Rotary Pick and Place Series

Consistently feed, insert, attach, and batch delicate materials and oddly shaped products at 30,000 PPH, with vacuum pick & place motion and ±0.02″ placement accuracy.

Automated Kitting, Carton Folding, Sealing and DOD Personalization. Master the art of folding and gluing with the FG-500, engineered for versatility and efficiency in diverse production environments.

The FG-500 system expertly coordinates carton kitting, gluing, folding, and personalization processes to deliver precision and efficiency in packaging operations. This robust system features inline high-accuracy affixing with a precision of ±0.4 mm and advanced 600 DPI printing capabilities, complemented by comprehensive quality assurance measures.

At the outset, all components are meticulously affixed to a flat carton carrier using fugitive glue. This prepares the carton for the application of secure glue, essential for robust packaging, followed by precise folding and compression of the front, back, and sides to form a securely sealed package.

Direct to Consumer Products

Sample Packs

Auto-Erect Cartons

The FG-500 system is designed to streamline the production process through an efficient and integrated workflow. From initial feeding and batching to final delivery, each stage is meticulously engineered to handle various materials with precision. The FG-500’s process flow incorporates advanced feeding mechanisms, precise alignment, and automated quality control, ensuring each product is processed accurately and efficiently, ready for the next stage without delay.

Key technologies include an advanced sheet feeding system, high-speed conveyors, dynamic folding units, and precise gluing mechanisms. Each component is integrated into the system to work synergistically, allowing for seamless transitions between different stages of the production process. This integration ensures consistent performance and reliability, making the FG-500 a powerhouse in automated packaging solutions.

Consistently feed, insert, attach, and batch delicate materials and oddly shaped products at 30,000 PPH, with vacuum pick & place motion and ±0.02″ placement accuracy.

An ultra-lightweight alloy folding attachment. The BF-100 delivers unmatched productivity for four and six-corner folding tasks.

The CEG-1 Cold Glue System is engineered for high-precision, tamper-proof adhesive applications.

Revolutionize your production with the HM-10 Hot Melt Glue System, offering precision application for a wide range of adhesive needs.

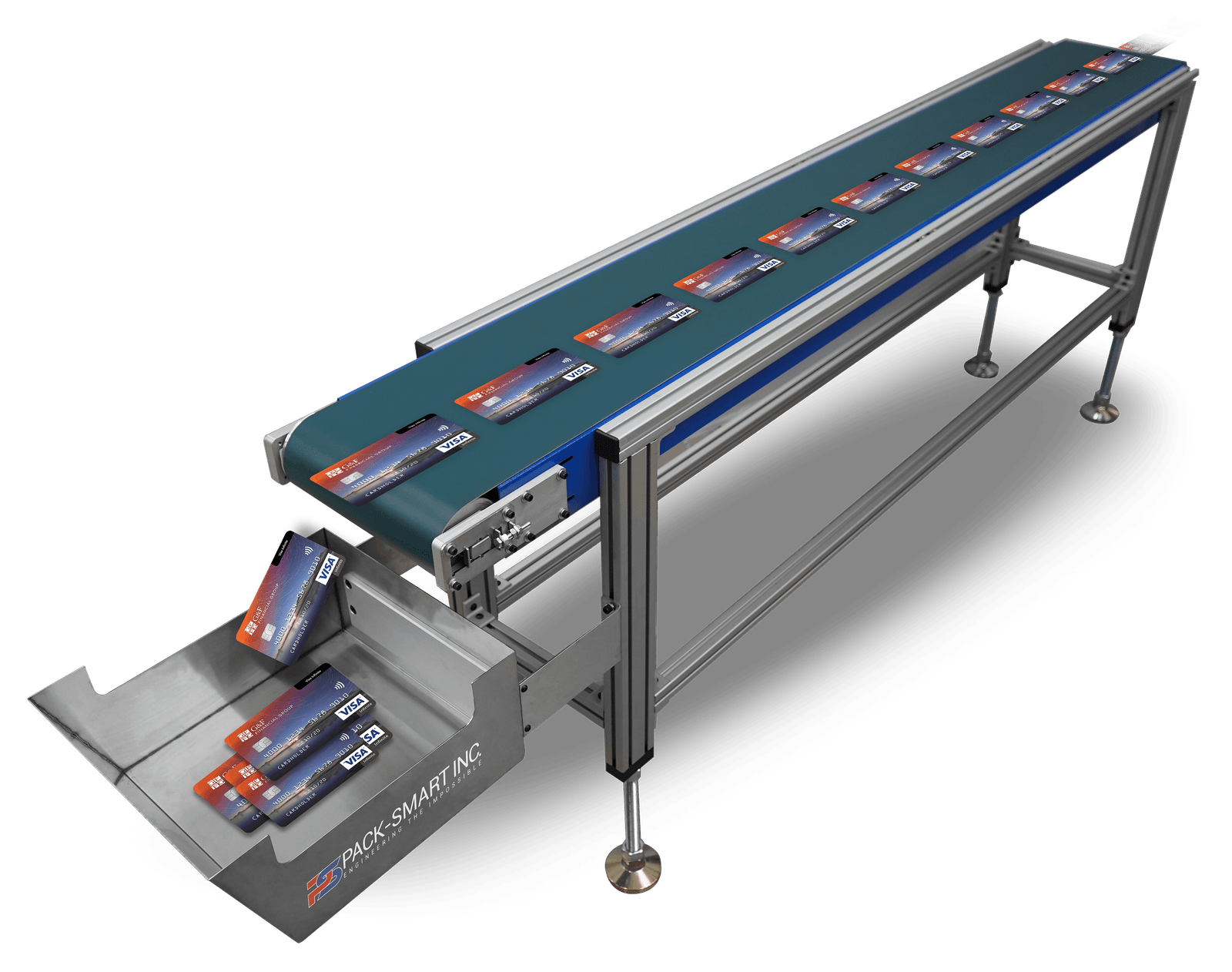

Discover the DL Series Shingled Delivery Transport, designed for efficient and ergonomic conveying of diverse printed materials.