Card to Bundle in One Pass

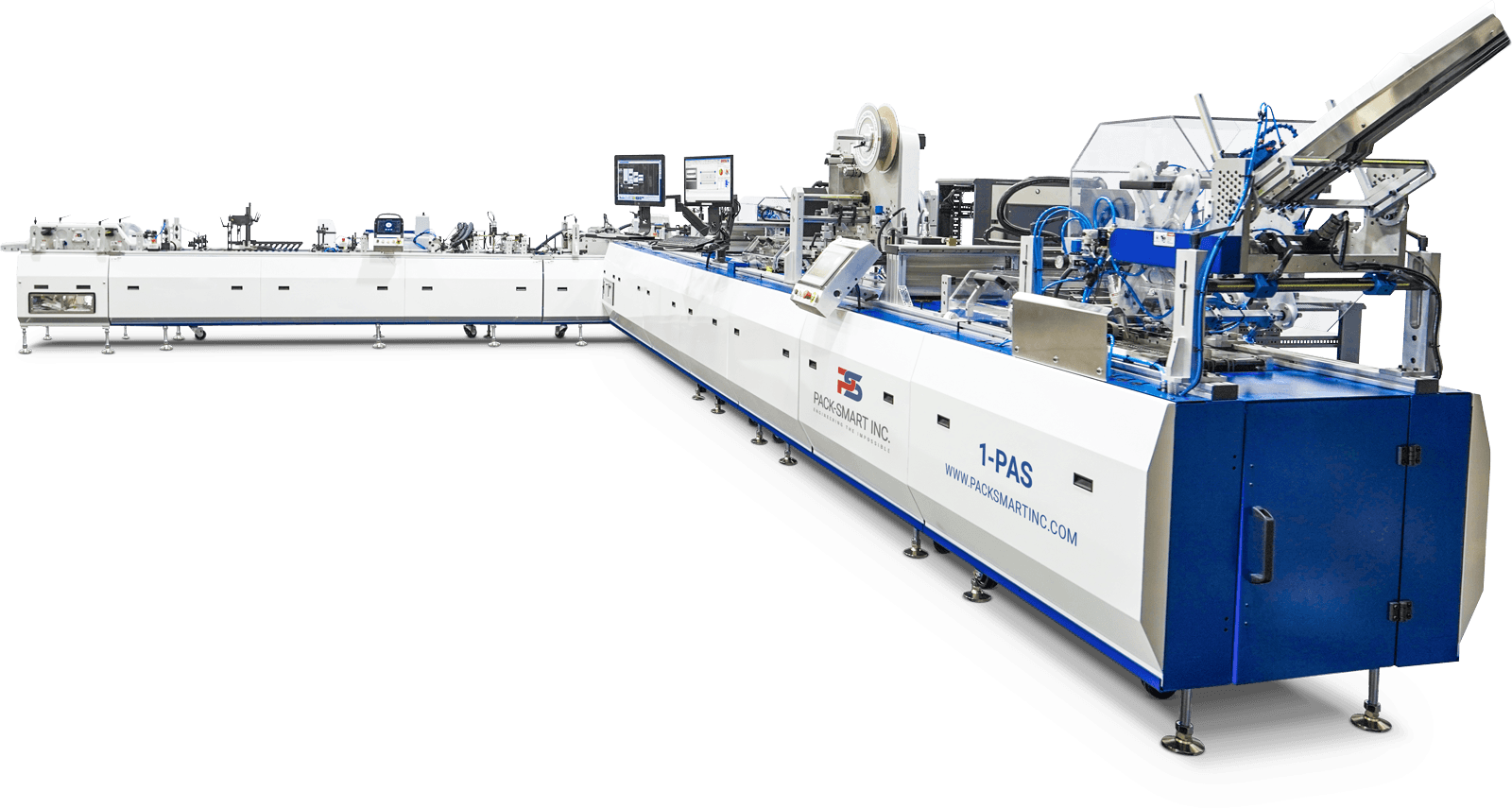

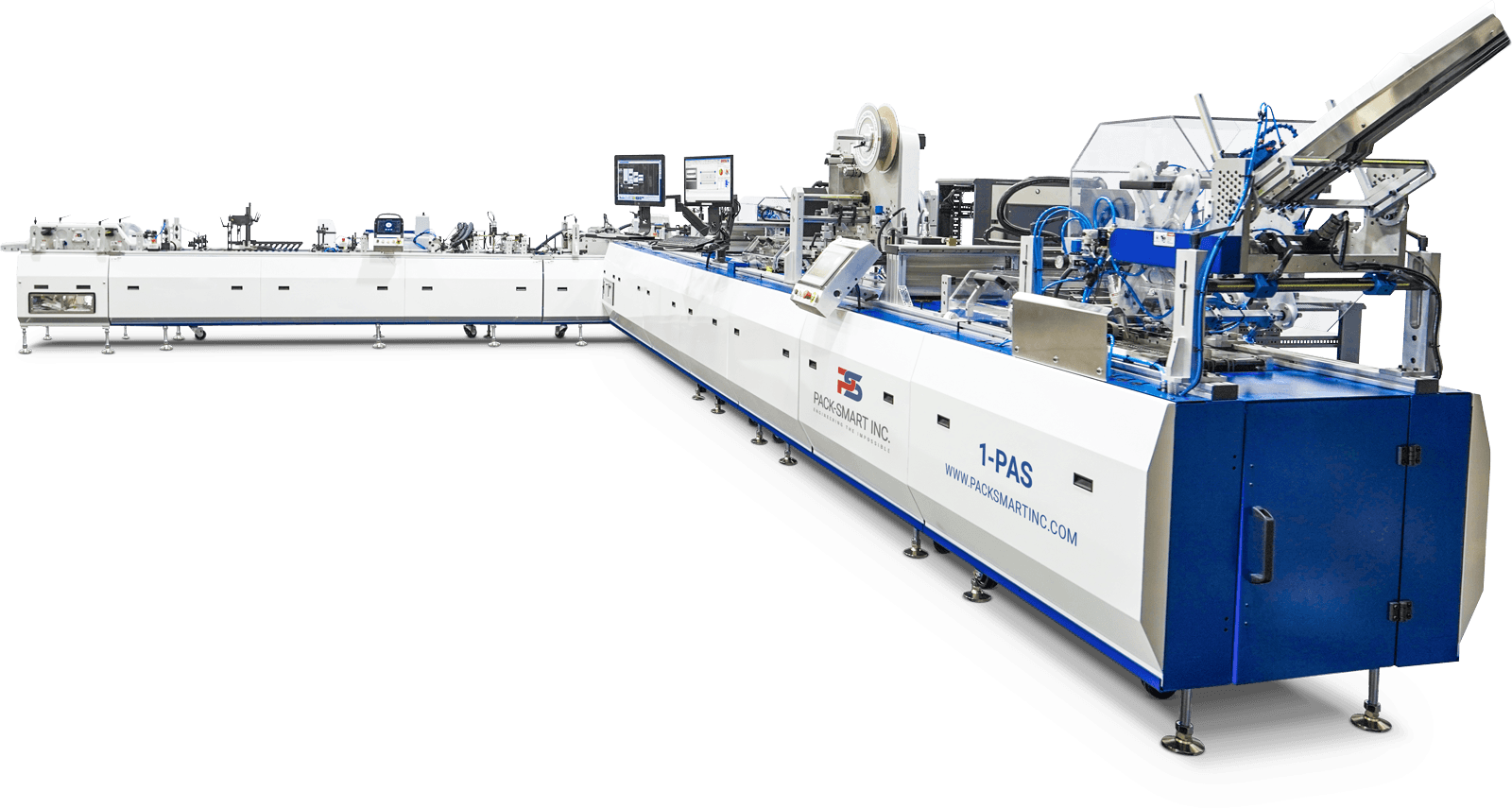

World’s first inline solution for high volume personalization, affixing, packaging and pack-out of secure open and closed loop cards at 20,000 PPH.

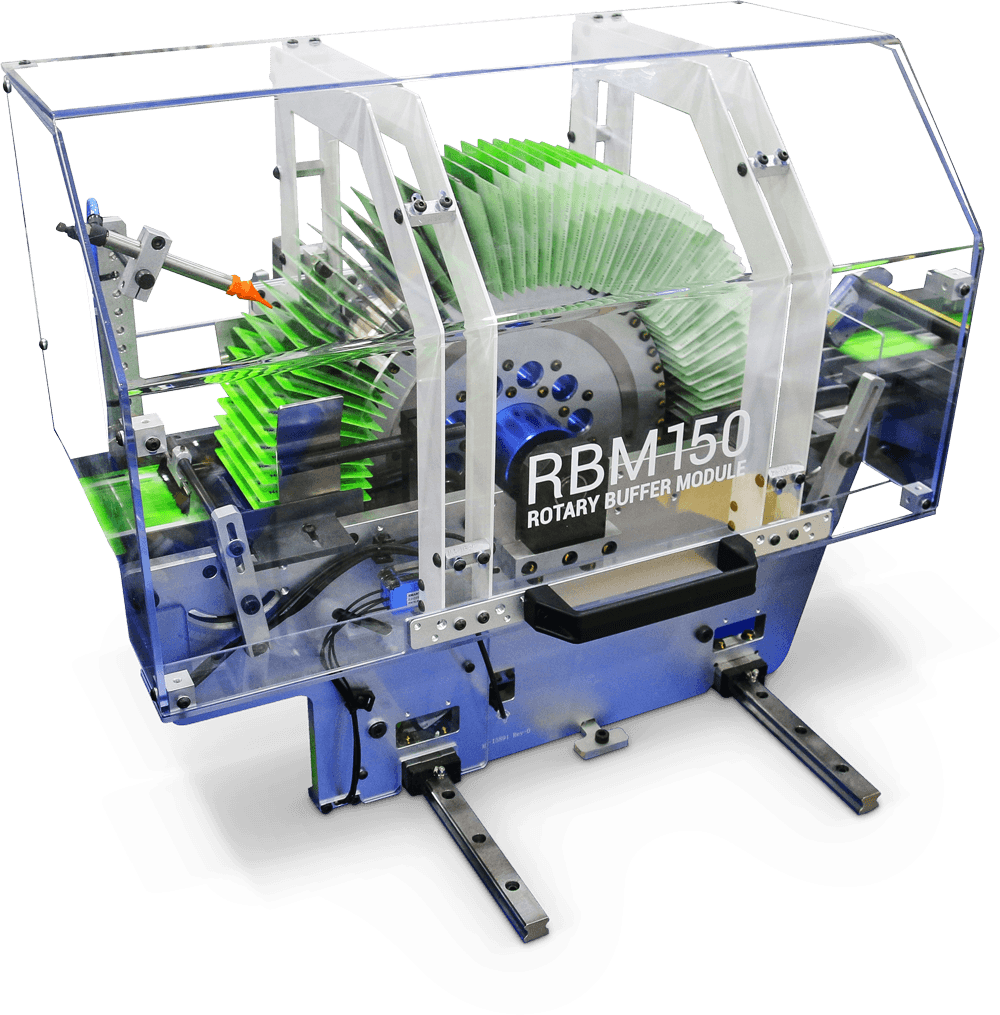

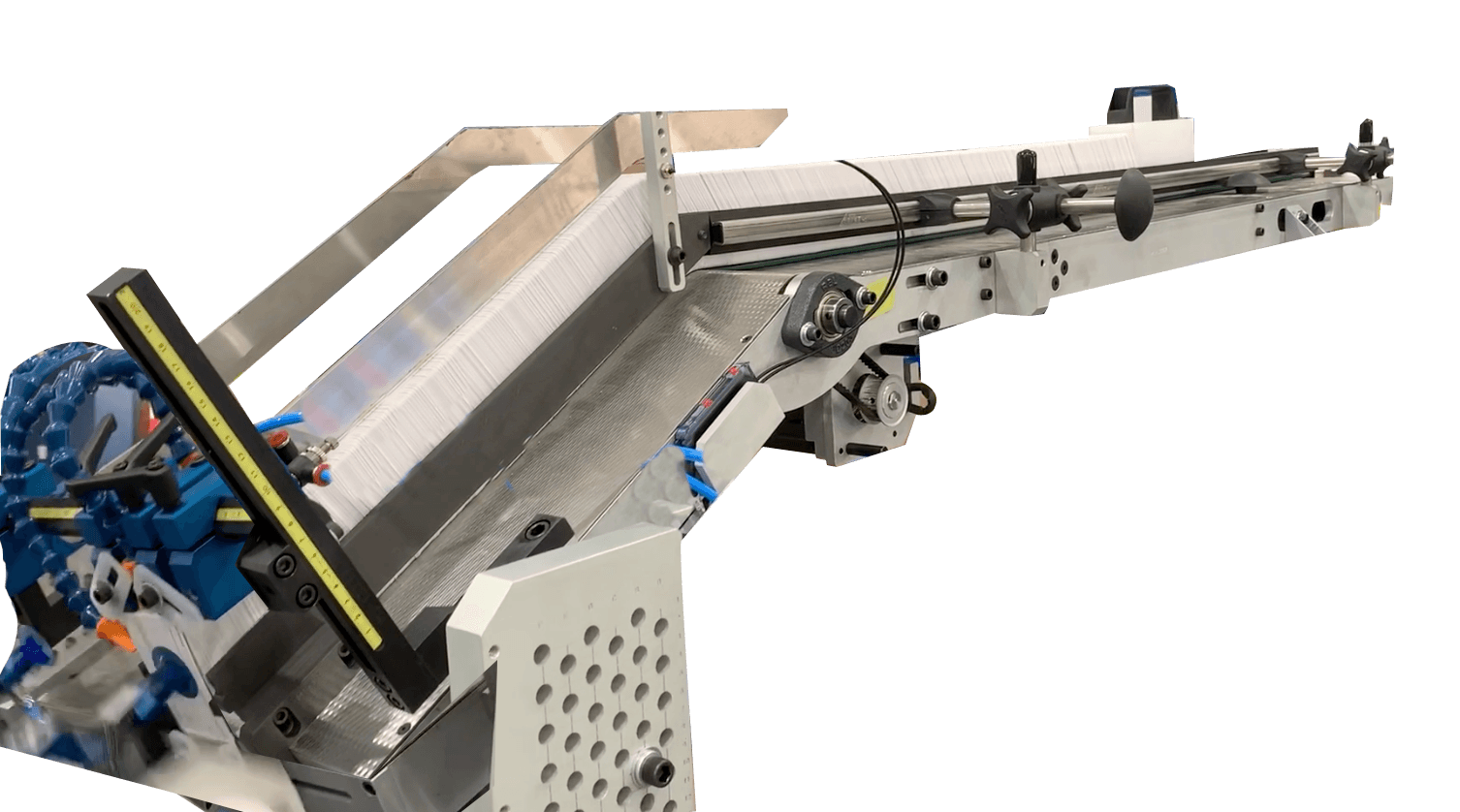

Streamline your production process with the RBM-150 Rotary Buffer Module, expertly designed to queue and synchronize serialized products for enhanced workflow efficiency.

The RBM-150 Rotary Buffer Module is an innovative solution designed to enhance the efficiency of production lines dealing with serialized documents and personalized products.

By queuing serialized documents while their corresponding components are produced, the RBM-150 ensures that matching items are perfectly synchronized, thereby eliminating the need for separate personalization of each item.

This module is essential for operations that require precise timing and matching of different production elements, such as in packaging, labeling, and document handling industries.

Membership & Loyalty

eCommerce

Retail

This module is standardized to accommodate the specific needs of production lines that require synchronized delivery and processing of serialized documents. The singular design ensures uniform performance and compatibility across all setups, focusing on optimizing and streamlining the buffering process without the need for different model variations.

This technology is used in the following automated systems.

World’s first inline solution for high volume personalization, affixing, packaging and pack-out of secure open and closed loop cards at 20,000 PPH.

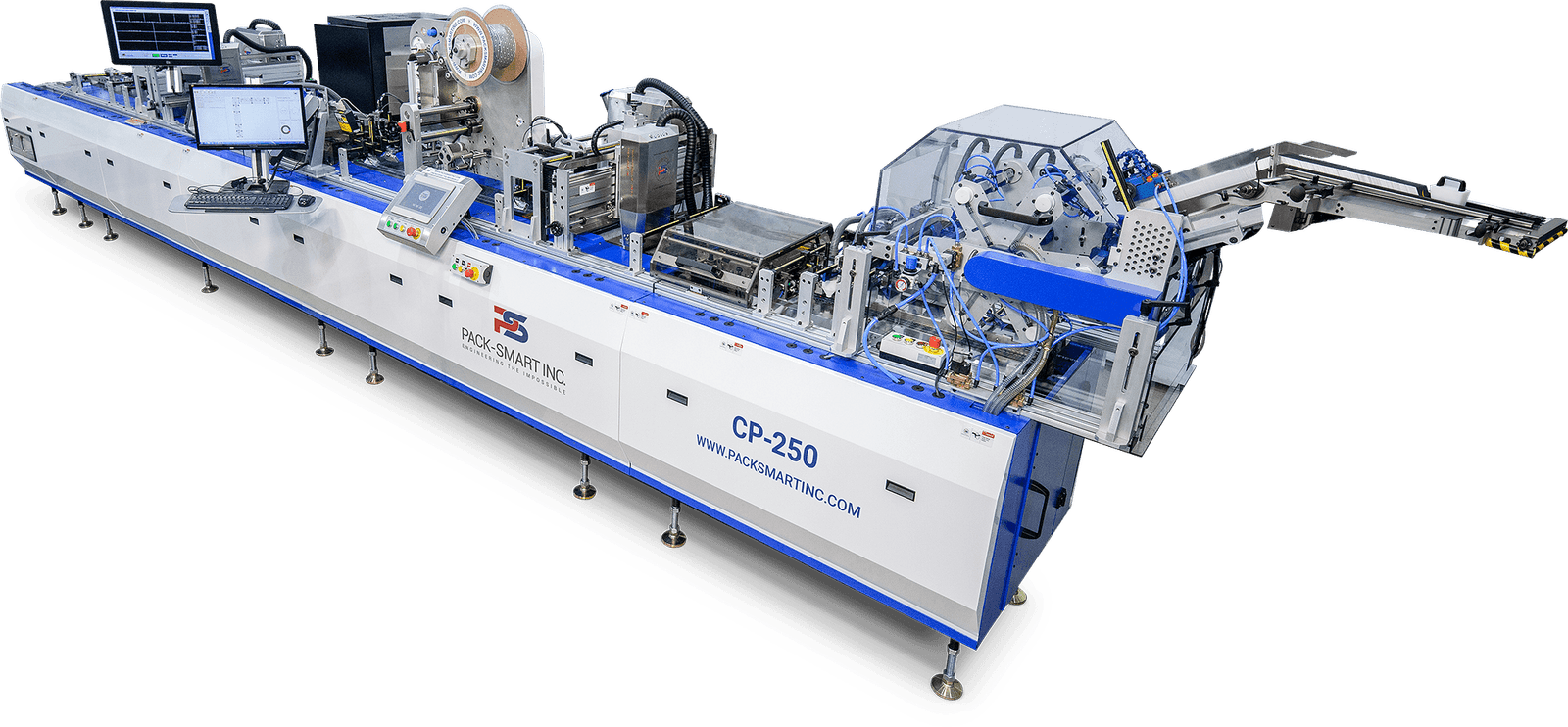

Inline card to carrier affixing, booklet tipping, 4-corner secure folding/gluing, and DOD personalization.

Related modules are available for inline applications.

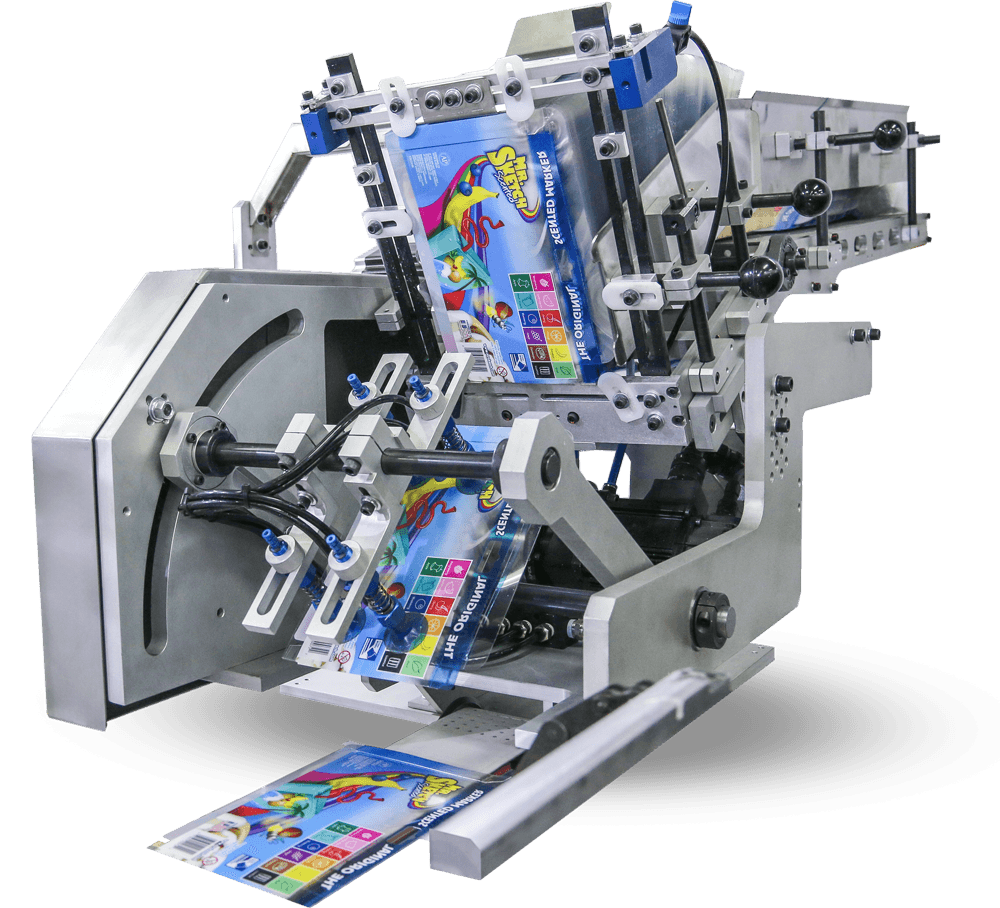

Consistently feed, insert, attach, and batch delicate materials and oddly shaped products at 30,000 PPH, with vacuum pick & place motion and ±0.02″ placement accuracy.

Maximize your production efficiency with the RPP Series, designed for high-speed, accurate handling of delicate materials and uniquely shaped products.

Elevate your production capabilities with the PG-900 Flexo Pattern Glue Module, designed for precise and flexible adhesive applications.

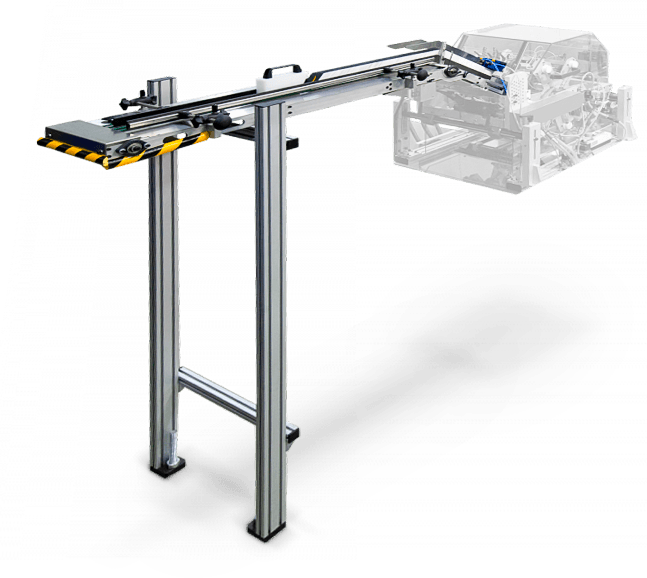

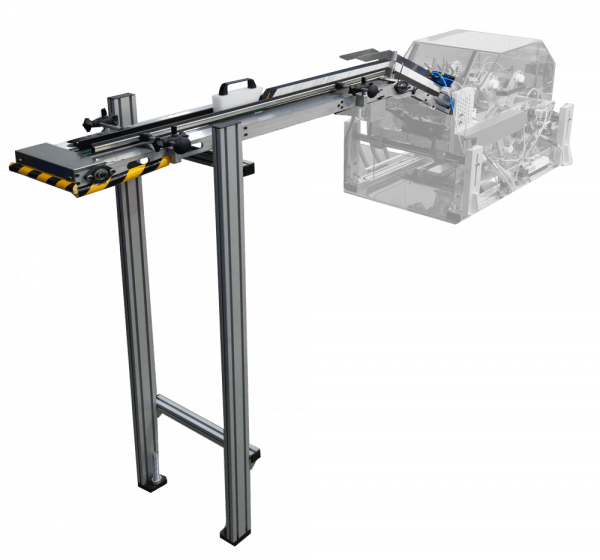

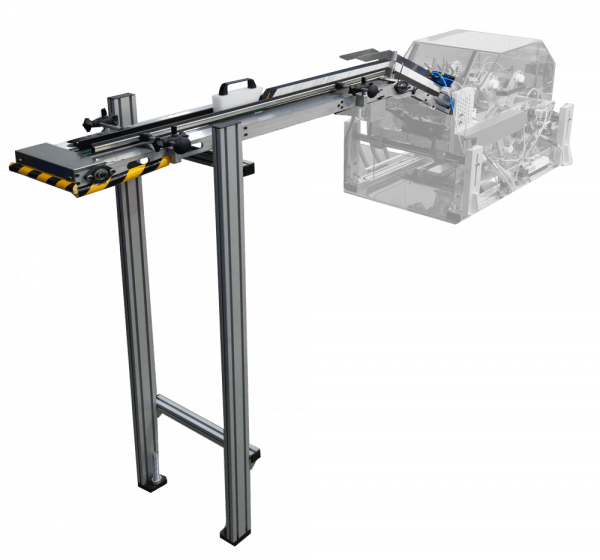

Maximize productivity with the AL Series Powered Autoloader. Designed to extend loading capacities and reduce manual reloading for high-speed applications, ensuring continuous operation and efficiency.

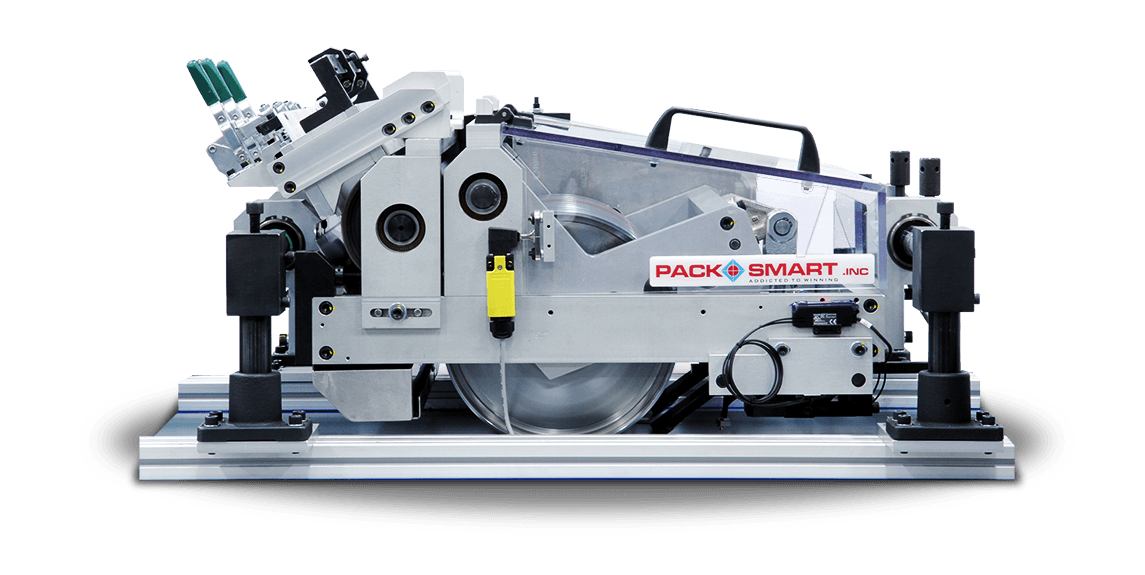

The AL Series Powered Autoloader revolutionizes material handling for high-speed applications by extending the loading capacities from 30″ to 68″.

This enhancement significantly reduces the frequency of manual reloading, allowing operators to focus on other tasks, thereby optimizing operational workflows.

With its robust design and compatibility with a wide range of materials like paper, plastic, and card stock, the AL Series is perfect for industries requiring high reliability and precision.

Engineered for optimal efficiency and reliability, this series sets the standard for high-capacity automated loading solutions.

AL-300

Basic model for smaller operations

AL-500

Mid-range model with increased capacity

AL-1100

High-capacity model for industrial use

This technology is used in the following automated systems.

World’s first inline solution for high volume personalization, affixing, packaging and pack-out of secure open and closed loop cards at 20,000 PPH.

Inline card to carrier affixing, booklet tipping, 4-corner secure folding/gluing, and DOD personalization.

With speeds up to 30,000 PPH, it is ideal for all your closed, secure, and open loop needs.

Related modules are available for inline applications.

Consistently feed, insert, attach, and batch delicate materials and oddly shaped products at 30,000 PPH, with vacuum pick & place motion and ±0.02″ placement accuracy.

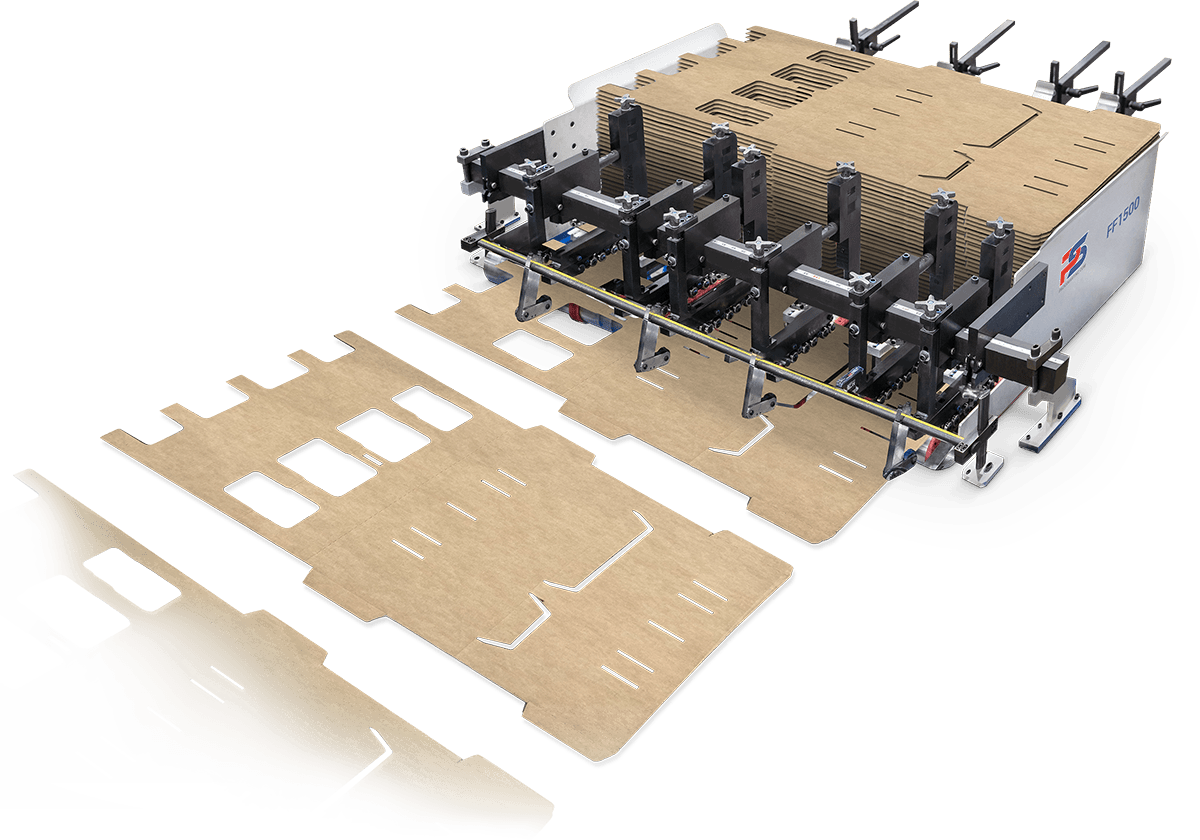

Reaching up to 600 products per minute, the SF Series is a perfect choice for handling light paper to heavy stock material.

The FF Series Friction Feeder can handle the lightest paper and is equally at home when dealing with heavy stock materials when called upon.