Blog

Navigating the EU Packaging and Packaging Waste Regulation (PPWR): What It Means for the Future of Packaging

Sustainability is no longer optional; the EU Packaging and Packaging Waste Regulation (PPWR) sets new standards for how businesses design, produce, and manage packaging waste. With ambitious targets to reduce environmental impact, enhance recyclability, and drive a circular economy, the PPWR is not just a regulatory shift—it’s a fundamental transformation in packaging.

Understanding these new regulations is critical for compliance, cost efficiency, and long-term sustainability for companies operating in packaging, manufacturing, and supply chain management.

This article explores:

- What the PPWR entails and why it matters

- Key challenges and opportunities for businesses

- Actionable steps to stay ahead of compliance

- The role of adhesives in sustainable packaging

- How Pack-Smart Inc. solutions align with the regulation

What Is the EU Packaging and Packaging Waste Regulation (PPWR)?

The PPWR is a set of EU-wide regulations designed to reduce packaging waste, improve recyclability, and promote sustainability across industries. Replacing the 1994 Packaging and Packaging Waste Directive, this regulation introduces stricter measures to ensure that all packaging is recyclable, reusable, or compostable by 2030.

Key Objectives of the PPWR

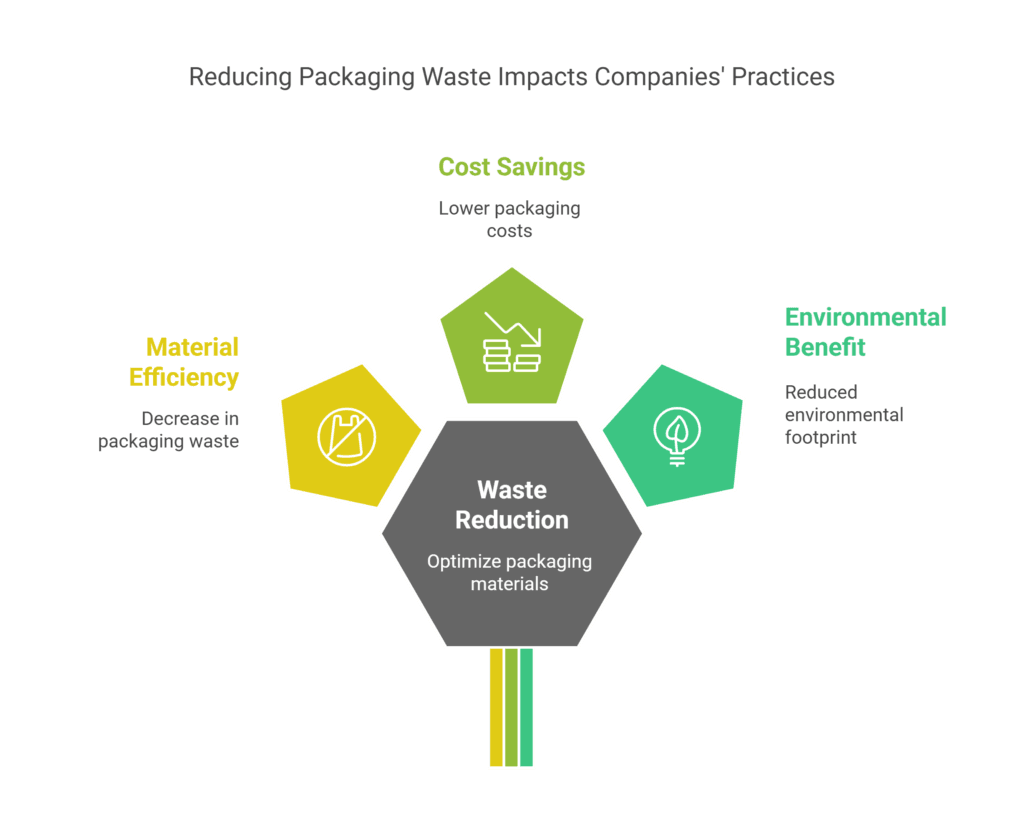

The EU Packaging and Packaging Waste Regulation (PPWR) sets clear targets to reduce waste, improve recyclability, and promote sustainable packaging practices. These objectives aim to minimize environmental impact, enhance material efficiency, and drive the transition toward a circular economy.

Reduce Packaging Waste

The regulation enforces strict waste reduction targets across all industries, requiring manufacturers to limit excessive material use, optimize packaging dimensions, and transition to more sustainable materials. Businesses must develop strategies to eliminate single-use packaging and replace it with multi-use or minimal-waste alternatives. Companies that fail to meet reduction goals may face increased regulatory pressure and financial penalties.

Increase Recyclability

By 2030, the EU mandates that 100% of all packaging must be reusable or recyclable, meaning businesses must redesign packaging to meet recyclability criteria, eliminate non-recyclable composites, and ensure compatibility with regional recycling systems. The push for mono-material packaging (where packaging consists of a single, easily recyclable material) is expected to become the industry standard. Companies will also need to collaborate with recyclers and invest in materials that align with existing recycling infrastructures.

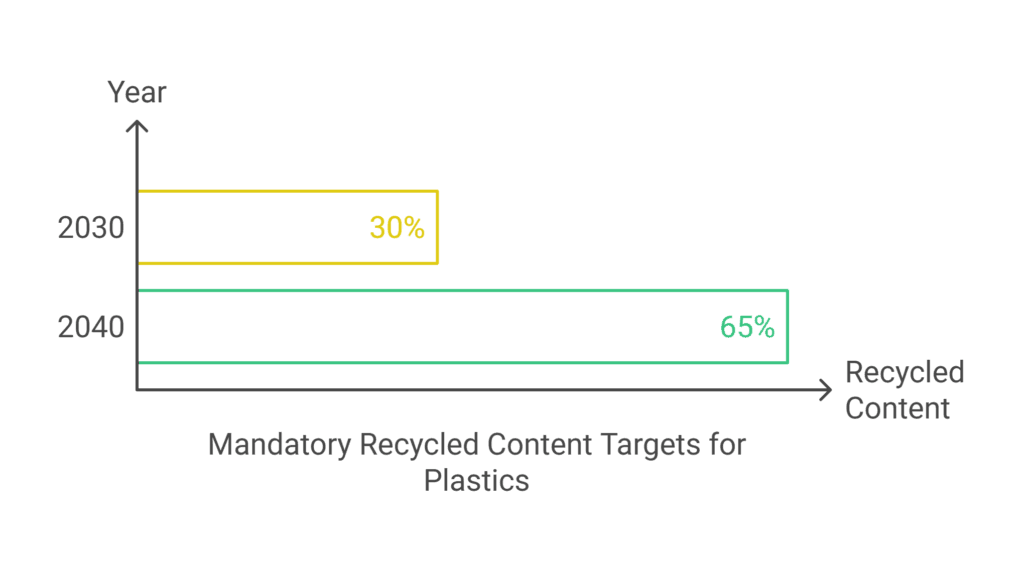

Promote a Circular Economy

The regulation prioritizes material recovery, increased recycled content usage, and the adoption of sustainable sourcing practices. Companies will be required to integrate post-consumer recycled materials (PCR) into their packaging, reducing dependence on virgin plastics and other resource-intensive materials. The move toward a circular economy model ensures that packaging materials are continuously repurposed, reducing landfill waste and minimizing environmental impact. Businesses that invest in closed-loop recycling systems and sustainable material innovations will be best positioned for compliance and long-term success.

Who Does the PPWR Impact?

The regulation applies to all businesses involved in packaging—from manufacturers and converters to brand owners and retailers. Whether you produce consumer goods, pharmaceuticals, food & beverage, or industrial packaging, compliance with PPWR is mandatory for any business operating within the EU.

Challenges and Opportunities for Businesses

The PPWR presents challenges and opportunities for businesses, requiring them to adapt to stricter sustainability regulations while embracing innovation in packaging design, materials, and automation to stay compliant, reduce waste, and enhance operational efficiency.

Adapting to Material Restrictions & Recycling Targets

- Challenge: Companies must phase out non-recyclable materials, redesigning their packaging to meet recyclability standards.

- Opportunity: Investing in innovative, sustainable packaging materials can position brands as industry leaders while reducing long-term costs.

Stricter Labeling and Traceability Requirements

- Challenge: The PPWR introduces mandatory recyclability labels and increased transparency for packaging composition.

- Opportunity: Smart labelling technologies (QR codes, RFID, and digital printing) provide real-time consumer education and enhance brand credibility.

Reducing Overpackaging Without Compromising Protection

- Challenge: Many industries, especially e-commerce, logistics, and retail, rely on excessive packaging layers to protect products, enhance branding, and meet shipping requirements—often leading to unnecessary waste.

- Opportunity: Advanced automation and digital converting technologies enable precision material usage, ensuring optimal protection with minimal waste. By leveraging intelligent cutting, adaptive sizing, and sustainable material handling, businesses can reduce packaging bulk while maintaining product integrity and compliance with PPWR standards.

The Role of Adhesives in Sustainable Packaging

While much attention is given to packaging materials, adhesives play a critical role in sustainability and recyclability. Traditional adhesives often contain solvents, petrochemical-based compounds, and non-recyclable components, making it difficult to separate bonded materials for efficient recycling. The PPWR pushes for solvent-free, biodegradable, and recyclable adhesives to minimize environmental impact.

Challenges with Traditional Adhesives

While adhesives play a crucial role in packaging, many conventional options contain solvents, petrochemical-based compounds, and non-recyclable components, making it difficult to separate bonded materials for efficient recycling. As sustainability regulations tighten, manufacturers face new challenges in adopting eco-friendly alternatives without compromising performance.

- Equipment Compatibility Issues: Many bio-based and solvent-free adhesives have a higher viscosity, requiring adjustments to application systems.

- Machinability & Processing: Adhesives that dry or cure slower can reduce production speeds and require additional process modifications.

- Recyclability Barriers: Non-removable adhesives contaminate recycling streams, making packaging harder to process.

Advancements in Sustainable Adhesives

To meet PPWR requirements and reduce environmental impact, the industry is shifting toward water-based, bio-based, and recyclable adhesives that offer strong bonding capabilities while improving recyclability, reducing emissions, and supporting circular economy initiatives.

- Water-Based Adhesives: Eliminate volatile organic compounds (VOCs) and improve safety while offering strong adhesion for flexible packaging.

- Solvent-Free & Bio-Based Adhesives: Made from natural resins, plant oils, and starches, these adhesives enhance sustainability without compromising bonding strength.

- Recyclable & Removable Adhesives: Designed for easy separation, allowing better material recovery and increased circularity in packaging.

- Cold & Hot Wheel Adhesives: Provide precision application, minimizing excess use while ensuring strong, secure packaging bonds.

How Pack-Smart Inc. Supports Compliance with PPWR

At Pack-Smart Inc., we don’t just engineer high-efficiency packaging solutions—we pave the way for a more sustainable future. Our automation and adhesive application technologies enable businesses to transition to eco-friendly adhesives without disrupting efficiency or performance.

Smart Packaging for Material & Adhesive Optimization

Our solutions reduce material waste by ensuring precise adhesive application, whether using cold glue, hot-melt, or bio-based adhesives. Advanced dispensing, drying, and vision inspection systems ensure consistency and accuracy.

Serialization & Track-and-Trace Capabilities

With PPWR’s labeling requirements, manufacturers must ensure recyclability transparency. Our track-and-trace solutions provide real-time data tracking, compliance reporting, and automated labeling to meet EU regulations.

Automation for Sustainable Packaging

Manual packaging processes often increase waste and reduce efficiency. Our automated packaging systems support various adhesive applications while also integrating precision material handling, waste reduction strategies, and recyclable packaging innovations to ensure compliance with PPWR standards.

By eliminating manual overuse, improving efficiency, and enabling recyclable bonds, Pack-Smart provides a complete, future-ready approach to sustainable packaging. Our technology optimizes adhesive application, minimizes material waste, and enhances production efficiency—allowing businesses to seamlessly transition to eco-friendly, regulation-compliant packaging solutions without sacrificing speed or quality.

How to Prepare for the PPWR

As the EU Packaging and Packaging Waste Regulation (PPWR) introduces stricter sustainability requirements, businesses must take a proactive approach to ensure compliance while maintaining efficiency. Implementing strategic improvements in materials, labeling, automation, and compliance tracking will help companies navigate these changes effectively.

Conduct a Packaging Audit

A thorough packaging audit is the first step toward identifying inefficiencies, reducing waste, and ensuring compliance with PPWR mandates. Businesses should evaluate their current materials, recyclability rates, and waste levels to pinpoint areas for improvement. Key considerations include:

- Material Selection: Are you using mono-material packaging that supports recyclability?

- Design Efficiency: Is there excessive void space or overuse of secondary packaging?

- Automation Integration: Can automation improve material usage and reduce unnecessary packaging?

By analyzing these factors, businesses can implement data-driven strategies to optimize sustainability while meeting regulatory requirements.

Implement Smart Labeling & Digital Solutions

Under PPWR, clear labeling and traceability are crucial for ensuring recyclability and compliance. Smart labeling technologies enable real-time tracking, authentication, and improved waste sorting, helping both consumers and recycling facilities process materials efficiently.

To meet labeling requirements, businesses should:

- Utilize QR codes and variable data printing for dynamic product traceability.

- Apply recycling labels and compliance markers to align with PPWR standards.

- Implement RFID and serialized tracking for enhanced visibility in sorting and waste management.

These solutions not only simplify compliance but also enhance customer engagement and supply chain transparency.

Invest in High-Efficiency Automation

Automation plays a critical role in reducing waste, improving production efficiency, and optimizing material usage. By integrating advanced digital converting, precision-cutting, folding, and affixing technologies, businesses can:

- Minimize overuse of adhesives and packaging materials.

- Enhance consistency in material application to eliminate unnecessary waste.

- Improve production scalability while maintaining compliance with PPWR sustainability goals.

By leveraging smart automation, companies can align with sustainability targets while maintaining speed and cost efficiency in packaging operations.

Stay Ahead of Regulations with Compliance Monitoring

With PPWR regulations evolving, businesses must stay informed to maintain compliance and avoid costly penalties. Partnering with supply chain experts, packaging engineers, and regulatory advisors ensures companies can:

- Monitor regulatory updates and adapt to new compliance requirements.

- Leverage data-driven reporting to track material sustainability and recyclability metrics.

- Implement continuous improvement strategies to stay ahead of industry changes.

By maintaining ongoing compliance monitoring, businesses can proactively adjust their packaging strategies, ensuring long-term sustainability and regulatory adherence.

Final Thoughts: The Future of Sustainable Packaging

The EU Packaging and Packaging Waste Regulation (PPWR) is more than a compliance requirement—it’s an opportunity for businesses to lead in sustainable innovation. Companies can reduce waste, improve efficiency, and enhance their brand’s environmental impact by adopting automation, precision material usage, and track-and-trace solutions.

At Pack-Smart Inc., we’re helping businesses seamlessly transition to sustainable, regulation-compliant packaging without sacrificing speed, security, or quality. If you’re ready to adapt to the EU Packaging and Packaging Waste Regulation (PPWR) and enhance your sustainability efforts, we’re here to help.