From 60 Hands to One Machine: The Future of Tray Forming is Here

This system not only delivered a 130% increase in productivity, but also transformed packaging from a production bottleneck into a scalable, strategic advantage.

Delivers unmatched automation, producing 3,500+ products per hour while ensuring 100% product integrity. Designed for scalability, accuracy, and seamless integration, this state-of-the-art system will transform your packaging operations with modular flexibility.

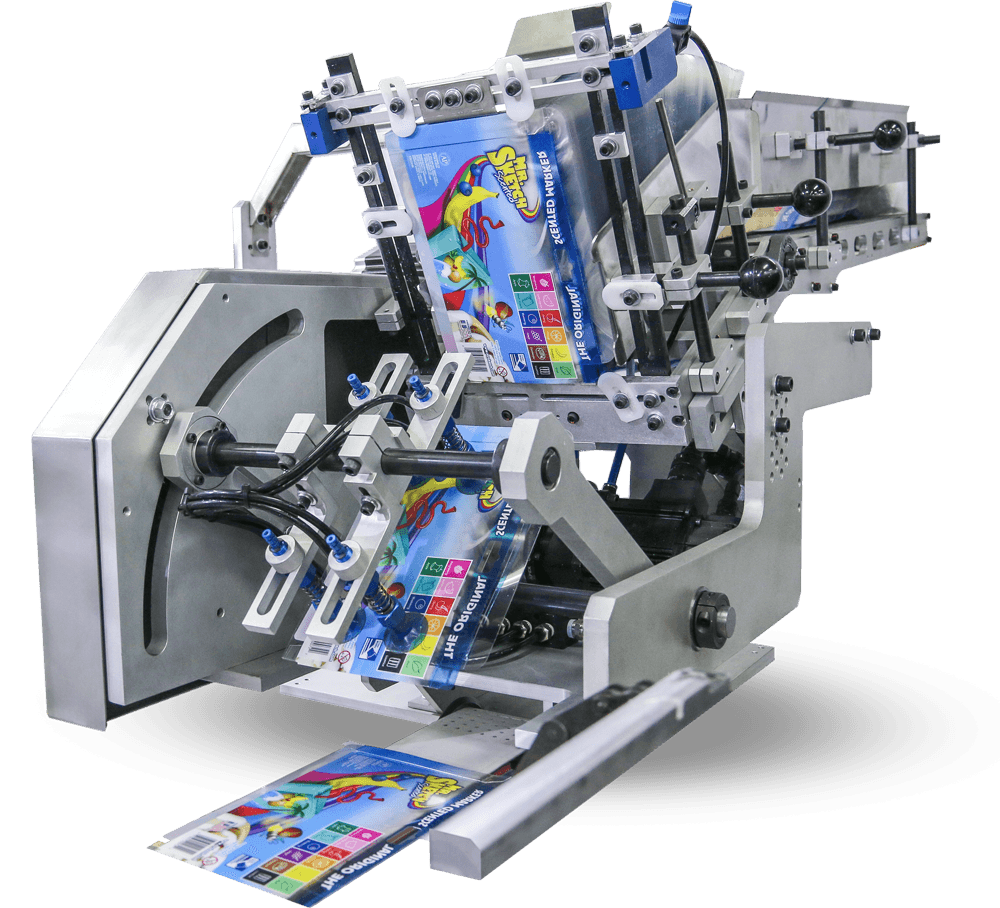

In industries where presentation, precision, and product integrity are non-negotiable, the TF-500 Tray Forming and Filling System sets a new standard. Designed for luxury goods, confectionery, electronics, and personal care packaging, this system ensures flawless tray formation and seamless product integration at high speeds.

Unlike traditional solutions, the TF-500 combines advanced motion control, automated 4-corner folding, and real-time vision inspection, making it the ideal choice for businesses looking to scale production while maintaining premium quality. From delicate chocolates to high-end consumer electronics, the

CASE STUDY

Lindt, the iconic Swiss chocolatier known for its premium confections like Lindor truffles and Excellence bars, turned to Pack-Smart Inc. to overcome a critical production challenge. Faced with rising labor costs, inconsistent quality, and capacity limitations, Lindt sought an advanced packaging solution that could dramatically reduce manual labor while increasing precision, reliability, sustainability and output.

Pack-Smart Inc. delivered with the TF-500 Tray Forming & Fulfillment System, a high-speed automation system that reimagines the entire packaging workflow for simplex tray forming.

This system not only delivered a 130% increase in productivity, but also transformed packaging from a production bottleneck into a scalable, strategic advantage.

The TF-500 Tray Forming and Filling System streamlines every stage of the packaging process, from precision tray forming and product placement to secure lid application and final delivery, ensuring high-speed, error-free operation with seamless automation.

The TF-500 Tray Forming and Filling System integrates advanced automation and intelligent motion control technologies to deliver precision, efficiency, and reliability at every stage of the tray packaging process. Each component is engineered to optimize performance, ensuring seamless operation and high-speed throughput.

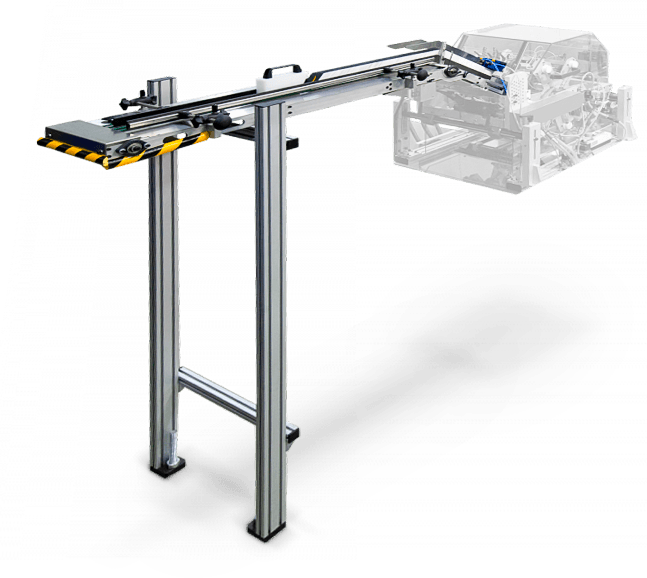

Maximize productivity with the AL Series Powered Autoloader. Designed to extend loading capacities and reduce manual reloading for high-speed applications, ensuring continuous operation and efficiency.

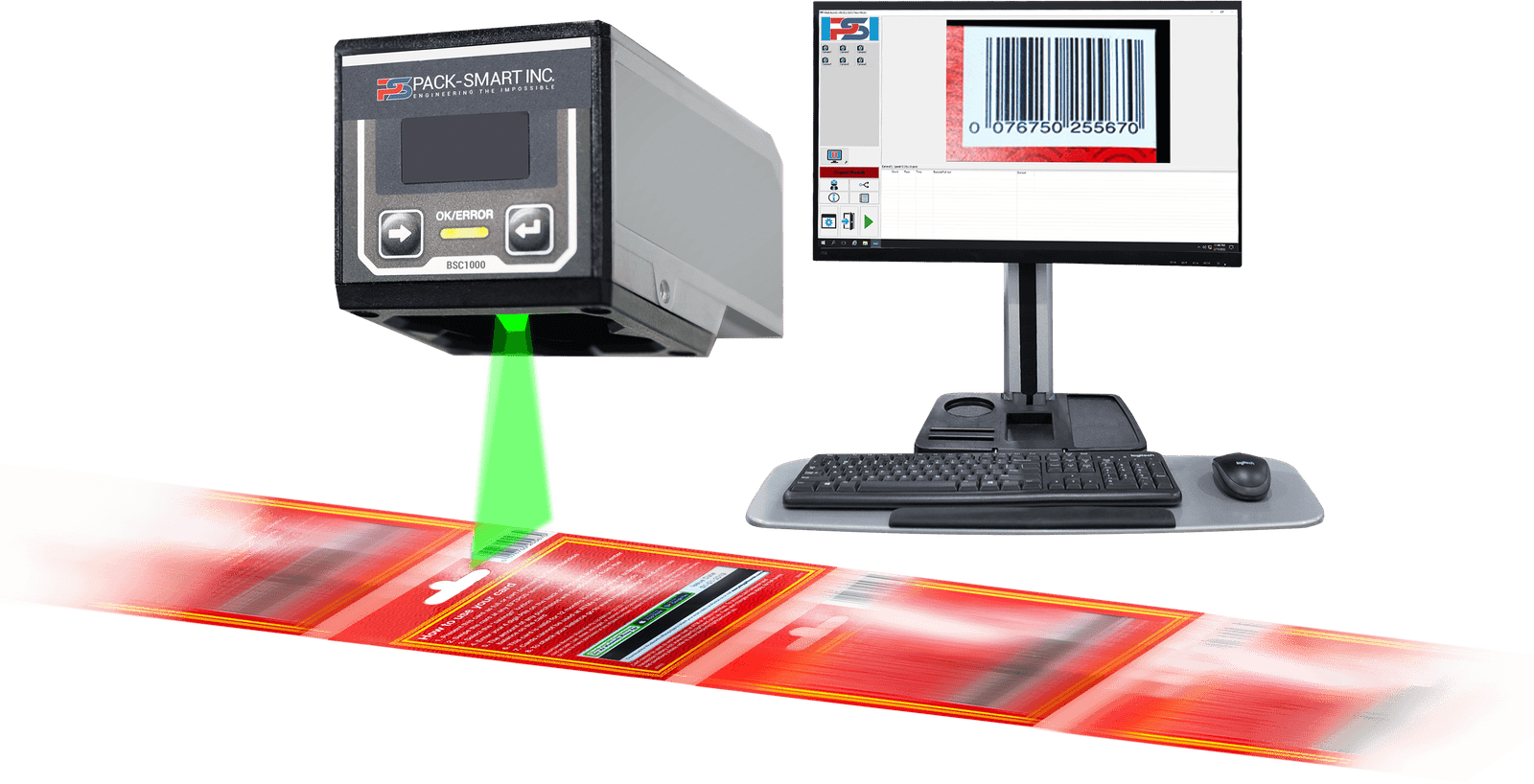

A user-friendly, fully packaged CCD reader, offering easy integration and several configurations to meet a variety of needs.

Smart Jet uses industry leading head technology to deliver UV Cured 600 DPI DOD Ink onto any surface.

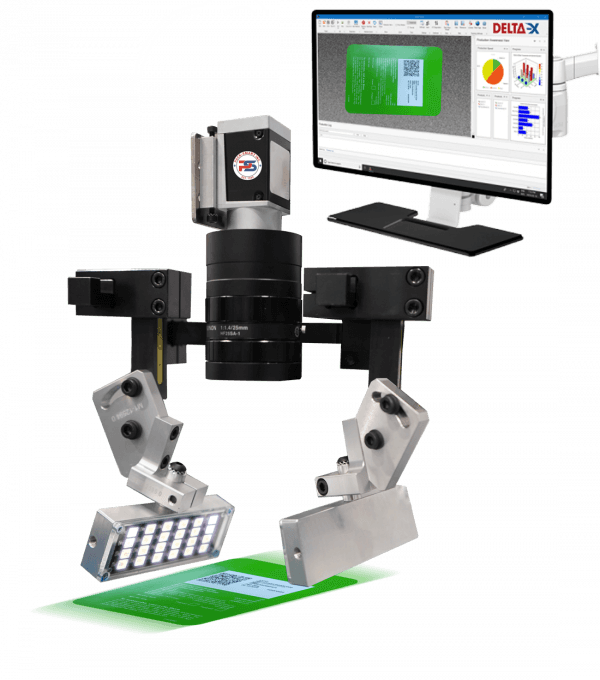

The VSC-1000 Vision System offers state-of-the-art vision scanning and real-time image processing, ideal for high-speed production environments.

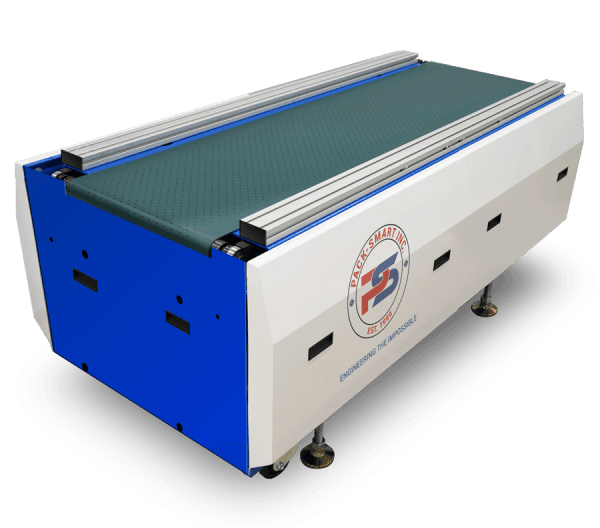

High torque servo driven vacuum transport conveys products at accurate speeds and controls product placement with 8 selectable vacuum zones.

Maximize your production efficiency with the RPP Series, designed for high-speed, accurate handling of delicate materials and uniquely shaped products.