Card to Bundle in One Pass

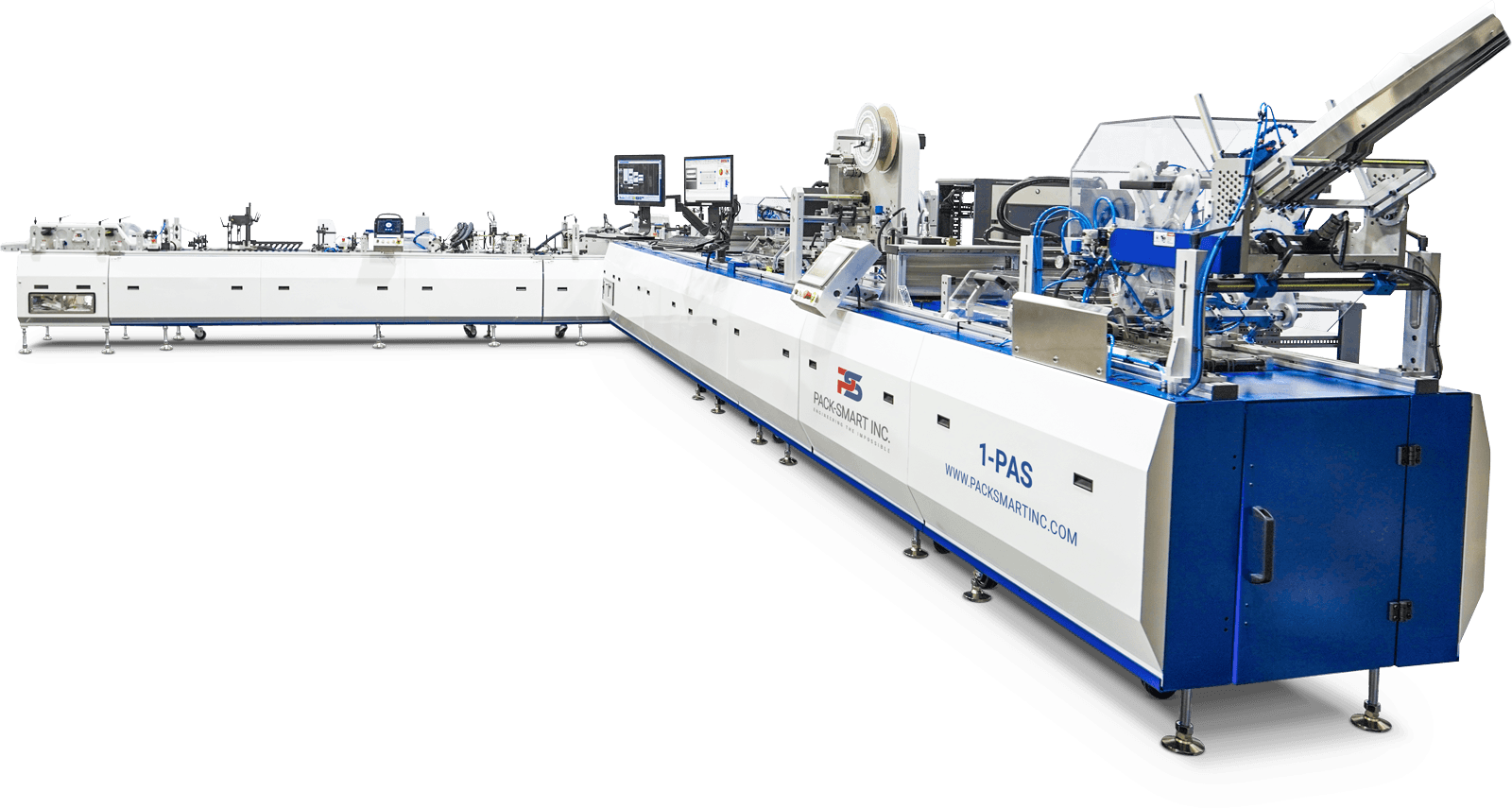

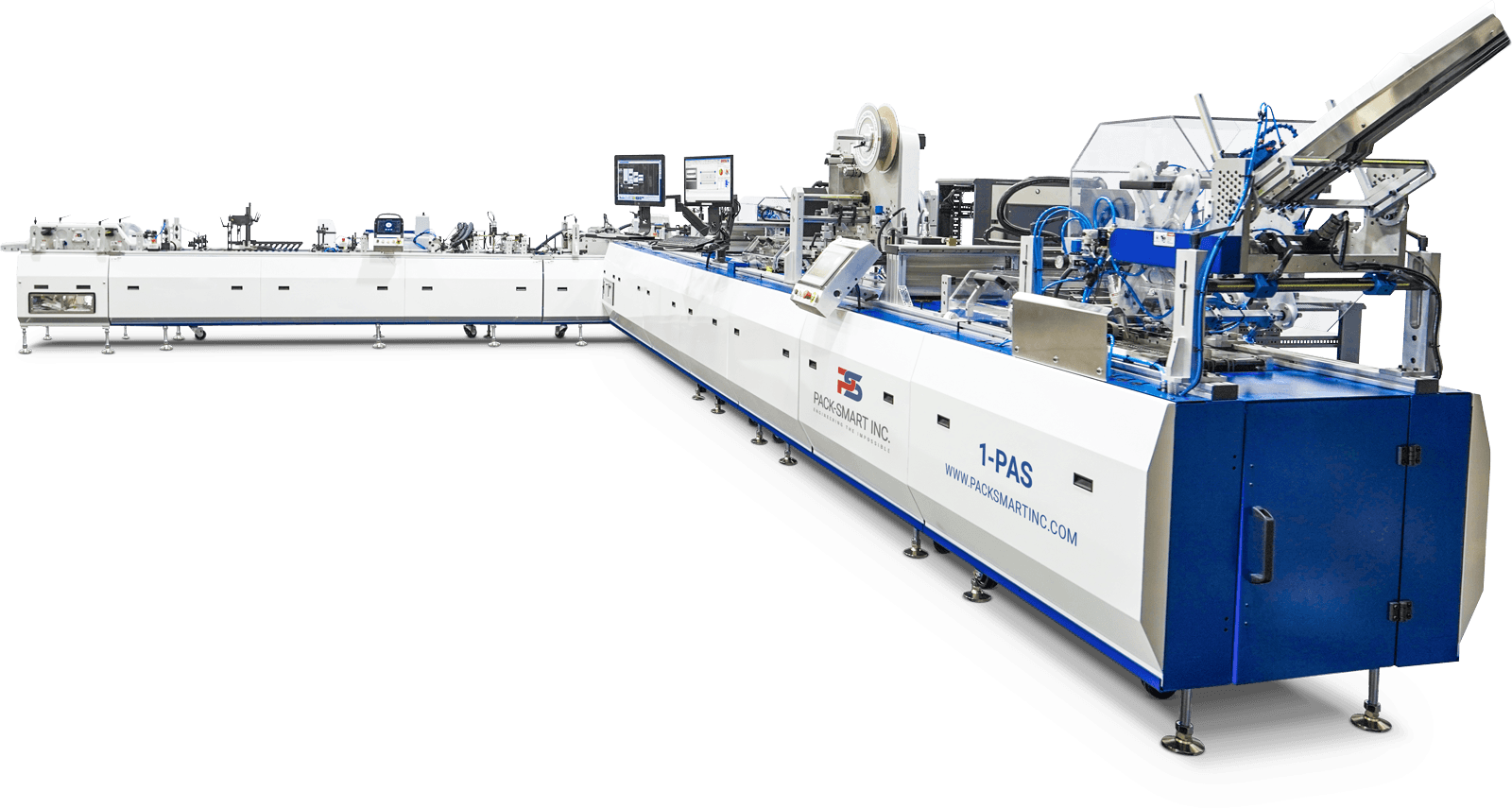

World’s first inline solution for high volume personalization, affixing, packaging and pack-out of secure open and closed loop cards at 20,000 PPH.

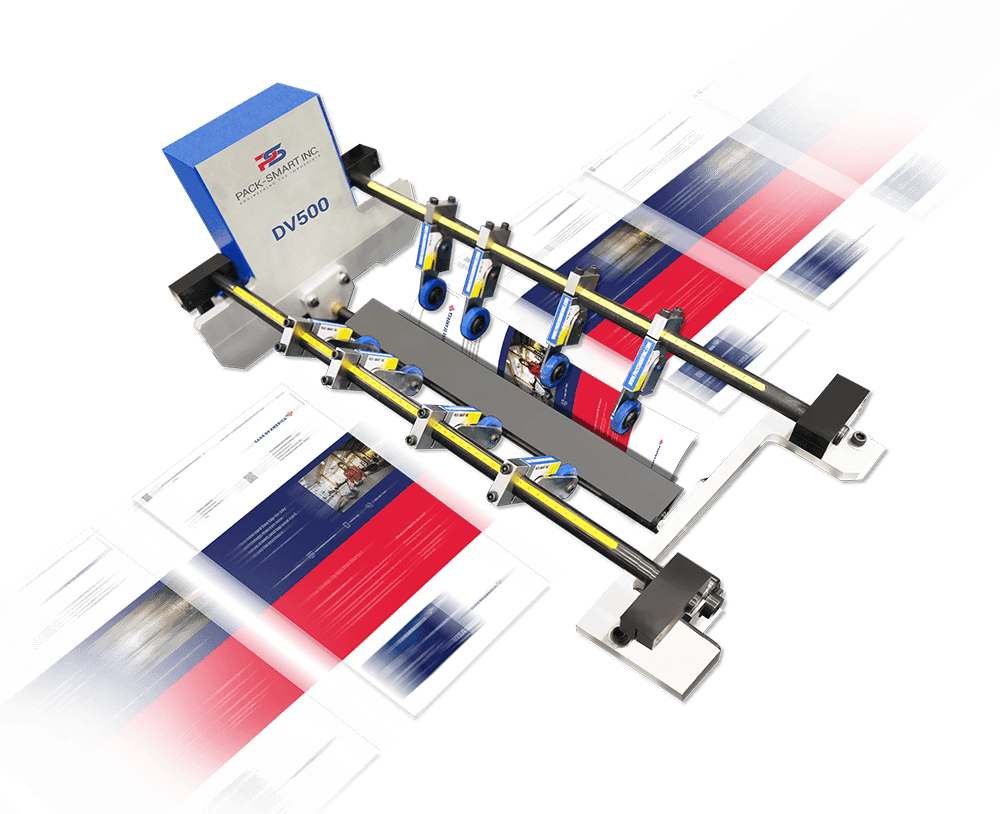

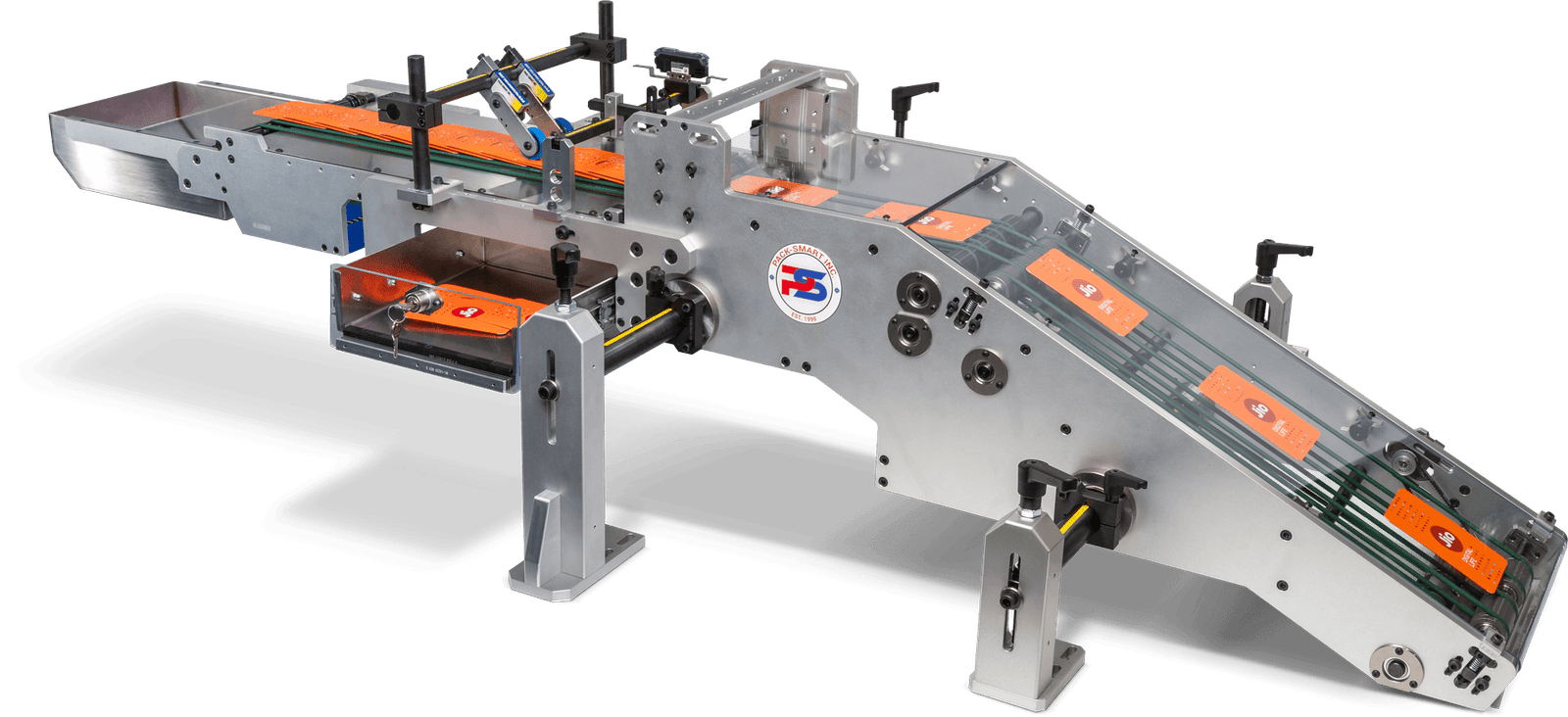

Revolutionize your production line with the DZ Series, High-Speed Zoned Divert Gate, crafted for precise, high-capacity product sorting and handling.

The DZ Series Zoned Divert Gate module redefines efficiency and accuracy in high-volume production settings. It features strategically placed zone-specific divert gates that allow for precise control and routing of products according to specific operational requirements.

This advanced system is equipped with state-of-the-art sensors and programmable logic controllers, enabling customizable operation and real-time adjustments to meet diverse production demands.

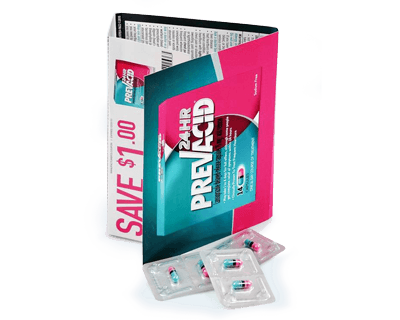

Pharmaceutical

eCommerce

Food and Beverage

Models catered to different operational scales, from small to large-sized products.

DV-250

250 mm gate width

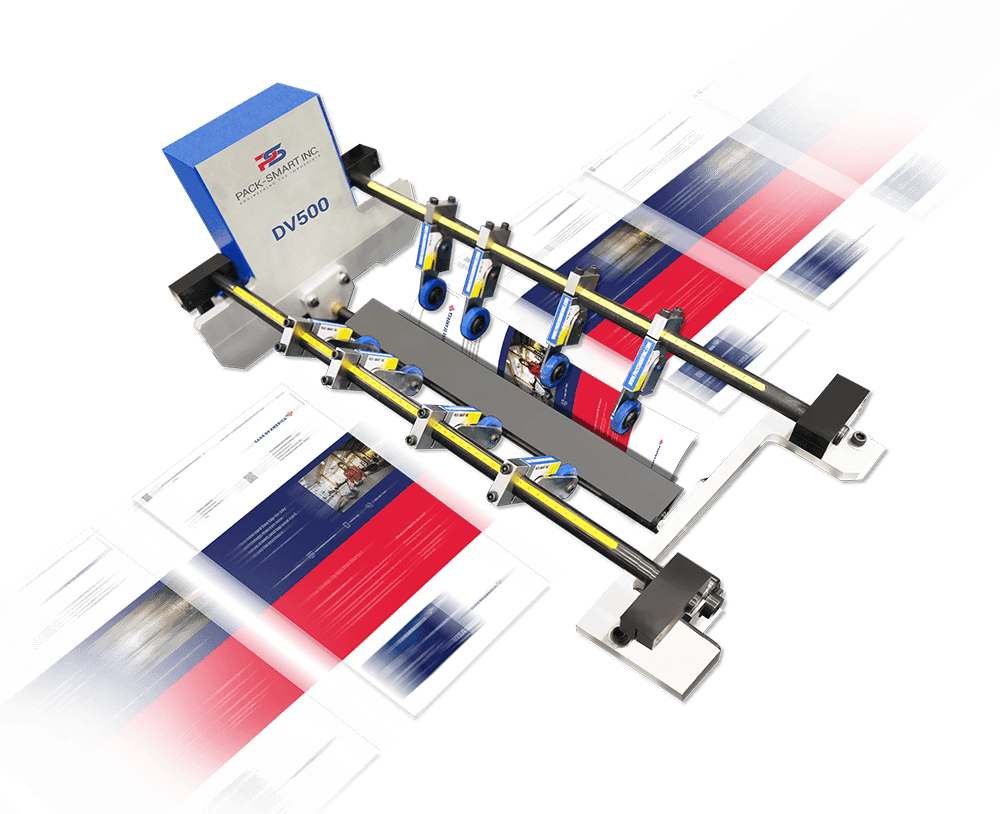

DV-500

500 mm gate width

This technology is used in the following automated systems.

World’s first inline solution for high volume personalization, affixing, packaging and pack-out of secure open and closed loop cards at 20,000 PPH.

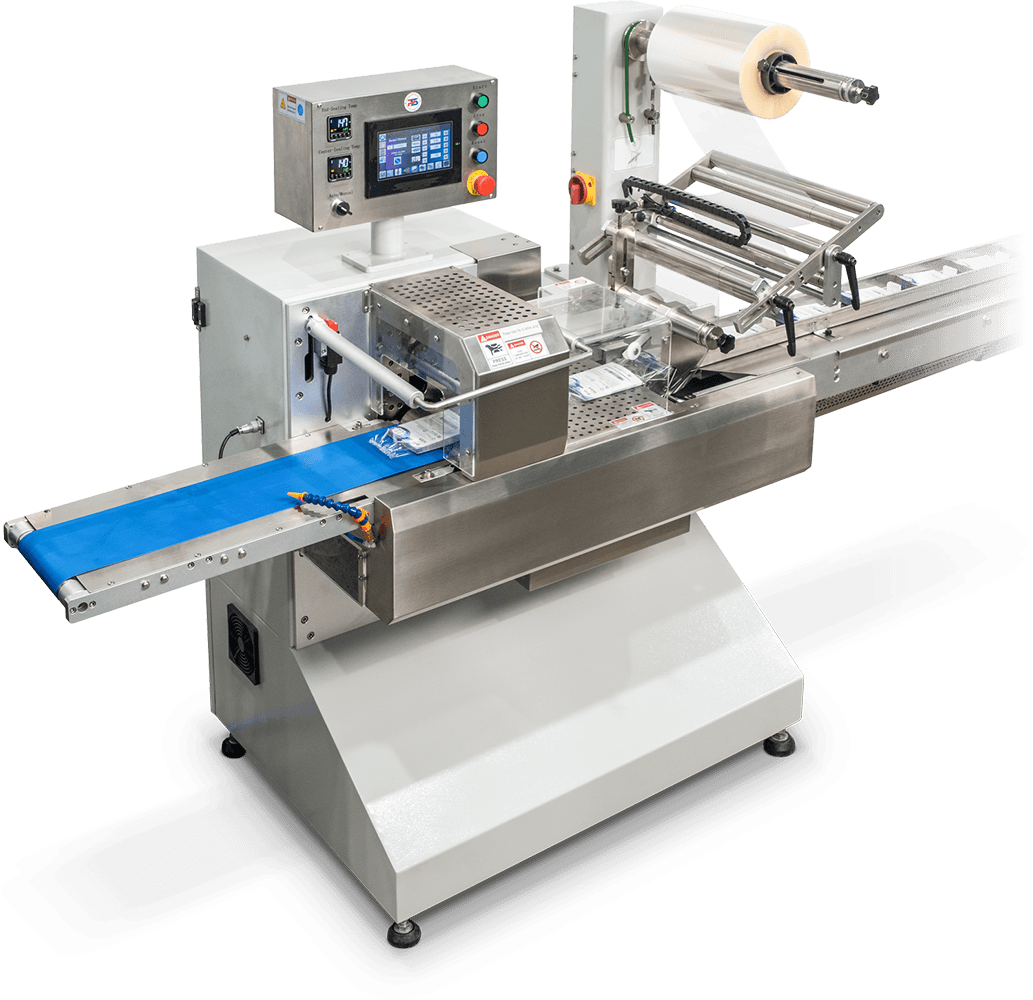

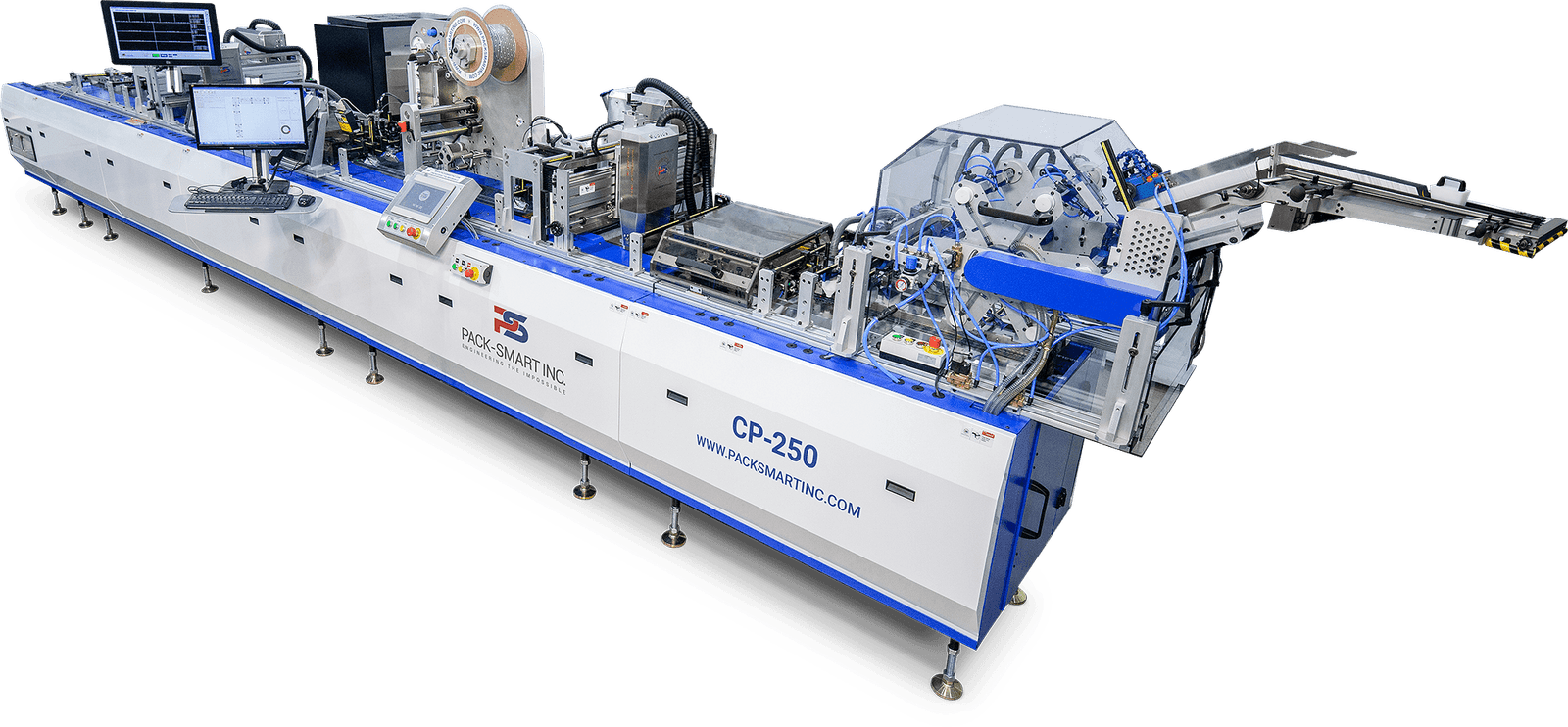

Discover the BA-250 Automated Pack-Out System, a high-speed solution for packaging fulfillment.

Engineered to meet the rigorous demands of EMV chip card encoding, this system combines advanced encoding capabilities with high-speed processing to deliver unparalleled efficiency.

Related modules are available for inline applications.

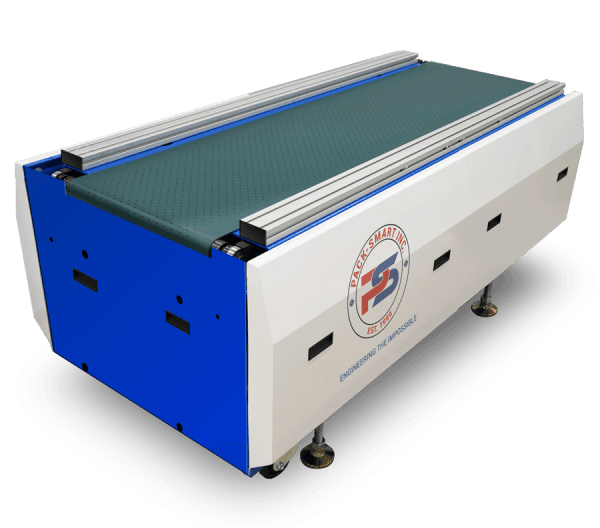

High torque servo driven vacuum transport conveys products at accurate speeds and controls product placement with 8 selectable vacuum zones.

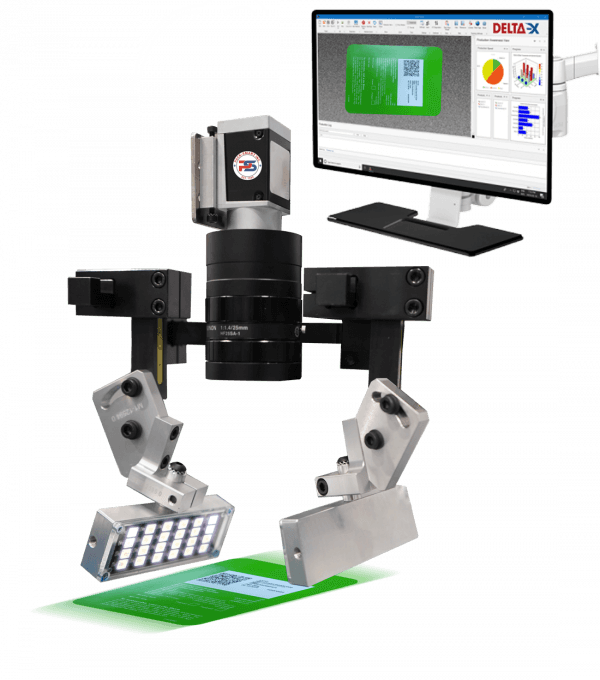

The VSC-1000 Vision System offers state-of-the-art vision scanning and real-time image processing, ideal for high-speed production environments.

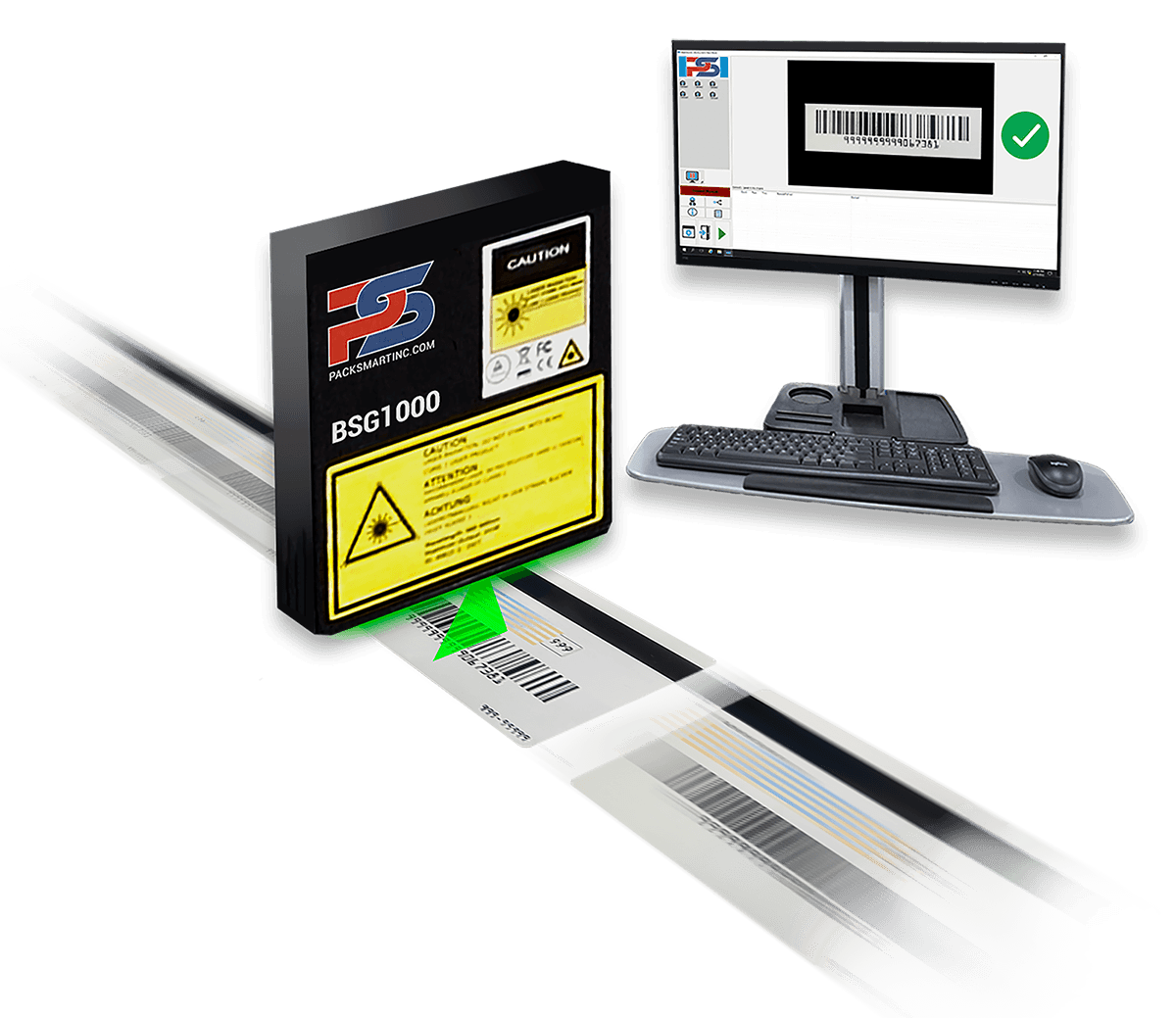

The BSG-1000 Barcode Scanning and Grading module is designed to ensure that all your barcoded products meet ISO standards for quality.

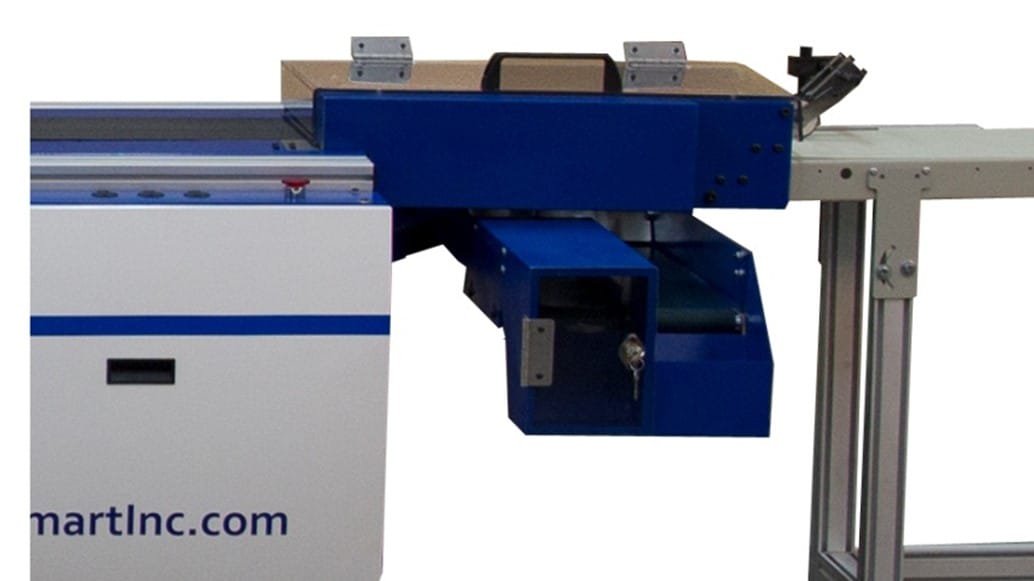

Enhance production line efficiency with the DO Series Overhead Divert, designed for high-speed, accurate product diversion and handling.

The DO Series Overhead Divert is engineered to seamlessly divert products from conveyor lines to overhead handling systems, facilitating manual sorting and bundling while ensuring continuous production flow.

This system is ideal for environments requiring high throughput and precise product handling.

The DO Series Overhead Divert is designed without variations, offering a standard, highly optimized configuration to meet the needs of diverse industrial applications. This singular design approach ensures uniform performance across all installations, facilitating seamless integration into existing production lines.

This technology is used in the following automated systems.

World’s first inline solution for high volume personalization, affixing, packaging and pack-out of secure open and closed loop cards at 20,000 PPH.

With speeds up to 30,000 PPH, it is ideal for all your closed, secure, and open loop needs.

Inline card to carrier affixing, booklet tipping, 4-corner secure folding/gluing, and DOD personalization.

Related modules are available for inline applications.

Elevate efficiency with the DZ Series Zoned Divert, designed for precise sorting and high-capacity handling in demanding industrial environments.