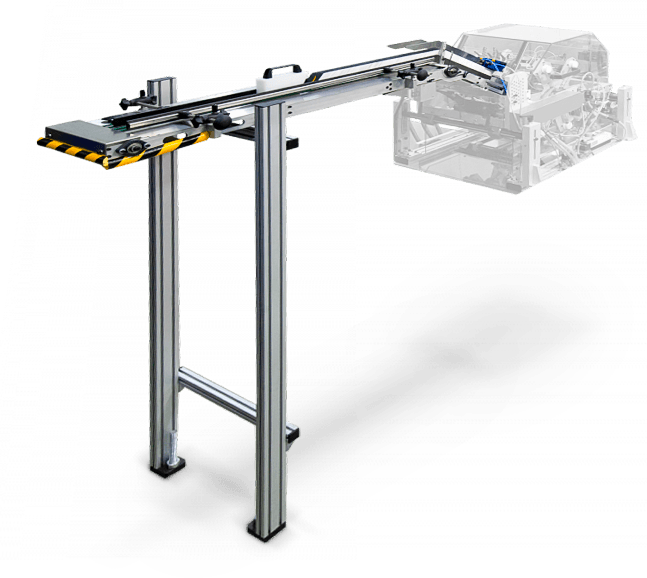

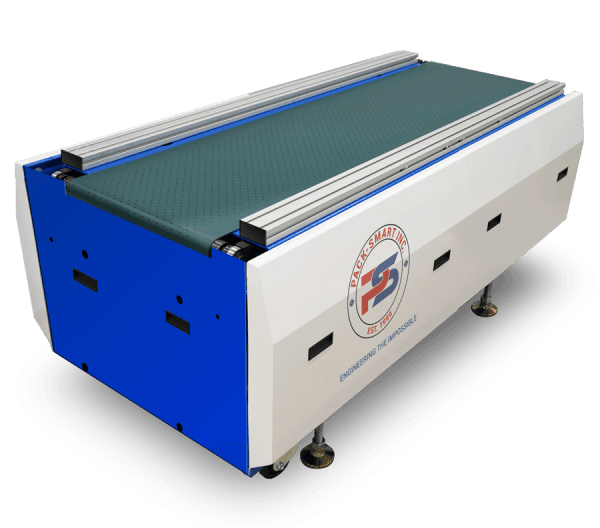

Powered Autoloader

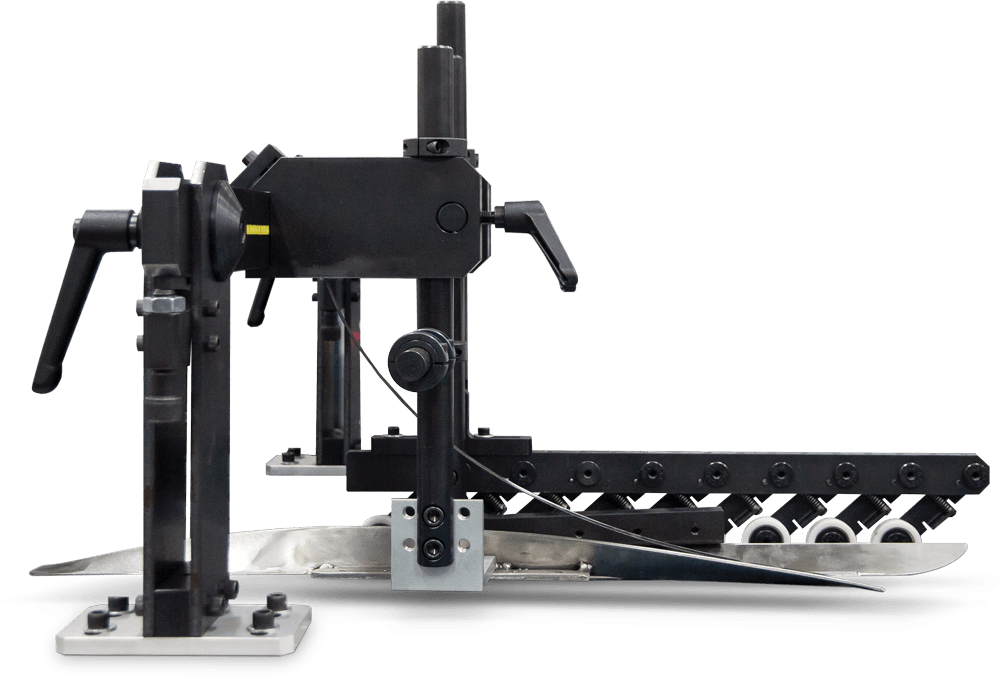

Maximize productivity with the AL Series Powered Autoloader. Designed to extend loading capacities and reduce manual reloading for high-speed applications, ensuring continuous operation and efficiency.

Delivers unmatched automation, producing 3,500+ products per hour while ensuring 100% product integrity. Designed for scalability, accuracy, and seamless integration, this state-of-the-art system will transform your packaging operations with modular flexibility.

In industries where presentation, precision, and product integrity are non-negotiable, the TF-3500 Tray Forming and Filling System sets a new standard. Designed for luxury goods, confectionery, electronics, and personal care packaging, this system ensures flawless tray formation and seamless product integration at high speeds.

Unlike traditional solutions, the TF-3500 combines advanced motion control, automated 4-corner folding, and real-time vision inspection, making it the ideal choice for businesses looking to scale production while maintaining premium quality. From delicate chocolates to high-end consumer electronics, the

The TF-3500 Tray Forming and Filling System streamlines every stage of the packaging process, from precision tray forming and product placement to secure lid application and final delivery, ensuring high-speed, error-free operation with seamless automation.

The TF-3500 Tray Forming and Filling System integrates advanced automation and intelligent motion control technologies to deliver precision, efficiency, and reliability at every stage of the tray packaging process. Each component is engineered to optimize performance, ensuring seamless operation and high-speed throughput.

Maximize productivity with the AL Series Powered Autoloader. Designed to extend loading capacities and reduce manual reloading for high-speed applications, ensuring continuous operation and efficiency.

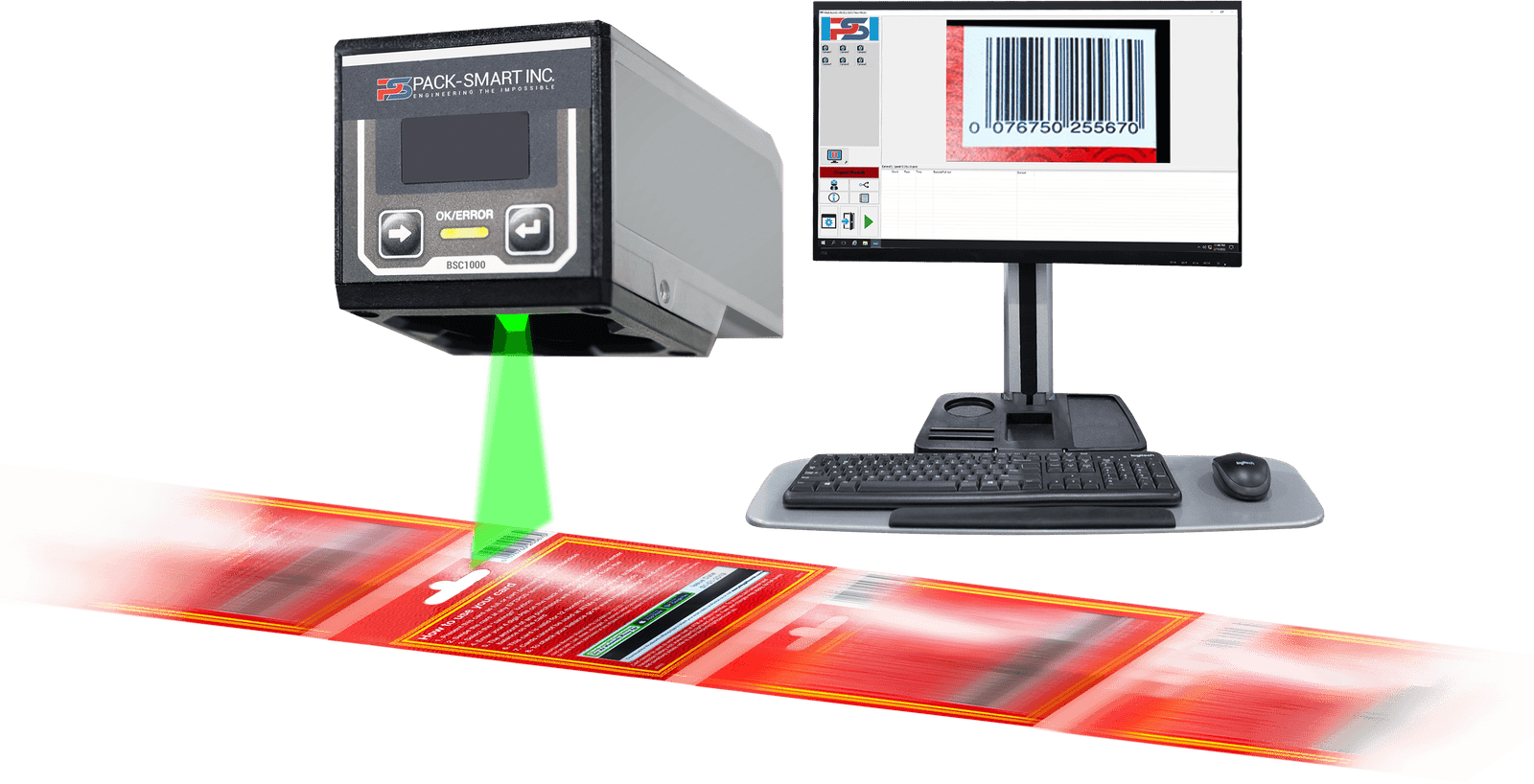

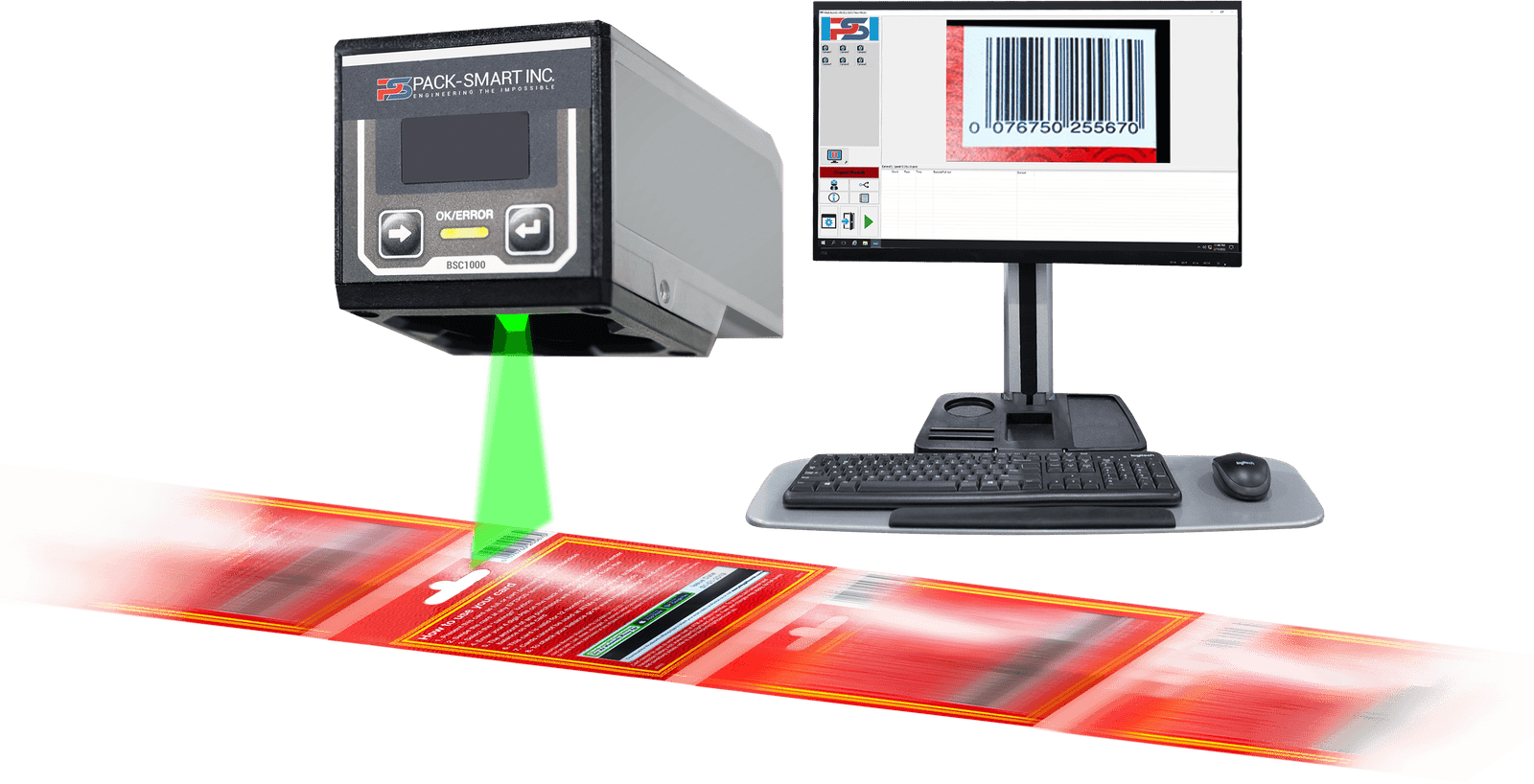

A user-friendly, fully packaged CCD reader, offering easy integration and several configurations to meet a variety of needs.

Smart Jet uses industry leading head technology to deliver UV Cured 600 DPI DOD Ink onto any surface.

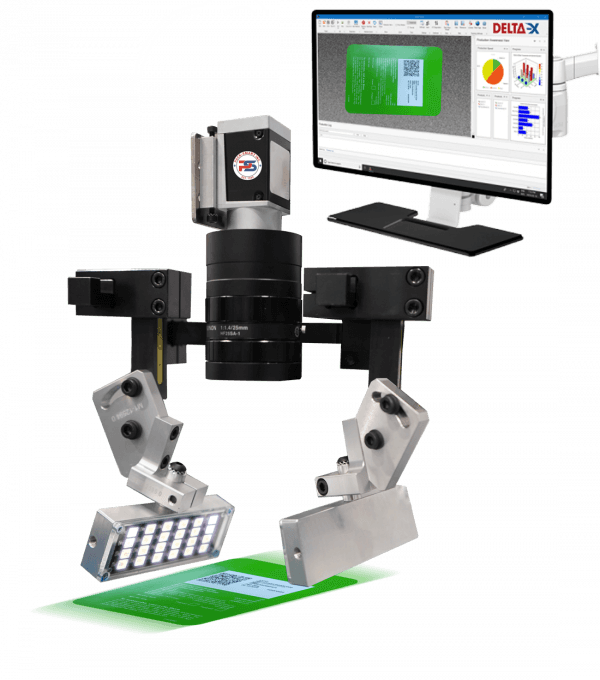

The VSC-1000 Vision System offers state-of-the-art vision scanning and real-time image processing, ideal for high-speed production environments.

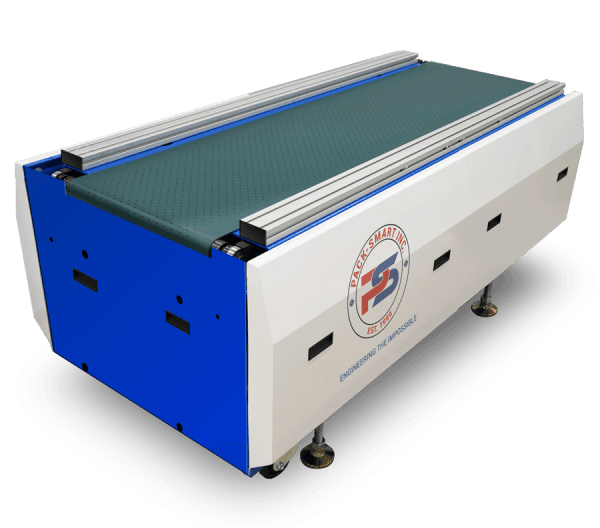

High torque servo driven vacuum transport conveys products at accurate speeds and controls product placement with 8 selectable vacuum zones.

Maximize your production efficiency with the RPP Series, designed for high-speed, accurate handling of delicate materials and uniquely shaped products.

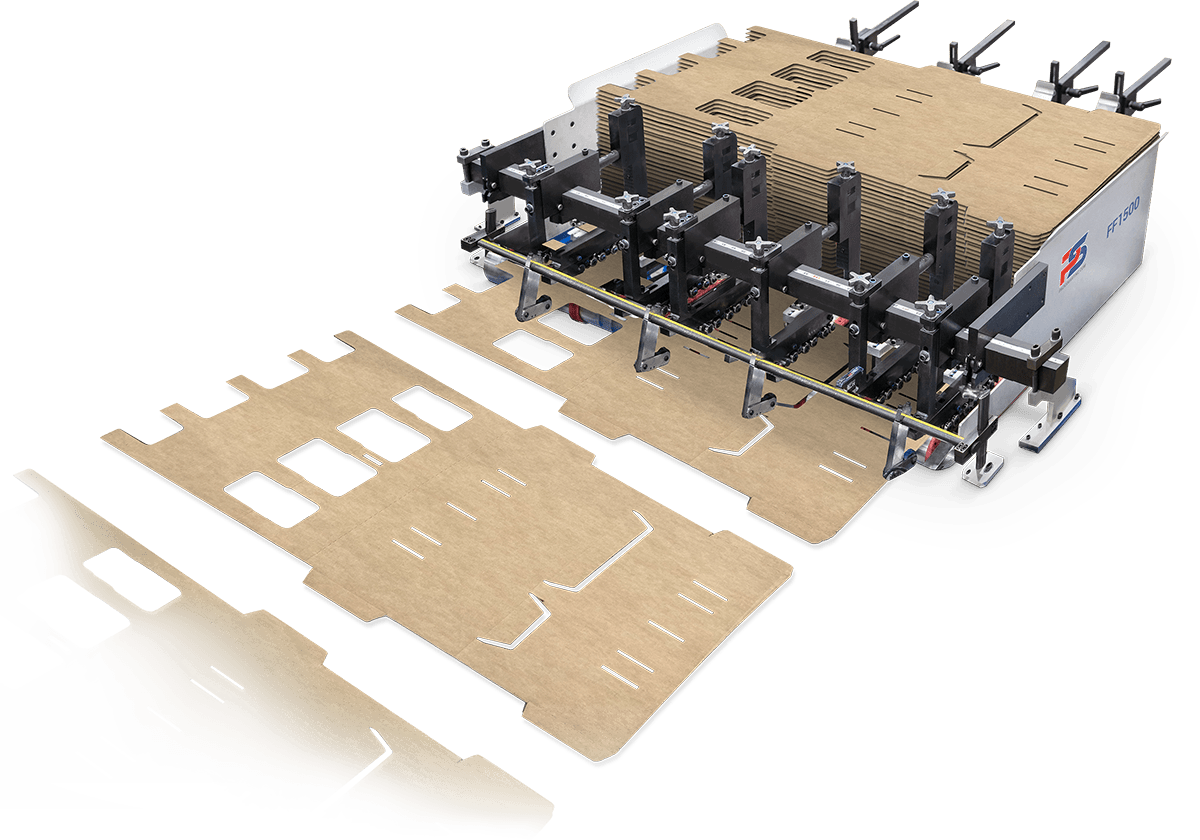

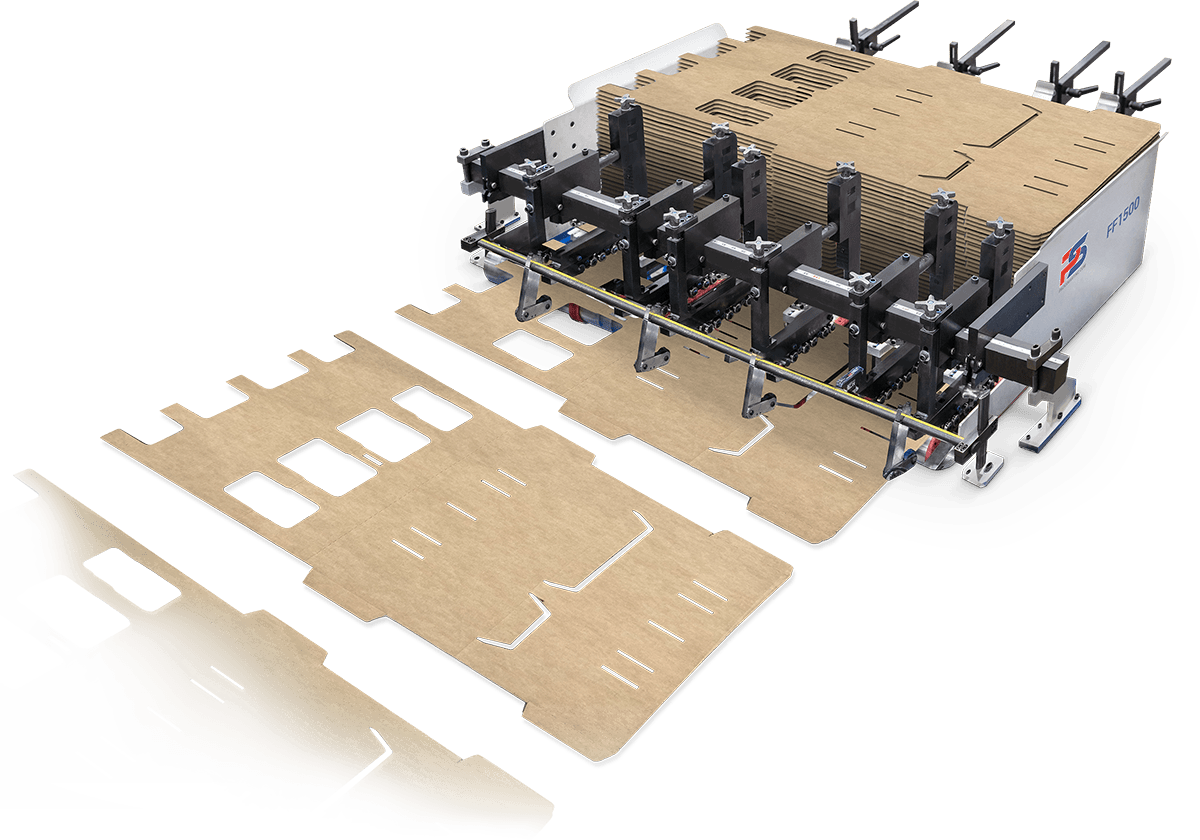

Specialty 60″ Corrugated Folder Gluer with Plastics Clips and Reinforcements for POP Displays.

FG-1500 specialty folder gluer series are built to enable the production of unconventional and complex products based on corrugated materials fitted with add-ons such as clips, windows, RFIDs, labels, and reinforcement inserts. FG series specialty folder gluers process E, B, C flute and double wall corrugated board with 60″ maximum blank width.

System utilizes a pick and place insert attachment, standard straight line and auto bottom functions, pre-fold and final fold sections, independently driven upper carriers with an extended final fold. Like all Pack-Smart high-performance finishing systems, the FG series are operator friendly with world-class reliability and unmatched flexibility.

POP Displays (Small)

POP Displays (Medium)

POP Displays (Large)

This workflow outlines each critical stage of the corrugated folding and gluing process, meticulously designed to ensure efficiency, precision, and quality from start to finish. Follow the path from material intake to final product assembly, experiencing how integrated technologies streamline operations and elevate output.

Each component is strategically integrated to enhance performance and reliability throughout the folding and gluing process. These technologies, from advanced feeding mechanisms to sophisticated software systems, represent the pinnacle of innovation, ensuring that every product meets the high standards of durability and design excellence expected in today’s competitive markets.

The FF Series Friction Feeder can handle the lightest paper and is equally at home when dealing with heavy stock materials when called upon.

Revolutionize your production with the HM-10 Hot Melt Glue System, offering precision application for a wide range of adhesive needs.

The CEG-1 Cold Glue System is engineered for high-precision, tamper-proof adhesive applications.

Maximize your production efficiency with the RPP Series, designed for high-speed, accurate handling of delicate materials and uniquely shaped products.

High torque servo driven vacuum transport conveys products at accurate speeds and controls product placement with 8 selectable vacuum zones.

The PF50-90 Plow Fold Module integrates seamlessly into production lines, offering both left and right folding configurations.

Reaching up to 600 products per minute, the SF Series is a perfect choice for handling light paper to heavy stock material.

Combine folding, gluing, affixing, personalization, and sorting in a single pass.

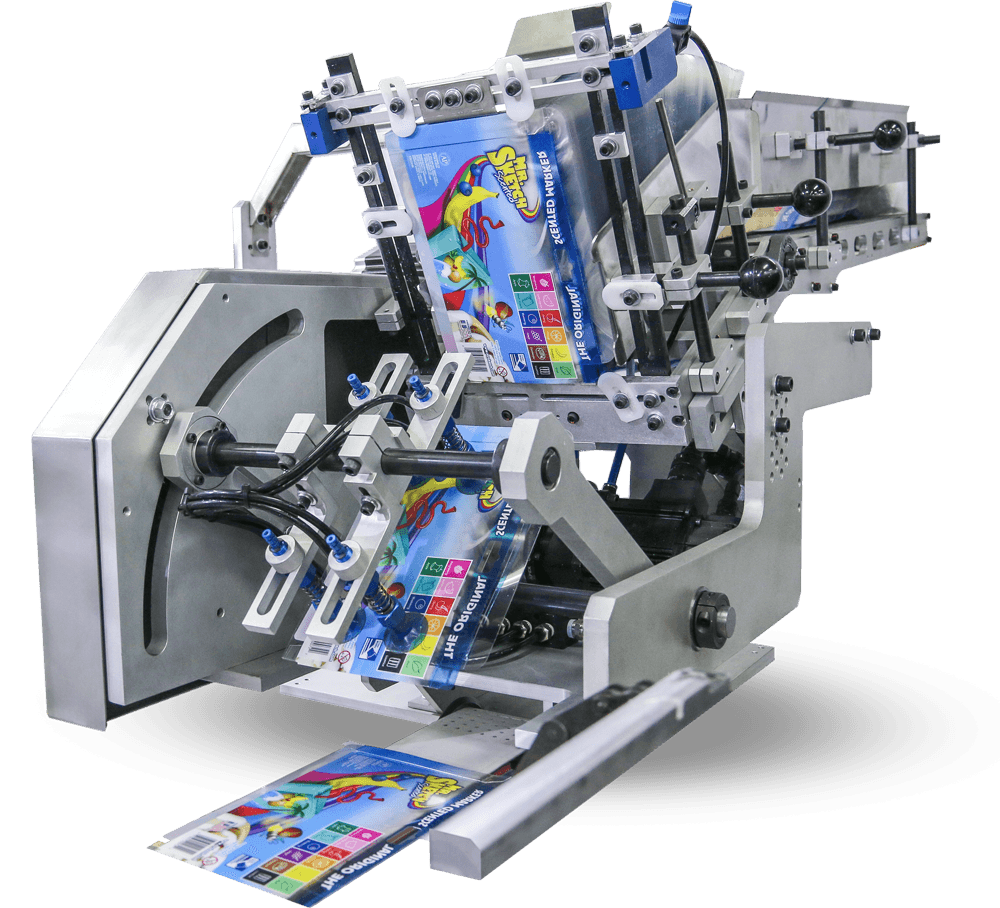

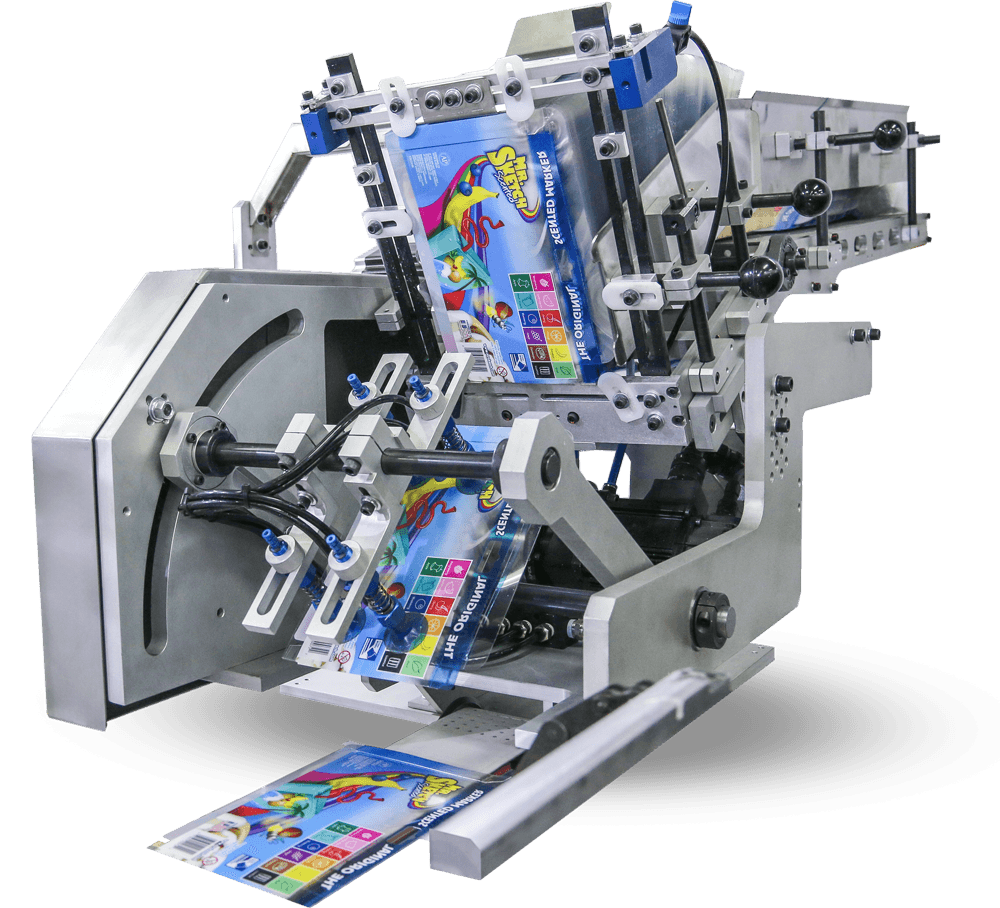

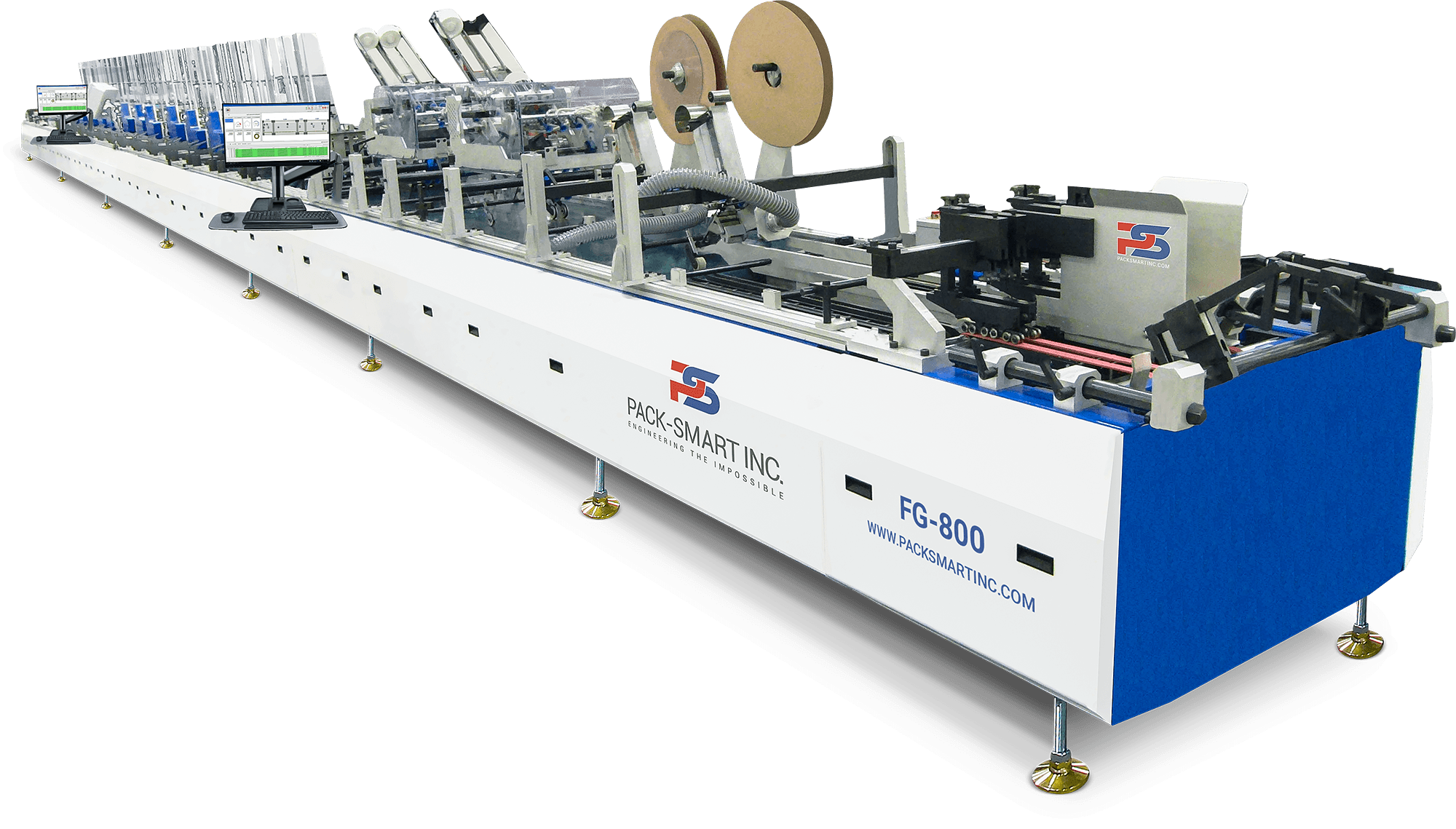

The FG-800 is designed to give the tools and flexibility needed to explore new manufacturing opportunities in the folding carton and specialty finishing world. The alignment of cartons is handled by a state-of-the-art registration module, which employs innovative servo technology making setups swift and effortless.

High Value Carton

Auto-Erect Cartons

The process flow for the FG-800 Rigid Window Affixing System is designed to ensure precise, secure, and efficient production of folding cartons. This system integrates each step, from initial material feeding and registration to final gluing and finishing, ensuring high-speed, accurate application with robust security measures.

The FG-800 Rigid Window Affixing System incorporates advanced technologies to enhance its performance and reliability. Key technologies include high-speed friction feeders, precision affixing mechanisms, advanced folding modules, and real-time data management systems. These technologies work together to ensure consistent, high-quality production of folding cartons.

Consistently feed, insert, attach, and batch delicate materials and oddly shaped products at 30,000 PPH, with vacuum pick & place motion and ±0.02″ placement accuracy.

The FF Series Friction Feeder can handle the lightest paper and is equally at home when dealing with heavy stock materials when called upon.

A user-friendly, fully packaged CCD reader, offering easy integration and several configurations to meet a variety of needs.

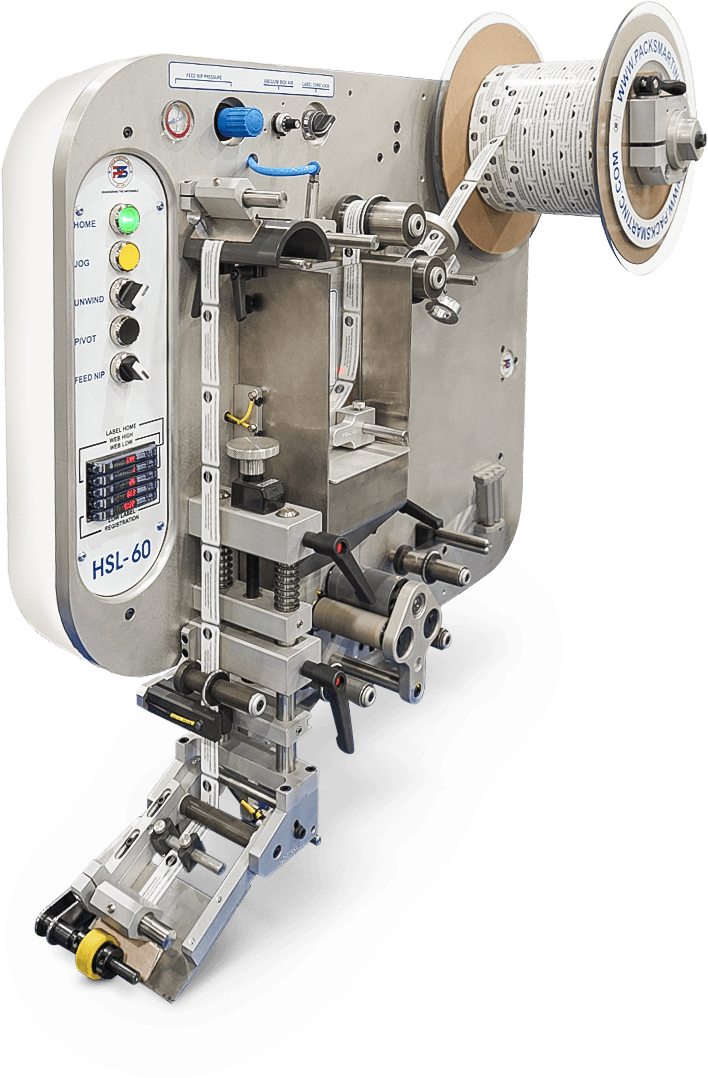

The HSL-60 is a highly versatile module that applies pressure sensitive labels at high speeds and accuracy for the most demanding precision-critical applications.

Reaching up to 600 products per minute, the SF Series is a perfect choice for handling light paper to heavy stock material.