Specialty Corrugated Folding and Finishing

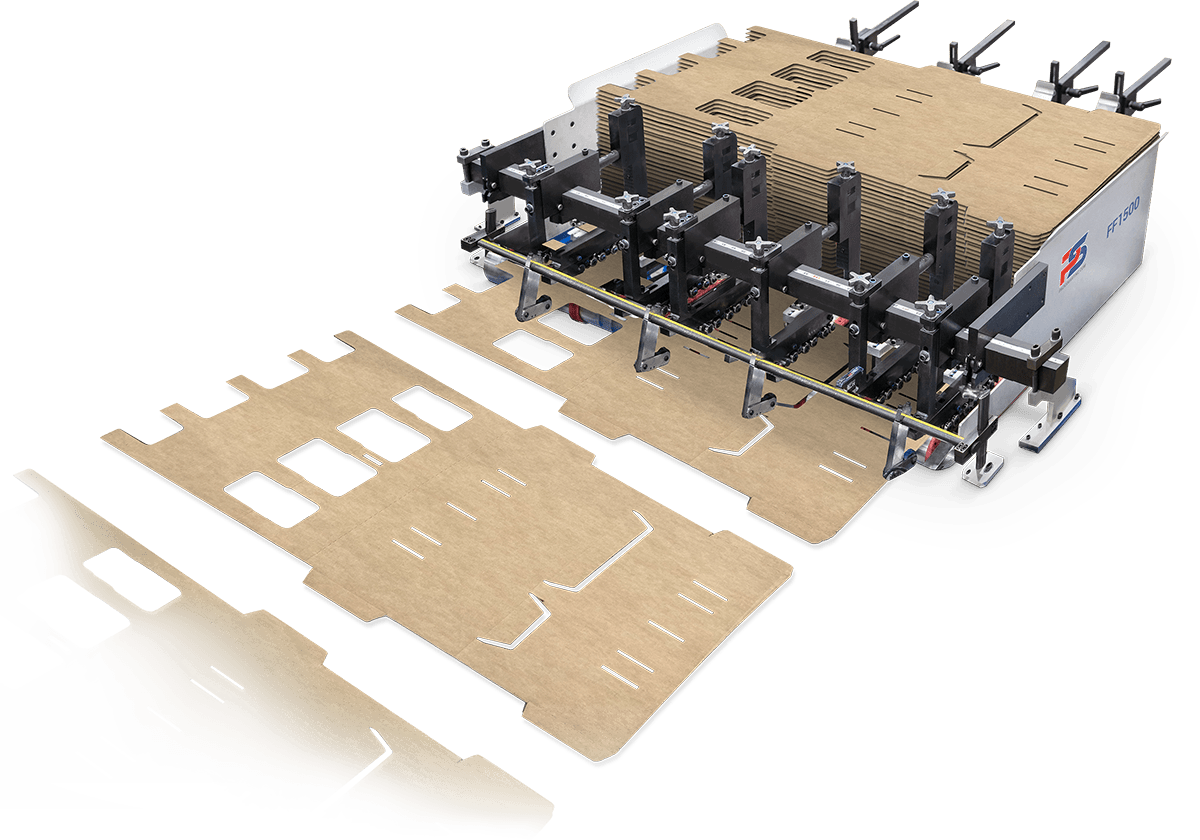

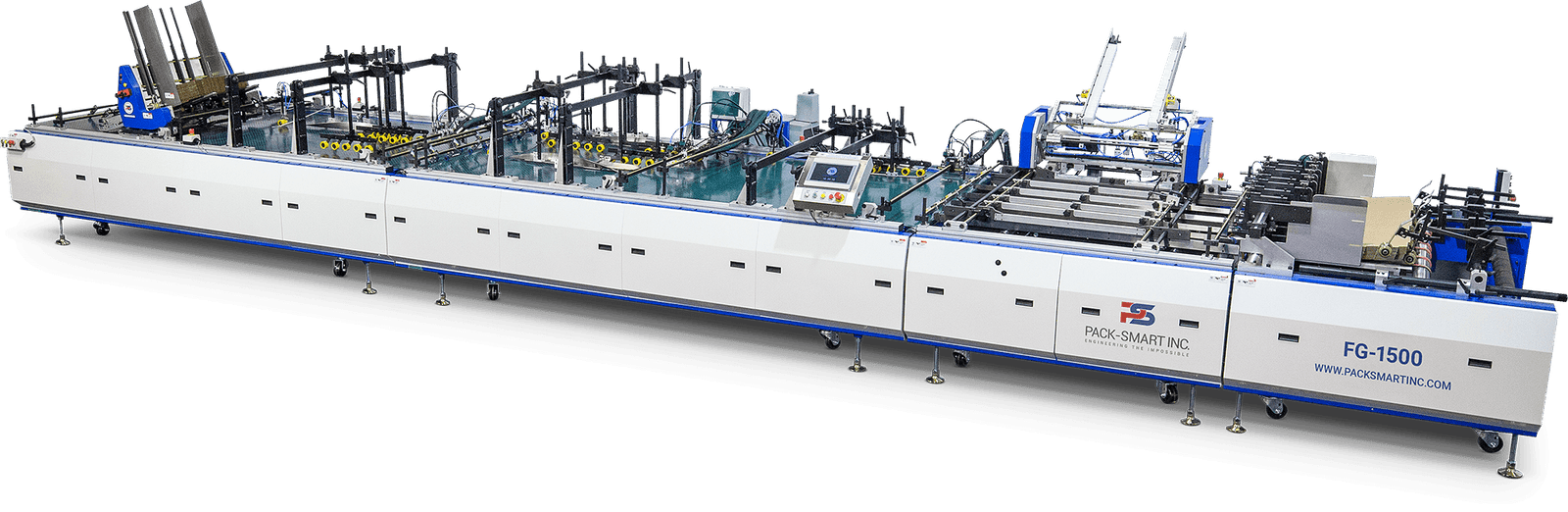

Specialty 60″ Corrugated Folder Gluer with Plastics Clips and Reinforcements for POP Displays.

The FF Series Friction Feeder can handle the lightest paper and is equally at home when dealing with heavy stock materials when called upon.

FF Series Primary Friction Feeder is designed with solid steel construction to ensure stability and high performance even in the toughest environments, resulting in high production speeds of up to 600 products per minute with equal product spacing.

From inserting coupons to collating signature or paint swatches, our friction feeders, operate on a 24/7 production schedule giving our customers increased production and control to get the job done.

Compact

Integrated solution for easily feeding

products up to 300 mm in width

Document

Feeding solution for easy integration with any

equipment and 3rd party finishing and packaging

lines up to 500 mm in width

Large Format

Feeding solution for products

up to 500 mm in width, using 16 suction cups

This technology is used in the following automated systems.

Specialty 60″ Corrugated Folder Gluer with Plastics Clips and Reinforcements for POP Displays.

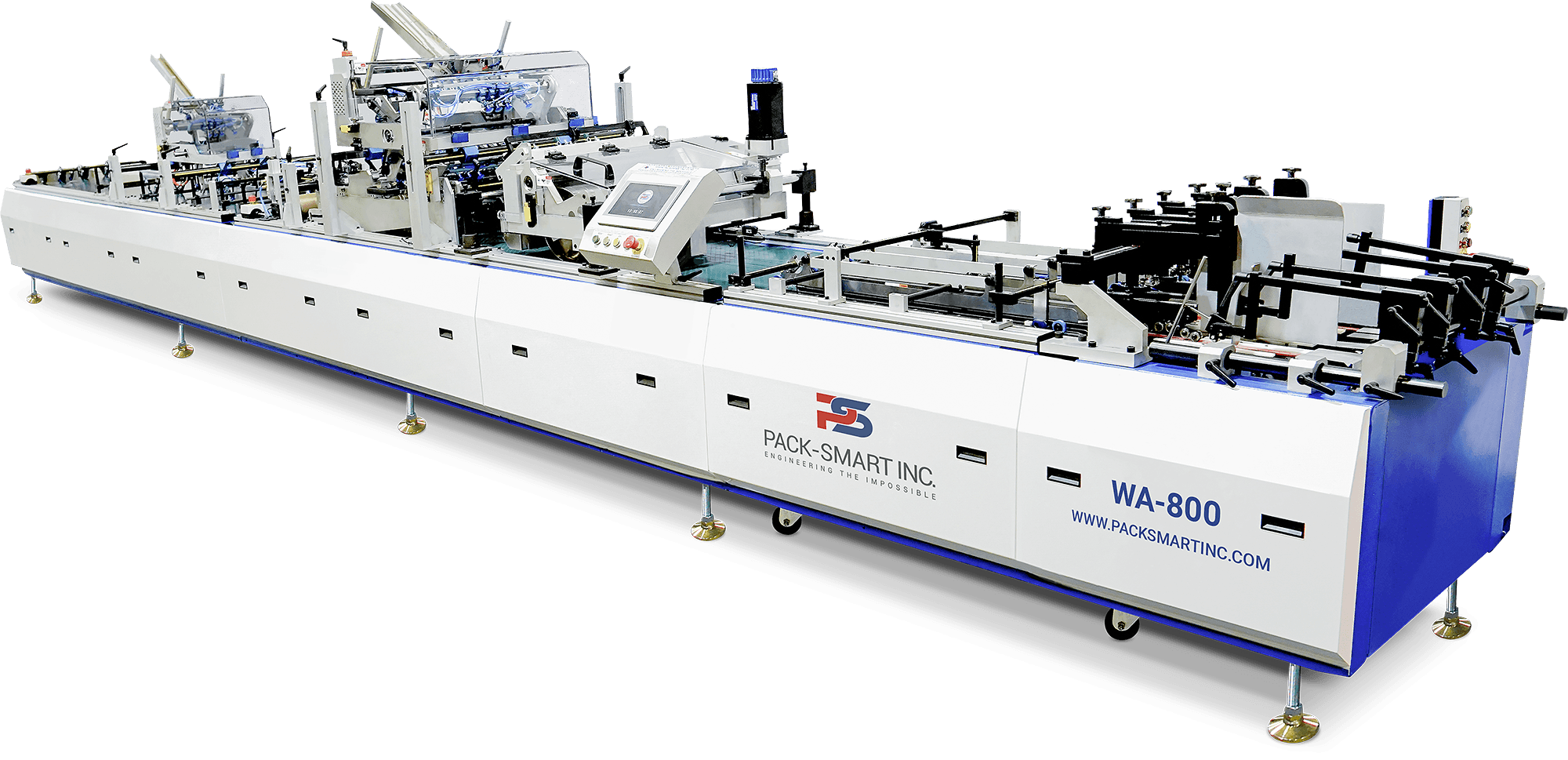

WA-800r delivers unmatched speed, accuracy and flexibility allowing affixing of rigid windows to virtually any carton product available.

Related modules are available for inline applications.

Consistently feed, insert, attach, and batch delicate materials and oddly shaped products at 30,000 PPH, with vacuum pick & place motion and ±0.02″ placement accuracy.

Reaching up to 600 products per minute, the SF Series is a perfect choice for handling light paper to heavy stock material.

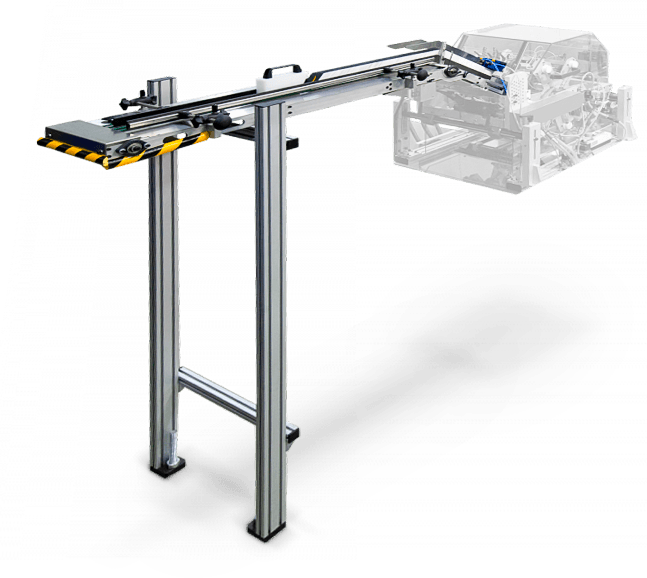

Maximize productivity with the AL Series Powered Autoloader. Designed to extend loading capacities and reduce manual reloading for high-speed applications, ensuring continuous operation and efficiency.