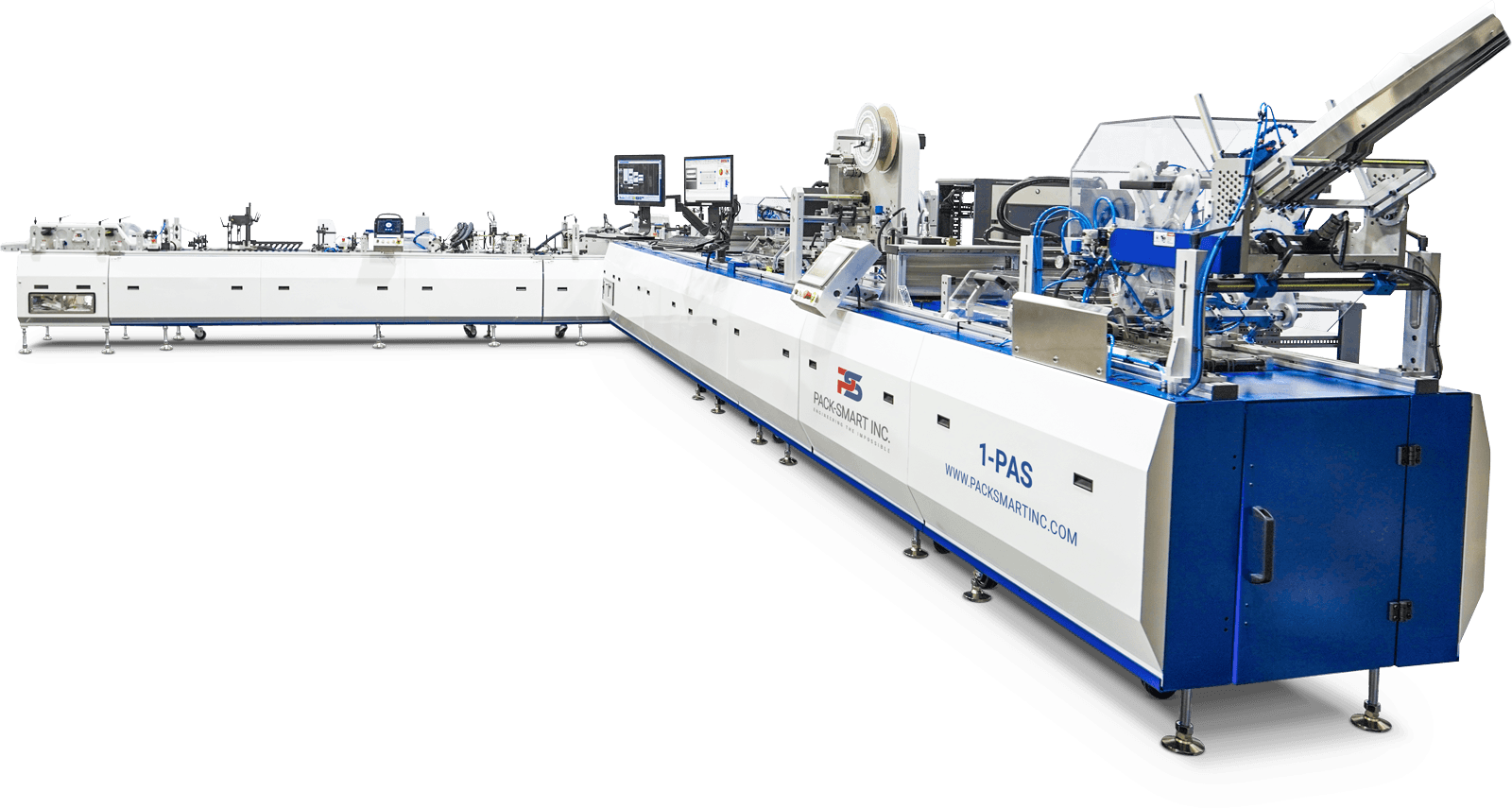

Card to Bundle in One Pass

World’s first inline solution for high volume personalization, affixing, packaging and pack-out of secure open and closed loop cards at 20,000 PPH.

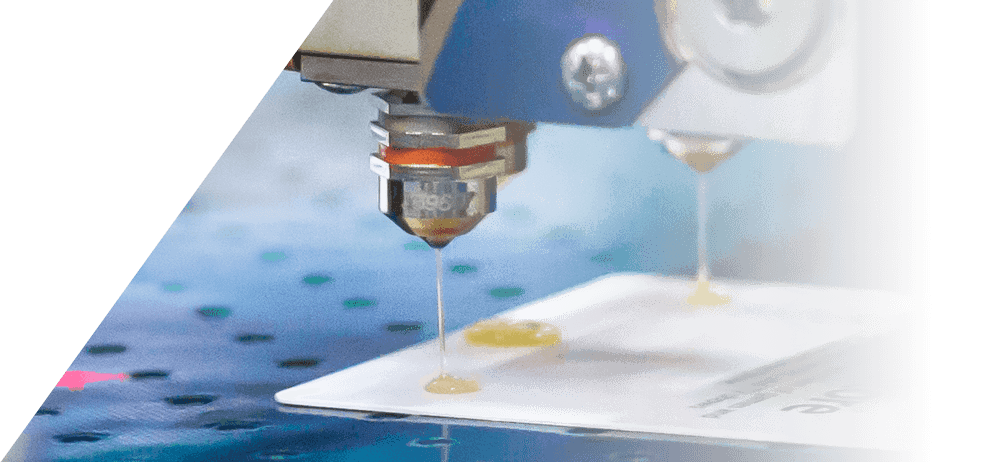

Designed for both fugitive and permanent bonding, this hot melt glue system offers unparalleled accuracy with up to 8 heads.

This technology is meticulously engineered to dispense hot extruded glue with exceptional control and precision. Whether you require a permanent bond or a temporary hold, the Hot Melt Glue system is equipped with versatile heads capable of creating dots, beads, or continuous patterns across a diverse range of materials. Its modular design seamlessly integrates into existing production lines or stands alone as a robust solution for all your gluing needs.

With its advanced temperature control, the Hot Melt Glue system ensures stable viscosity, providing a protective seal and tamper-evident security for a variety of packaging applications. The system’s four applicator heads are designed to minimize spillage, maximizing efficiency and safeguarding against waste. Embrace the benefits of a low-maintenance, energy-efficient hot gluing system with Pack-Smart’s HM Series.

Membership & Loyalty

eCommerce

Retail

The HM-10 Hot Melt Glue system is available in various configurations, including options with 4 to 8 heads, to accommodate different production scales and application complexities.

This technology is used in the following automated systems.

World’s first inline solution for high volume personalization, affixing, packaging and pack-out of secure open and closed loop cards at 20,000 PPH.

Inline card to carrier affixing, booklet tipping, 4-corner secure folding/gluing, and DOD personalization.

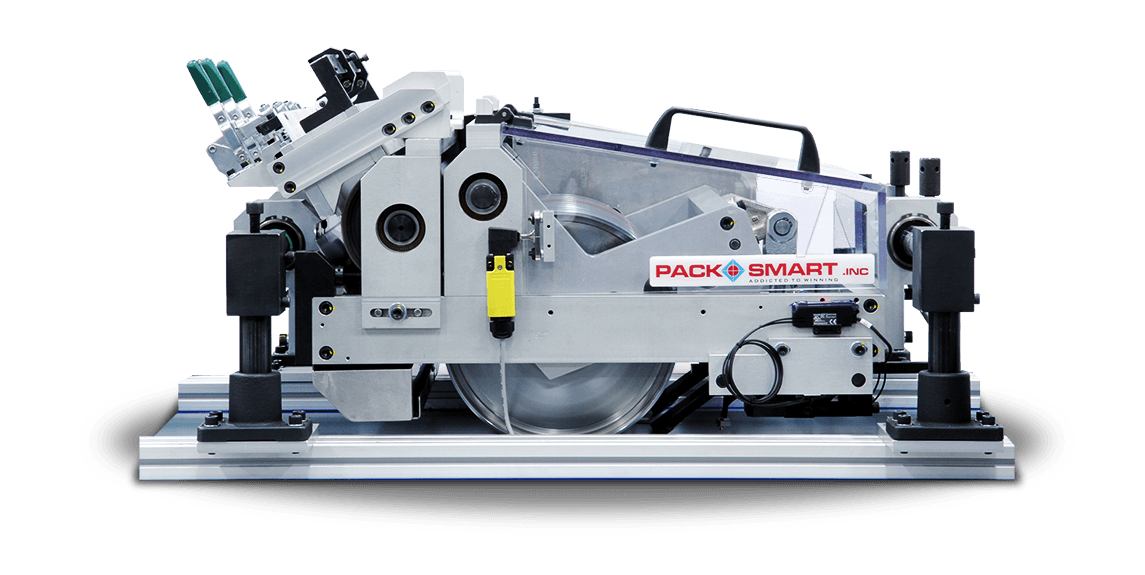

Related modules are available for inline applications.

The CEG-1 Cold Glue System is engineered for high-precision, tamper-proof adhesive applications.

Elevate your production capabilities with the PG-900 Flexo Pattern Glue Module, designed for precise and flexible adhesive applications.