Blog

LPR-Ready | Automated License Plate Recognition Vision Inspection System

License Plate Recognition (LPR) is a cornerstone of modern traffic enforcement, toll collection, and security systems. It relies on accurate and readable license plates for seamless operation. To meet these stringent requirements, manufacturers must ensure that every license plate is LPR-ready and flawless in visibility and durability.

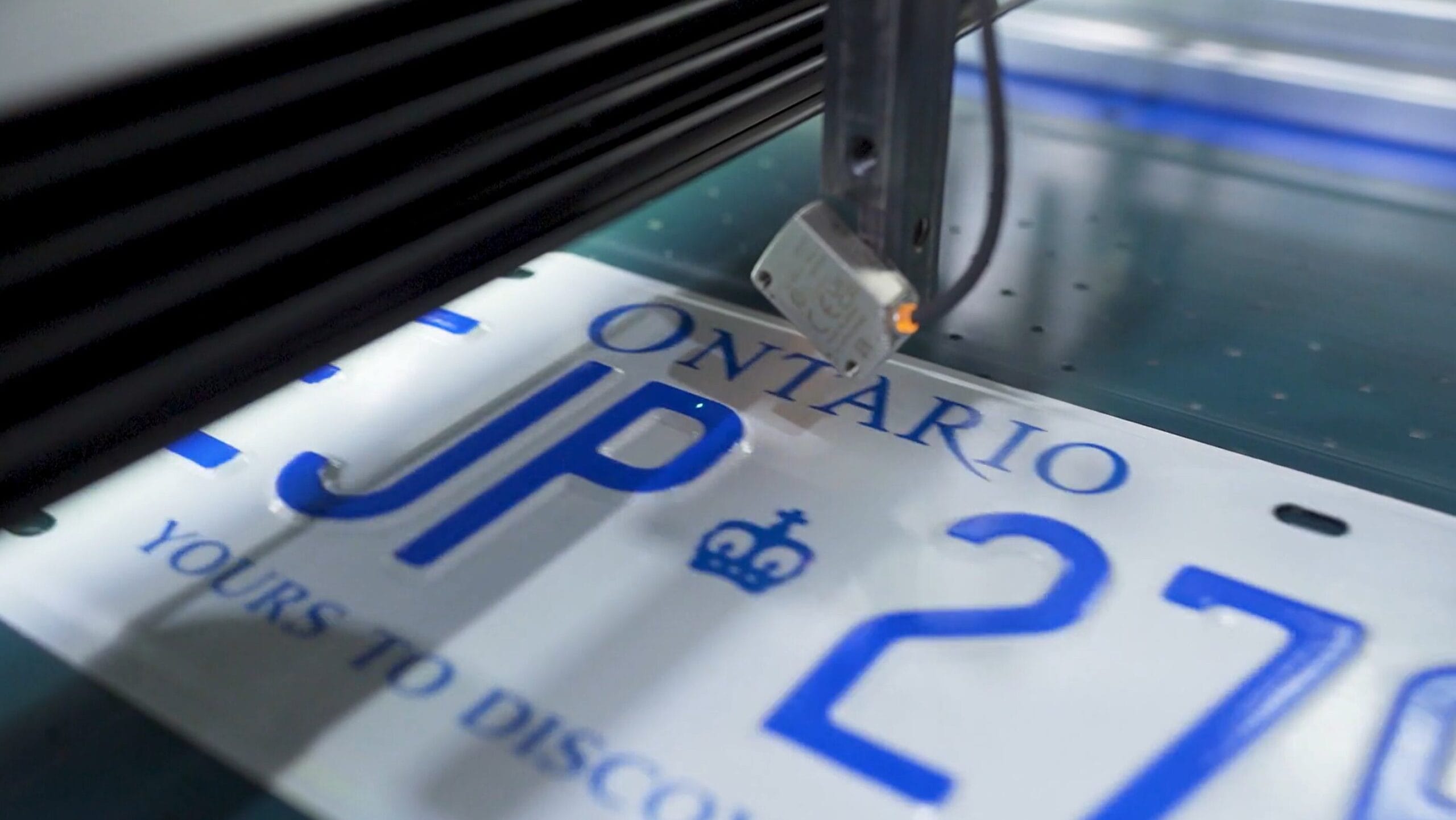

Incorporating vision inspection technology in manufacturing is no longer an option—it’s a necessity. From automated license plate recognition (ALPR) systems to license plate readers (LPR cameras), the accuracy of license plate production directly impacts the performance of these systems.

Here’s how advanced vision inspection systems help manufacturers ensure that their plates meet LPR compliance and contribute to efficient, high-quality production.

The Importance of LPR-Ready License Plates

In most countries, Automatic Number-Plate Recognition (ANPR) systems play a critical role in law enforcement, toll collection, automated traffic management, fleet operations, and everyday vehicle tracking. To ensure seamless identification, compliance, and long-term durability, precision in license plate manufacturing is essential.

License plates must be easily readable by LPR cameras and function reliably in varied weather and lighting conditions. These systems rely on advanced imaging and optical character recognition (OCR) software to process vehicle data accurately. Learn more about how LPR technology functions and its role in automated vehicle tracking.

By using automatic number plate recognition (ANPR) systems, businesses and authorities rely on the accuracy of license plates to perform critical tasks such as:

- Vehicle identification for tolling and parking enforcement.

- Security checks at entry points and for law enforcement.

- Real-time tracking in traffic management systems.

With license plate recognition software, plates must be identifiable and resistant to wear and tear. Manufacturers must employ vision inspection systems to ensure each plate’s readability, durability, and compliance with LPR standards.

Key Benefits of Vision Inspection in License Plate Manufacturing

Automated vision inspection systems provide manufacturers with the tools to maintain high-quality standards while improving efficiency. Here’s why LPR compliance is crucial for license plate manufacturing:

LPR Compliance & Regulatory Adherence: With LPR camera systems becoming more advanced, manufacturers must meet strict government requirements for license plate reflectivity, character alignment, and embossing depth. Advanced vision inspection systems allow manufacturers to continuously monitor and verify that their plates comply with LPR standards, ensuring they are readable by automatic license plate recognition software under various conditions.

Real-Time Defect Detection: LPR systems demand that every plate be precise and accurate. Vision inspection systems help detect defects such as misprints, misalignments, and poor embossing before plates leave the production line. This ensures that plates are fully compatible with LPR systems and ready for use in vehicle tracking and tolling systems.

Ensuring Serialization and Traceability: Automated license plate recognition involves using RFID tags, barcodes, and serial numbers that must be accurately applied to the plates. Vision systems verify the accuracy of these identifiers, ensuring that plates meet regulatory standards and can be efficiently tracked.

How Vision Systems Improve Efficiency in License Plate Production

Precision in license plate production starts long before a plate reaches the road. From material preparation to embossing and coating, every step must be carefully inspected to ensure flawless readability, durability, and compliance with LPR systems.

Material and Coating Inspection

Before a license plate is embossed or printed, the material preparation stage is pivotal in ensuring quality. LPR systems depend on plates that maintain high contrast and visibility in poor lighting or under harsh weather conditions.

Vision inspection systems ensure:

- Contaminant detection on raw material surfaces, ensuring no interference with coating adhesion.

- Uniform coating verification ensures background colors meet the reflectivity standards for LPR readability.

Reflective Sheeting & Alignment Inspection

The reflective sheeting to the plates must be perfectly aligned to ensure visibility. LPR cameras depend on uniform reflection for clear, readable data capture.

- Alignment checks ensure accurate positioning of the reflective sheeting.

- Adhesion quality checks ensure the reflective material is securely attached without delamination or bubbling, which could affect LPR accuracy.

Embossing & Character Inspection

The legibility of the embossed characters is essential for accurate license plate recognition. If the embossing is too shallow or the characters are misaligned, LPR cameras may fail to capture accurate data.

Vision inspection systems ensure:

- Precise alignment of characters, ensuring accurate plate scanning by LPR systems.

- Correct embossing depth for clear, readable characters.

Area Scan vs. Line Scan: Choosing the Right Vision System for Your Production Line

When selecting a vision inspection system for license plate manufacturing, choosing between area scan and line scan technology is crucial for ensuring production efficiency and LPR compliance. Each technology offers unique advantages, but the most effective solution is often a combination of both to achieve full-scale quality control.

Both area scan and line scan systems serve distinct but complementary roles, ensuring that no defect goes undetected at any stage of production. While area scan vision is best for detailed, high-resolution inspections at fixed points, line scan vision provides continuous, real-time quality control across multiple inspection zones.

Each inspection system plays a crucial role in ensuring that every license plate meets the highest quality standards for durability, accuracy, and traceability.

- VSC-1000 Area Scan Vision captures high-resolution, full-frame images, enabling precise analysis of coatings, embossing depth, and character clarity at key inspection points.

- VSC-2000 Line Scan Vision continuously scans moving plates in real time, providing seamless inspection of serialization, barcodes, and alignment at multiple points in the production process.

By working together, these systems eliminate defects, improve LPR compliance, and maximize production efficiency, ensuring that every plate is LPR-ready from the moment it leaves the production line.

VSC-1000 Area Scan Vision (Single Inspection Point)

The VSC-1000 is designed for detailed, high-resolution inspections at critical points in production.

It ensures that plates meet stringent quality control standards before progressing further down the line.

- Ensures reflective material adhesion meets LPR visibility standards for accurate scanning.

- Captures full-frame images for in-depth analysis.

- Best suited for stationary plates, verifying coating uniformity, embossing precision, and character legibility.

VSC-2000 Line Scan Vision (Multiple Inspection Points)

For high-speed production lines, the VSC-2000 continuously scans moving plates in real time, identifying defects without slowing production.

Seamlessly integrates into high-speed production, ensuring every plate meets LPR system requirements before leaving the line.

- Scans plates on the move, providing instant defect detection across multiple inspection zones.

- Tracks embossing, serialization, and barcode accuracy to ensure full traceability.

- Seamlessly integrates into high-speed production, ensuring every plate meets LPR system requirements before leaving the line.

Why Pack-Smart’s Vision Systems Are the Industry Standard

Both the VSC-1000 Area Scan and VSC-2000 Line Scan systems are engineered to meet the high demands of license plate production. They are built to:

- Ensure LPR compliance by accurately inspecting every aspect of plate production.

- Streamline quality control in high-speed environments with automated defect detection.

- Maximize production efficiency while ensuring regulatory adherence at every stage.

With Pack-Smart’s vision systems, manufacturers can confidently meet LPR standards, enhance traceability, and ensure the long-term durability of every license plate.

Conclusion: Making Sure License Plate Manufacturing is LPR-Ready

License plates are vital in modern vehicle tracking, tolling, and security systems. The accuracy of these plates directly impacts the performance of automatic license plate recognition systems.

By adopting advanced vision inspection systems, manufacturers can ensure that every plate meets LPR compliance while optimizing production efficiency. Pack-Smart’s VSC-1000 and VSC-2000 systems lead the way in intelligent, automated inspection, ensuring manufacturers remain ahead of regulatory requirements and industry demands.

Contact Pack-Smart today to discover how our vision inspection systems can elevate your license plate manufacturing process.