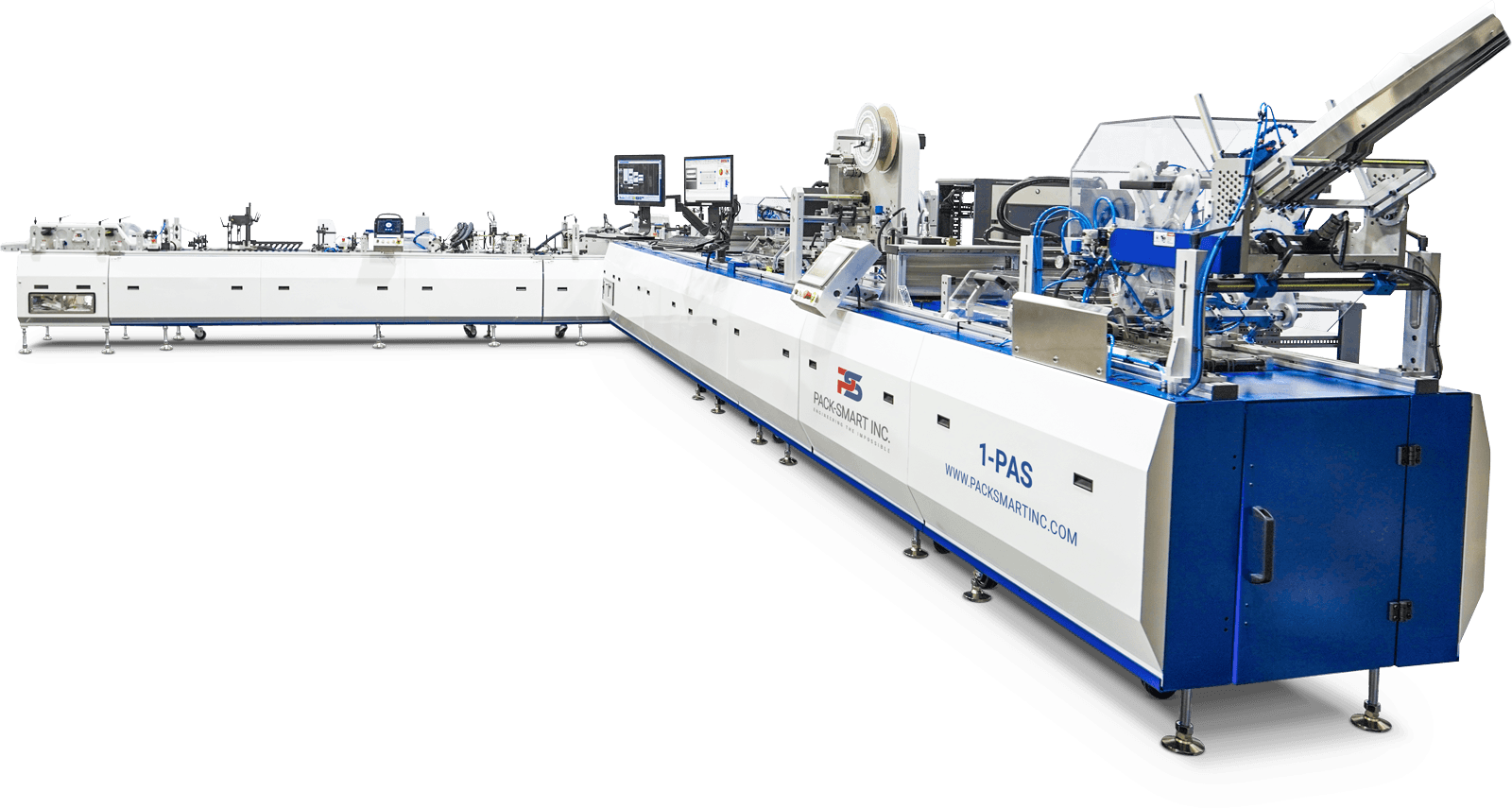

Card to Bundle in One Pass

World’s first inline solution for high volume personalization, affixing, packaging and pack-out of secure open and closed loop cards at 20,000 PPH.

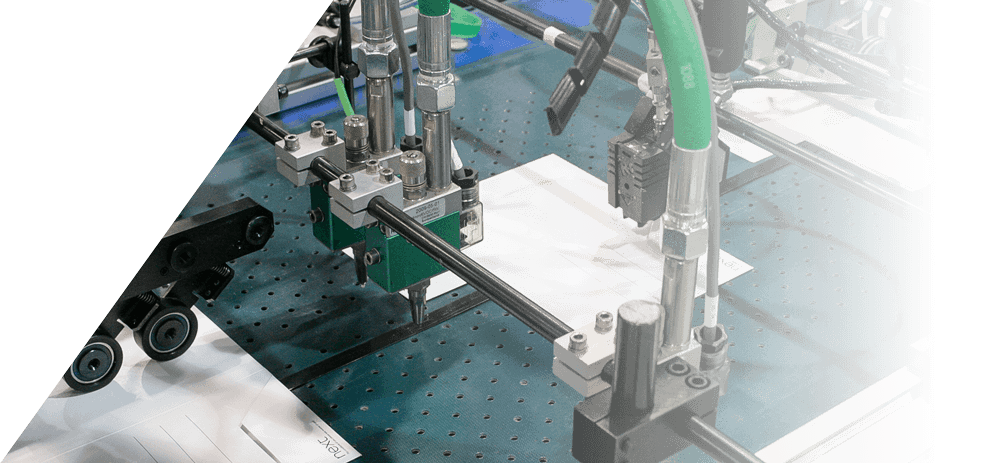

Revolutionize your production with the CEG-1 Cold Glue System, engineered for high-precision, tamper-proof adhesive applications.

The CEG-1 Cold Glue System is specifically engineered for secure, tamper-proof sealing applications, offering precision and efficiency in dispensing cold extruded glue.

This system is distinguished by its capability to handle up to eight glue heads simultaneously, delivering dot, bead, or continuous glue patterns across a wide range of materials, including PVC, card stock, corrugated cardboard, plastic film, and metals.

It’s designed to integrate seamlessly with various production lines, particularly where permanent sealing is crucial.

The CEG-1 Cold Glue System is uniquely designed to accommodate various production scales without the need for different models, emphasizing its flexibility and adaptability to multiple operational setups.

This technology is used in the following automated systems.

World’s first inline solution for high volume personalization, affixing, packaging and pack-out of secure open and closed loop cards at 20,000 PPH.

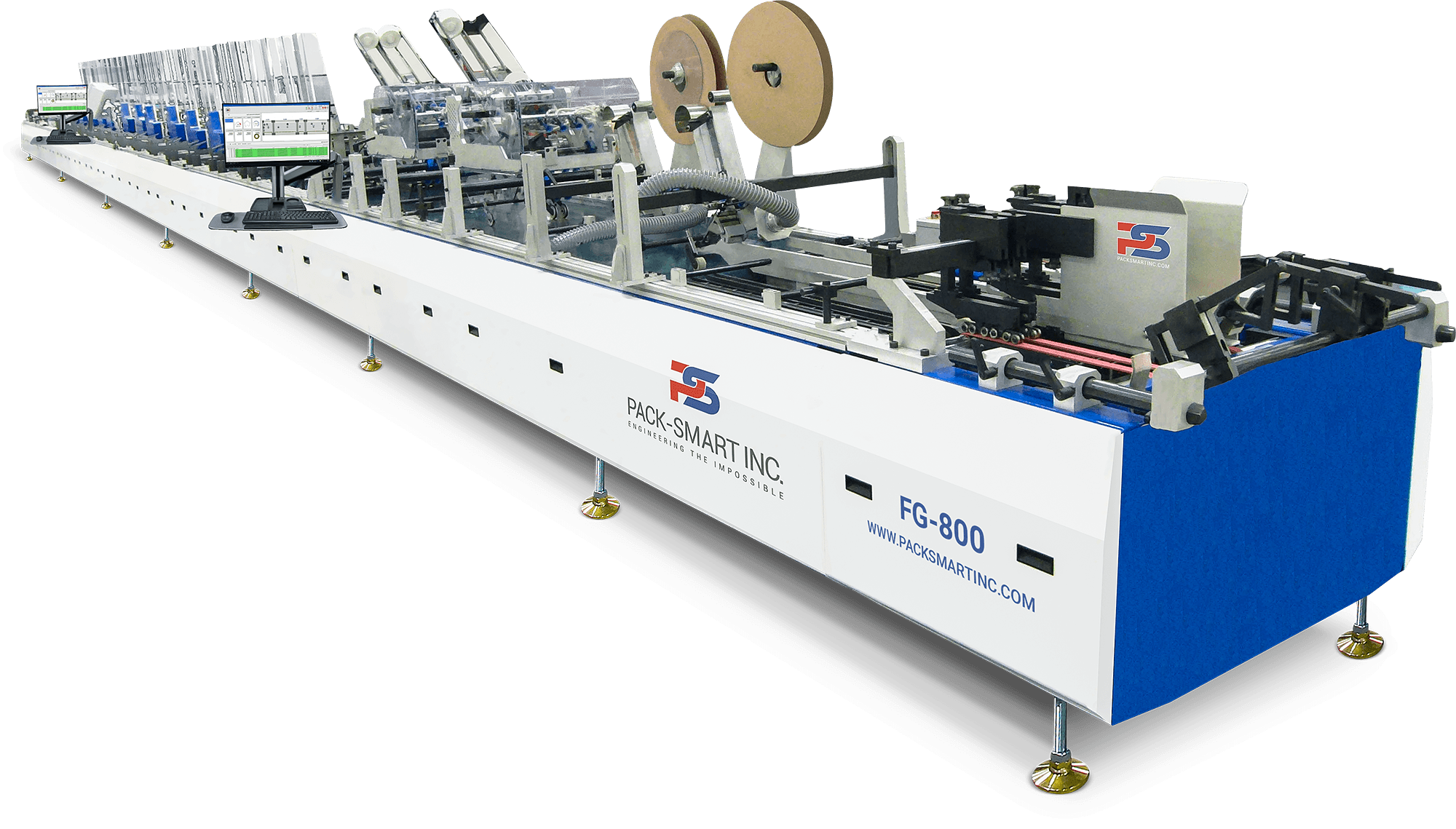

Inline card to carrier affixing, booklet tipping, 4-corner secure folding/gluing, and DOD personalization.

Combine folding, gluing, affixing, personalization, and sorting in a single pass.

Related modules are available for inline applications.

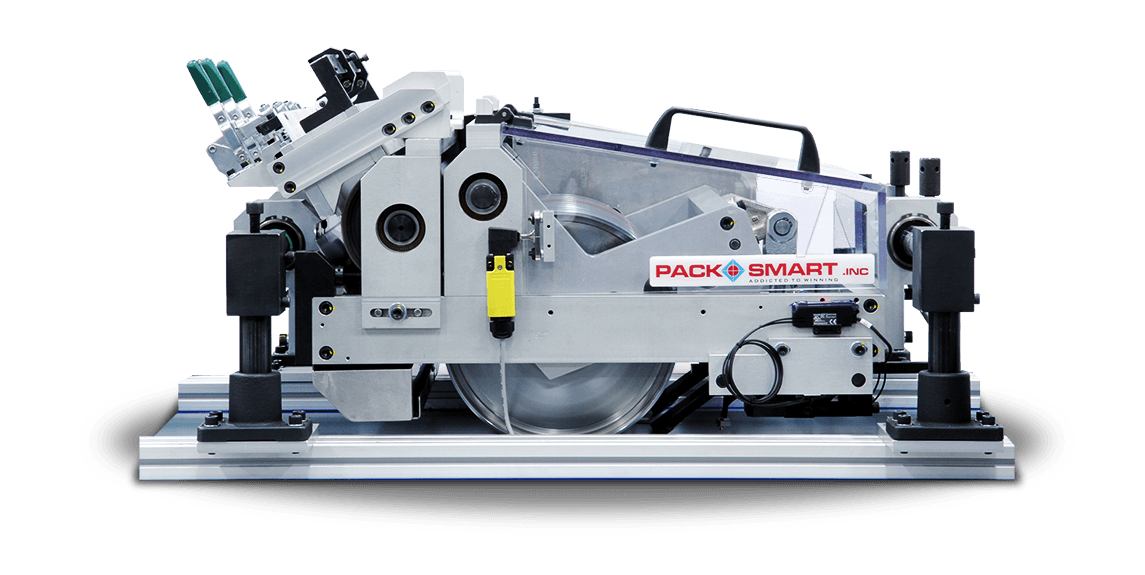

Revolutionize your production with the HM-10 Hot Melt Glue System, offering precision application for a wide range of adhesive needs.

Elevate your production capabilities with the PG-900 Flexo Pattern Glue Module, designed for precise and flexible adhesive applications.