Blog

SIM to eSIM Packaging Systems: Machines, Vision, and Throughput at Scale

Physical SIMs once guaranteed instant trust: insert card, connect, done. eSIM removes the plastic, but not the risk. Today, the first five minutes after activation define everything: seamless onboarding builds loyalty, while failure triggers churn, costly support, and reputational damage.

eSIM Packaging & Activation exists to make those first minutes predictable. Most operators already ship printed activation materials through their converters; what’s missing is an industrial-grade backbone that holds placement at speed, verifies every critical mark, and leaves an audit-ready trail. That’s where Pack-Smart Inc. sits — machines, vision, and right-sized product data so the scan works and the operation scales.

eSIM Packaging Systems & Activation — Up Front

Operators already ship eSIM activation carriers and kits, but execution is fragile without an industrial backbone. Small drifts in print, placement, or finish become big problems at scale.

Without continuous inspection and proper governance, activations remain vulnerable to errors, inefficiencies, and compliance gaps.

Pack-Smart Inc. closes that gap:

- High-throughput automation enabling millions of consistent, first-scan activations, accuracy at speed, shift after shift.

- Inline personalization and fulfillment with 100% verification, critical marks, and assemblies checked before anything moves downstream.

- Delta-X TRUST Product Data Management for compliance, traceability, and engagement, identities governed, histories exportable.

Executive value is immediate: lower cost-to-serve, accelerated revenue capture, and bulletproof compliance that secures licenses and builds regulator confidence.

Talk technology first, because technology protects the experience. When a camera meets a poorly placed eSIM QR code, the customer feels it instantly. When a fold tugs at a reveal, operations feel it for weeks. The point of an eSIM packaging system is simple: translate carrier intent into reliable, repeatable output on the line — every shift, every run, every region.

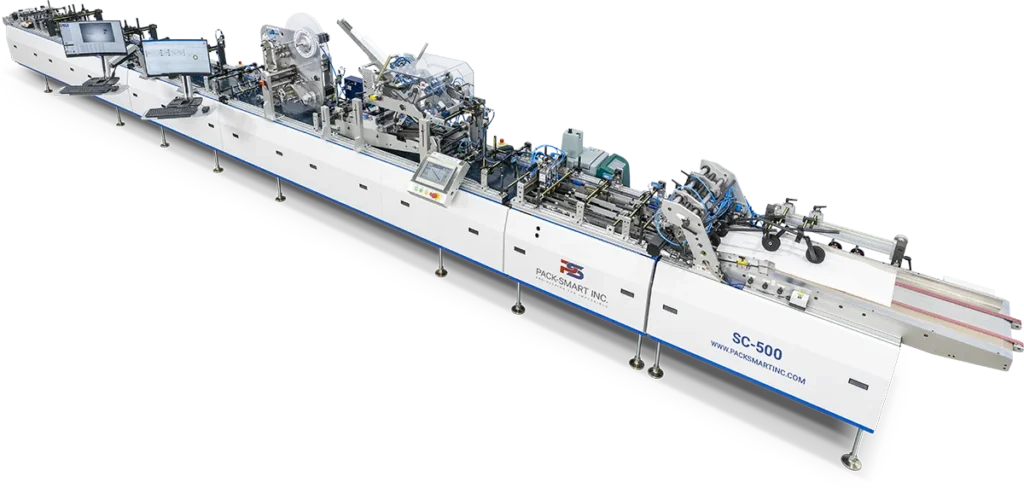

SC-500 Secure eSIM Packaging System: Precision Where Scanability Lives

The SC-500 Secure eSIM Packaging System is engineered for the work telecom eSIM packaging & onboarding depends on: card-to-carrier affixing, booklet tipping, and secure four-corner folding/gluing, under continuous control with inline inspection. In plain terms, it keeps every critical feature, especially the eSIM QR window, exactly where the design intended: quiet zone protected, glare minimized, edges straight, tolerances tight.

Why the SC-500 is the right machine for Secure eSIM packaging & activation:

- Tight placement tolerances keep labels, windows, panels, and reveals centered, so the eSIM QR code scans on the first try.

- Inline machine-vision verifies presence, position, contrast, and quiet-zone integrity before any unit moves downstream.

- Secure fold/glue construction protects peel- or scratch-reveal elements and resists tamper or drift through handling.

- Optional inline personalization applies per-unit marks (alphanumeric, short codes) and verifies them without a secondary pass.

- Serialization and aggregation attach unit → bundle → case → pallet identities as part of the run, not after it.

- Governed rejection handling removes non-conforming pieces automatically, preventing costly escapes at pack-out.

- Recipe-driven changeovers quickly return the machine to validated settings when carriers, SKUs, or artwork change.

In practice, the SC-500 Secure eSIM packaging system refuses to let minor errors compound. A window that drifts half a millimeter is corrected before it becomes a pallet of returns. A reveal panel that skews is caught before it ships. Operators see a steady rhythm, start the run, watch the vision gates hold the envelope, and keep moving. Leadership sees fewer surprises and a first pass yield that holds as volumes climb.

Carrier Architecture: Where Design Meets Machinery

Carriers are the stage on which activation happens. We partner with your in-house design and engineering teams to ensure the carrier architecture aligns with the realities of high-speed production:

- Mechanical alignment. We review panel sizes, fold sequences, glue patterns, and reveal geometries against SC-500 capabilities to protect tolerances and uptime.

- Material behavior. We advise on coatings and stocks that maintain contrast in the QR field and minimize camera glare, curl, or fiber lift during fold.

- Feature protection. We validate window placement, perforations, and scratch/peel solutions to ensure they survive handling while opening cleanly for the customer.

The goal is simple: your carrier concept remains yours; the way it runs on a high-throughput line becomes predictable.

Creative Implementation: Quiet Zones, Type, and Visual Hierarchy

We also collaborate with your creative teams or marketing agencies on design implementation details that make activation obvious and repeatable:

- Quiet-zone discipline. The code’s breathing room is enforced in artwork and verified on the line — no crowding from icons or patterns.

- Finish control. Matte or satin windows around the code reduce glare; foil and varnish stay clear of the scan path.

- Instruction clarity. A short, three-step block, large type, plain language, reduces hesitation and support calls.

- Fallback hygiene. Short URLs or short codes are placed away from the QR so the eye lands where it should first.

This is the practical glue between brand expression and production reality. The result is a carrier that resembles the mock-up and functions like an engineered part.

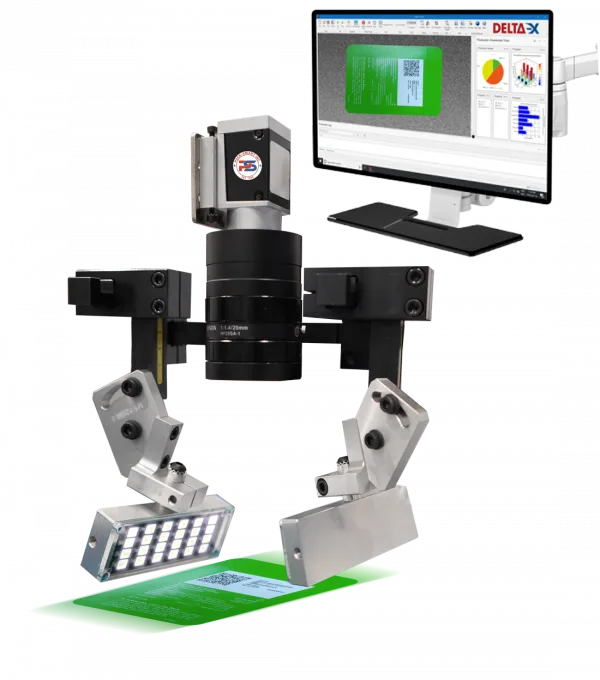

Inline Machine-Vision Inspection: The Quiet Guardian of the eSIM QR Code

Nothing in eSIM packaging matters more than the moment the camera reads the code. Machine-vision inspection protects that moment by turning design rules into live guardrails on the line.

Vision checks the presence and placement of the eSIM QR code and human-readable ID. It watches contrast and quiet-zone integrity as substrates, inks, and finishes vary. It classifies defects, smears, skew, and misapplies, and removes them before pack-out, so brand trust doesn’t rely on luck.

Just as importantly, it surfaces trends teams can act on: sheen creeping into the window, adhesive spread crowding a symbol, a fold introducing just enough curl to bother a phone camera.

Good carrier design, combined with great vision, is how telecom eSIM onboarding starts cleanly the first time, not the third.

Serialization, Aggregation, and Traceability: Identity That Travels

A scannable carrier is useful; a traceable unit is operationally robust. Treating identity as part of production means every unit leaves the line with a unique, verified signature, and every bundle, case, and pallet knows its children. That single decision changes how teams work:

- Inventory reconciles faster because parent-child relationships are reliable.

- Exception handling gets shorter because the correct record exists without digging.

- Returns are investigated with facts, not guesses.

- Campaigns can be compared with evidence, not anecdotes.

This is the difference between printing a code and running identity as a system.

Delta-X TRUST Product Data Management: Traceability & Consumer Engagement Without Slowing the Line

Delta-X TRUST is our enterprise Product Data Management platform that sits behind the machinery. It keeps activation packaging honest by governing identities, capturing production/inspection events, and making histories exportable, without turning telecom eSIM onboarding into a software project. The machines do the work; Delta-X TRUST proves the work.

In practice, you get a light, reliable spine for identity and movement, unit to bundle to case to pallet — so reconciliation, audits, and exception reviews take hours, not weeks.

When you choose to extend the moment post-scan, the same backbone supports high-level consumer engagement insights without bloating the line.

What it delivers (succinctly):

- Consistent code sets across lines, shifts, and vendors. No identity drift.

- Inline event capture for production, inspection, serialization, and aggregation.

- Real-time traceability through distribution for investigations and compliance.

- Audit-ready exports on demand, no ad-hoc data stitching.

Right-sized software, engineered to serve the systems so your throughput stays high, and your data stands up to scrutiny.

How Systems, Vision, and Data Stay in Lockstep

When eSIM Packaging Systems & Activation runs well, it feels unremarkable — in the best way.

Operators load validated artwork and recipes; vision checks that the eSIM QR code sits exactly where it should with the contrast it needs; affixing, folding, and revealing features happen in a single, predictable rhythm; units that fall short never see a carton; identities attach and aggregate as part of the flow; histories are exportable the same day.

It’s not theatrical. It’s professional. And it’s how you protect customer trust while meeting throughput promises.

Sustainable eSIM Packaging Without Sacrificing Scan Success

Sustainability should be felt, not just reported. With the right substrates and coatings, your converter leads to sustainable eSIM activation carriers that keep scan windows low glare, maintain contrast in the code field, and resist smudges that frustrate cameras.

The SC-500 Secure eSIM packaging system enforces the rest: consistent folds that don’t distort codes, stable adhesion that doesn’t ooze into quiet zones, and inspection that flags substrate drift before it becomes a headache.

The outcome is simple: recycled or paper-based carriers that still scan cleanly, feel premium, and move at line speed.

Beyond the Line: Aligning Supply Chain, Distribution, and Customer Success

eSIM packaging & activation doesn’t end at the last station. We work with your supply chain and distribution teams to maintain aggregation integrity from carton to dock, ensuring shipments reconcile cleanly and inventory reflects reality.

We coordinate with customer success to keep human-readable IDs and documentation aligned with support workflows — so when a call comes in, the record is already there. The benefit is operational calm: fewer “where is it?” moments, fewer returns, and faster revenue recognition.

Why Pack-Smart Inc. for Secure eSIM Packaging & Activation

We’re a machinery-and-engineering company first. Our focus is building production systems that hold placement at speed, verify every critical mark, and keep output consistent shift after shift. The SC-500 Secure eSIM Packaging System delivers that discipline on the floor; inline vision makes scanability a fact, not a hope; and Delta-X TRUST keeps identities and histories governed without turning operations into a software project.

Our track record spans security-sensitive markets, telecom/SIM, payments, premium, and government card applications, where uptime, accuracy, and auditability aren’t optional. The same engineering rigor that protects payment and ID programs translates directly to telecom eSIM onboarding: codes that scan the first time, carriers that behave the same across shifts, and shipments that reconcile without drama.

We also plug into your teams where it counts: carrier architecture with design/engineering, implementation details with creative and agencies, and downstream hand-offs with supply chain, distribution, and customer success. That’s how the whole operation moves from concept to volume without losing the plot.

Final Word: eSIM Packaging & Activation Starts with the Right eSIM Packaging Machines

If you’re buying for eSIM packaging & activations, start where outcomes are decided: the line. Artwork won’t rescue a code placed a millimeter off, and clever copy won’t help if inspection isn’t catching drift. What does? A setup engineered to hold tolerances at speed, verify every critical mark, and keep identity intact from unit to pallet, so eSIM QR codes scan on the first attempt and carriers behave the same across shifts.

Choose machinery that treats activation like a system. With SC-500 as the secure packaging backbone, inline vision as a first-class control, and Delta-X TRUST governing identity and history, launches move faster, cost-to-serve drops, compliance holds, and every activation becomes a loyalty-building moment.

Bottom line: Pack-Smart Inc. turns eSIM packaging & activation from a vulnerable weak link into a strategic growth lever — where every activation is secure, compliant, and loyalty-building.