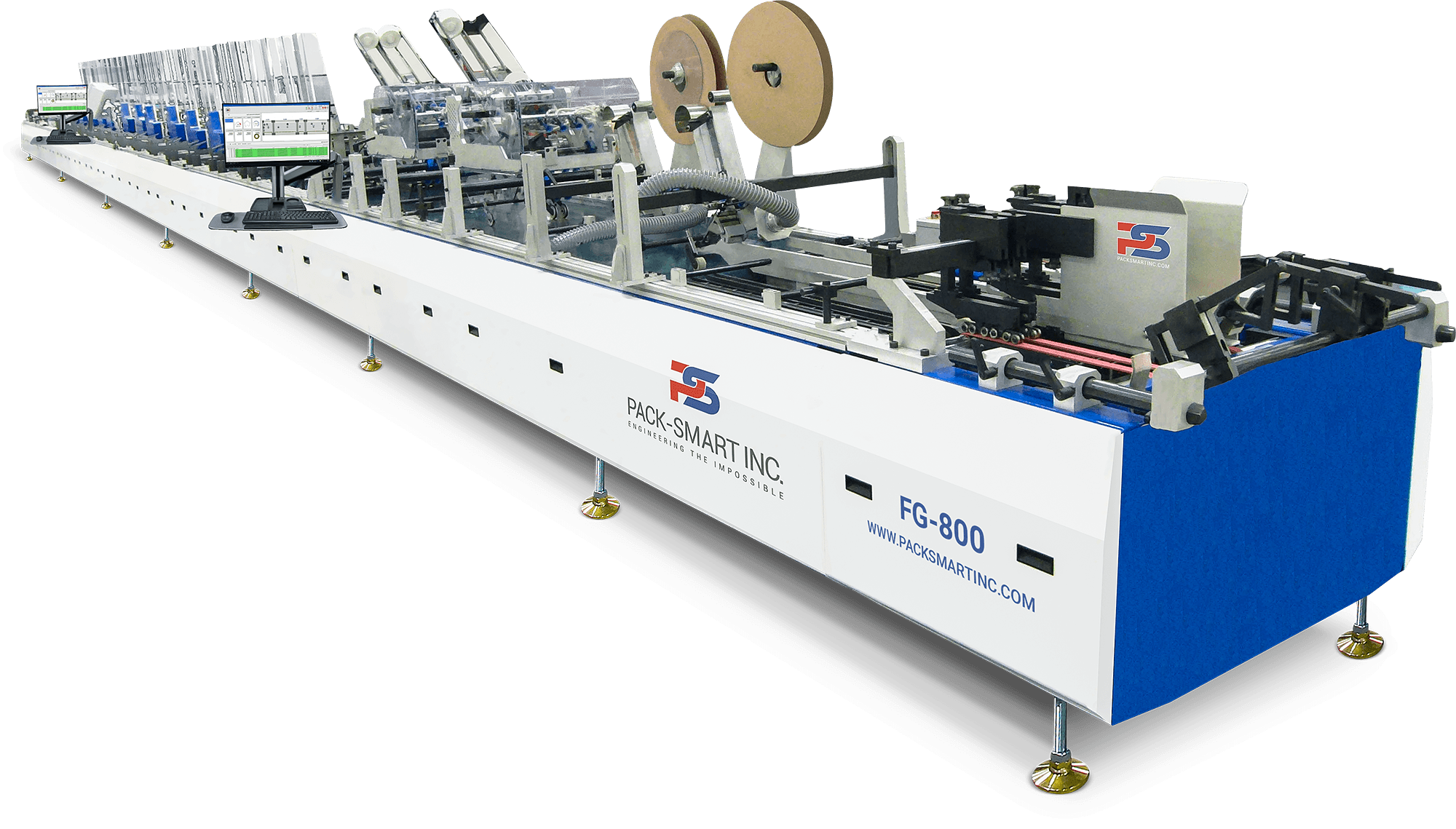

Inline card to carrier affixing, booklet tipping, 4-corner secure folding/gluing, and DOD personalization.

This system is equipped with sophisticated sensors and control systems that adjust parameters in real-time to suit varying material specifications and environmental conditions.

WA-800r delivers unmatched speed, accuracy and flexibility allowing affixing of rigid windows to virtually any carton product available.

Related modules are available for inline applications.

The FF Series Friction Feeder can handle the lightest paper and is equally at home when dealing with heavy stock materials when called upon.

Reaching up to 600 products per minute, the SF Series is a perfect choice for handling light paper to heavy stock material.

Consistently feed, insert, attach, and batch delicate materials and oddly shaped products at 30,000 PPH, with vacuum pick & place motion and ±0.02″ placement accuracy.