Blog

Packaging Design for Brand Trust: 4 Strategic Shifts Reshaping 2026

Packaging design for brand trust has become non-negotiable. In sectors where counterfeiting, regulatory compliance, and consumer confidence determine market success, your packaging either builds trust or undermines it.

For pharmaceutical brands facing serialization mandates, payment card issuers fighting fraud, and personal care companies battling grey market diversion, packaging is no longer just about shelf appeal. It’s your first line of defense and your most visible promise to consumers.

But trust doesn’t come from adding security features after the fact. It’s built when packaging design, connected technology, and production systems work together from the start. Here’s how leading brands are doing it and why it matters for your next product launch.

Why Packaging Design for Brand Trust Matters More Than Ever

Brands don’t build trust through marketing campaigns alone. It’s reinforced—or destroyed—at every physical touchpoint between your product and your customer.

Your packaging communicates trustworthiness before anyone reads your claims, scans your QR code, or opens the box. The question is whether that communication is intentional or accidental.

In regulated industries, the stakes are higher. Pharmaceutical companies face FDA scrutiny and patient safety responsibilities. Payment card issuers face fraud losses totaling $28.58 billion globally in 2020. Personal care brands fight counterfeits that damage reputation and customer relationships.

Traditional packaging design focused on differentiation and shelf impact. That’s still important, but it’s incomplete. Today’s packaging must also provide signal authenticity, enable verification, support compliance, and create cognitive clarity amid visual overload and consumer skepticism.

Pack-Smart Inc. has been engineering packaging solutions for regulated sectors for over 25 years. We’ve watched packaging performance metrics evolve from “does it stand out” to “does it build lasting trust.” The brands winning now understand this shift and design for it deliberately.

The following four strategic shifts show how packaging design for brand trust is being put into practice across connected technologies, typography, human-centered design principles, and color systems.

Connected Packaging Technology: Verification Builds Trust at Scale

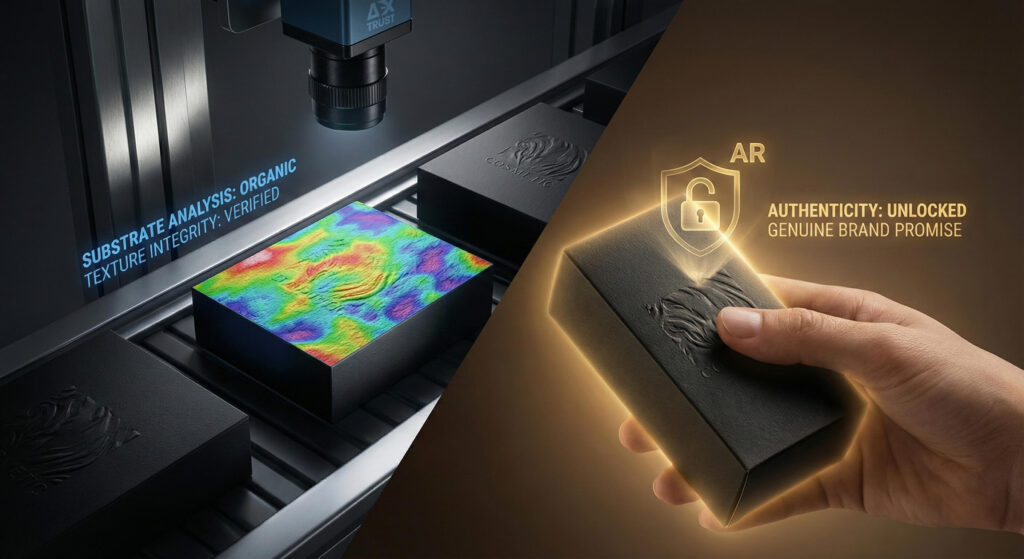

Connected packaging technology transforms passive containers into active trust mechanisms.

When you integrate QR codes, NFC tags, or RFID into packaging design, you’re not just adding a marketing feature; you’re creating a verification layer that reassures consumers, builds confidence, and demonstrates your commitment to authenticity and safety.

The impact is greatest in sectors where trust failures carry measurable consequences. In the pharmaceutical industry, connected packaging supports FDA serialization requirements and helps patients verify medication authenticity. In payment cards, it enables activation tracking and tamper detection, reducing fraud. In personal care, it lets consumers confirm they’re buying genuine products, not counterfeits.

However, connected packaging technology only builds trust when teams implement it as a production system, not bolt it on afterward.

That’s where Delta-X Trust creates measurable impact. Our platform seamlessly integrates serialization, track-and-trace, and anti-counterfeiting capabilities into your existing packaging workflows, ensuring smooth adoption without disrupting production throughput. In pharmaceutical applications, Delta-X Trust supports DSCSA and EU FMD compliance while maintaining efficiency. For payment card manufacturers, it manages PCI DSS-compliant data flows and enables real-time activation verification. In personal care, it provides brand authentication that aligns with current operations, reducing integration concerns.

The technical challenge isn’t generating unique codes. It’s managing those codes across production runs, integrating inspection systems, handling exceptions, and maintaining audit-ready data streams at line speed.

Pack-Smart Inc. engineers packaging lines where connected technology, print systems, vision inspection, and data governance work together. Because trust at scale requires precision at every step.

When connected packaging technology is done right, consumers don’t just see your brand — they can verify it. That verification compounds trust over time.

Strategic Typography: Clarity Signals Trustworthiness

Typography in packaging design has shifted from an aesthetic choice to a trusted instrument.

In high-stakes categories, typography carries warnings, dosage instructions, compliance statements, and verification cues. If those elements aren’t immediately readable across production tolerances and product lifecycles, trust erodes.

However, strategic typography does more than improve legibility. It signals deliberateness and control—two critical components of brand trust.

Large-scale, expressive lettering performs well not because it’s bold, but because it communicates confidence and reduces cognitive friction. When consumers can quickly read, understand, and remember key information, they perceive the brand as more trustworthy.

This packaging design principle matters across contexts. On retail shelves, straightforward typography helps consumers navigate SKUs and verify product details. On screens, it ensures packaging looks consistent across e-commerce listings and social shares. During post-purchase use, it supports proper product handling and compliance.

New display technologies are expanding the possibilities of typography. OLED screens and other embedded formats allow text to shift dynamically, creating opportunities for real-time communication. But this increases—not decreases—the importance of typographic discipline.

For Pack-Smart Inc., clients in regulated sectors, typography also integrates with variable data and serialization logic. Pharmaceutical packaging requires typography systems that remain stable while serialized numbers change. Payment card packaging demands typography that works alongside magnetic stripes, EMV chips, and activation codes.

The operational implication: typography must be developed with print execution, inspection requirements, and data governance in mind. Decisions can’t be finalized in isolation and handed to production teams afterward.

When typography supports both cognition and verification, it becomes infrastructure for brand trust.

Human-Centered Packaging Design: Imperfection as Trust Signal

As automation improves, achieving visual perfection has become easier and less effective as a trust signal.

Counterfeits can be polished. AI-generated designs can be flawless. Generic templates can look professional. So, perfection alone doesn’t differentiate authentic products anymore.

As a result, consumers are gravitating toward packaging that reflects human judgment and intentional design choices. Tactile elements, material authenticity, and thoughtful imperfection function as cues that someone—not just an algorithm—made decisions.

This packaging design trend intersects directly with anti-counterfeiting strategies. In beauty and personal care, tactile cues often serve as informal authenticity checks. Consumers run their fingers over the embossing, feel the substrate weight, and notice the finishing details. These signals aren’t documented in brand guidelines, but they influence perceived legitimacy.

Within pharmaceutical packaging, material quality and print discipline directly affect perceived safety.When tactile cues and print registration are precise, supply chain professionals can trust the medication’s authenticity, reinforcing their confidence in the packaging process.

In payment card packaging, tamper-evident features must be both functional and easy to detect. Consumers need to see and feel that the package hasn’t been compromised. That’s where human-centered design thinking meets anti-counterfeiting engineering.

Pack-Smart’s role is to preserve trust cues through production variability. Coating inconsistencies, compression tolerances, and poor finishing often erase expressive details. Our packaging lines maintain tactile integrity while hitting throughput targets and cost requirements.

We validate these elements through vision inspection and quality controls that extend beyond print registration to include substrate handling, finishing consistency, and material authenticity.

Human-centered packaging design doesn’t mean abandoning precision. It means choosing where precision serves functionality and where controlled variation builds trust.

Functional Color Systems: Recognition Reduces Risk

Color in packaging design has evolved from brand expression to trust infrastructure.

In regulated, high-trust sectors, color serves as a recognition cue that accelerates SKU identification, reduces selection errors, and supports memory encoding under cognitive load.

This matters in pharmaceutical packaging, where color coding helps patients distinguish medications and prevents dosing errors. It matters in payment card packaging, where color differentiation supports activation workflows and reduces fulfillment mistakes. It matters in personal care, where color consistency signals product authenticity and helps consumers verify purchases.

But functional color systems only build trust when they’re controlled through production.

That’s where packaging design for brand trust becomes an operational discipline. Teams must specify color systems with real production constraints in mind—substrate variability, coating interactions, print method constraints, and inspection capabilities.

At Pack-Smart inc., we develop color systems that account for these variables upfront. For pharmaceutical clients, that means color specifications that remain compliant and distinguishable across batch runs. For payment card manufacturers, it means color tolerances that support both brand recognition and machine vision inspection. For personal care brands, it means color consistency that survives distribution channels and shelf life.

The neutral “eco-beige” aesthetic that dominated sustainable packaging is losing effectiveness. Not because sustainability matters less, but because visual ambiguity undermines brand recognition. When every natural product uses the same muted palette, none of them builds a distinctive memory.

As a result, brands are finding that fewer, more emotionally resonant colors outperform neutral palettes—not because they attract attention, but because they reduce cognitive effort and support faster recognition.

When color is treated as infrastructure rather than decoration, it conveys brand trust before any words are read.

How to Implement Packaging Design for Brand Trust

These strategic shifts don’t call for surface-level redesigns. They require operational changes in how packaging decisions are made, governed, and validated.

Integrate Trust Into Design Systems, Not After

Connected packaging, typography, tactile elements, and color must work together as a coherent trust system. Leading organizations consolidate ownership and enforce consistency across touchpoints.

The question isn’t whether individual elements look good. It’s whether they compound trust over time and across contexts.

Treat Serialization and Authentication as Production Requirements

Anti-counterfeiting packaging and track-and-trace capabilities fail when treated as add-ons. They succeed when integrated into production workflows from the start.

Pack-Smart engineers packaging lines where serialization, inspection, data capture, and exception handling operate at line speed without sacrificing quality or compliance.

Validate Design Intent Through Production Constraints

Typography, tactile cues, and color systems must survive real manufacturing conditions. That means specifying them with substrate tolerances, coating interactions, print methods, and inspection capabilities in mind.

Design decisions finalized in isolation and handed downstream lead to trust failures in production.

Measure Trust Signals, Not Just Aesthetic Appeal

Emerging performance metrics include verification success rates, SKU selection accuracy, consumer verification activity, and counterfeit detection speed.

Packaging design for brand trust must be evaluated on how reliably it builds confidence and enables verification.

Build Cross-Functional Accountability

Decisions affecting connected packaging, typography standards, material authenticity, and color systems shape brand trust over the years. They require visibility across design, operations, compliance, and leadership teams.

Trust isn’t a design deliverable. It’s an operating model.

Why Pack-Smart for Packaging Design That Builds Trust

Pack-Smart Inc. has engineered packaging solutions for regulated high-trust sectors for over 25 years. We understand that brand trust is built through precision, not promises.

Our Delta-X Trust platform integrates serialization, track-and-trace, and anti-counterfeiting capabilities into production workflows that maintain uptime, compliance, and cost control. For pharmaceutical companies navigating FDA requirements, payment card issuers fighting fraud, and personal care brands protecting authenticity, we deliver systems that work at scale.

We don’t just design packaging. We engineer trust infrastructure that survives manufacturing realities and meets regulatory scrutiny.

Because in 2026, the brands that win aren’t the ones with the prettiest packaging. They’re the ones consumers can verify, remember, and trust.

Ready to build packaging that earns trust at scale? Let’s talk.