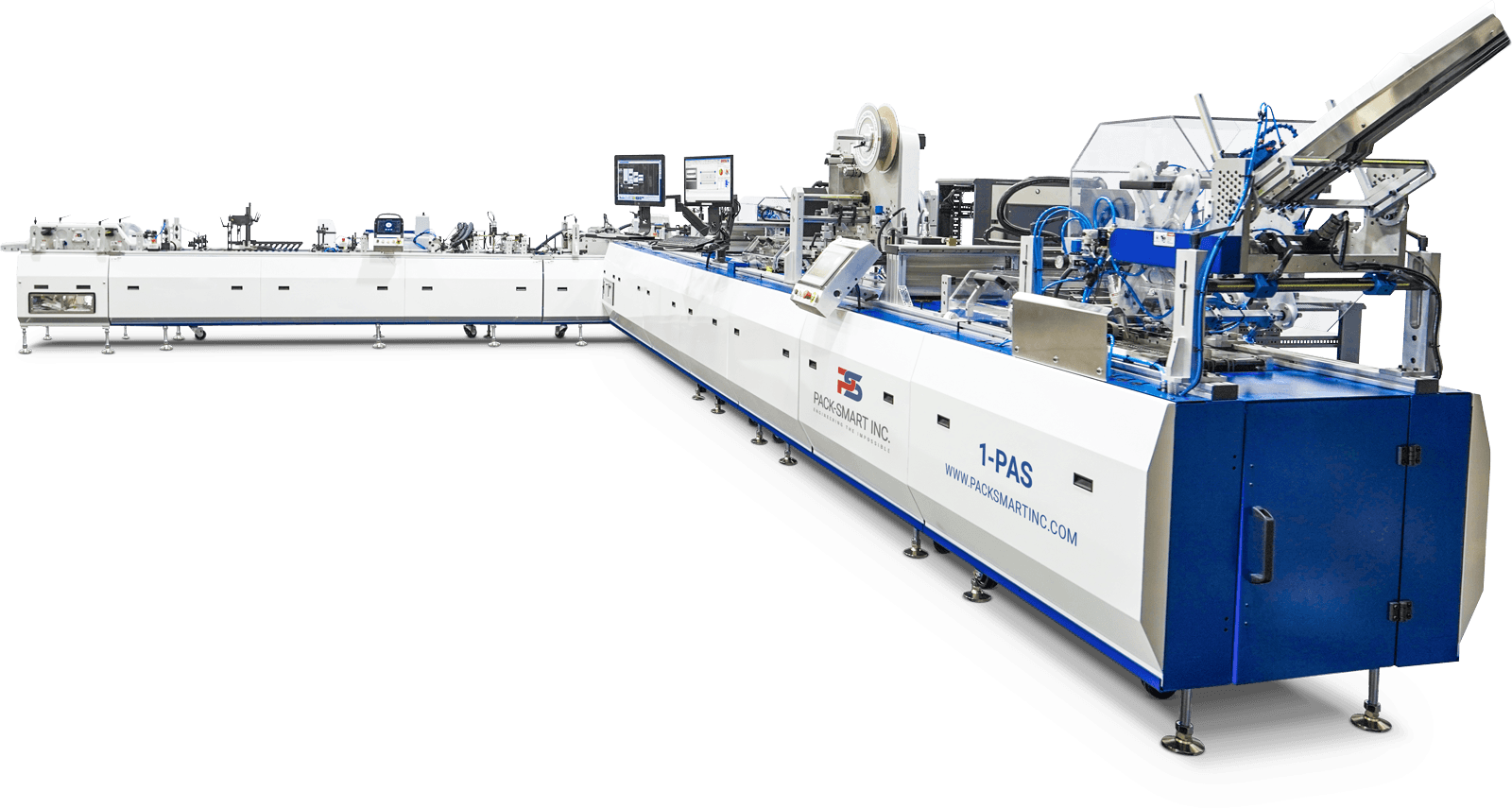

Card to Bundle in One Pass

World’s first inline solution for high volume personalization, affixing, packaging and pack-out of secure open and closed loop cards at 20,000 PPH.

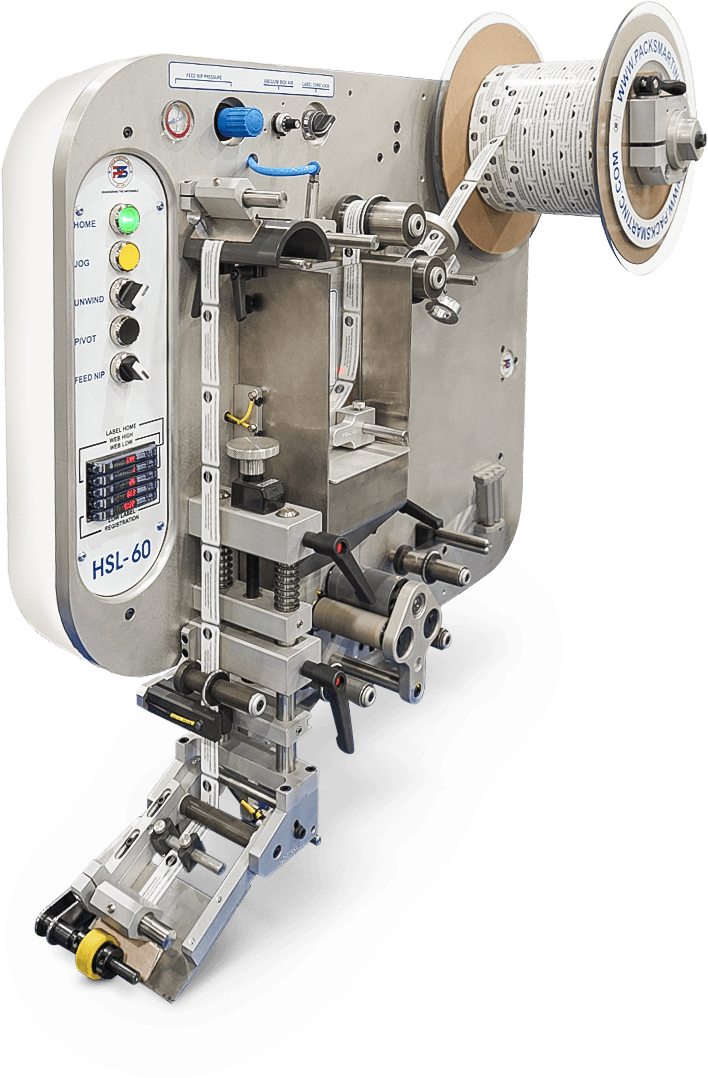

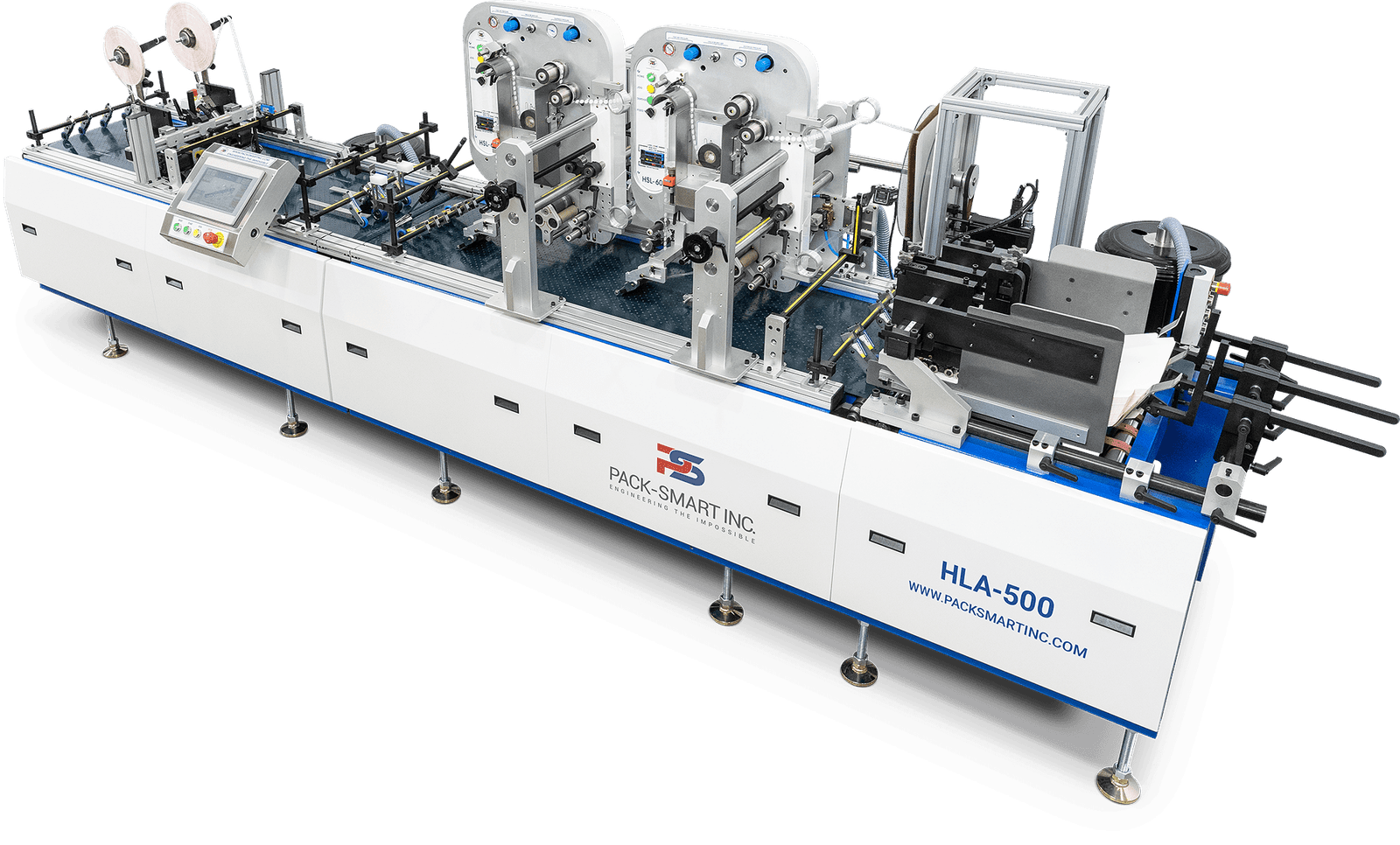

The HSL-60 Label Applicator is a highly versatile module that applies pressure-sensitive labels at high speeds and accuracy for the most demanding precision-critical applications.

With the ability to apply all varieties of pressure-sensitive labels at line speeds up to 200 m/min (660 ft/min), the HSL-60 High-Speed Label Applicator can apply 400 labels per minute, with a best-in-class placement accuracy of ±0.4 mm.

The HSL-60 Labeller will accurately apply labels to any product in line with any printing, converting, and packaging production lines. When operating in a “Zero Downtime“ configuration, the HSL-60 Tandem system allows for safe “on the fly” roll changes eliminating downtime required for roll changes.

This system is an ideal solution for a wide range of applications, including but not limited to applying Hi/Lo double-sided tape, scratch-off labels, magnetic stripe application, Velcro dots, RFID labels, and security tags.

The HSL-60 High-Speed Labeller is available in various configurations, designed to handle multiple labeling applications with precision. With options to support diverse production scales and material types, the HSL-60 adapts seamlessly to complex workflows, ensuring efficiency and accuracy across industries.

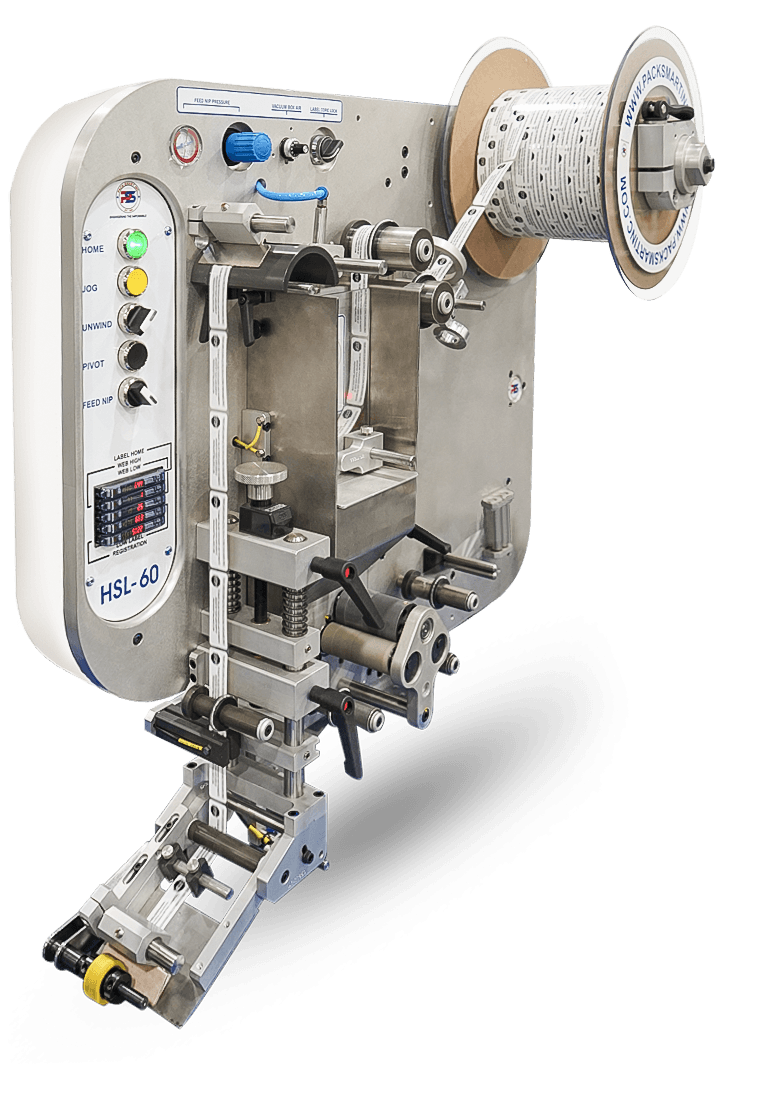

Multiple Labeller

This technology is used in the following automated systems.

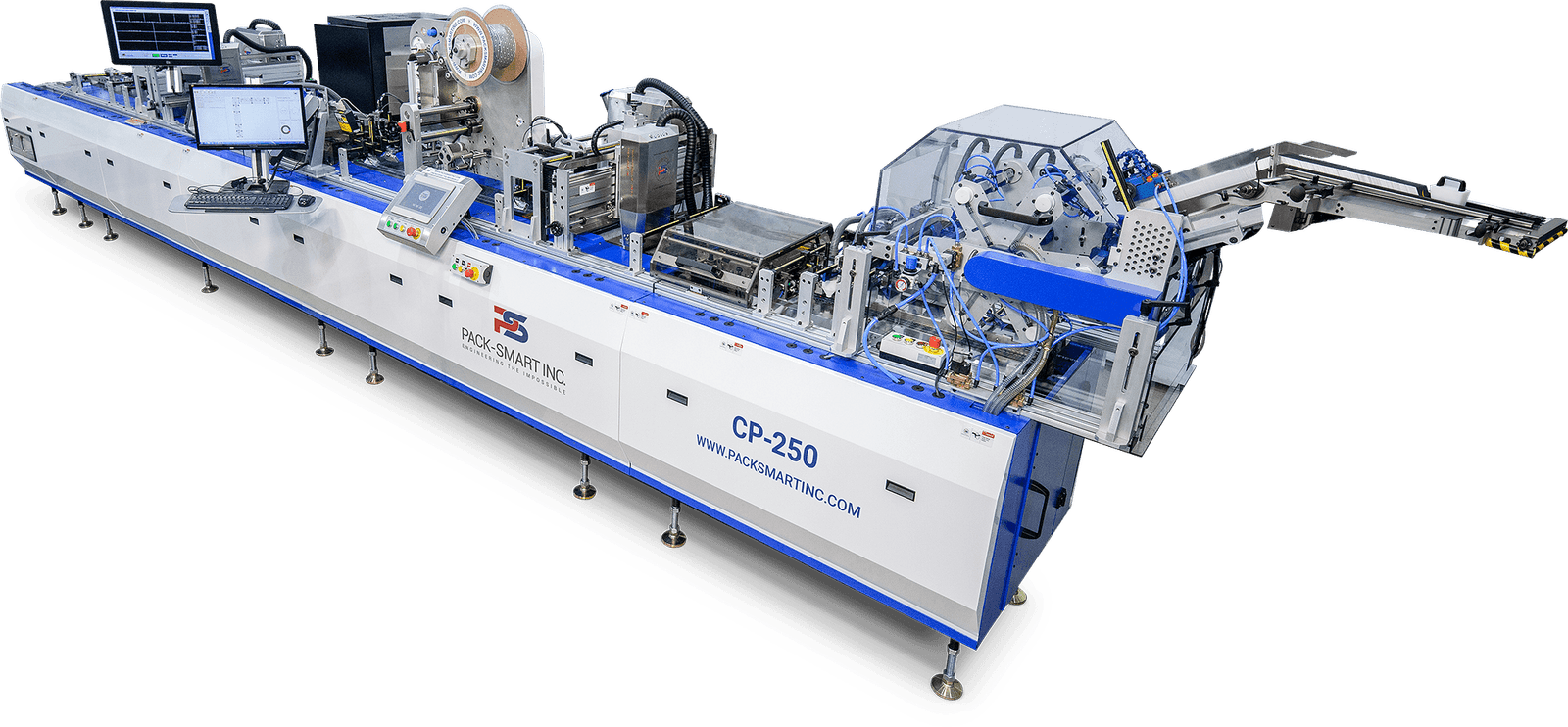

World’s first inline solution for high volume personalization, affixing, packaging and pack-out of secure open and closed loop cards at 20,000 PPH.

Inline card to carrier affixing, booklet tipping, 4-corner secure folding/gluing, and DOD personalization.

With speeds up to 30,000 PPH, it is ideal for all your closed, secure, and open loop needs.

This system is equipped with sophisticated sensors and control systems that adjust parameters in real-time to suit varying material specifications and environmental conditions.

Related modules are available for inline applications.

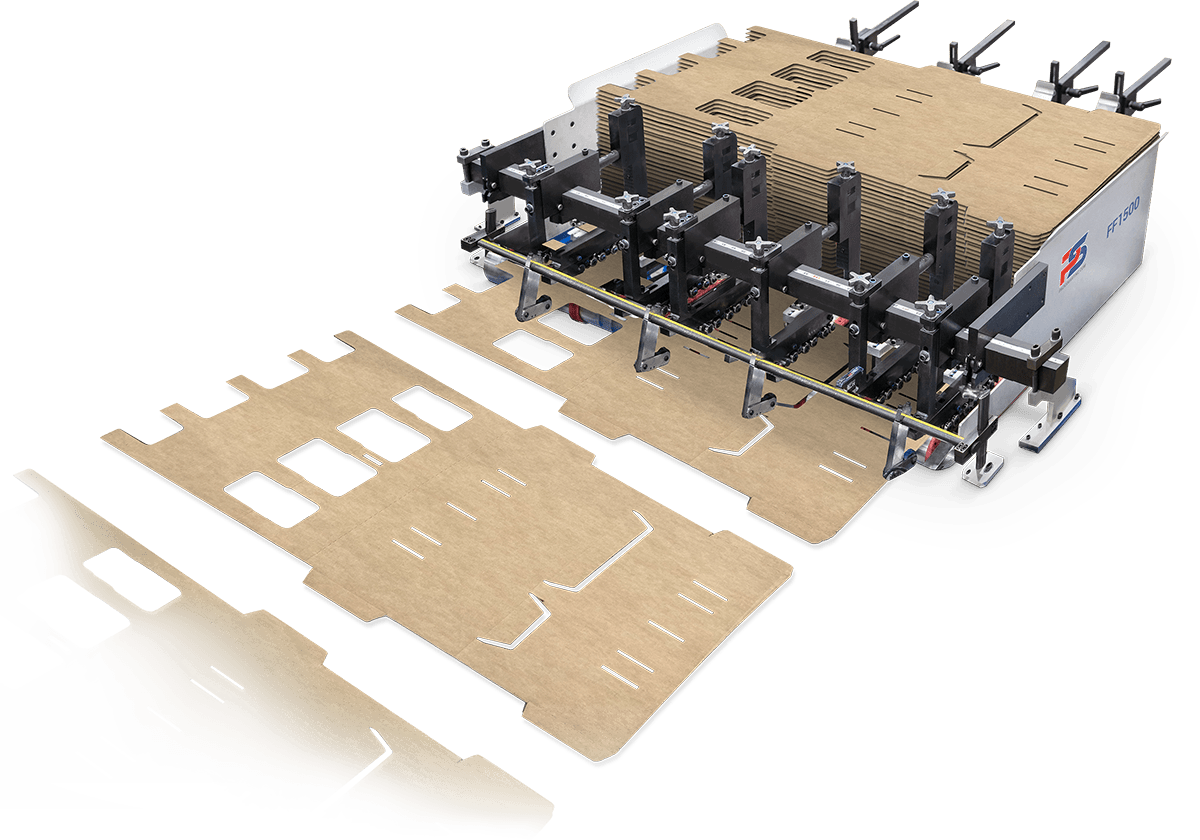

Consistently feed, insert, attach, and batch delicate materials and oddly shaped products at 30,000 PPH, with vacuum pick & place motion and ±0.02″ placement accuracy.

The FF Series Friction Feeder can handle the lightest paper and is equally at home when dealing with heavy stock materials when called upon.

Smart Jet uses industry leading head technology to deliver UV Cured 600 DPI DOD Ink onto any surface.