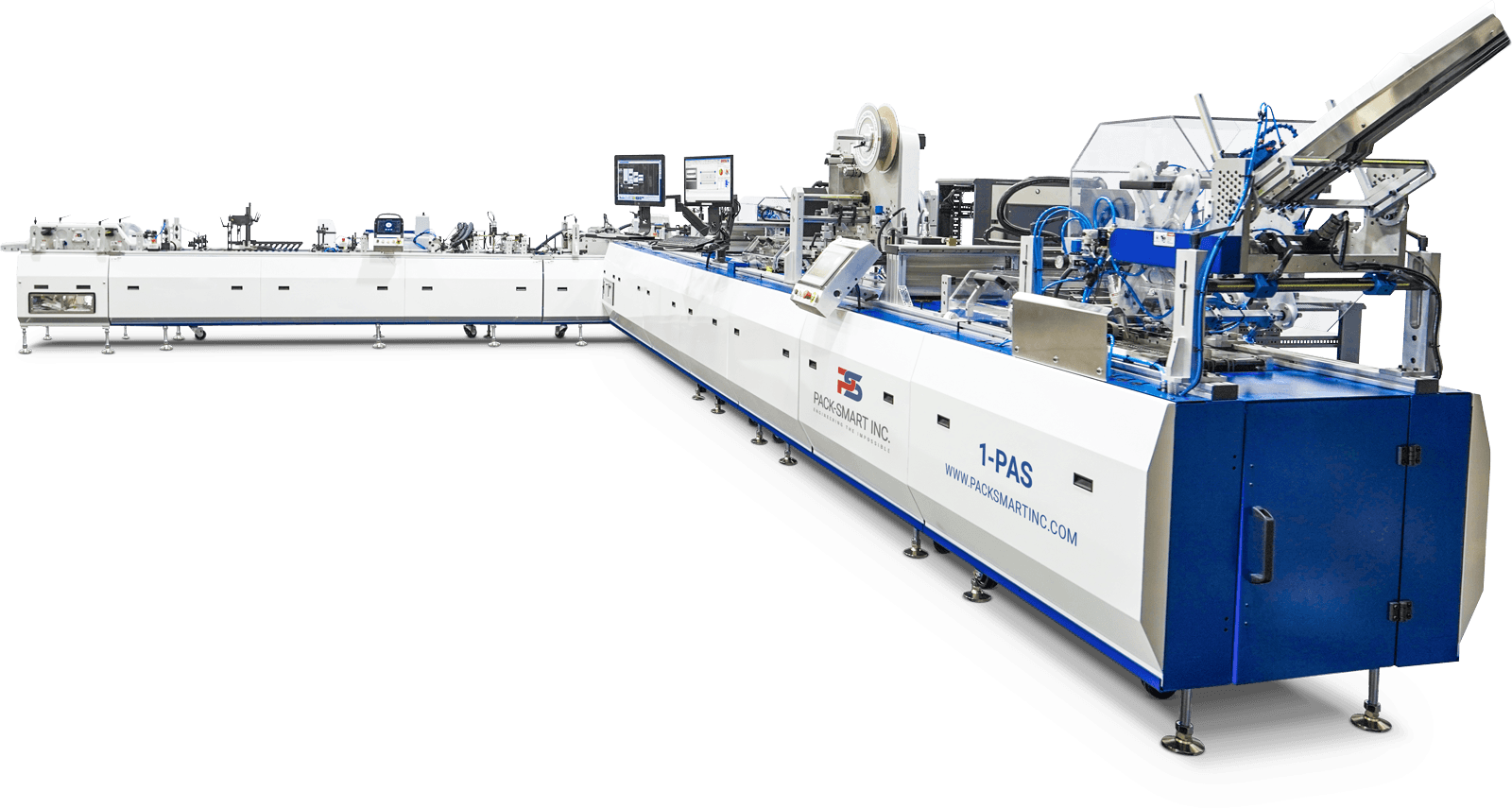

Card to Bundle in One Pass

World’s first inline solution for high volume personalization, affixing, packaging and pack-out of secure open and closed loop cards at 20,000 PPH.

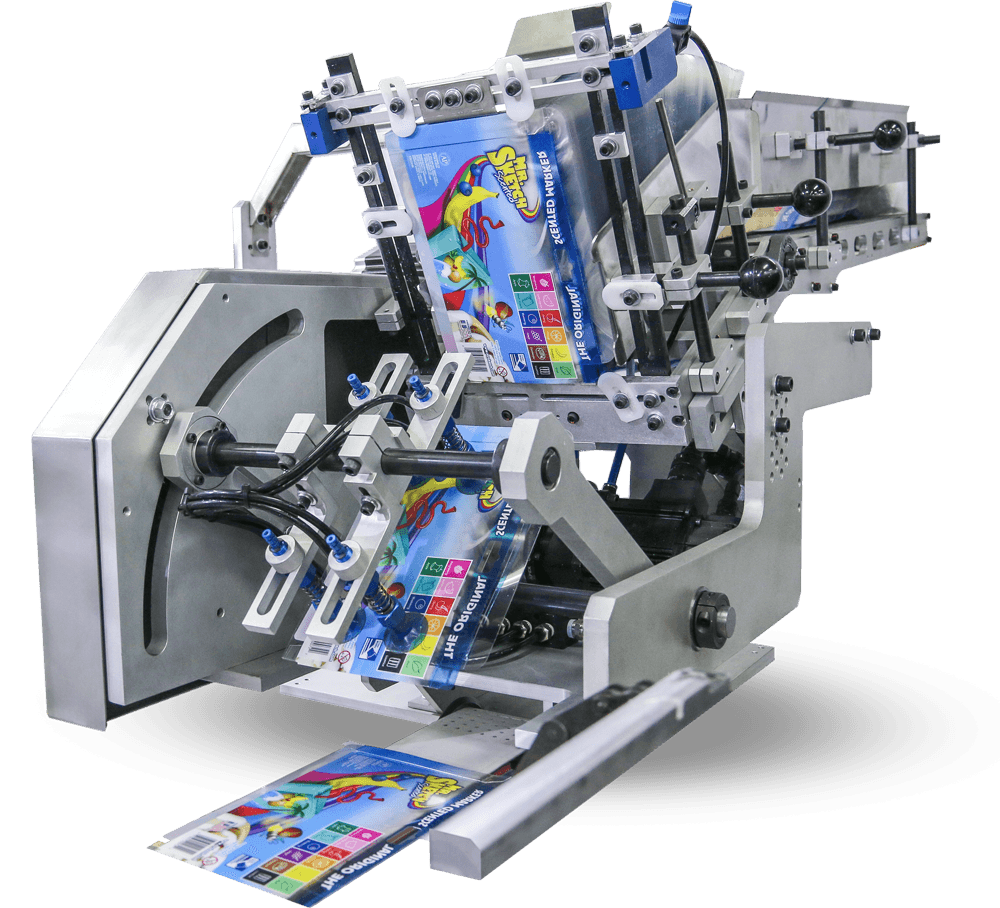

Enhance your production line with the ICR-500 Inline Compression Roller, designed for efficient, high-speed compression of products with hot glue adhesion.

The ICR-500 Inline Compression Roller is engineered to provide superior compression for products requiring hot glue adhesion.

This advanced module uses a rolling overhead drum to compress products inline, ensuring strong adhesion without damaging the product.

With features designed to maximize throughput, efficiency, and safety, the ICR-500 is an essential component for high-speed packaging lines, particularly in secure card packaging, premium branding, and specialty print finishing applications.

This technology is used in the following automated systems.

World’s first inline solution for high volume personalization, affixing, packaging and pack-out of secure open and closed loop cards at 20,000 PPH.

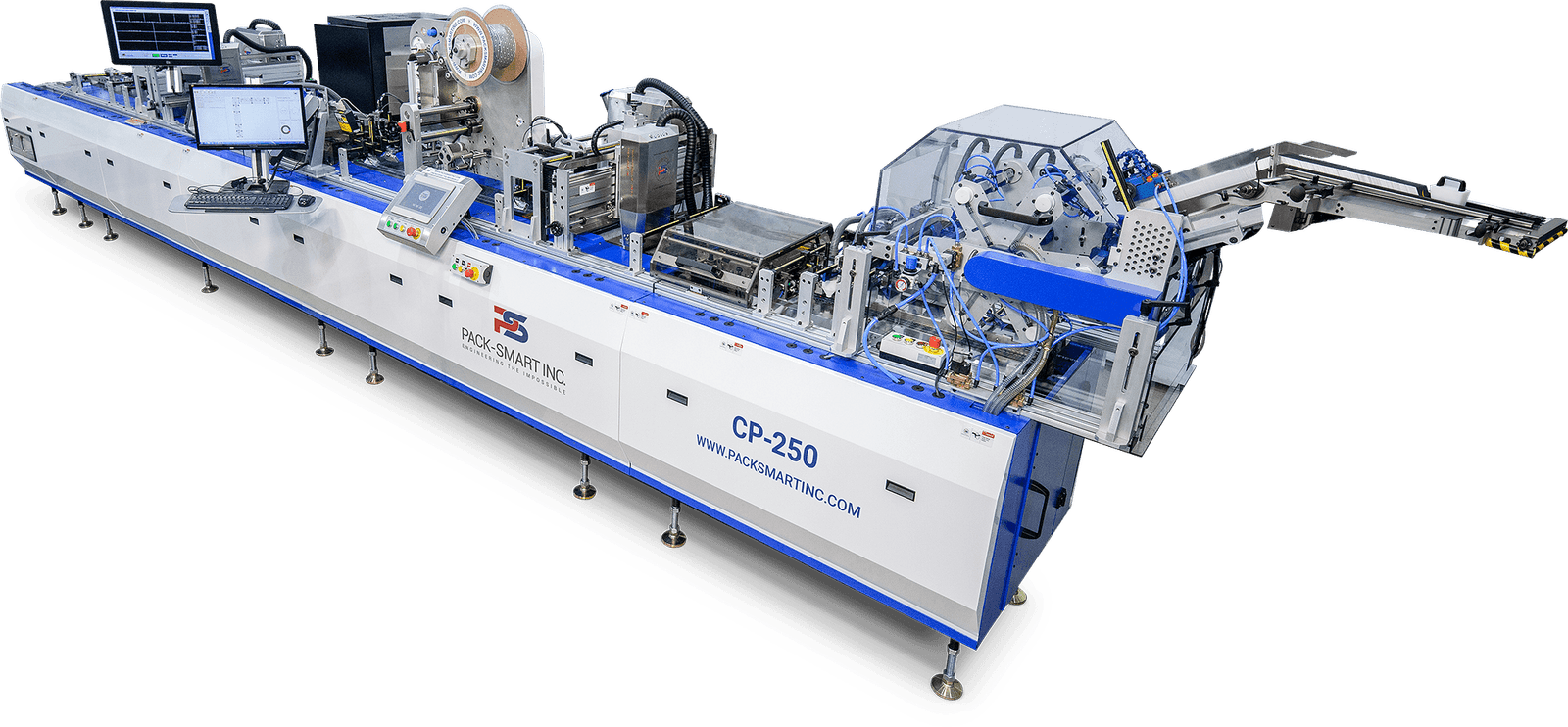

With speeds up to 30,000 PPH, it is ideal for all your closed, secure, and open loop needs.

Inline card to carrier affixing, booklet tipping, 4-corner secure folding/gluing, and DOD personalization.

Engineered to meet the rigorous demands of EMV chip card encoding, this system combines advanced encoding capabilities with high-speed processing to deliver unparalleled efficiency.

Related modules are available for inline applications.

Consistently feed, insert, attach, and batch delicate materials and oddly shaped products at 30,000 PPH, with vacuum pick & place motion and ±0.02″ placement accuracy.

Maximize your production efficiency with the RPP Series, designed for high-speed, accurate handling of delicate materials and uniquely shaped products.