Blog

A Guide to eSIM Activation Packaging

When you activate a new phone, you often point its camera at a small card with a QR code. Within seconds, the phone connects to the network. This simple action hides a complex industrial process built to succeed on the first try.

The first five minutes of eSIM activation are crucial. As one Pack-Smart Inc. principle states, “The chip is now embedded, but the first five minutes still decide completion, satisfaction, and support load.” A failed scan leads to frustration, wasted time, and higher support costs.

This guide reveals the unseen system that make eSIM activation reliable. It focuses on three pillars: precision machinery, automated inspection, and digital traceability. Together, these systems turn design intent into consistent, error-free packaging.

The eSIM Activation Core Challenge: A Perfect Scan, Every Time

The packaging process protects one thing above all — the eSIM QR code. If the camera cannot read it instantly, the customer feels the failure.

Several issues can block a perfect scan:

- Poor placement: The code sits slightly off-center, confusing the phone’s focus.

- Quiet-zone intrusion: Glue or text crowds the empty border around the code.

- Glare and contrast issues: Glossy coatings reflect light, obscuring the code.

- Physical defects: Smears, mis-applied labels, or folded stock distort readability.

The quiet zone is critical. Just as you need silence to hear a whisper, a phone’s camera needs clear space around the code to decode it.

To prevent these problems, high-precision machinery forms the foundation of production, actively preventing eSIM activation issues.

The Solution Part 1: Precision Machinery That Protects the eSIM Activation Code

The goal of the manufacturing machinery is to translate the designer’s intent into reliable, repeatable output on the production lin, ensuring the first unit is identical to the millionth. This means taking a digital design and creating a physical product that is identical every single time.

The SC-500 Secure Card Packaging system is central to this process. This system plays a distinct role in protecting the integrity of the QR code and the overall secure package. The goal is to make the first unit identical to the millionth.

| System | Primary Role & Key Benefit |

| SC-500 Secure Card Packaging for eSIM, SIM, Gift Cards, Financial Cards, Loyalty Cards, and more. | This is the “surgical” platform, engineered for high-accuracy work like card-to-carrier affixing, booklet tipping, and secure four-corner folding/gluing. Its key benefit is ensuring that critical features, especially the eSIM QR code, are placed perfectly and the quiet zone is protected from glues or misaligned folds. |

This system provides the physical precision needed to build a high-quality secure package. But to guarantee that every single unit meets the standard, another system is needed to verify their work in real-time.

The Solution Part 2: The “Quiet Guardian” of Quality

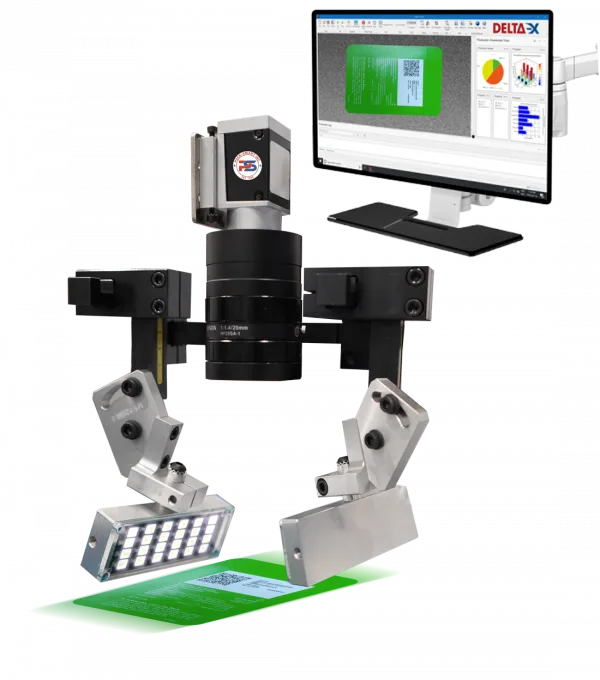

This is where Inline Machine-Vision Inspection comes in. Described as the “Quiet Guardian,” this automated system acts as a set of “live guardrails” on the production line. Using high-speed cameras and software, it inspects every single item as it moves through the machine, ensuring nothing is left to chance.

The vision system performs four essential checks to protect the scannability of the QR code and the quality of the package:

- Presence and Placement: Verifies the QR code is exactly where it should be, preventing packages with missing or misaligned codes from ever leaving the factory.

- Contrast and Glare: Ensures the code is clear and not obscured by shiny finishes, making it readable in a wide variety of real-world lighting conditions.

- Quiet-Zone Integrity: Confirms no glue, ink, or other elements have crowded the code’s scannable area, protecting it from any interference.

- Defect Classification: Identifies and flags units with common physical flaws like “smears, skew, and mis-applies,” ensuring they are automatically removed from the production line.

By performing these checks on every unit, the vision system ensures that small errors are caught and corrected instantly, before they can become a widespread problem. This moves the process from verifying the physical item to tracking its digital identity.

The Solution Part 3: The Digital Fingerprint for Every Package

A flawless package is valuable, but a traceable one is powerful. Each eSIM carrier receives a unique digital identity managed by Delta-X TRUST software.

Two connected processes build this traceability:

- Serialization: Assigns every carrier a unique ID, like a fingerprint.

- Aggregation: Links each unit to its bundle, case, and pallet—creating a clear digital “family tree.”

This structure transforms daily operations:

- Faster inventory: Scanning one pallet reveals every serialized item inside.

- Smarter problem-solving: If an issue appears, teams locate only the affected units—no guesswork.

- Better insight: Shipment data shows which packaging designs perform best in market trials.

Delta-X TRUST keeps these records secure and audit-ready, turning packaging data into business intelligence.

Conclusion: How It All Works Together

Precision machinery, machine vision, and digital traceability work together to create a flawless activation experience.

- A validated design loads into the system.

- Precision machinery assembles the carrier and places the QR code.

- The vision system inspects every unit and rejects defects automatically.

- Delta-X assigns a digital identity to each verified package and tracks it downstream.

When these elements operate in unison, telecom brands gain faster launches, fewer support calls, and greater confidence in every shipment.

Ultimately, eSIM activation success starts on the production line—long before a customer opens the box. Tight tolerances, real-time inspection, and verified data transform complexity into trust. That’s how Pack-Smart ensures every scan works the first time, every time.

Ready to see precision in action?

Explore how Pack-Smart’s automation and data solutions can streamline your packaging operations. Contact our team or visit our Solutions Center to learn more.