Blog

Elevating Trust in High-Security Manufacturing: The Case for a Secure Document Inspection System

When you’re producing passports, national ID cards, or high-value financial instruments, “close enough” simply isn’t. Even a hairline scratch, a tiny delamination bubble, or a misaligned NFC chip can undermine both public safety and your bottom line. That tension between speed and perfection, between audit-readiness and human fallibility, is precisely why Pack-Smart Inc. engineered the HyperVision 3500, a purpose-built Secure Document Inspection System.

By integrating sub-micron optics, AI-driven defect analysis, embedded NFC validation, and end-to-end data capture into a single modular platform, the HyperVision 3500 not only automates inspection but also redefines what ‘100% yield’ and ‘audit-ready compliance’ mean in practice, instilling confidence in the thoroughness of the process.

In this comprehensive article, you’ll learn:

- What drove the creation of a next-gen secure document inspection system

- Which pain points does it resolve now, and how does it future-proof your line

- A deep architectural tour of HyperVision 3500, told as a continuous workflow

- Quantifiable advantages that translate directly into ROI

- A real-world case study invitation to see it in action

- Who benefits most, and why

Let’s dive in.

From Vision to Reality: Why HyperVision 3500 Was Engineered

Secure-document producers operate at the intersection of national security, finance, and personal identity. The pressure is immense, and failure is not an option. When regulators tightened standards, mandating multi-layer security features, embedded NFC or RFID elements, and 100% electronic traceability, legacy inspection methods reached their limit. Human inspectors cannot consistently detect sub-10-micron defects, nor can they generate audit-ready digital logs on demand. This is the high-stakes environment that the HyperVision 3500 was designed to relieve.

Pack-Smart’s development team distilled that challenge into three mandates:

- Sub-Micron Precision: Automated detection at 10 μm resolution, ten times finer than human vision.

- Instant Traceability: A timestamped, immutable digital ledger for every unit via Delta-X Tracker.

- Modular Scalability: Plug-and-play hardware and software modules that adapt in minutes to new substrates, security features, or throughput changes.

By combining Delta-X Vision Intelligence (AI-powered defect analysis) with Delta-X Tracker (end-to-end data orchestration), HyperVision 3500 solves both the accuracy and compliance gaps, and does so on a production scale.

Today’s Pain Points and Tomorrow’s Imperatives

Inconsistent Detection and Costly Rework

Imagine a batch of 10,000 passport covers moving through a high-speed line. Even a 1% miss rate means 100 defective units — potential passport rejections, border delays, or worse. Manual checks miss micro-scratches, air bubbles in laminates, and tiny NFC misalignments. Each escape comes at a cost, in terms of money, time, and reputation.

Bottlenecks and Fragmented Data

When a defect is spotted, the line stops. Operators pull samples, log results on paper or spreadsheets, and send batches back for rework. Meanwhile, audit teams scramble to piece together production histories from scattered records, slowing compliance by days or weeks.

Emerging Materials and Features

Upcoming substrates include metal foils, holographic laminates, biometric overlays, demand-adaptable optics, and AI models. Running multiple validation steps (print quality, lamination bond, NFC functionality) in series on a legacy line can add minutes per unit, which is untenable at scale.

HyperVision 3500 tackles these:

- Precision at Every Step: Cameras and 3D scanners detect defects imperceptible to manual inspection.

- Continuous, Real-Time Data: Every scan, pass/fail decision, and chip validation feeds Delta-X Tracker for instant audit reporting.

- AI-Driven Predictive Maintenance: On-board analytics monitor camera health, lighting calibration, and mechanical alignment, triggering alerts before a drift turns into downtime.

- Modularity for the Future: Swap in new cameras, lighting arrays, or NFC modules as standards evolve — no forklift upgrade required.

A Workflow Narrative: Walking Through HyperVision 3500

Rather than bullet lists, let’s imagine you’re standing next to the line. Here’s what happens to a single cover:

Step 1: Infeed & Material Handling

A stack feeder holds thousands of passport covers and protective separator sheets. At a programmed interval, a robotic pick-and-place arm lifts the top cover, peels away its protective sheet, and places it onto a vacuum-stabilized conveyor.

The sheet loops back for collection, minimizing material waste and ensuring each cover enters the inspection station perfectly aligned and ready for optics.

Step 2: Inner-Side Inspection

As the cover glides forward, vision cameras capture 8K high-resolution images of its inner surface. These 2D images highlight surface imperfections, scratches, pits, and air bubbles down to 10 μm in size. Simultaneously, a 3D delamination scanner measures bond integrity, flagging any adhesion failures before they become structural issues.

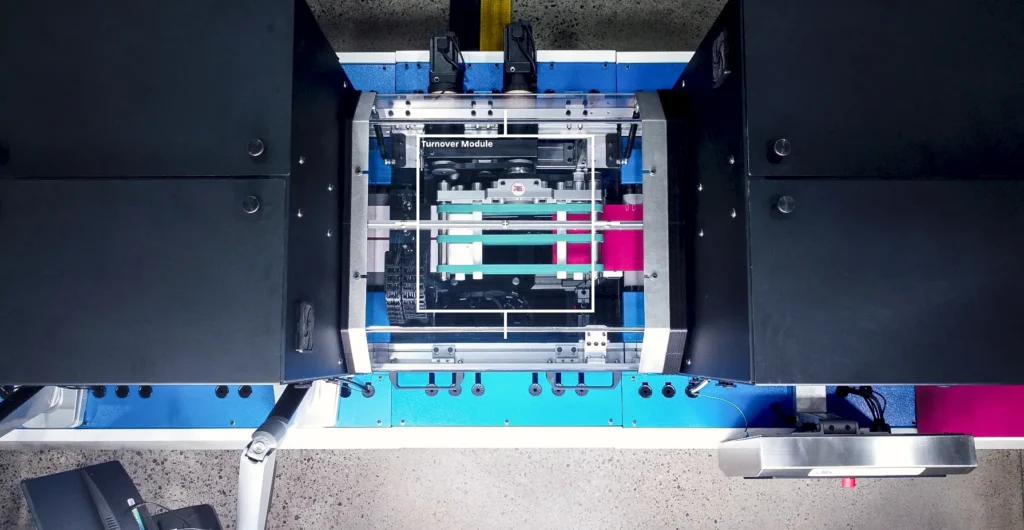

Step 3: Seamless Turnover

Without skipping a beat, a turnover module grips the cover edges and flips it, exposing the outer side. All motion is synchronized: cameras, lighting, and conveyor speed adjust to maintain imaging consistency.

Step 4: Outer-Side Inspection & NFC Validation

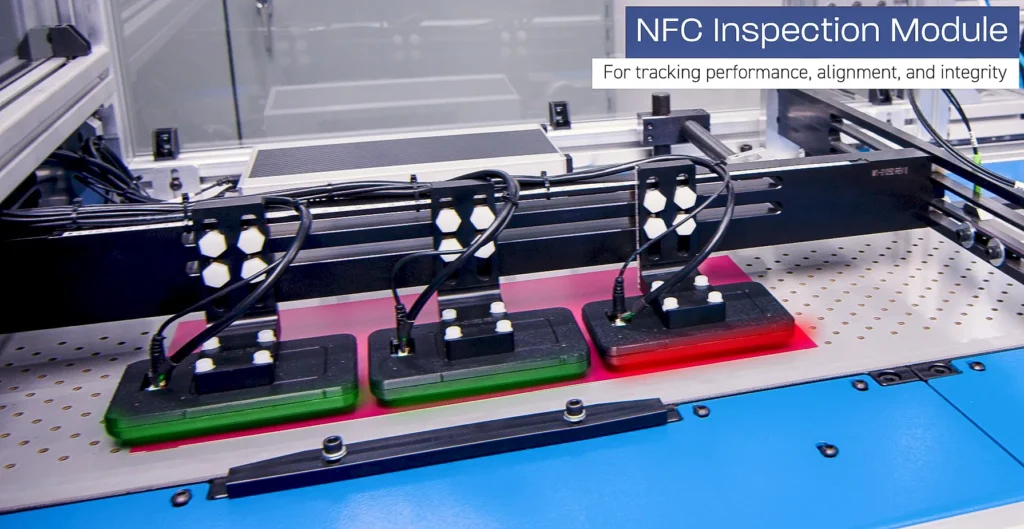

Now, the cameras capture the printed surface, checking for color uniformity, print clarity, and embossed security features. Immediately after, the NFC Validation Module slides an RF antenna close to the embedded chip, executing read/write cycles in milliseconds to confirm antenna alignment and chip functionality.

Step 5: Data Capture and Sorting

Based on combined optical and NFC results, an on-board PLC triggers robotic diverters. Good covers roll down the release conveyor; defective ones are routed to a rework bin. Meanwhile, Delta-X Tracker logs every inspection image, pass/fail flag, and chip test result — creating a complete, timestamped digital record.

Step 6: Marking, Labeling, and Handoff

Finally, each passing cover receives a printed registration mark or applied barcode linking it to its inspection record. A jogger aligns output stacks, ready for binding or packaging, ensuring the next stage sees only verified, compliant covers.

Watch the full technical walkthrough of the HyperVision 3500

Operational Advantages That Drive ROI

In real terms, HyperVision 3500 delivers:

- 85% Defect Reduction: Automated, AI-driven inspection slashes escape within weeks of installation.

- 50% Throughput Boost: Continuous feed, synchronized robotics, and real-time sorting keep lines moving at peak speed — no operator slowdown.

- Minutes-Long Audit Reports: Delta-X Tracker aggregates complete production histories in under five minutes, versus days with legacy logs.

- Predictive Uptime: Analytics monitor component health, cameras, lighting, conveyors – alerting teams before drift or wear causes downtime.

- Adaptable Growth: Modular add-ons (new cameras, lighting, NFC tests) install in hours, not weeks — protecting your capital investment as demands evolve.

These aren’t theoretical gains; they directly reduce scrap costs, minimize labor, and accelerate compliance sign-off, feeding directly into your P&L.

Proof Over Promise: A Real-World Case Study

A leading national passport printer approached us after struggling with unpredictable defect rates and lengthy audit cycles. Their legacy inspection process relied on manual checks, which repeatedly caused production stoppages and consumed a considerable amount of operator hours. Compliance teams spent days — or even weeks — piecing together inspection records from spreadsheets and paper logs, delaying critical shipments and audits.

After integrating the HyperVision 3500 into their line, they achieved:

- Seamless, continuous inspection without line stoppages

- Automated, timestamped data capture at every inspection stage

- Instant visibility into defect trends, enabling proactive quality interventions

Rather than piecing together scattered logs, their quality managers now pull complete audit reports in seconds. Production planners regain hours previously lost to manual scrutiny, and operators shift from repetitive checks to exception-handling and higher-value tasks.

Download the complete case study for an in-depth look at their implementation journey, operational learnings, and the qualitative benefits they’ve realized.

Implementing HyperVision 3500: Best Practices for Success

Adopting a Secure Document Multi-Layer Inspection System of this caliber requires more than hardware installation, it demands a collaborative roadmap:

- Cross-Functional Alignment. Begin by uniting quality, operations, and IT teams. Establish clear success metrics, defect reduction targets, throughput goals, and audit timeframes so every stakeholder shares the same north star.

- Pilot & Calibration. Roll out HyperVision 3500 on a pilot line. Use Delta-X Vision Intelligence’s learning mode to fine-tune AI models against your specific substrates and print processes. Fine adjustments to lighting and conveyor speed ensure the system captures every defect profile unique to your environment.

- Data-Driven Optimization. Within days, you’ll gather thousands of inspection data points. Review defect patterns in Delta-X Tracker dashboards to identify root causes and determine whether they originate from lamination issues, print variances, or chip misalignments. Address these upstream to drive continuous improvement.

- Scale & Expand. Once goals are met, typically an 80%+ defect reduction, replicate the configuration across other lines, swapping in additional modules as needed for new document formats or security features.

By following this phased approach, organizations achieve rapid ROI while embedding a culture of precision and accountability throughout their secure printing operations.

Who Stands to Gain — and Why They’ll Care

Not all manufacturers or industries face the same stakes, but any operation where document integrity underpins revenue, reputation, or public safety will find HyperVision 3500 indispensable.

Government Printers tasked with issuing passports, visas, and national IDs must meet rigorous security standards and adhere to rapid issuance cycles—zero-defect guarantees that foster greater citizen trust and streamline border control processes.

Financial Card Producers in debit, credit, and gift card markets fight an uphill battle against counterfeiters. Integrated NFC and print-security checks ensure that each card leaving the line carries authenticated credentials, safeguarding the brand’s reputation and customer trust.

High-security printers used by military, law enforcement, or diplomatic personnel operate under zero-tolerance mandates. Automated, AI-driven inspections and immutable audit trails ensure compliance with global standards, including ICAO, ISO 14298, and EMV.

OEMs & System Integrators serving these industries can leverage HyperVision 3500 as a turnkey solution, avoiding the complexity of piecing together disparate vision, robotics, and data systems.

Ultimately, any executive responsible for quality, compliance, or throughput in secure-document manufacturing will see immediate value in HyperVision 3500’s unified approach to Document Verification and Document Security.

Conclusion: The Future of Secure Document Manufacturing

The age of manual guesswork and fragmented audits is over. Counterfeiters are growing increasingly sophisticated by the day, and regulatory landscapes continue to tighten. To stay ahead, secure-document producers must invest in systems that combine precision, automation, and data intelligence. HyperVision 3500, Pack-Smart’s Secure Document Inspection System, delivers on this promise, detecting 10 μm defects, validating NFC chips in real time, and logging every inspection event in a digital ledger.

By adopting a system engineered for zero-defect yields, rapid throughput, and full audit-readiness, manufacturers not only safeguard their margins and brand integrity but also position themselves as leaders in an increasingly security-driven world. Whether you produce passports, national IDs, credit cards, or any high-value secure documents, HyperVision 3500 offers a clear path to operational excellence and regulatory peace of mind.

Ready to see it for yourself? Chat with a inspection specialist today and discover how HyperVision 3500 can transform your secure document line, because in high-security manufacturing, trust is non-negotiable.