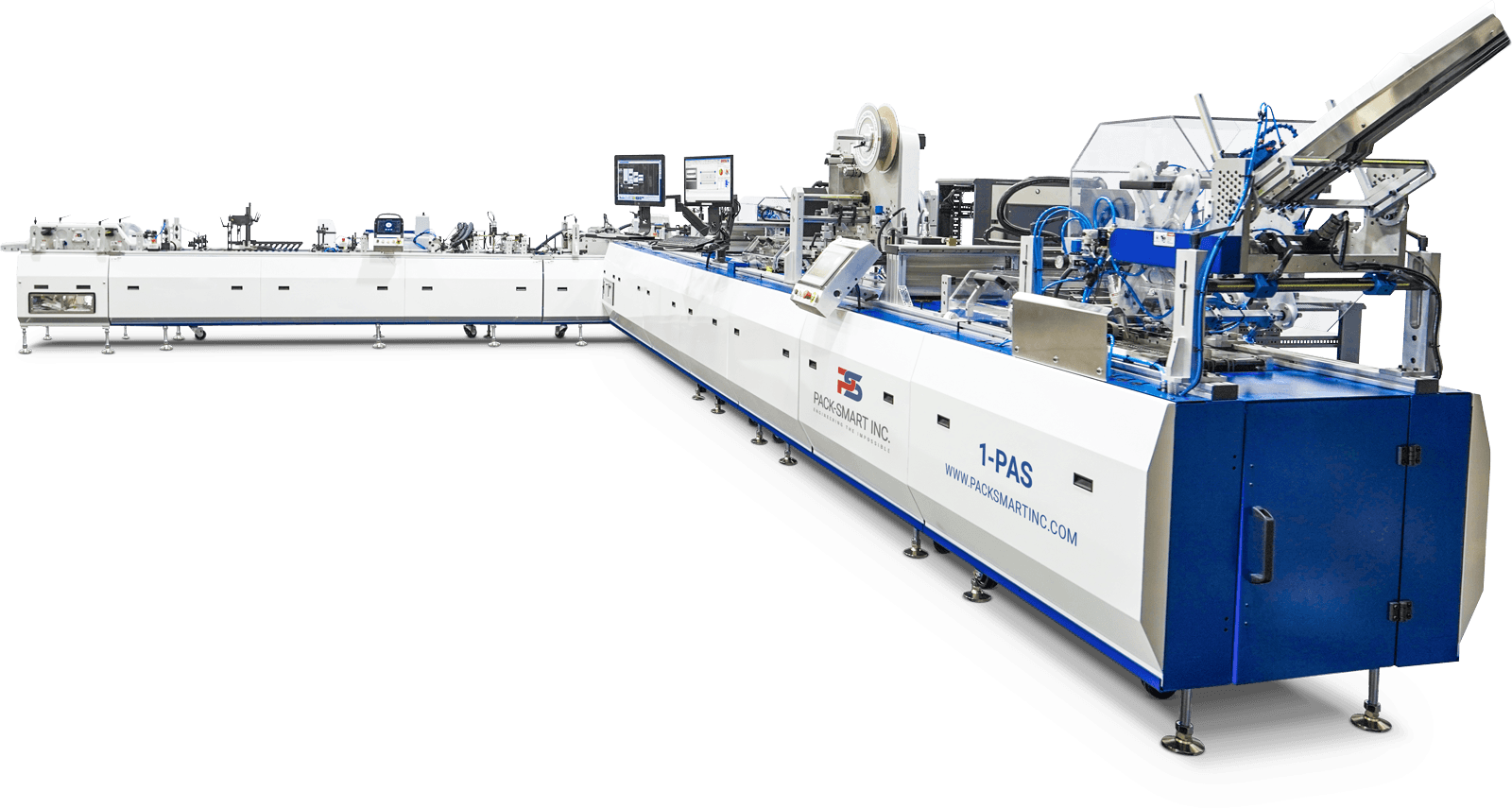

Card to Bundle in One Pass

World’s first inline solution for high volume personalization, affixing, packaging and pack-out of secure open and closed loop cards at 20,000 PPH.

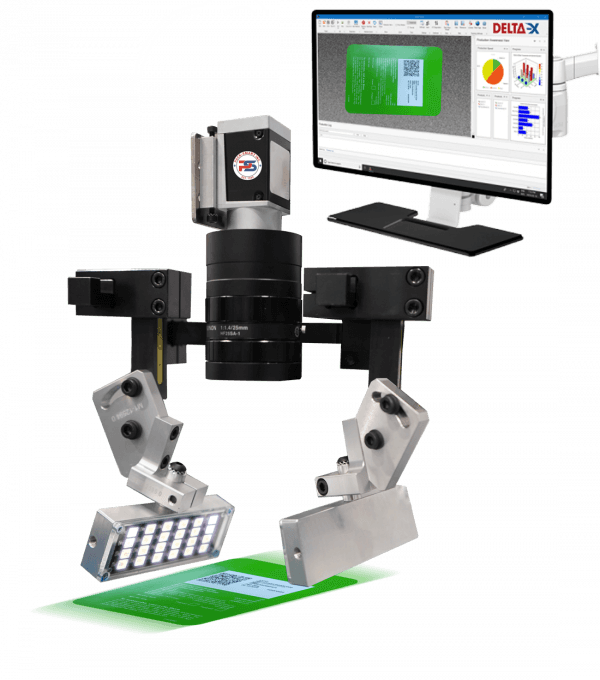

The VSC-1000 Vision Scan system can manage up to 8 camera inputs with 4 parallel channels, allowing asynchronous management with real-time hardware.

The VSC-1000 Vision System offers state-of-the-art vision scanning and real-time image processing, ideal for high-speed production environments.

Equipped with advanced OCR, barcode reading, and image recognition capabilities, this system ensures precise quality control, enhances product integrity, and reduces waste by identifying defects early in the production process.

Barcode Codification and Grading

Label and Placement Verification

Printing Verification

The VSC1000 is adaptable with a range of customization options to suit various industrial requirements, ensuring seamless integration into existing production lines.

This technology is used in the following automated solutions.

World’s first inline solution for high volume personalization, affixing, packaging and pack-out of secure open and closed loop cards at 20,000 PPH.

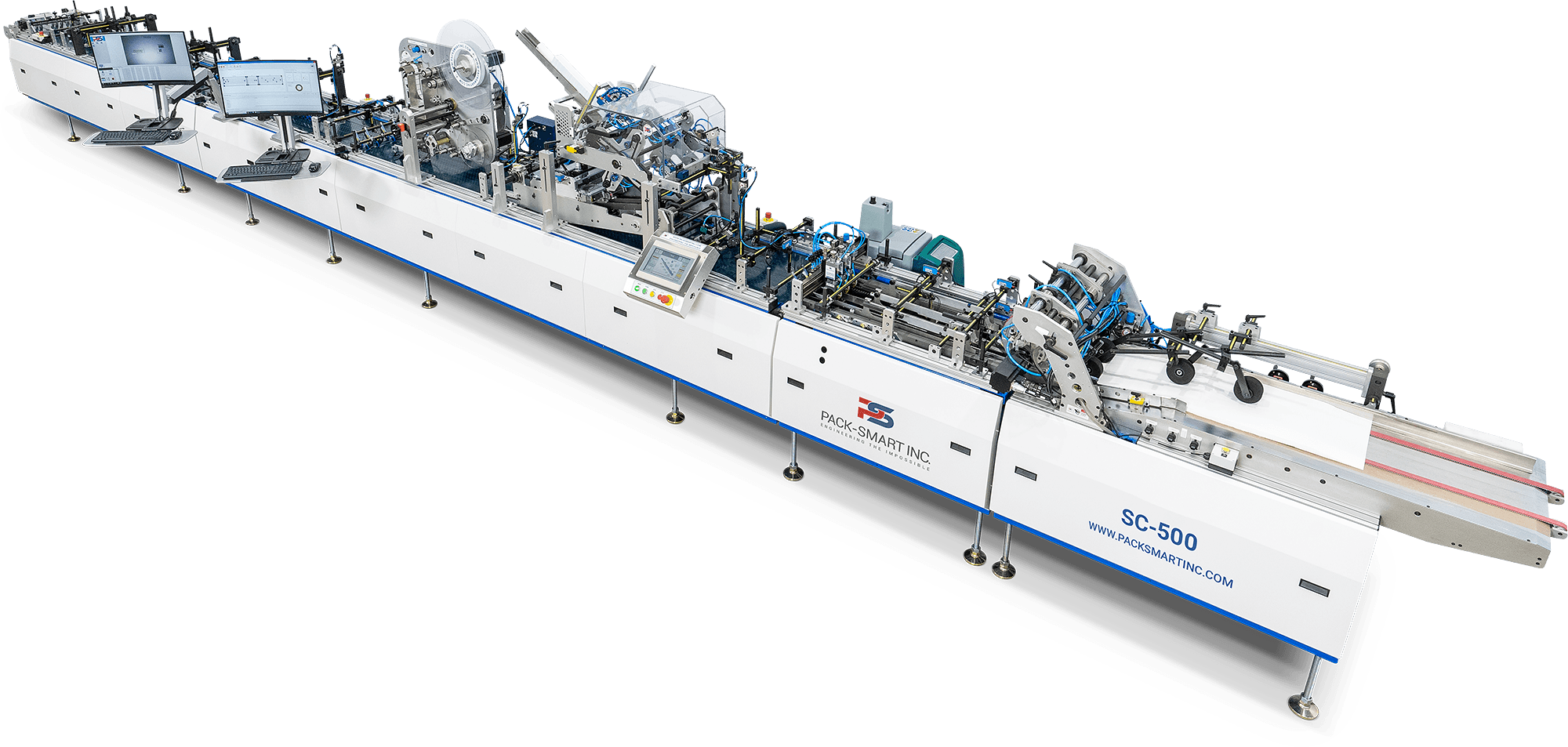

Explore the FG-500 Folding and Gluing System for high-precision carton packaging. With ±0.4 mm accuracy, 600 DPI printing, and real-time quality assurance, achieve flawless packaging outcomes.

Inline card to carrier affixing, booklet tipping, 4-corner secure folding/gluing, and DOD personalization.

Related modules are available for inline applications.

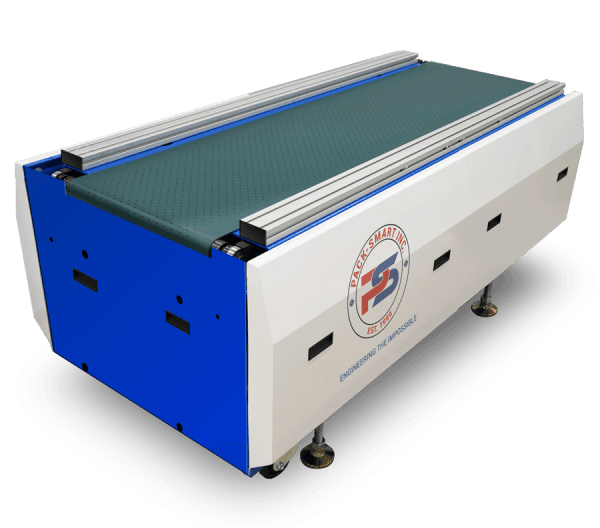

High torque servo driven vacuum transport conveys products at accurate speeds and controls product placement with 8 selectable vacuum zones.

Smart Jet uses industry leading head technology to deliver UV Cured 600 DPI DOD Ink onto any surface.

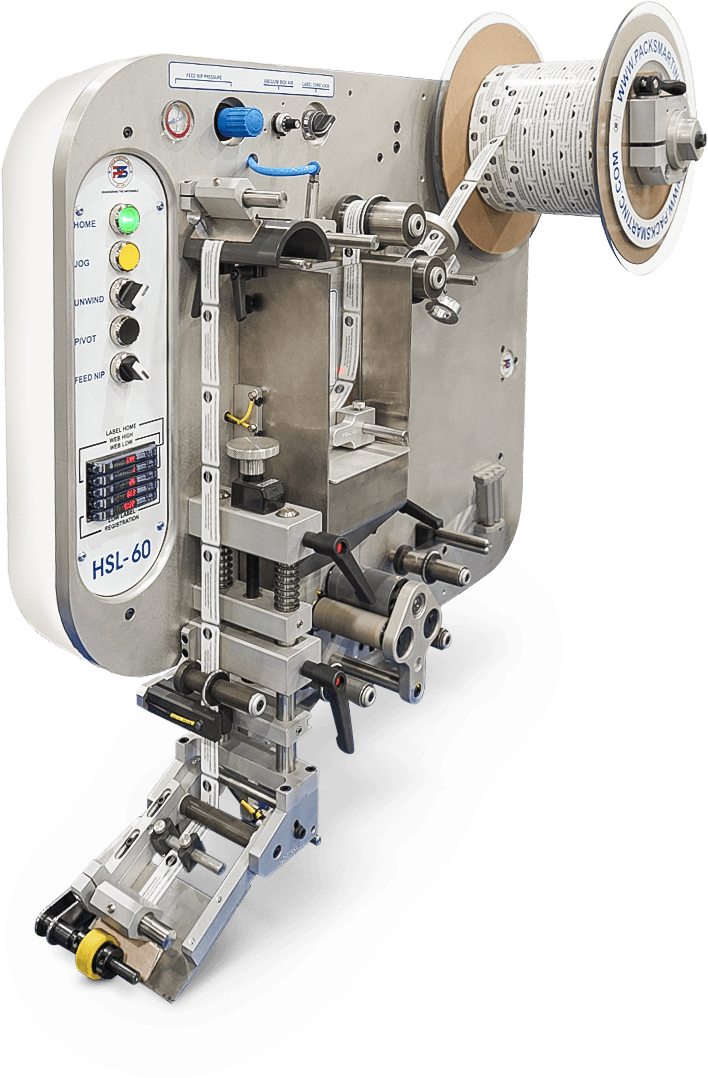

The HSL-60 is a highly versatile module that applies pressure sensitive labels at high speeds and accuracy for the most demanding precision-critical applications.