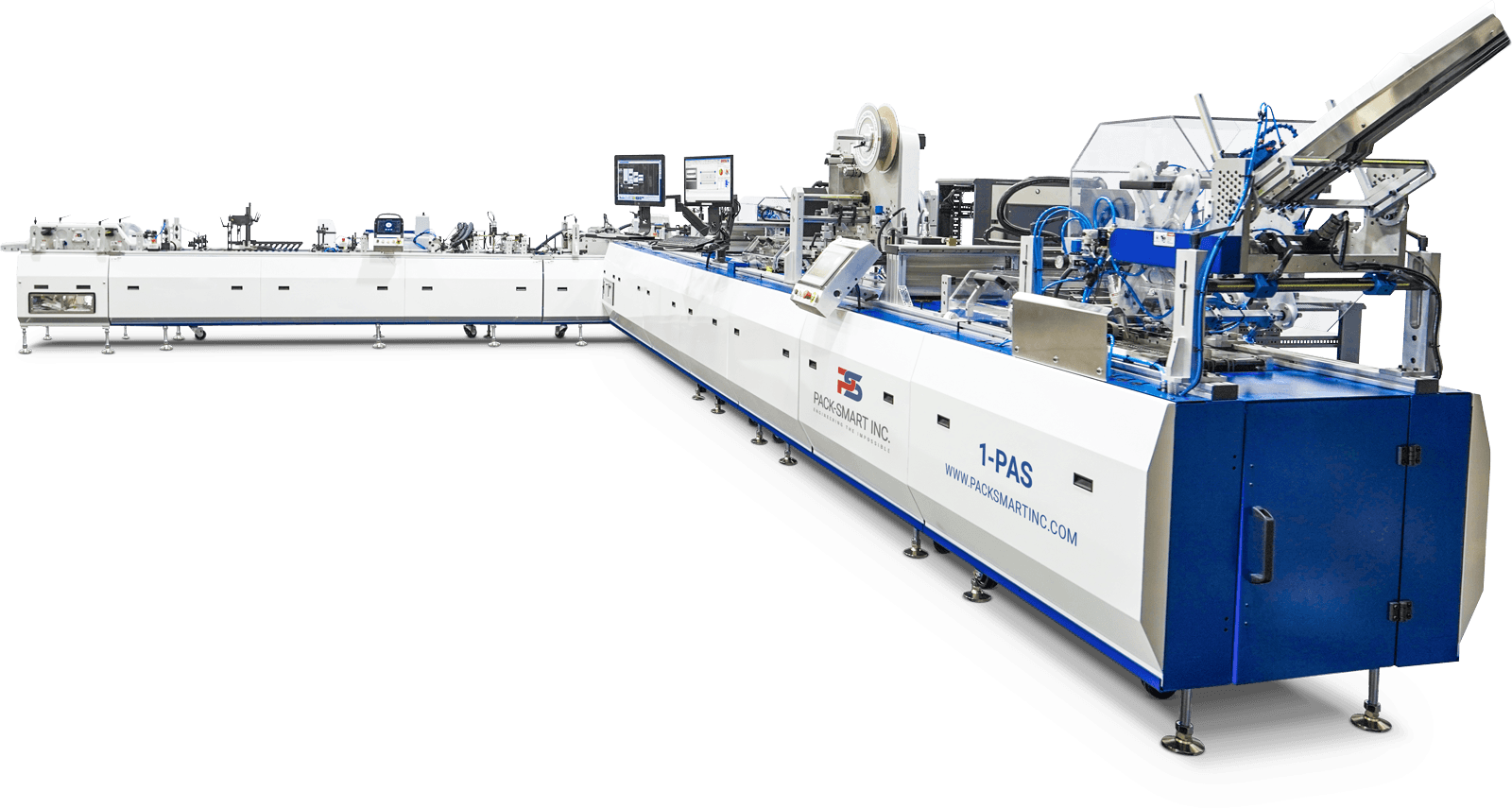

Card to Bundle in One Pass

World’s first inline solution for high volume personalization, affixing, packaging and pack-out of secure open and closed loop cards at 20,000 PPH.

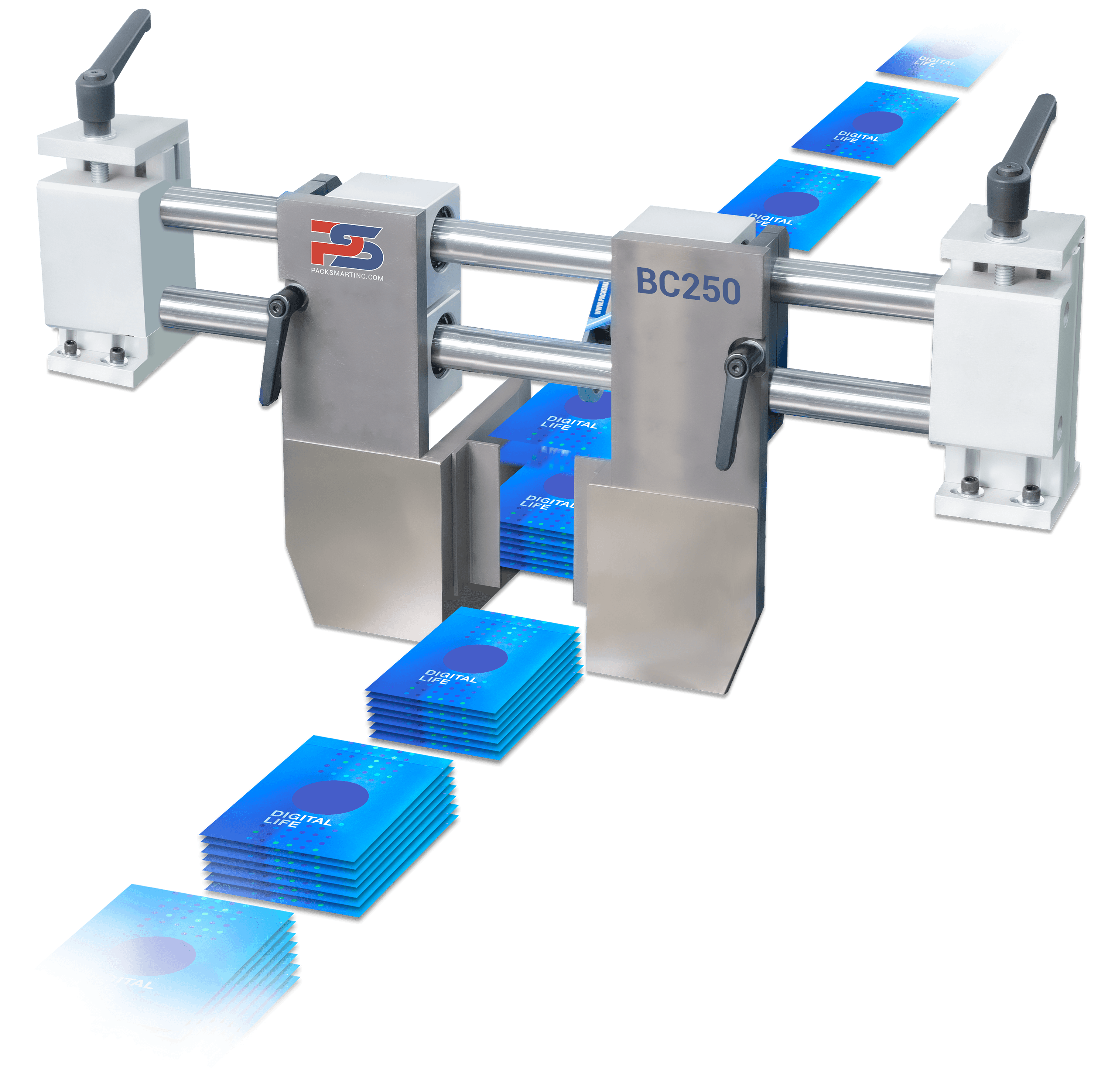

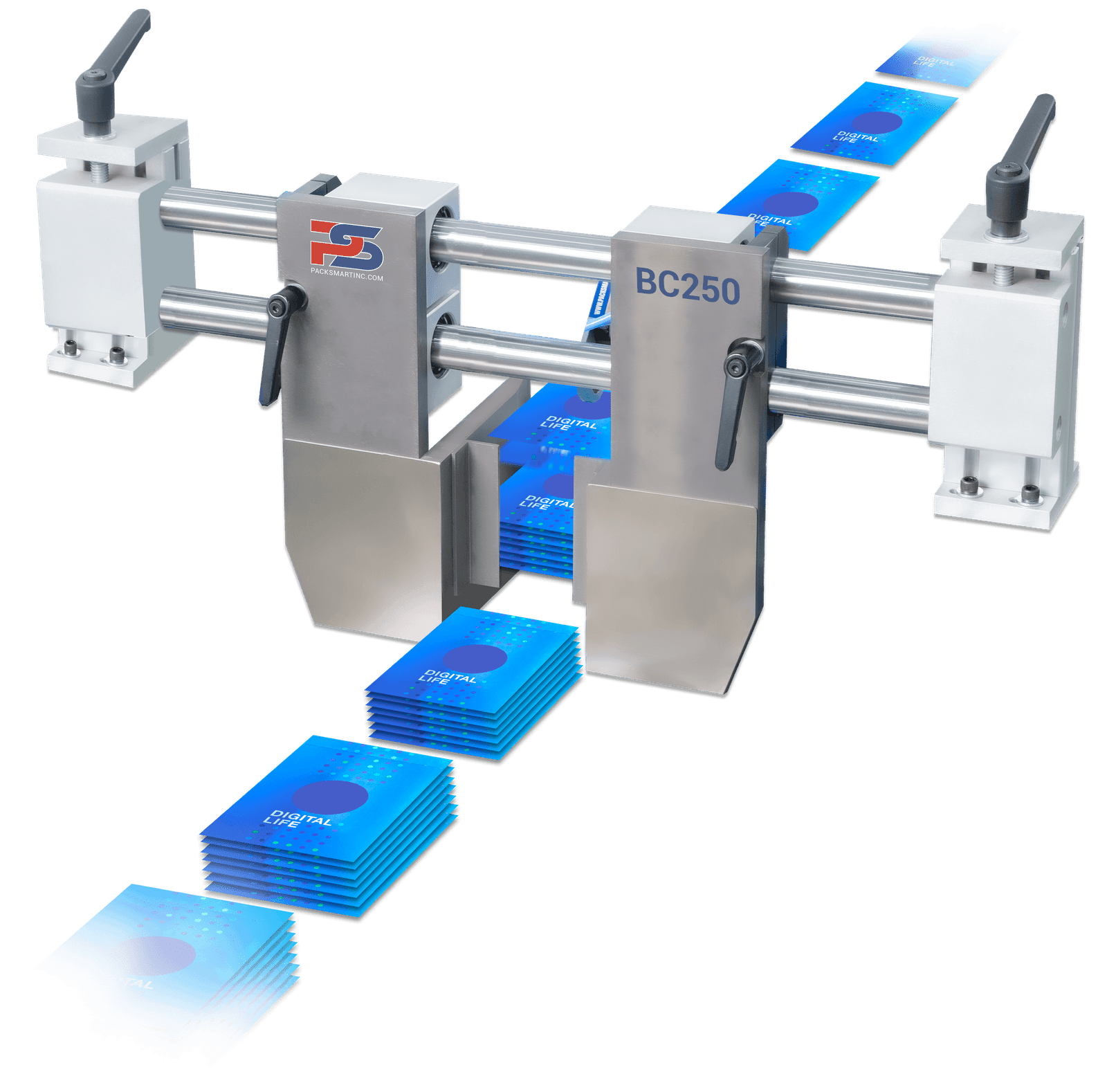

Efficiently batching and bundling single products into precise groups with the batch counting and bundling module, designed for a wide range of materials and applications.

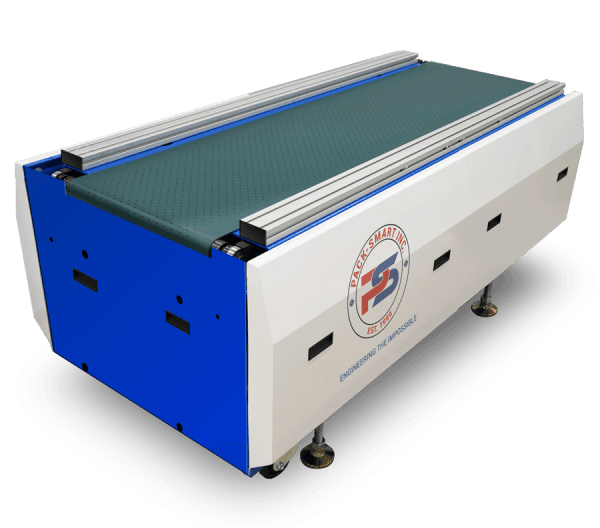

The BC Series Batch Counter from Pack-Smart brings advanced automation and precision to your batching and bundling processes.

Designed to accumulate individual products into accurate, numbered batches, it seamlessly delivers them onto existing conveyors for efficient handling.

Engineered to support a wide variety of materials, this versatile solution is perfect for industries demanding high accuracy and speed, including pharmaceuticals, direct mail, and card manufacturing.

The BC Series is available in two models to cater to different size ranges and production requirements:

BC-250

Optimized for small to medium products

BC-500

Best suited for medium to large products

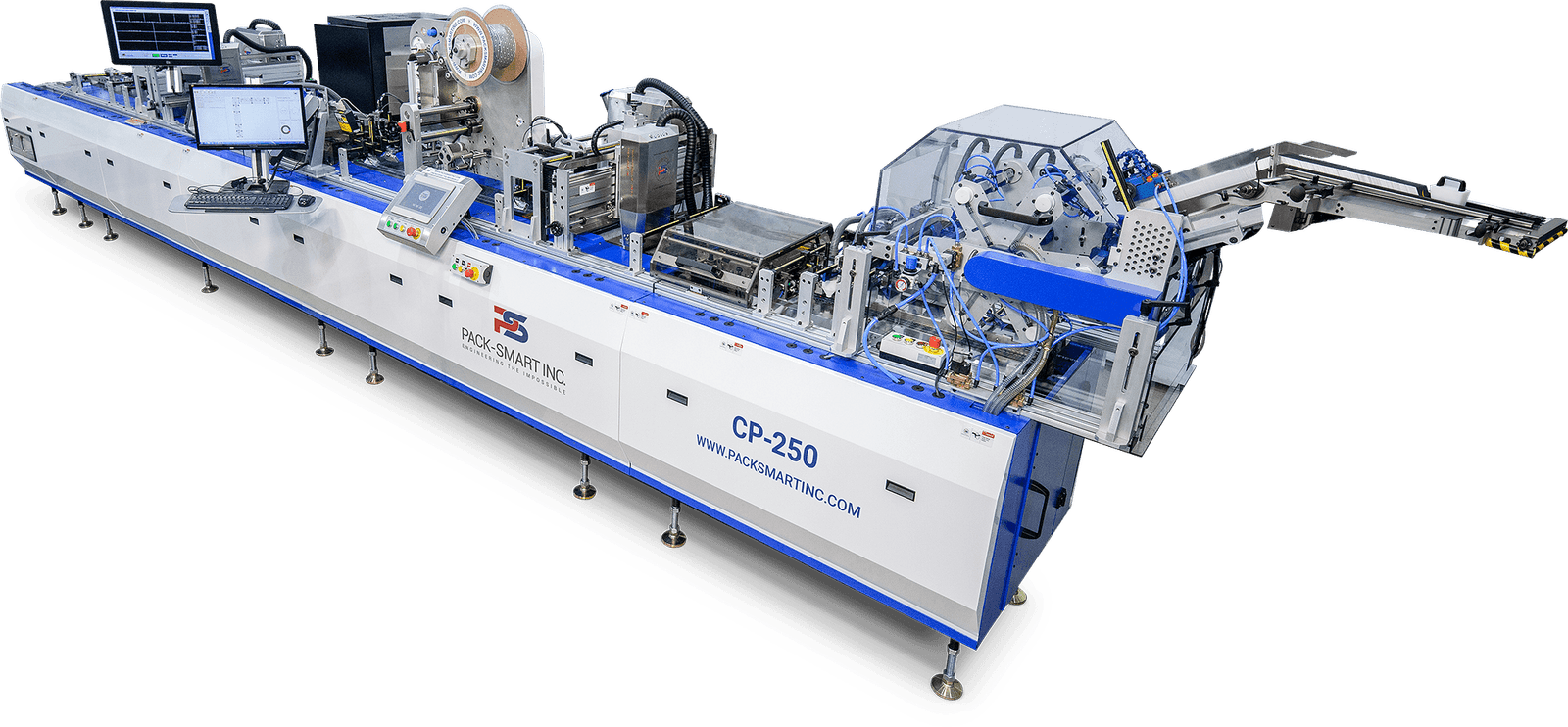

This technology is used in the following automated systems.

World’s first inline solution for high volume personalization, affixing, packaging and pack-out of secure open and closed loop cards at 20,000 PPH.

With speeds up to 30,000 PPH, it is ideal for all your closed, secure, and open loop needs.

Inline card to carrier affixing, booklet tipping, 4-corner secure folding/gluing, and DOD personalization.

Related modules are available for inline applications.

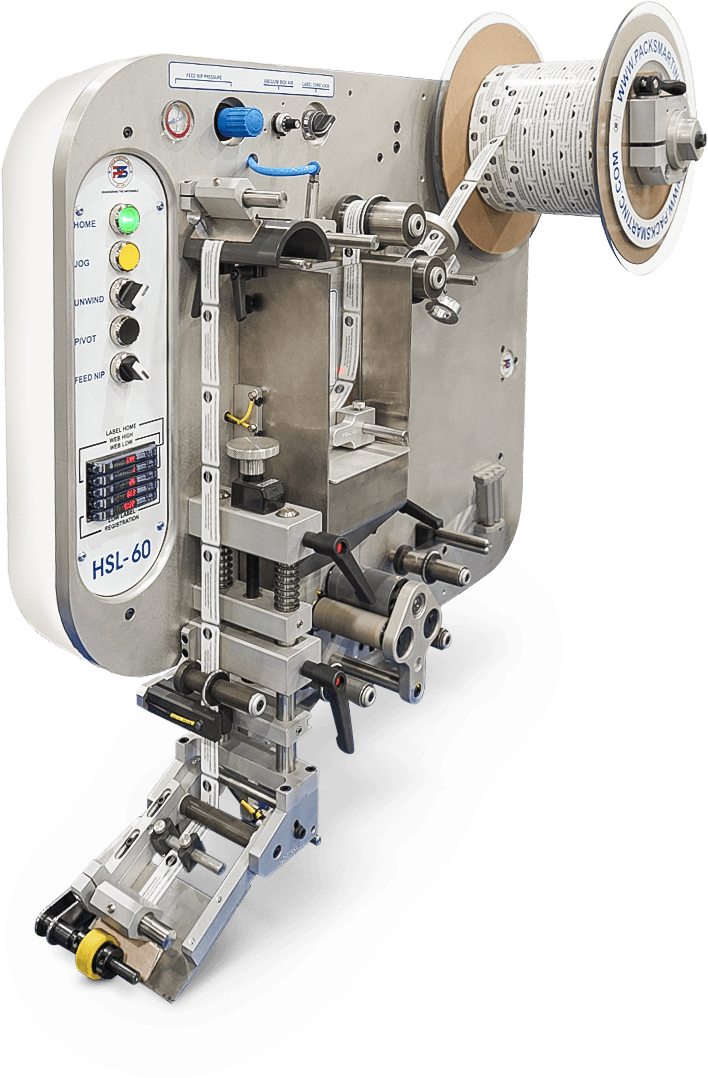

The HSL-60 is a highly versatile module that applies pressure sensitive labels at high speeds and accuracy for the most demanding precision-critical applications.

High torque servo driven vacuum transport conveys products at accurate speeds and controls product placement with 8 selectable vacuum zones.

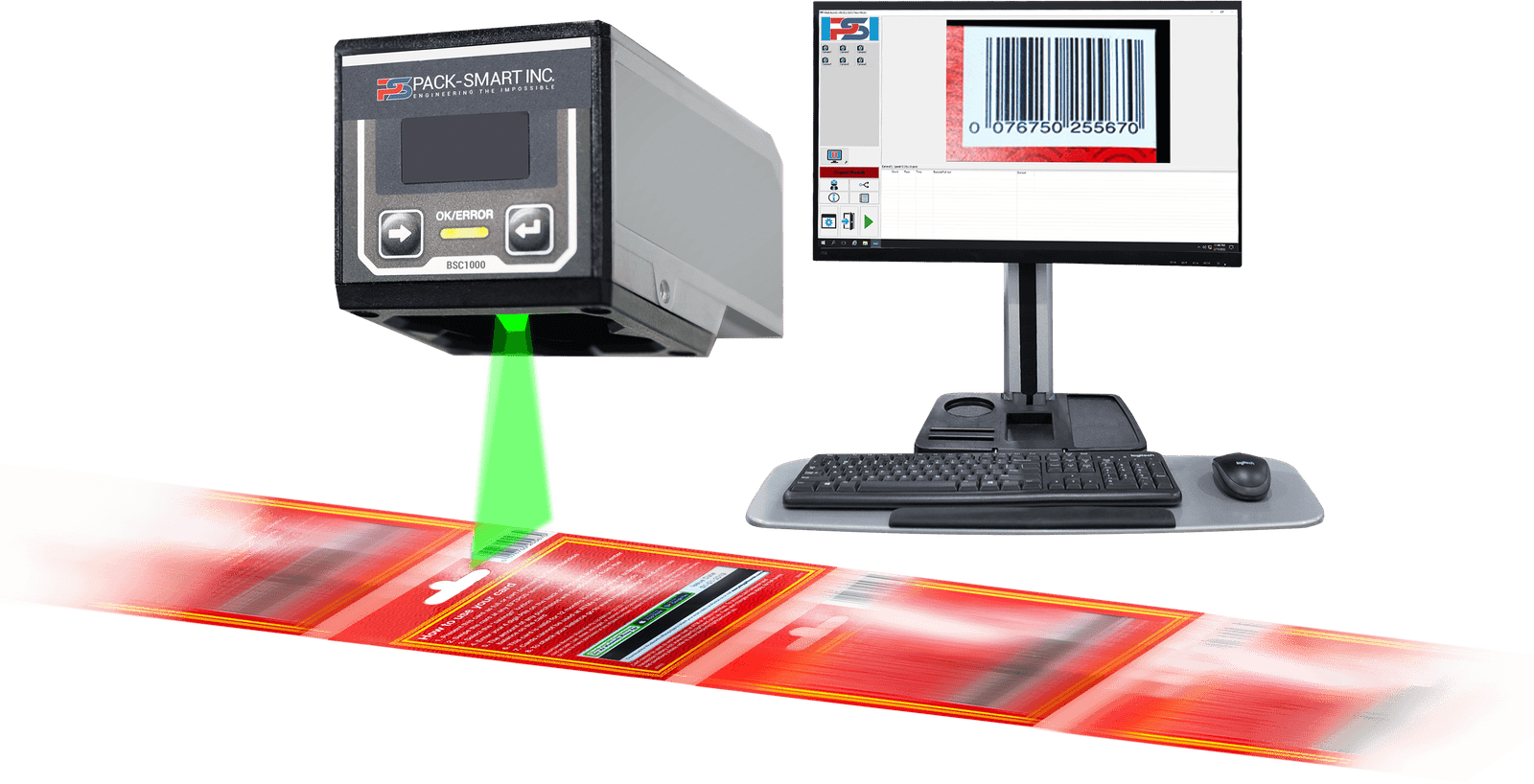

A user-friendly, fully packaged CCD reader, offering easy integration and several configurations to meet a variety of needs.