Rotary Pick and Place Series

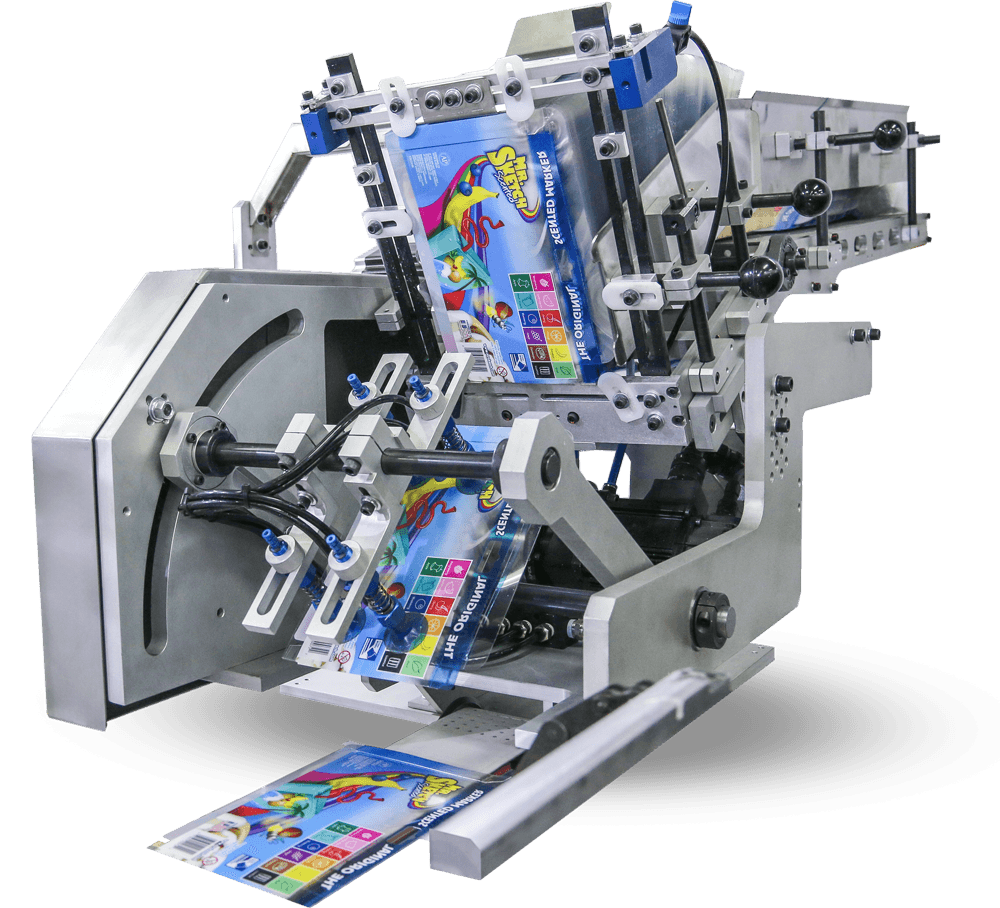

Consistently feed, insert, attach, and batch delicate materials and oddly shaped products at 30,000 PPH, with vacuum pick & place motion and ±0.02″ placement accuracy.

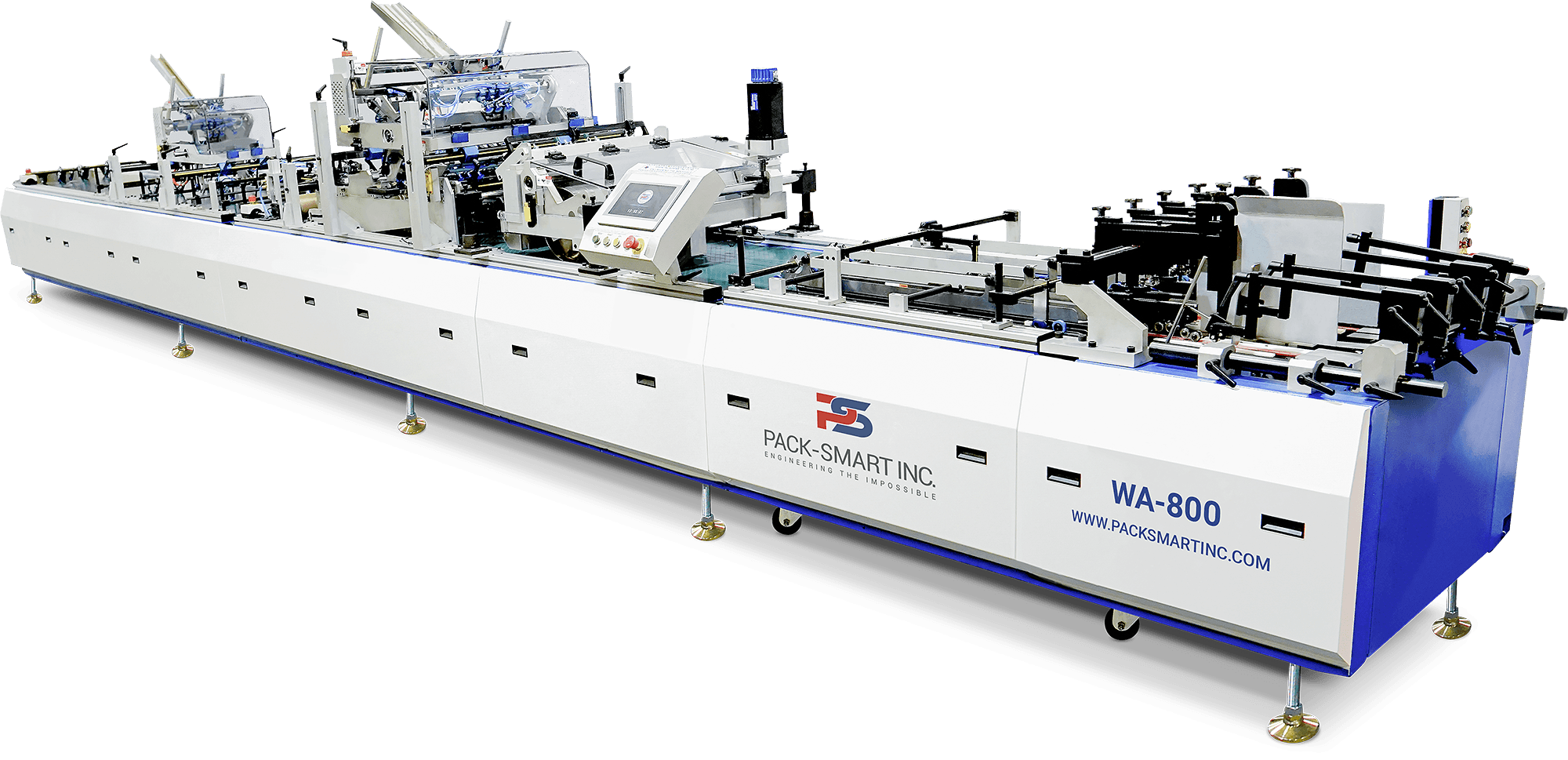

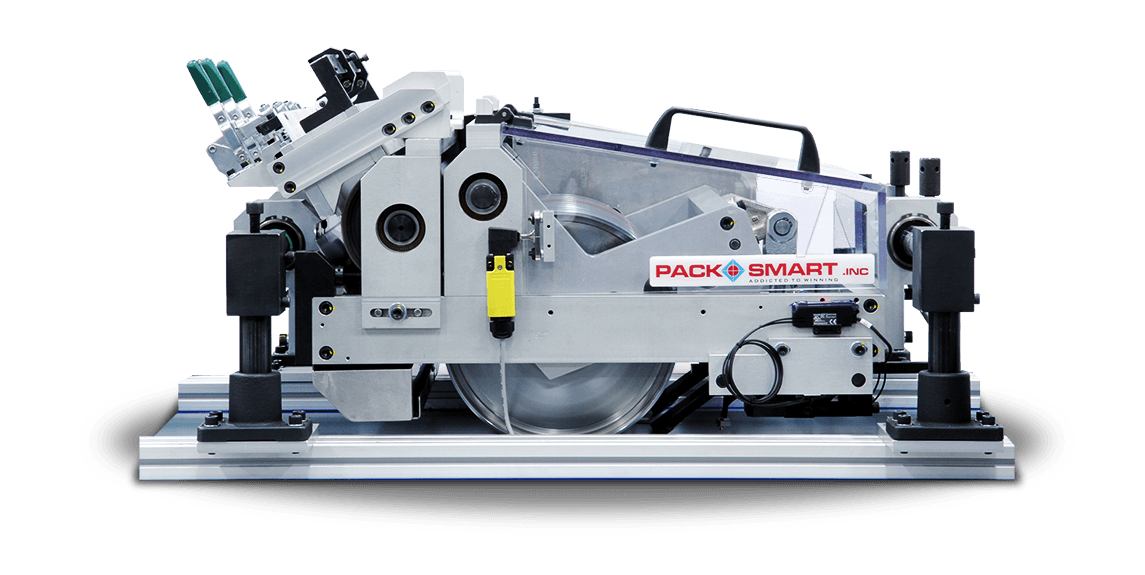

WA-800r delivers unmatched speed, accuracy and flexibility allowing affixing of rigid windows to virtually any carton product available.

WA-800r Rigid Window Affixing System is the fastest machine on the market, producing rigid window cartons for any market that incorporates high visibility packaging at low ‘per-unit’ costs and speeds up to 25,000 products per hour.

Due to our modular system approach, it is ideally suited to simultaneously carry out other in-line processes such as folding and gluing, creasing, tipping, braille inspection and digital imaging.

High Value Cartons

Specialty Packaging

The process flow for the WA-800r Rigid Window Affixing System is meticulously designed to ensure precise, secure, and efficient affixing of rigid windows to various packaging types. This system integrates each step, from initial material feeding to final quality inspection, ensuring high-speed, accurate application with robust security measures.

The WA-800r Rigid Window Affixing System incorporates state-of-the-art technologies to enhance its performance and reliability. Key technologies include advanced feeding mechanisms for consistent material handling, precision window placement technology for accurate affixing, and real-time monitoring systems to ensure quality and efficiency throughout the process.

Consistently feed, insert, attach, and batch delicate materials and oddly shaped products at 30,000 PPH, with vacuum pick & place motion and ±0.02″ placement accuracy.

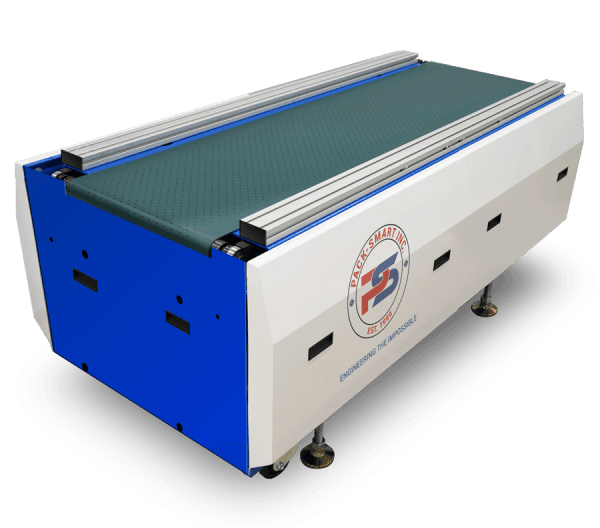

High torque servo driven vacuum transport conveys products at accurate speeds and controls product placement with 8 selectable vacuum zones.

Maximize your production efficiency with the RPP Series, designed for high-speed, accurate handling of delicate materials and uniquely shaped products.

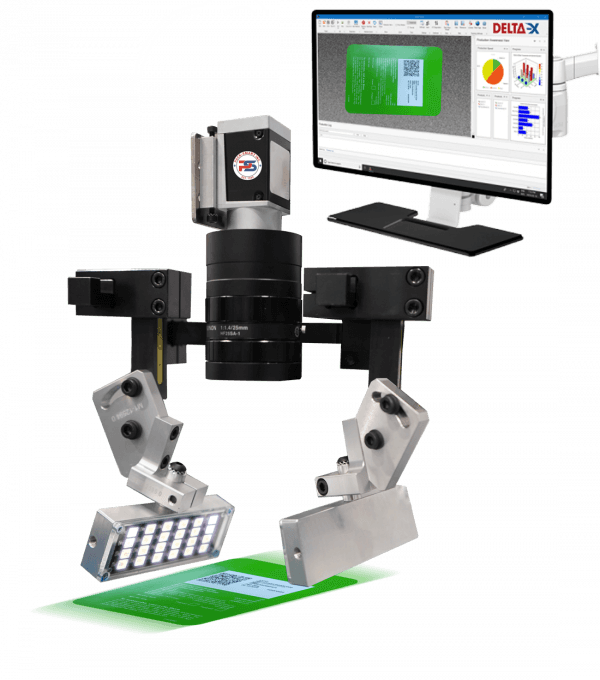

The VSC-1000 Vision System offers state-of-the-art vision scanning and real-time image processing, ideal for high-speed production environments.

Elevate your production capabilities with the PG-900 Flexo Pattern Glue Module, designed for precise and flexible adhesive applications.

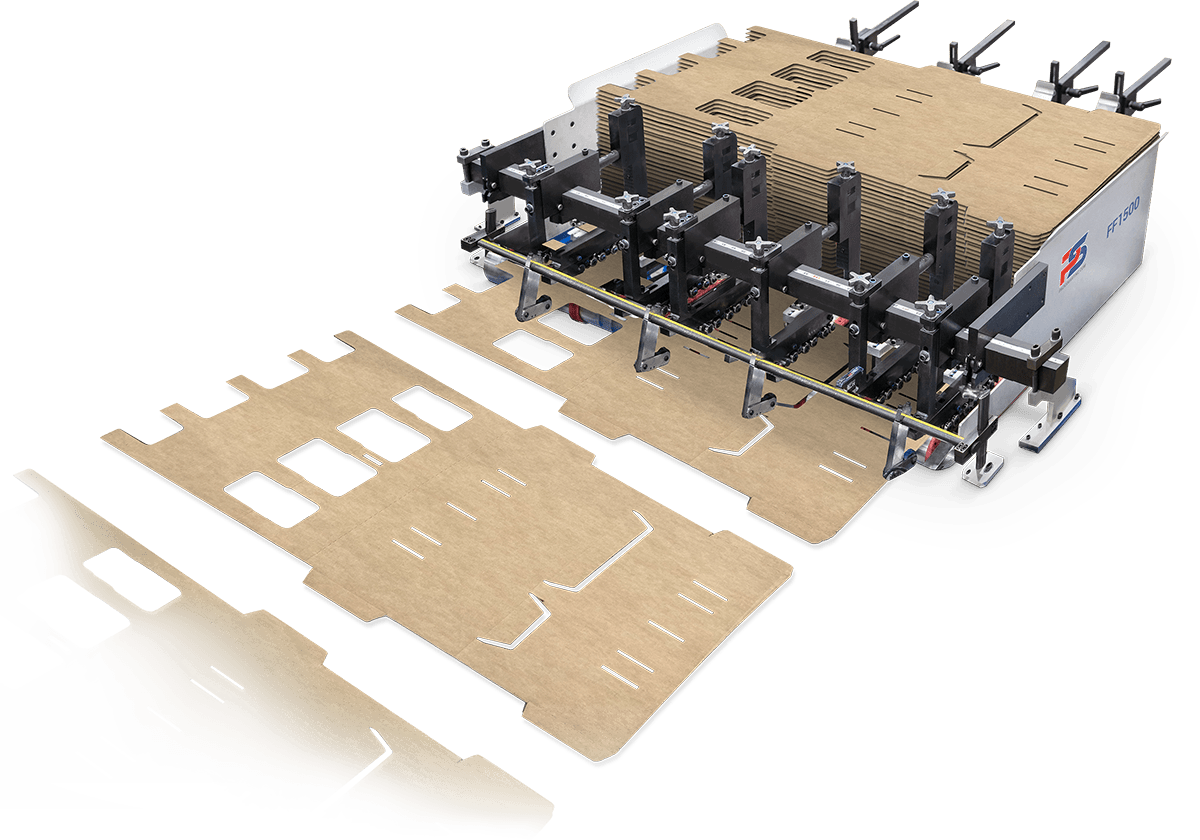

The FF Series Friction Feeder can handle the lightest paper and is equally at home when dealing with heavy stock materials when called upon.

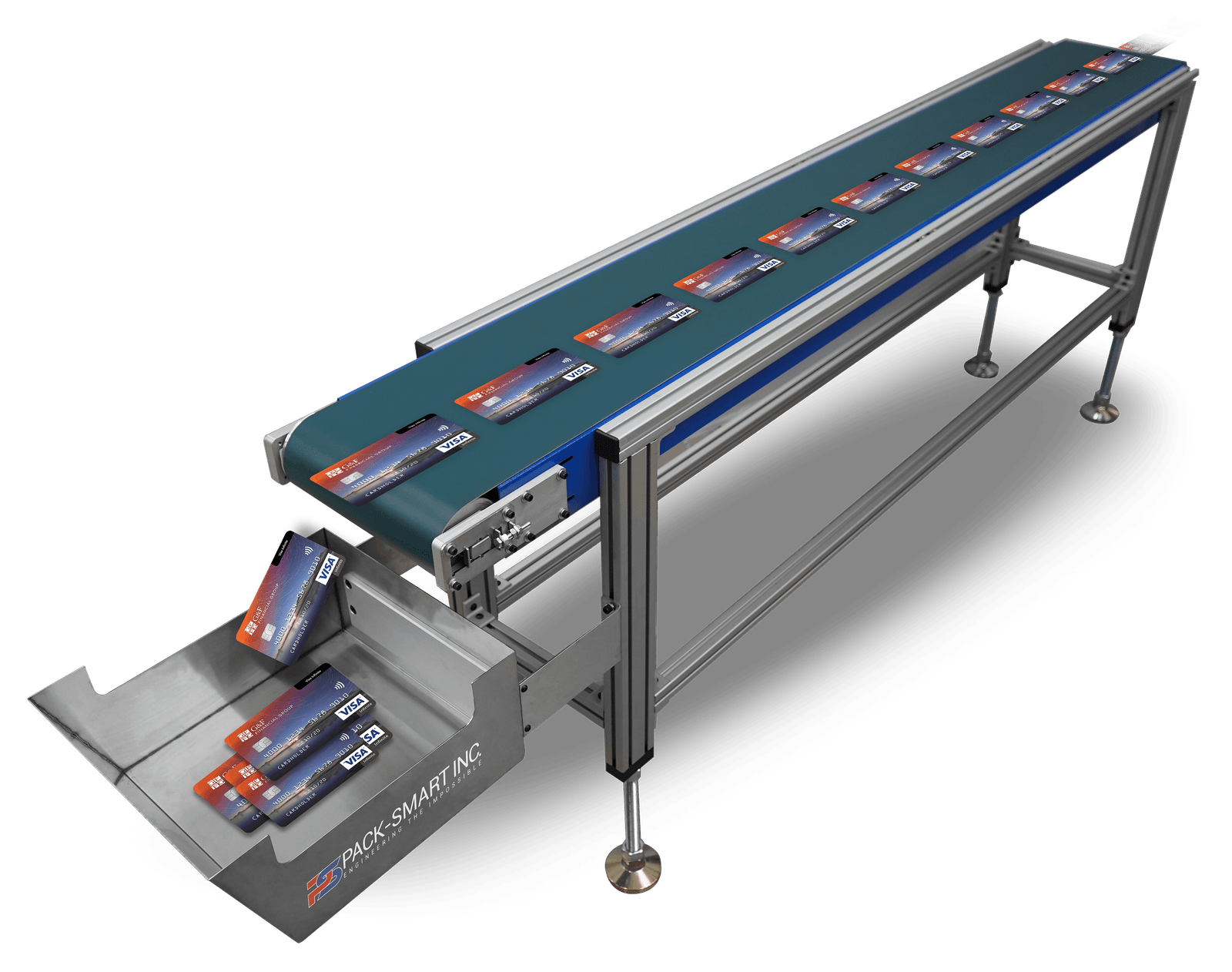

Discover the DL Series Shingled Delivery Transport, designed for efficient and ergonomic conveying of diverse printed materials.