Rotary Pick and Place Series

Consistently feed, insert, attach, and batch delicate materials and oddly shaped products at 30,000 PPH, with vacuum pick & place motion and ±0.02″ placement accuracy.

Inline card to carrier affixing, booklet tipping, 4-corner secure folding/gluing, and DOD personalization.

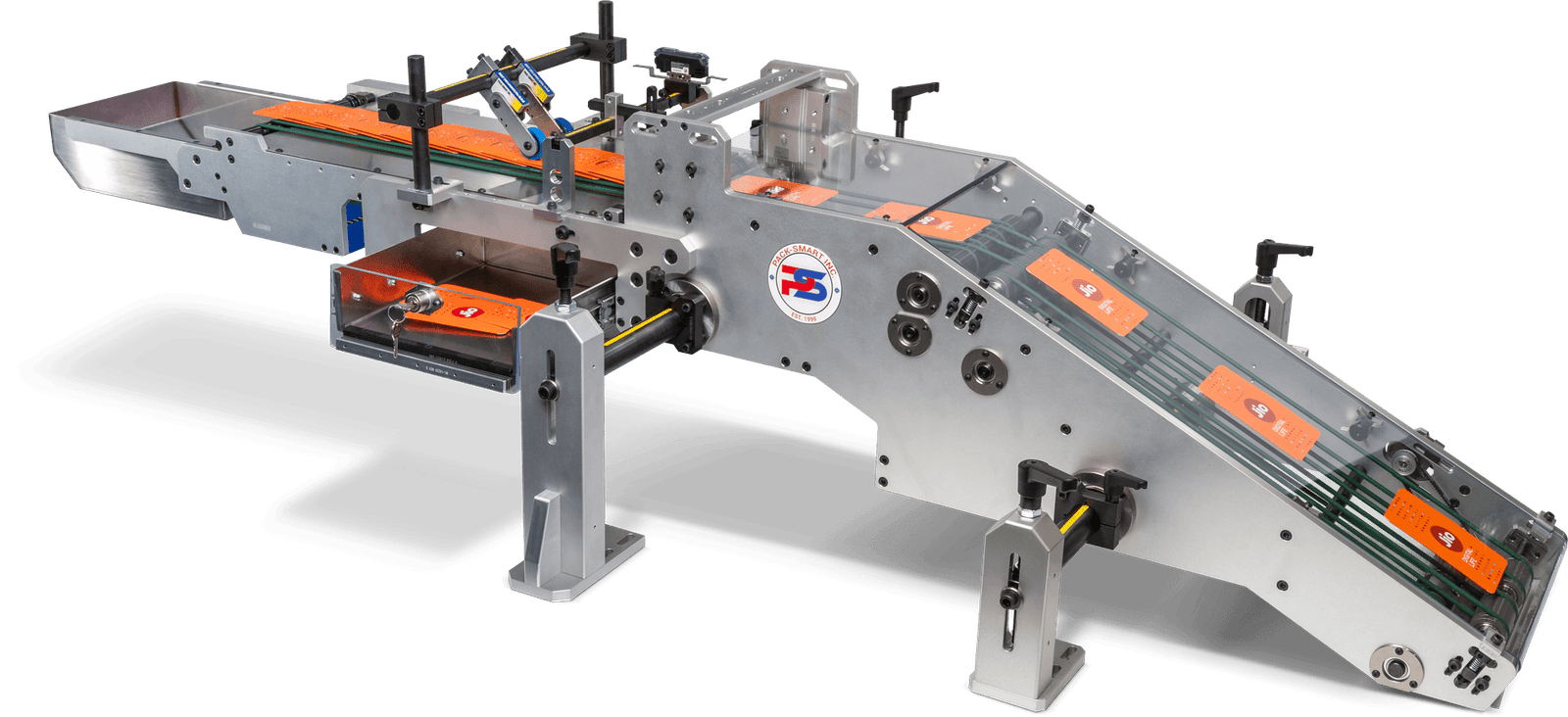

Pack-Smart’s SC-500 machines are the golden standard for the fastest fulfillment, secure packaging, and pack-out of SIM, phone, loyalty, and gift cards at speeds up to 24,000 products per hour.

Fully automated inline capabilities of special carrier and card affixing, booklet tipping, 4-corner secure folding/gluing, and personalization.

The process flow for the SC-500 Secure Card Packaging System is meticulously designed to ensure high-speed, secure, and precise packaging of cards. This system integrates each step, from initial card feeding to final packaging, ensuring seamless operations with a focus on security and efficiency.

The SC-500 Secure Card Packaging System incorporates advanced technologies to enhance its performance and reliability. Key technologies include high-speed card feeders for rapid processing, precision affixing and folding mechanisms for accurate card placement, and real-time data tracking systems to ensure secure and traceable operations.

Consistently feed, insert, attach, and batch delicate materials and oddly shaped products at 30,000 PPH, with vacuum pick & place motion and ±0.02″ placement accuracy.

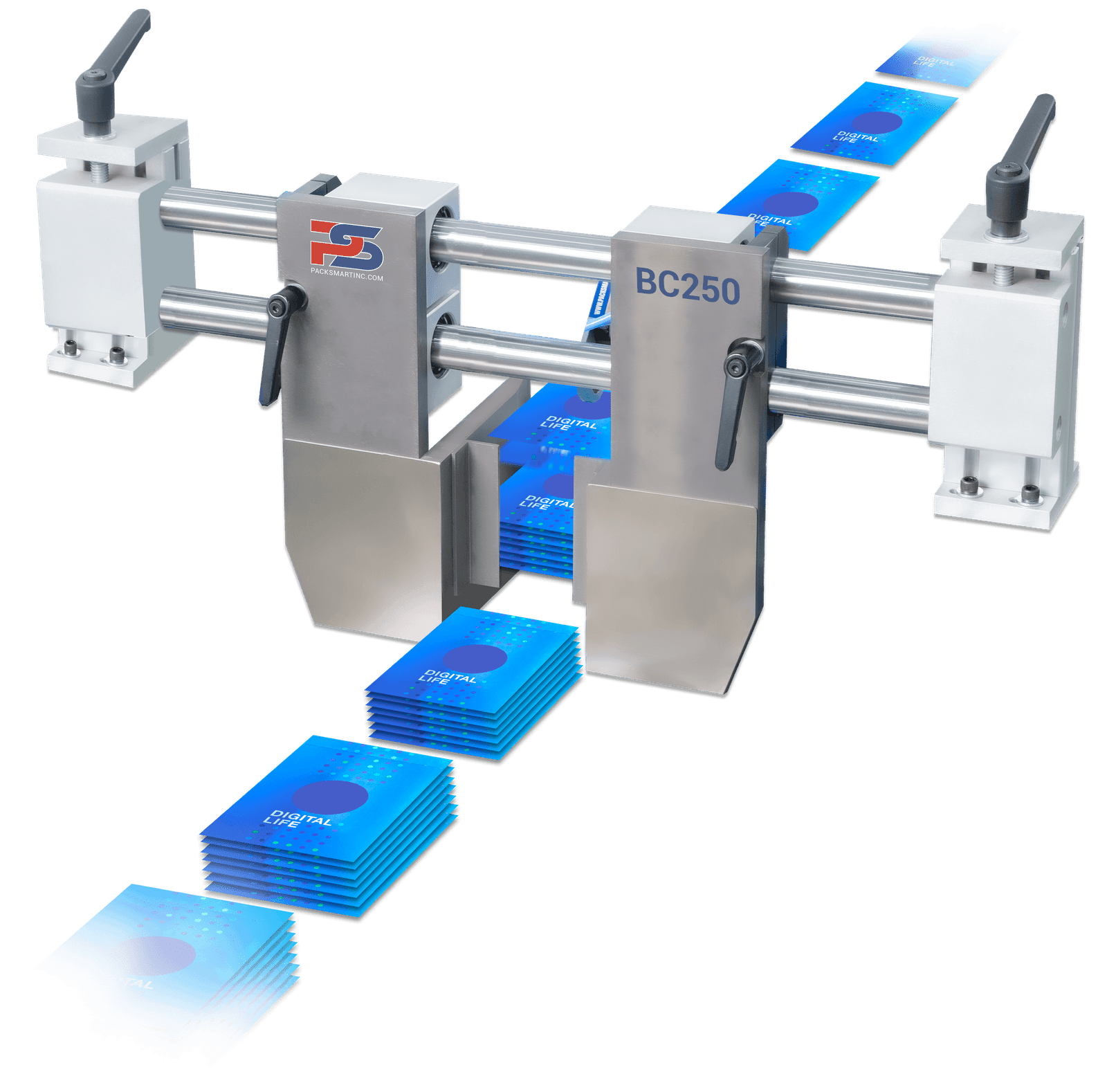

Efficiently batch single products into precise groups with Pack-Smart’s BC Series, designed for a wide range of materials and applications.

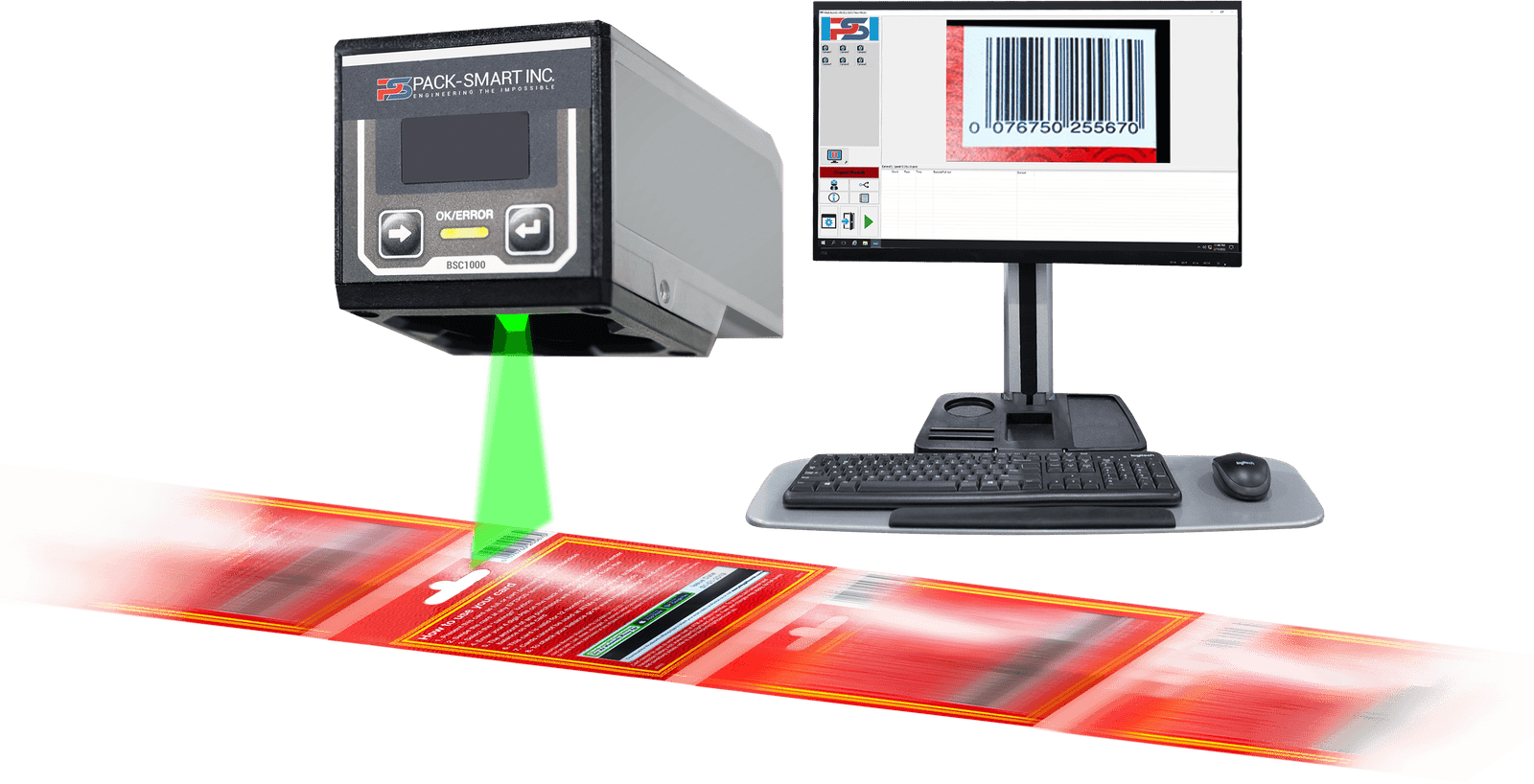

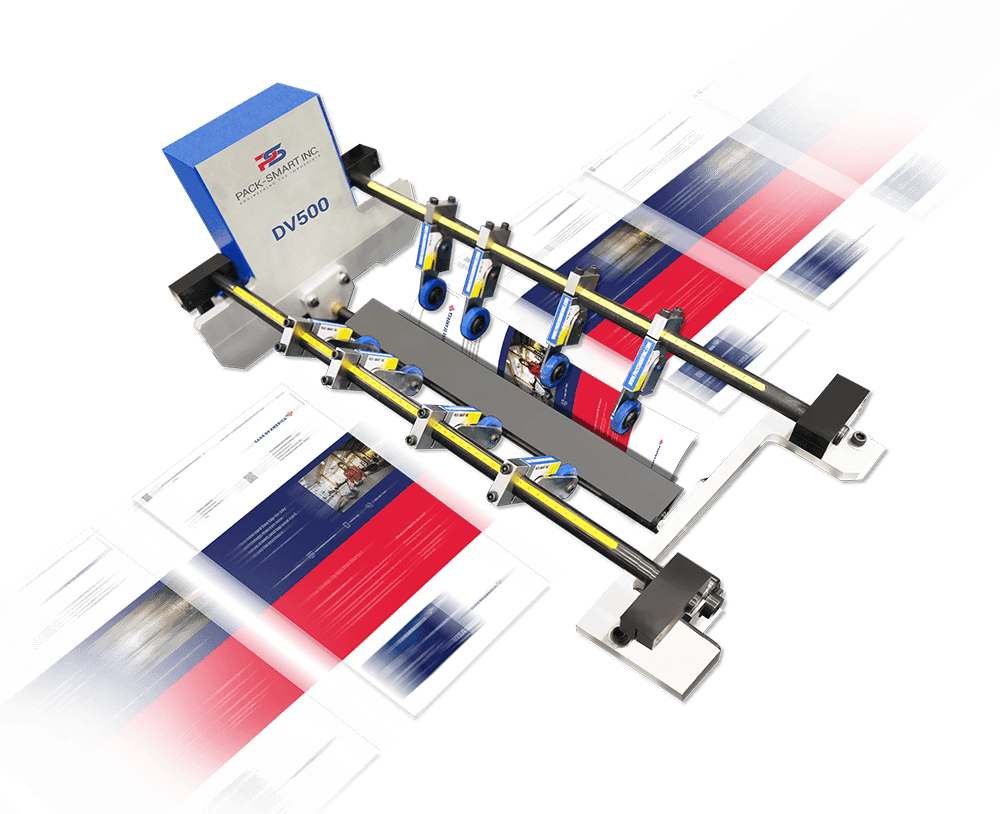

A user-friendly, fully packaged CCD reader, offering easy integration and several configurations to meet a variety of needs.

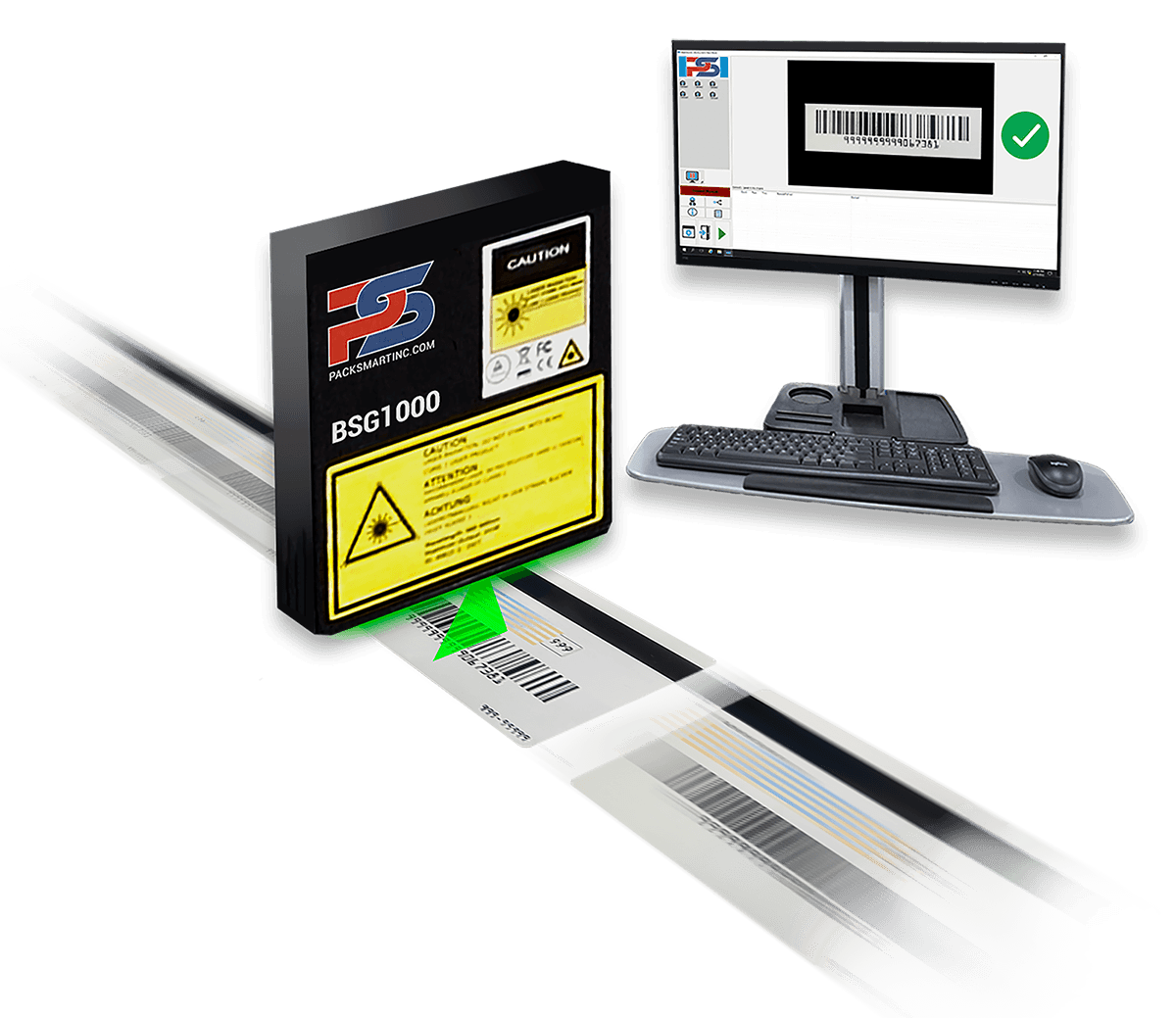

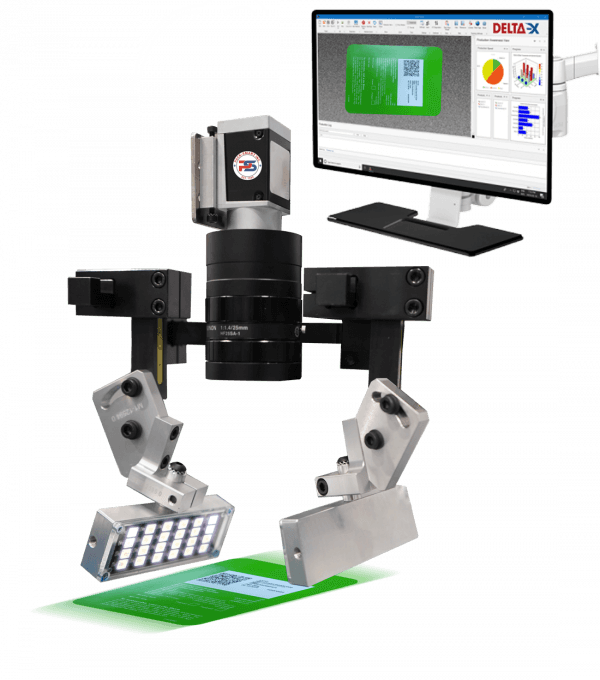

The BSG-1000 Barcode Scanning and Grading module is designed to ensure that all your barcoded products meet ISO standards for quality.

Enhance production line efficiency with the DO Series Overhead Divert, designed for high-speed, accurate product diversion and handling.

Elevate efficiency with the DZ Series Zoned Divert, designed for precise sorting and high-capacity handling in demanding industrial environments.

Revolutionize your production with the HM-10 Hot Melt Glue System, offering precision application for a wide range of adhesive needs.

The VSC-1000 Vision System offers state-of-the-art vision scanning and real-time image processing, ideal for high-speed production environments.