Blog

Data Integrity in Motion: How Pack-Smart Inc. and Delta-X Trust Simplify Complexity in Clinical Trial Serialization

Clinical trials depend on precision, where every serialized code, label, and record represents patient safety, data reliability, and scientific truth. When serialization fails, compliance and confidence collapse.

Precision Defines Every Outcome

Today’s global trials generate thousands of unique product identifiers across hundreds of sites. Coordinating those identities with consistent oversight has become one of the greatest challenges in the life-sciences supply chain.

Contract Research Organizations (CROs) must maintain end-to-end visibility across study centers, while Contract Manufacturing Organizations (CMOs) must ensure that every serialized product matches its verified digital identity. When these stakeholders operate on disconnected systems, data breaks, and so does compliance.

This is where Pack-Smart Inc. and Delta-X Trust™ unite physical and digital precision.

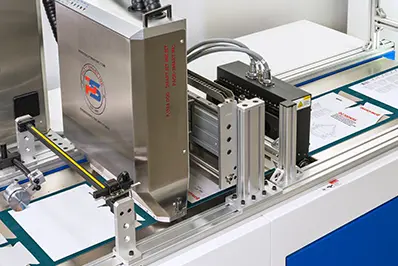

With Pack-Smart Inc. Clinical Variable Data Printing (CVDP) technology and the Delta-X Trust Integrity Suite, every code, label, and record is verified, traceable, and auditable in real time. CVDP ensures precise on-line printing and vision inspection, while Delta-X Trust extends that integrity through enterprise-level serialization, code management, and digital oversight.

Together, they deliver total alignment, connecting the production floor to the sponsor’s compliance platform through continuous, validated data flow.

The Real Risk: Data Fragmentation

Most compliance issues don’t start on the line, they emerge between systems.

Each transition in a clinical supply chain introduces new data points: batch codes, shipment logs, expiry dates, and site identifiers. When even one record fails to synchronize, small discrepancies can ripple through entire studies.

Regulators define what “good data” means through the ALCOA+ principles: data must be attributable, legible, contemporaneous, original, and accurate. These standards guide every compliant data-integrity system across the life-sciences sector.

Yet, without integrated serialization and traceability, these principles can break down. Duplicate records, mislabeled kits, and missing identifiers can invalidate batches, create costly reworks, or trigger failed audits.

The solution lies in closed-loop clinical trial serialization — linking code creation, printing, inspection, and verification into one continuous, validated process.

Delta-X Trust and Pack-Smart Inc. make this possible by uniting the physical act of labeling with the digital record of every serialization event.

Precision Starts on the Line

Data integrity begins where the product is born.

Pack-Smart Inc. systems integrate with Delta-X Trust Tracker™ — a machine-native serialization solution that oversees every print, inspection, and rejection event directly at line level. Built for high-speed serialization, CVDP handles thousands of unique identifiers per hour, applying, verifying, and logging each label, insert, or carton with sub-millimeter accuracy.

Late-stage personalization is now a defining advantage for clinical and pharmaceutical manufacturing. With Pack-Smart’s CVDP systems, serialization, coding, and labeling can occur at the final packaging stage, enabling real-time adjustments for study design changes, regional regulations, or language localization without reprinting entire batches. This flexibility, powered by variable data printing (VDP) and DXT Tracker™, ensures every product remains compliant, current, and uniquely traceable even as protocols evolve.

Every serialized unit becomes a verified digital twin of its physical product. Vision inspection ensures accuracy, while the Tracker module confirms the data’s integrity before it ever leaves the floor.

As highlighted by Thermo Fisher Scientific / Patheon, packaging and labeling now function as strategic levers in clinical development – not just as compliance steps, but as data-driven assets that reduce risk and enhance agility. For CMOs, this precision means fewer manual checks and higher throughput. For CROs, it means unbroken visibility across every study material.

Real-Time Tracking Through Delta-X Trust

Once serialized data leaves the production floor, DXT Tracker™ maintains that integrity across every handoff.

Each identifier is tied to its origin record, including batch, operator, and destination. Tracker synchronizes this data in real time, ensuring that what was printed, shipped, and administered always aligns.

This transforms clinical trial serialization from a post-production compliance task into a proactive intelligence layer. Manufacturers gain line-to-market traceability, CROs receive live shipment data, and sponsors see verified product movement across their networks.

The result is operational transparency, faster recalls when needed, and a complete digital audit trail ready for inspection at any moment.

Closing the Loop: From Bedside to Oversight

Every action in a clinical trial generates data, and the true advantage lies in how quickly that data returns to the source.

With DXT Tracker™ and DXT Insight™, every serialized unit begins verified and remains that way throughout its lifecycle. Once a vial, kit, or package reaches the clinical site, every scan or interaction feeds back into a centralized analytics layer.

When a nurse scans a vial before administration, the system instantly validates product identity, expiry, and assignment, then logs the event automatically. If storage conditions, temperature, or handling deviate from protocol, alerts are triggered instantly. Replacement shipments can be initiated without delay, protecting both compliance and patient safety.

- For CMOs, this creates a new quality paradigm with live visibility into how products perform in the field.

- For CROs, it delivers continuous oversight rather than post-hoc analysis.

- For sponsors, it offers verifiable confidence in every product’s journey from production to patient.

This is clinical trial traceability in action, connecting serialized data, field events, and regulatory compliance in one closed-loop ecosystem.

Late-stage personalization also enhances traceability at the patient interface. Through Delta-X Trust, serialized data and late-applied identifiers converge, allowing personalized kits, dosing instructions, or language variants to be linked back to each verified digital record. Combined with variable data printing, this creates a feedback-rich loop between field use and production data, improving adaptability and reducing waste across trials.

Unified Oversight for CMOs and CROs

When Pack-Smart Inc. Automation and Delta-X Trust Software work in tandem, complexity turns into control.

The DXT Integrity Suite integrates directly with Clinical Trial Management Systems (CTMS), bridging manufacturing and oversight platforms. Data captured during production, shipment, and administration remains synchronized across all systems, ensuring continuous alignment between CMOs, CROs, and sponsors.

The suite includes:

- Creator — generating secure GS1-compliant identifiers and symbology’s.

- Allocator — distributing code pools intelligently across lines, sites, and vendors.

- SiteCentral — managing production oversight and job dispatching at the plant level.

- Tracker — providing serialization control directly on the machine.

- Insight — converting serialized data into actionable market intelligence.

- Crypt — securing all transactions and audit records through encryption and digital signatures.

Built with role-based permissions, the Delta-X Trust ecosystem ensures that only authorized users access sensitive product or patient data. CROs can review field analytics, while CMOs monitor production, without exposing confidential sponsor information.

Key advantages include:

- Unified Visibility: Production, shipment, and clinical data within one connected system.

- Automated Validation: Every event verified against its digital origin record.

- Regulatory Readiness: Full digital genealogy of every product and label for submission to FDA or EMA.

- Operational Efficiency: Real-time alerts and automated reporting reduce rework and downtime.

For CROs, that means faster site startup and complete chain-of-custody visibility. For CMOs, it means simplified compliance, lower waste, and streamlined data exchange with study sponsors.

The Delta-X Trust Advantage

Pack-Smart Inc. delivers precision at production. Delta-X Trust ensures that precision never leaves the system.

Together, they create a single source of truth for clinical trial serialization, uniting manufacturing intelligence with digital traceability from the packaging line to the patient’s bedside.

For organizations developing the next generation of therapies, this integration is more than a compliance requirement, it’s a strategic advantage.

Delta-X Trust transforms serialization from a regulatory burden into a foundation for continuous learning, operational improvement, and patient trust.

When every identifier tells a verifiable story, integrity stops being a checkbox — it becomes a competitive edge.