Rotary Pick and Place Series

Consistently feed, insert, attach, and batch delicate materials and oddly shaped products at 30,000 PPH, with vacuum pick & place motion and ±0.02″ placement accuracy.

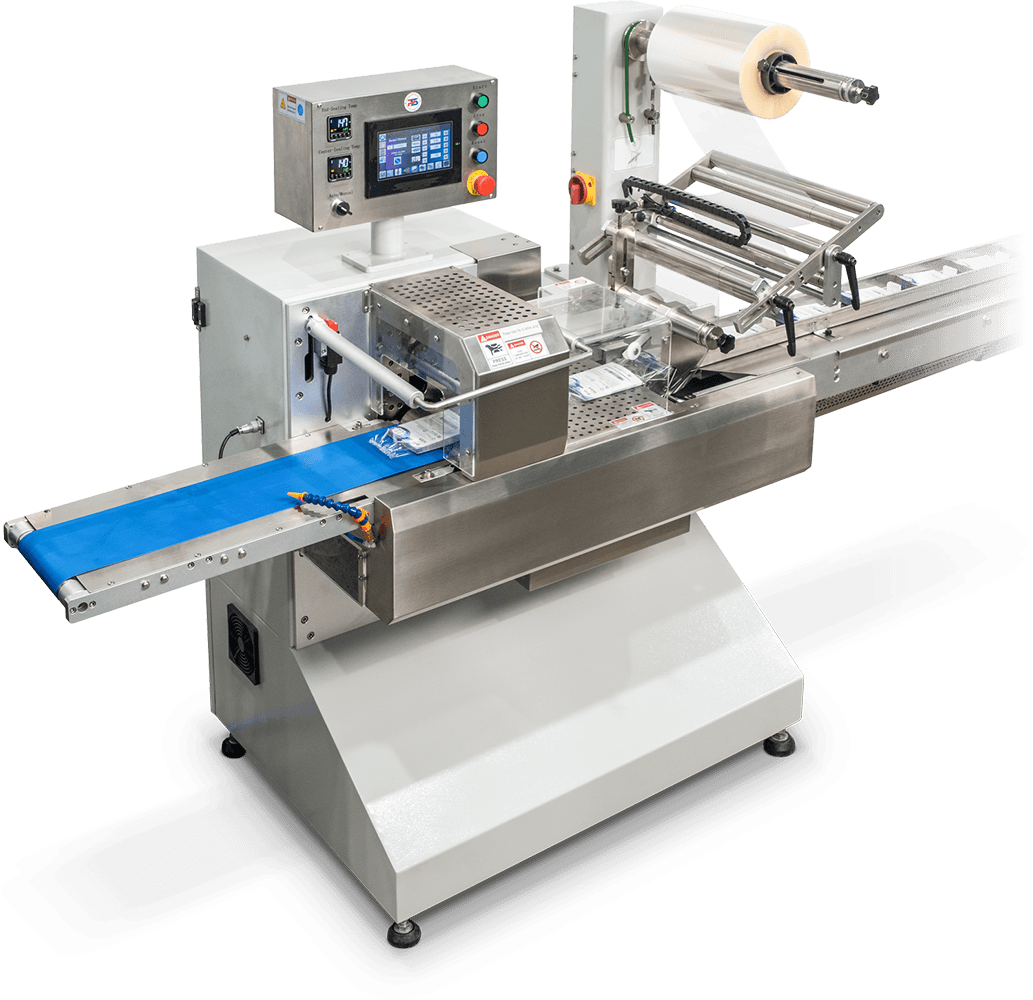

Maximize efficiency with the BA-250, a fully automated pack-out fulfillment system designed for wrapping, inline batching, bundling, and labeling, enhancing throughput up to 2,000 bundles per hour.

The BA-250 Pack-Out Fulfillment System is Pack-Smart’s state-of-the-art solution for inline batching, wrapping, and aggregate labeling, delivering up to 2,000 finished bundles per hour with precision and reliability.

This advanced system seamlessly integrates key functions, including batching, wrapping, scanning, weighing, and quality assurance. Each bundle, case, and pallet is labeled with pinpoint accuracy, streamlining workflow efficiency and ensuring end-to-end traceability for high-demand production environments.

The BA-250 exemplifies streamlined operational excellence, featuring a process flow that optimizes speed and precision. From material handling to the final inspection, each stage of the process is meticulously engineered to enhance productivity and ensure the highest quality output.

The BA-250 integrates a suite of cutting-edge technologies that elevate its operational capabilities. It incorporates advanced sensors for real-time monitoring, precision actuators for accurate material handling, and sophisticated software for seamless automation.

These technologies work in harmony to ensure the BA-250 delivers exceptional performance, making it a robust solution for industries seeking to leverage technological advancements for improved efficiency and quality.

Consistently feed, insert, attach, and batch delicate materials and oddly shaped products at 30,000 PPH, with vacuum pick & place motion and ±0.02″ placement accuracy.

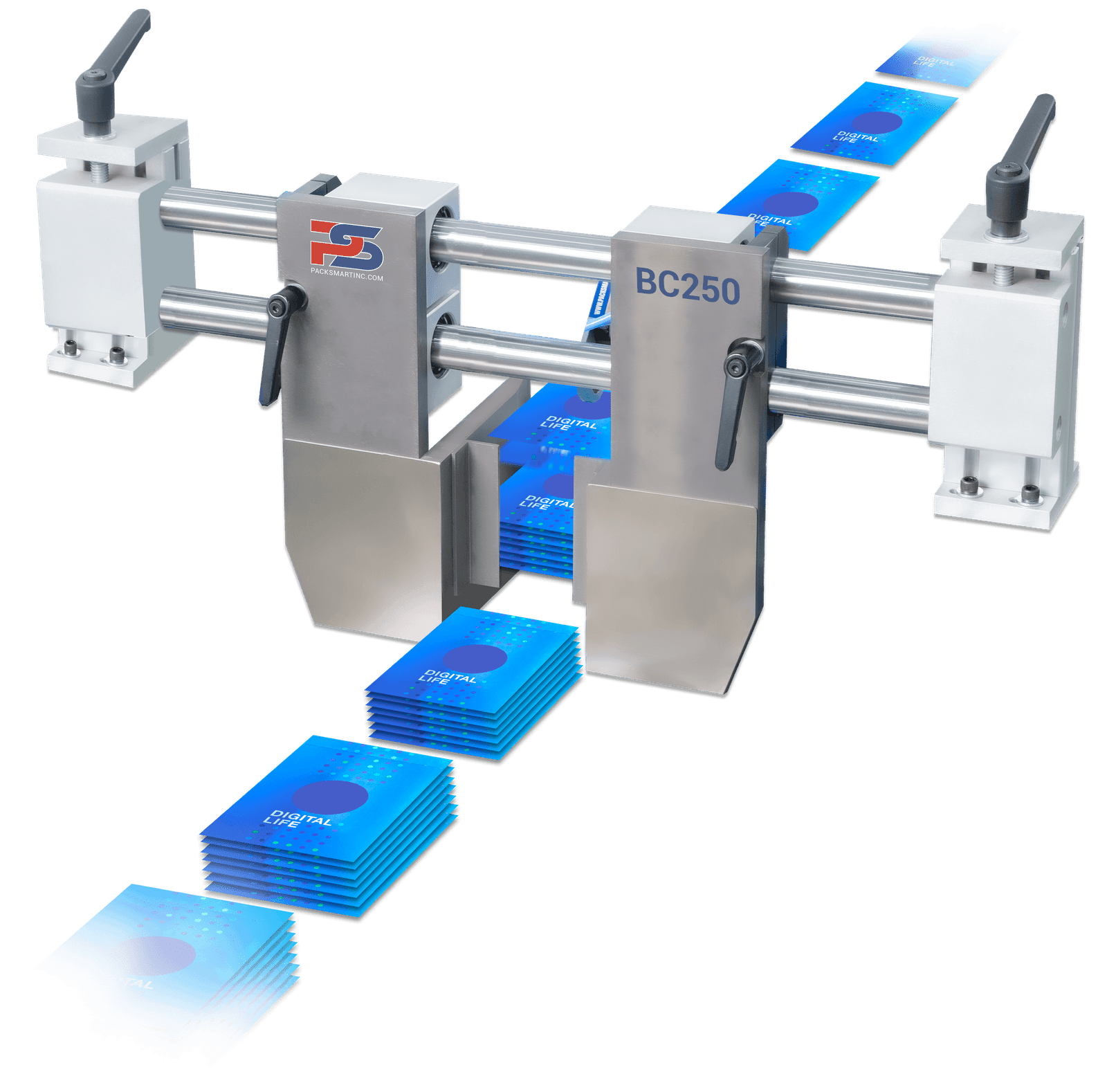

Efficiently batch single products into precise groups with Pack-Smart’s BC Series, designed for a wide range of materials and applications.

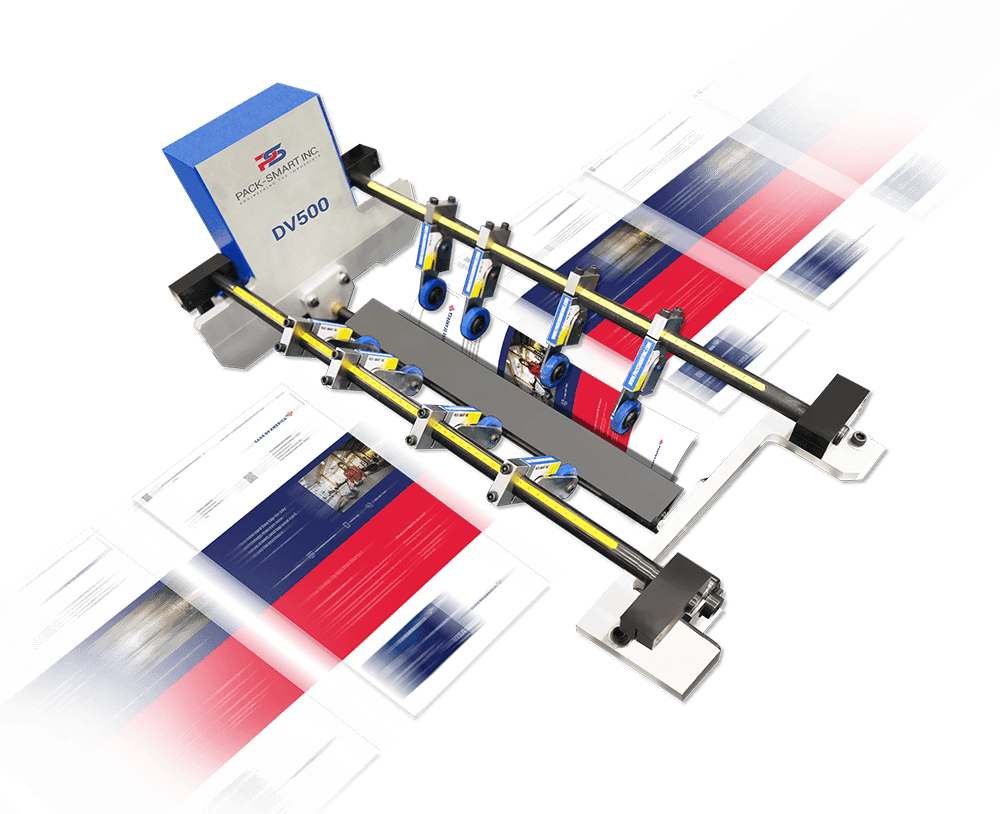

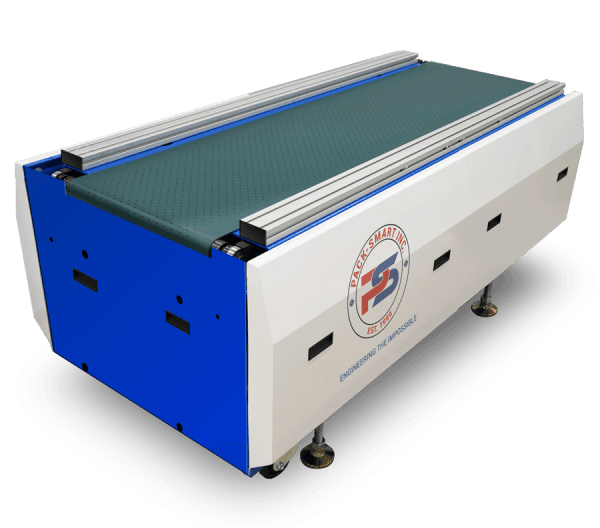

Elevate efficiency with the DZ Series Zoned Divert, designed for precise sorting and high-capacity handling in demanding industrial environments.

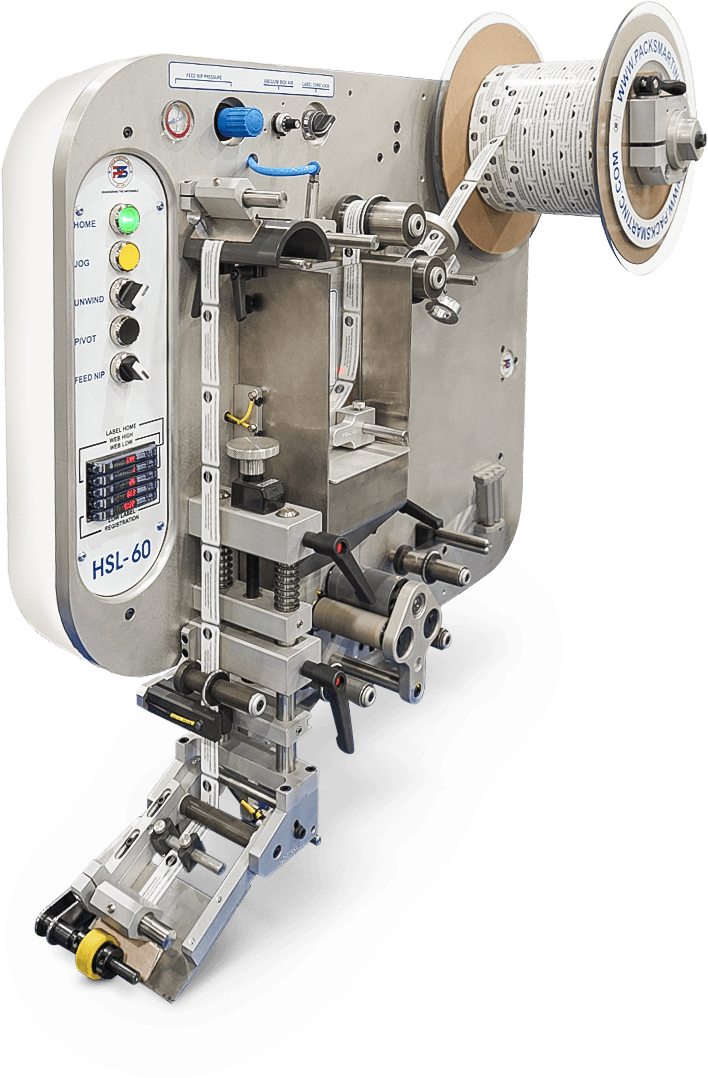

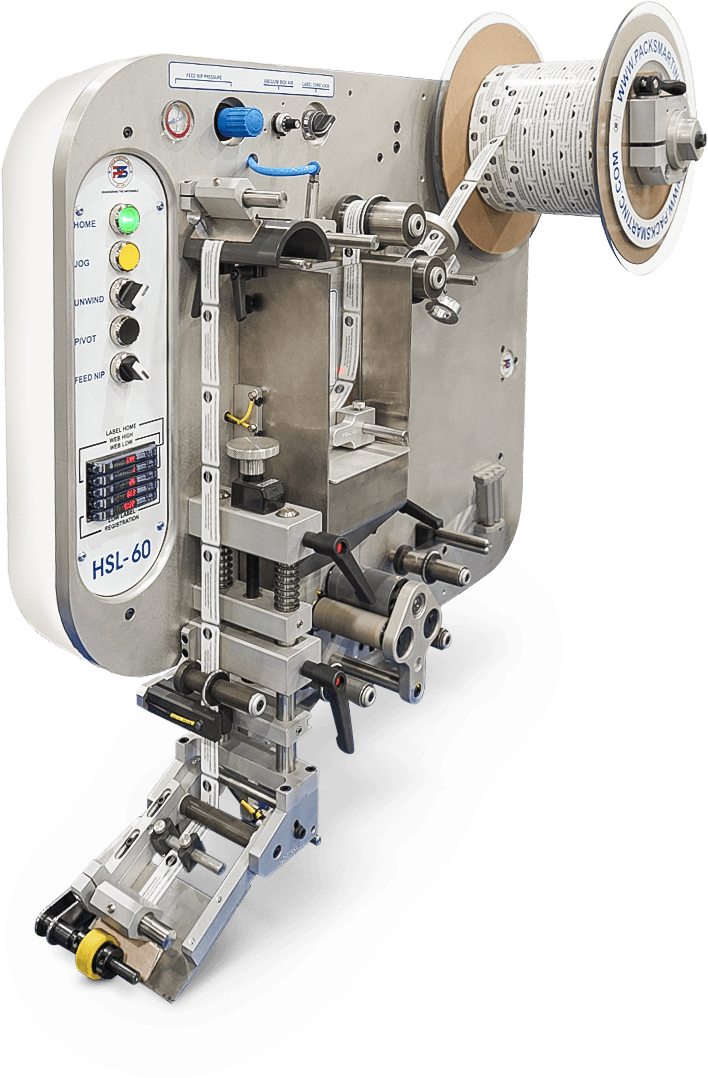

The HSL-60 is a highly versatile module that applies pressure sensitive labels at high speeds and accuracy for the most demanding precision-critical applications.

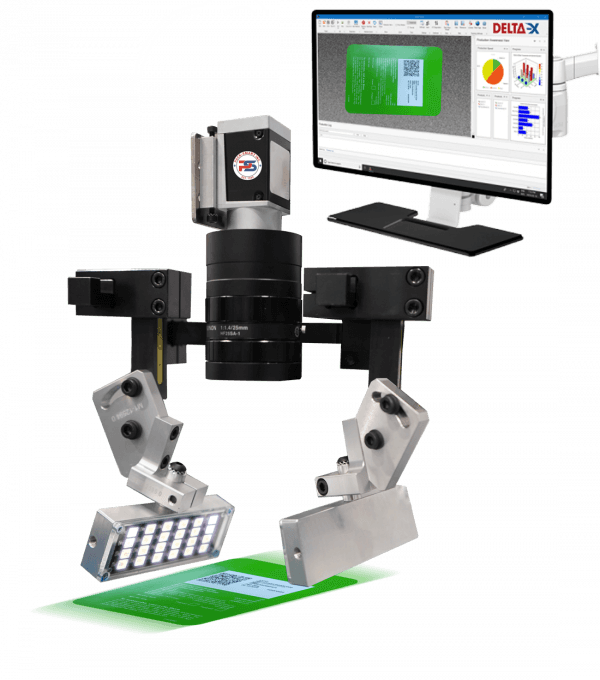

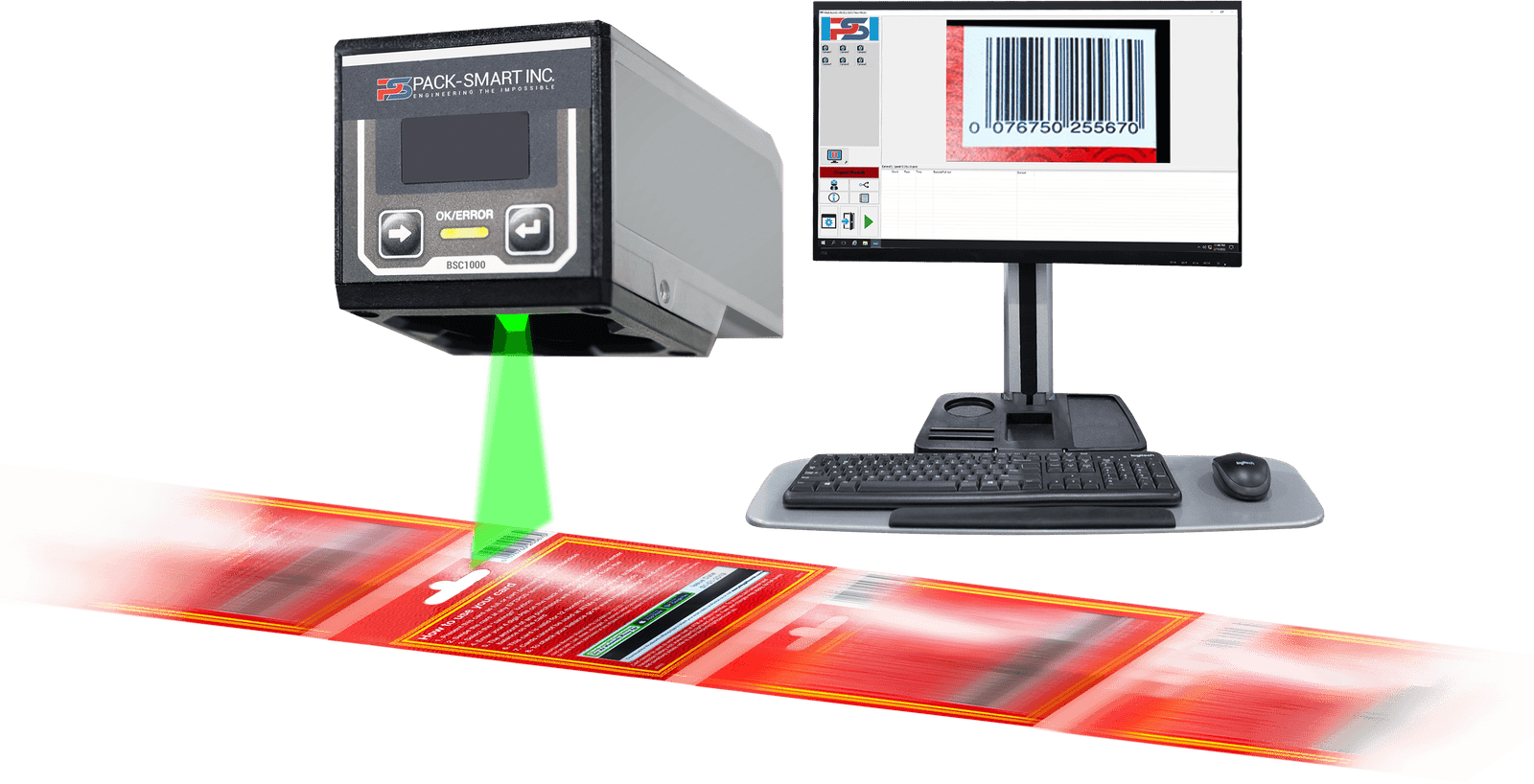

The VSC-1000 Vision System offers state-of-the-art vision scanning and real-time image processing, ideal for high-speed production environments.

Revolutionize your production line with the 3DF-1, designed to sort, orient, and affix loose 3D products with unparalleled speed and precision.

3DF-1 uses a high speed vibratory bowl to handle delicate format 3D products. Once the parts are sorted and correctly oriented, they are transfered to a redundant set of buffers.

These buffered parts are then transfered to lugged horizontal track which allows smooth control of the products at the same time meeting the feeding request of the line. A precise rotary motion pick and place system will deliver them from the lugs to the packaging line.

Fast Moving Consumer Goods

Pharmaceutical Products

The 3DF-1 operates within a highly structured process flow designed to maximize both precision and efficiency in 3-dimensional product feeding. Starting with the automated feeding of items into the system, each component is carefully aligned and transported through various stages of handling and assembly.

Utilizes a high-speed vibratory bowl combined with a vacuum-assisted rotary head for precise product handling and placement. This system ensures gentle handling of 3D products, reducing waste and increasing efficiency. The integrated fiber-optic sensing guarantees exact product positioning, enhancing the overall precision of the production process.

Consistently feed, insert, attach, and batch delicate materials and oddly shaped products at 30,000 PPH, with vacuum pick & place motion and ±0.02″ placement accuracy.

Maximize your production efficiency with the RPP Series, designed for high-speed, accurate handling of delicate materials and uniquely shaped products.

High torque servo driven vacuum transport conveys products at accurate speeds and controls product placement with 8 selectable vacuum zones.

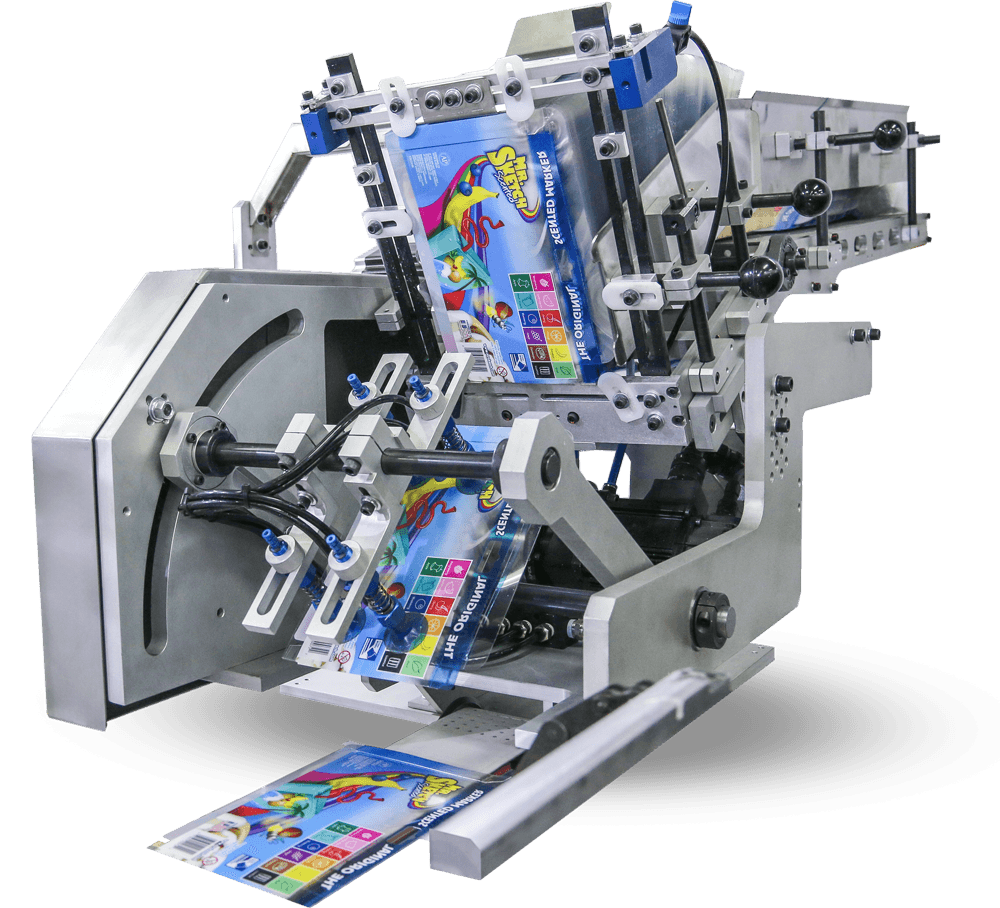

Combine folding, gluing, affixing, personalization, and sorting in a single pass.

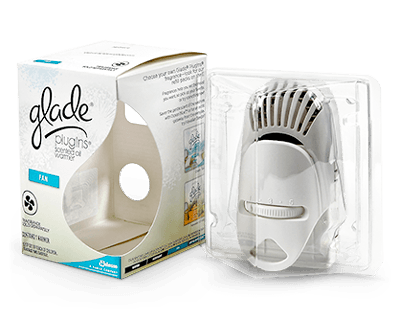

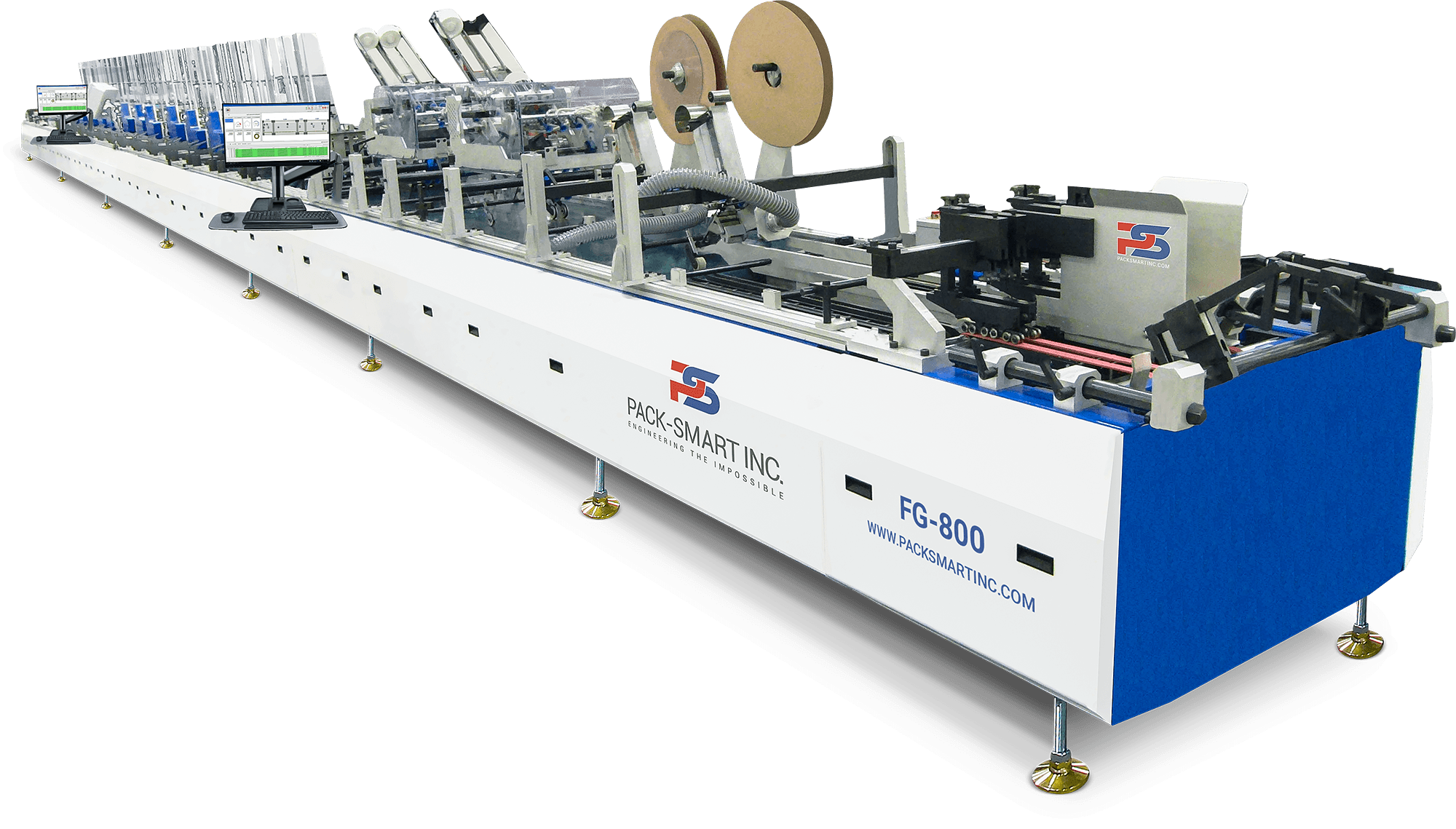

The FG-800 is designed to give the tools and flexibility needed to explore new manufacturing opportunities in the folding carton and specialty finishing world. The alignment of cartons is handled by a state-of-the-art registration module, which employs innovative servo technology making setups swift and effortless.

High Value Carton

Auto-Erect Cartons

The process flow for the FG-800 Rigid Window Affixing System is designed to ensure precise, secure, and efficient production of folding cartons. This system integrates each step, from initial material feeding and registration to final gluing and finishing, ensuring high-speed, accurate application with robust security measures.

The FG-800 Rigid Window Affixing System incorporates advanced technologies to enhance its performance and reliability. Key technologies include high-speed friction feeders, precision affixing mechanisms, advanced folding modules, and real-time data management systems. These technologies work together to ensure consistent, high-quality production of folding cartons.

Consistently feed, insert, attach, and batch delicate materials and oddly shaped products at 30,000 PPH, with vacuum pick & place motion and ±0.02″ placement accuracy.

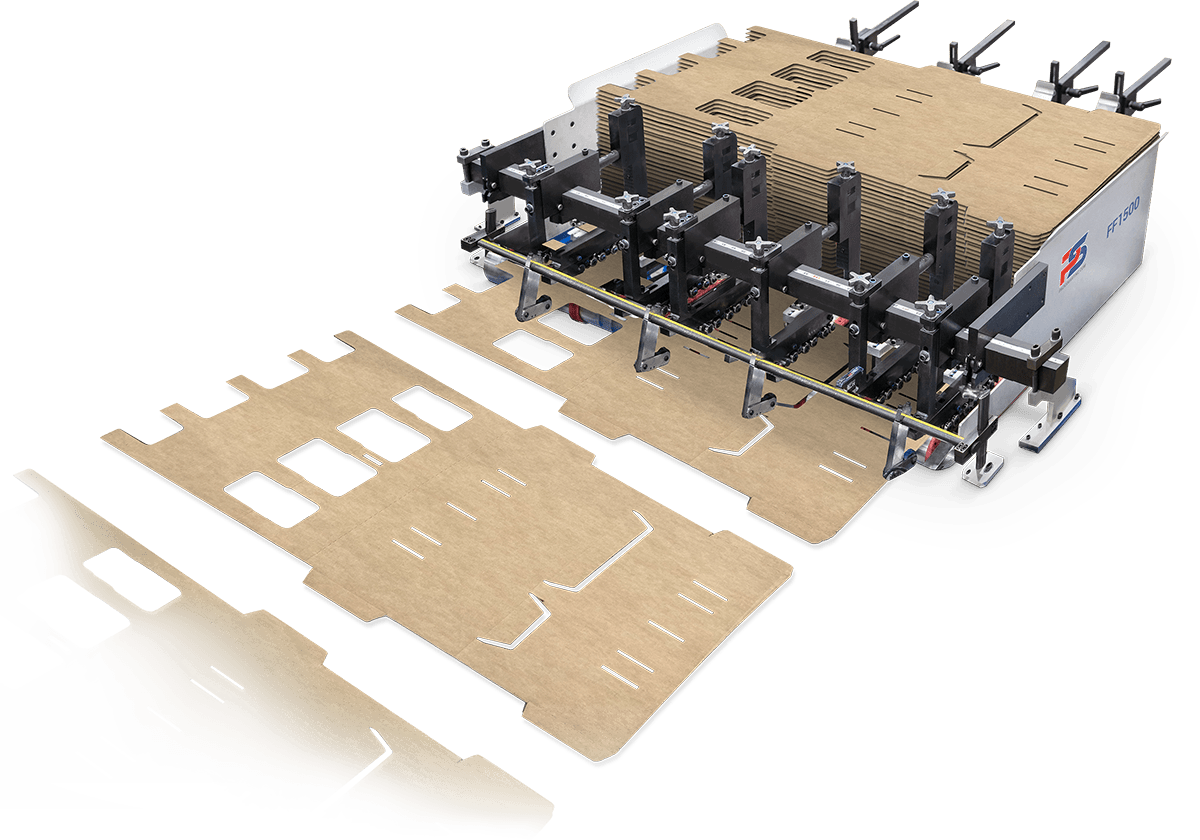

The FF Series Friction Feeder can handle the lightest paper and is equally at home when dealing with heavy stock materials when called upon.

A user-friendly, fully packaged CCD reader, offering easy integration and several configurations to meet a variety of needs.

The HSL-60 is a highly versatile module that applies pressure sensitive labels at high speeds and accuracy for the most demanding precision-critical applications.

Reaching up to 600 products per minute, the SF Series is a perfect choice for handling light paper to heavy stock material.