Card to Bundle in One Pass

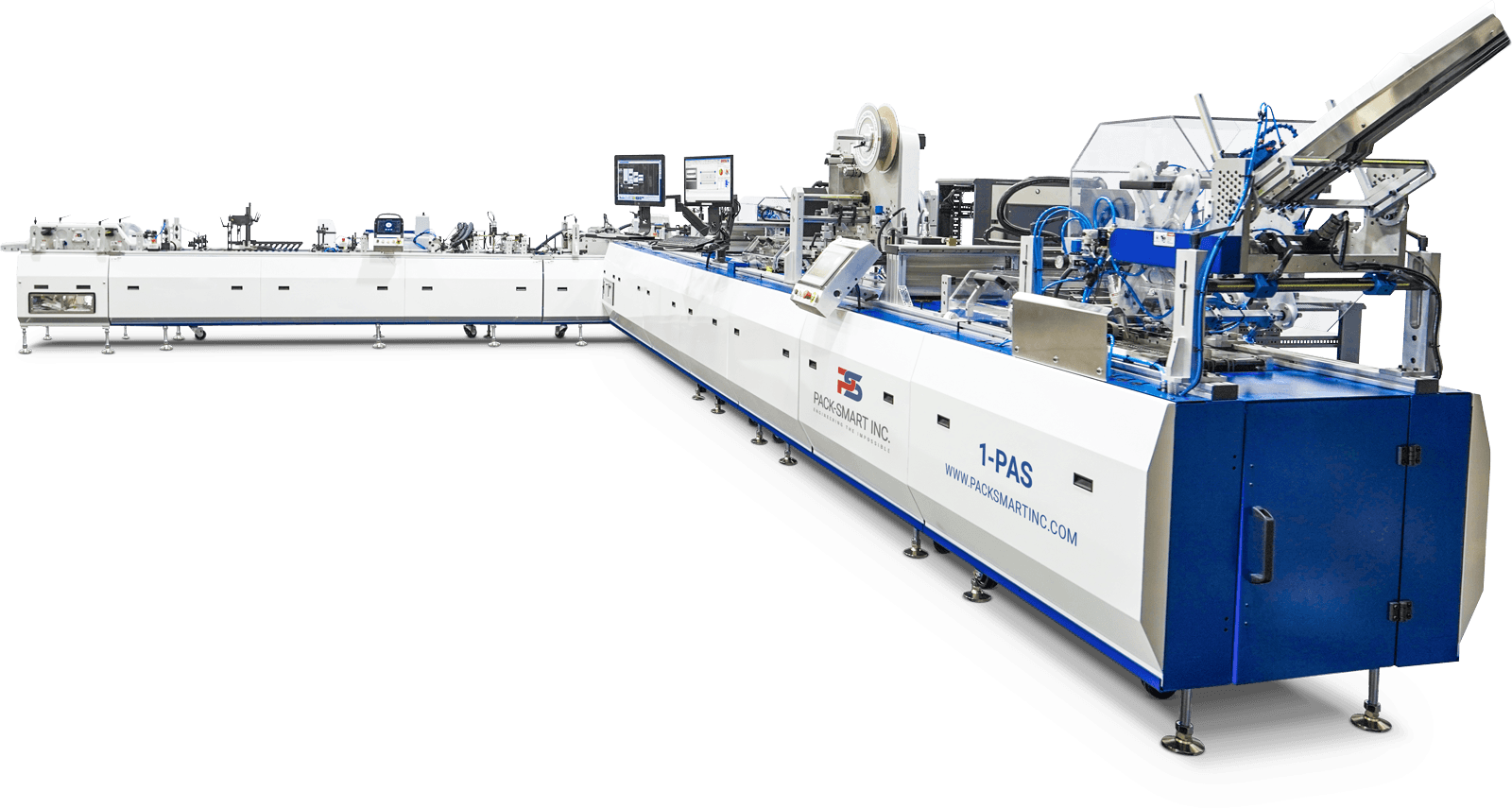

World’s first inline solution for high volume personalization, affixing, packaging and pack-out of secure open and closed loop cards at 20,000 PPH.

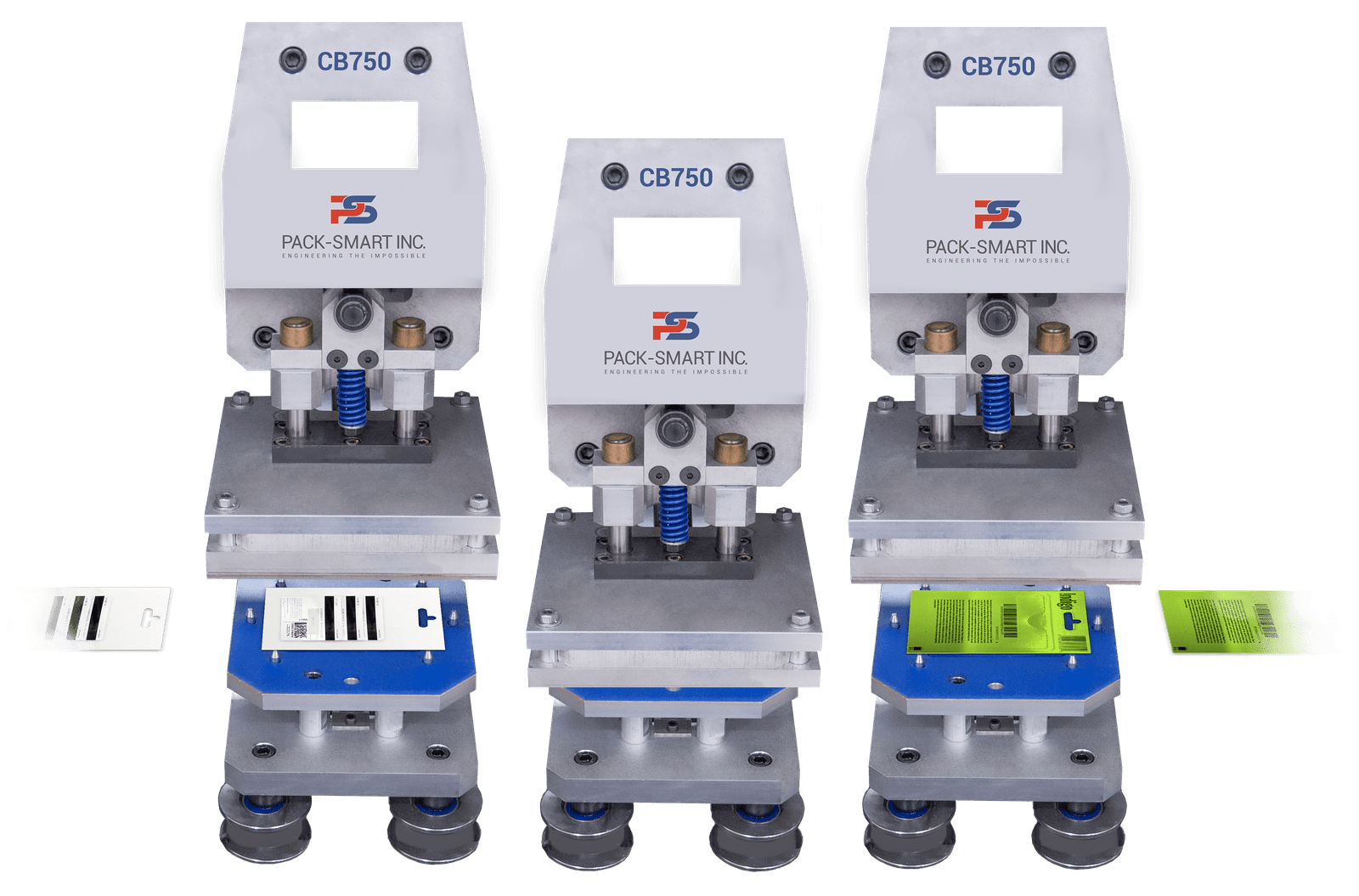

Elevate your packaging efficiency with the CB-7500 Continuous Motion Blister Seal module, designed for high-speed, precise sealing of blister packs.

The CB-750 Continuous Motion Blister Seal module is a cutting-edge solution designed to optimize high-speed packaging processes.

Capable of processing between 6,000 to 9,600 carriers per hour, this module leverages advanced servo control and heat sealing technology to ensure precise and secure packaging.

Ideal for industries requiring rapid and reliable blister sealing, the CB-750 enhances productivity and maintains stringent quality standards.

Multipack Open Loop

eCommerce

This technology is used in the following automated systems.

World’s first inline solution for high volume personalization, affixing, packaging and pack-out of secure open and closed loop cards at 20,000 PPH.

With speeds up to 30,000 PPH, it is ideal for all your closed, secure, and open loop needs.

Inline card to carrier affixing, booklet tipping, 4-corner secure folding/gluing, and DOD personalization.

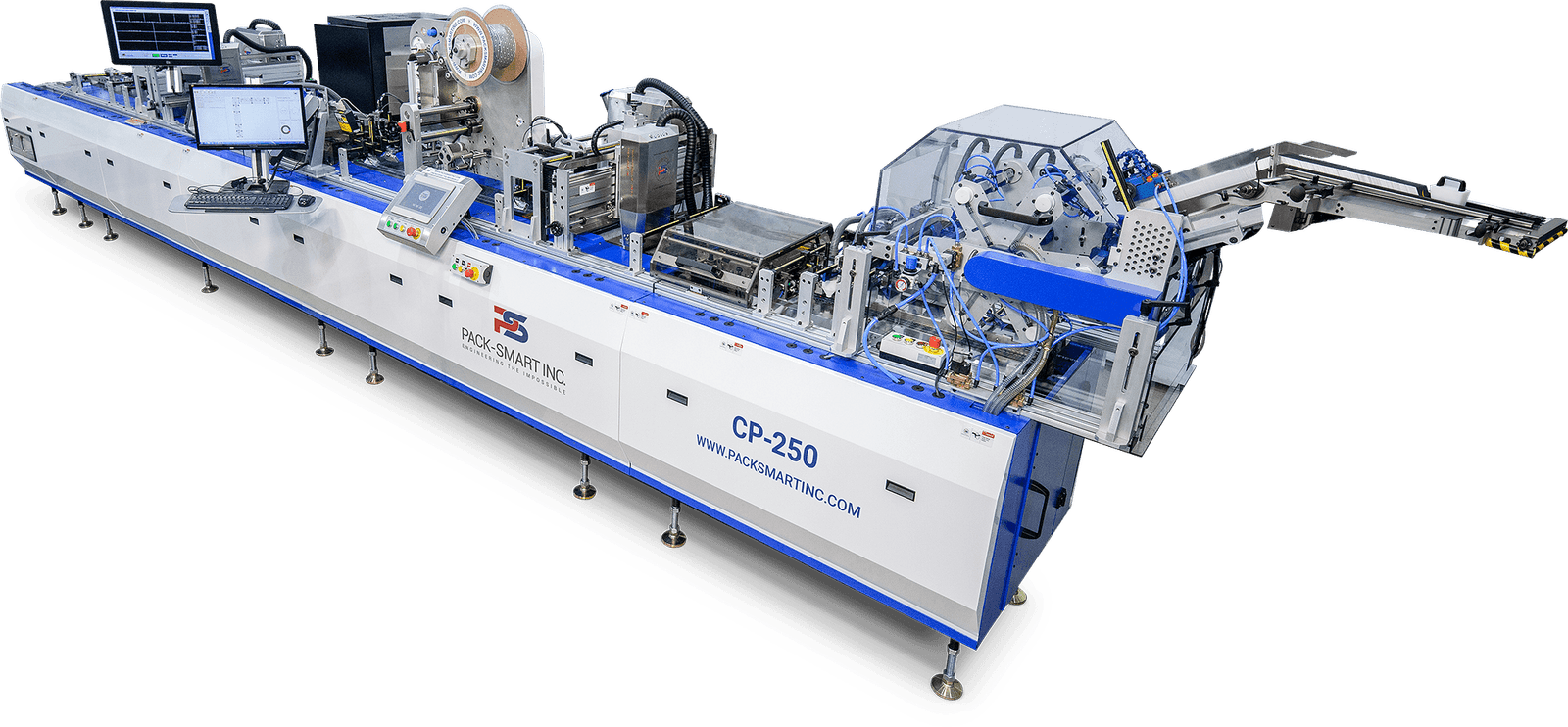

Engineered to meet the rigorous demands of EMV chip card encoding, this system combines advanced encoding capabilities with high-speed processing to deliver unparalleled efficiency.

Related modules are available for inline applications.

The CEG-1 Cold Glue System is engineered for high-precision, tamper-proof adhesive applications.

Revolutionize your production with the HM-10 Hot Melt Glue System, offering precision application for a wide range of adhesive needs.