Rotary Pick and Place Series

Consistently feed, insert, attach, and batch delicate materials and oddly shaped products at 30,000 PPH, with vacuum pick & place motion and ±0.02″ placement accuracy.

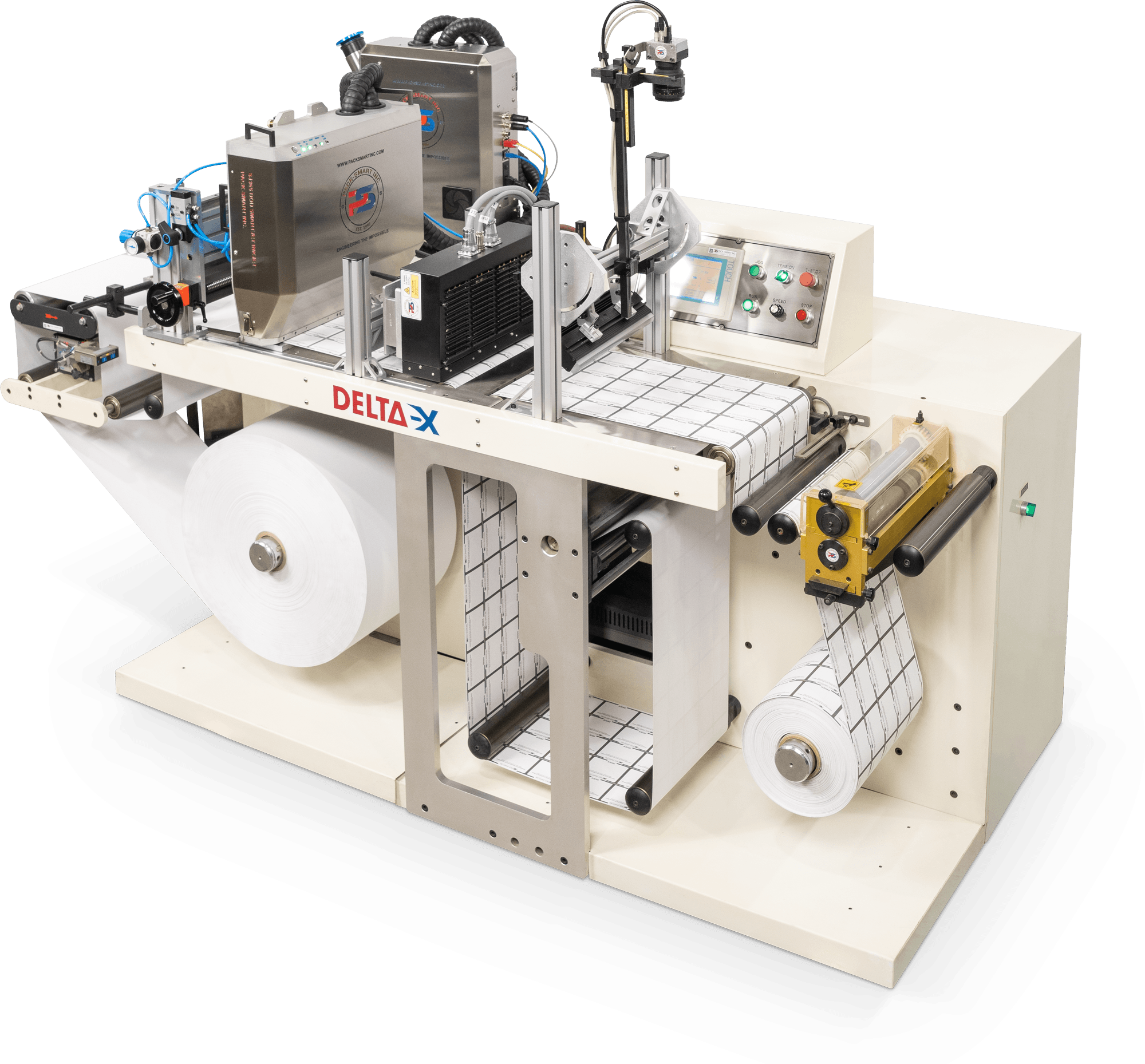

Revolutionize your label and flexible packaging production with the WP-360, offering unmatched speed and precision in web digital printing, inspection, and tracking.

The WP-360 is a state-of-the-art web personalizing system that integrates advanced digital printing with comprehensive inspection and tracking.

Capable of handling speeds up to 500 feet per minute, this system uses UV cured ink to adhere to any surface, ensuring high-quality print on diverse substrates.

The integrated high-resolution line scan camera and Delta-X tracking system ensure flawless production by identifying and addressing defects in real time.

Pressure Sensitive Labels

Flexographic Narrow Web

The WP-360 operates through a meticulously designed process flow that ensures efficiency and precision throughout its operations. This system seamlessly integrates various stages, from initial feeding and alignment to final verification, each tailored to enhance throughput and ensure the highest quality of end products. This comprehensive approach not only speeds up production but also minimizes errors, making it an indispensable solution for industries requiring high precision and reliability.

The WP-360 incorporates a range of advanced technologies that collectively boost its performance and versatility. Featuring state-of-the-art sensors for accurate data collection, sophisticated software algorithms for seamless process integration, and robust mechanical components designed for longevity and precision, the WP-360 stands out as a technologically advanced solution. These technologies are pivotal in delivering the system’s promise of high productivity and consistent quality, tailored to meet the dynamic demands of modern manufacturing environments.

Consistently feed, insert, attach, and batch delicate materials and oddly shaped products at 30,000 PPH, with vacuum pick & place motion and ±0.02″ placement accuracy.

Smart Jet uses industry leading head technology to deliver UV Cured 600 DPI DOD Ink onto any surface.

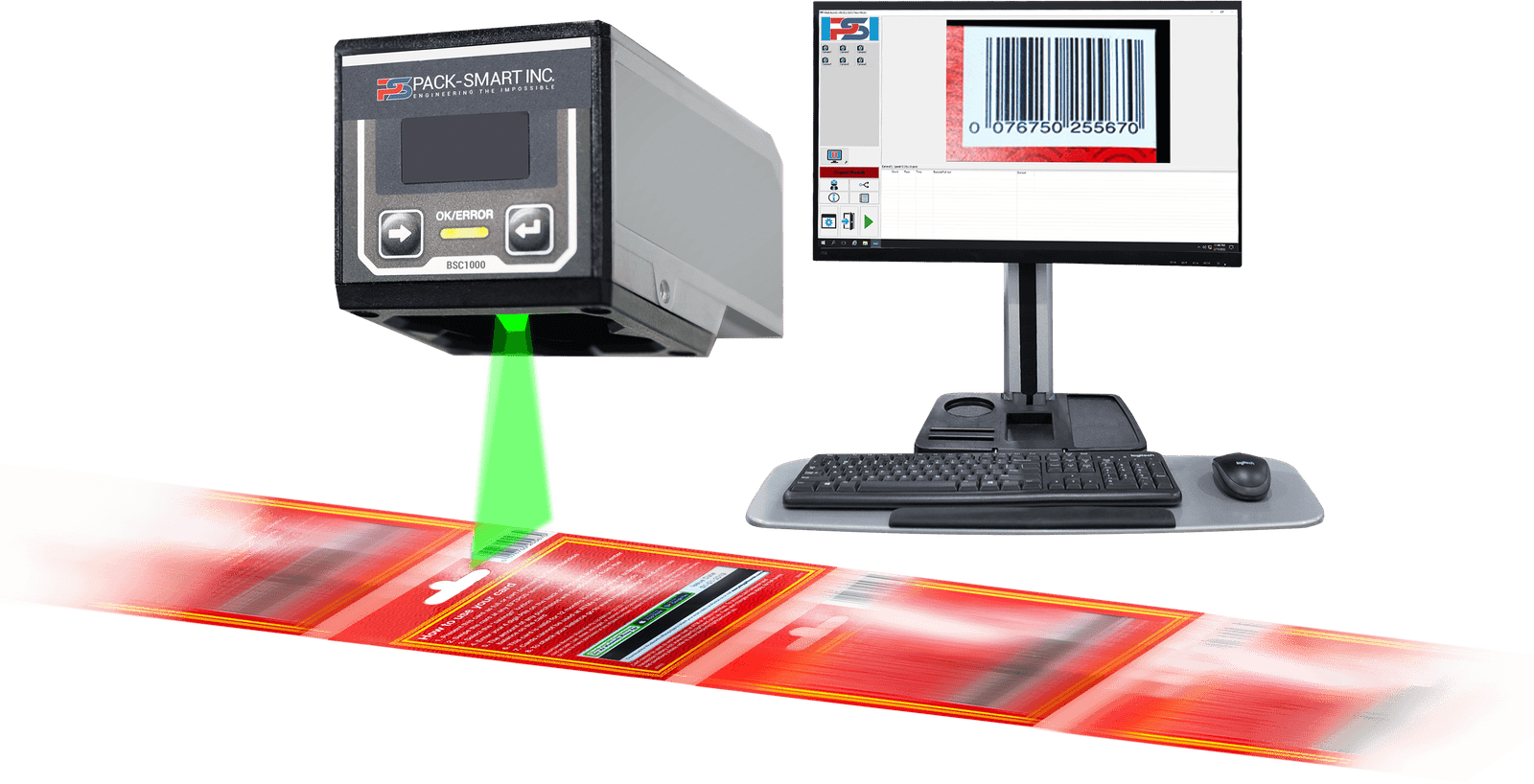

A user-friendly, fully packaged CCD reader, offering easy integration and several configurations to meet a variety of needs.

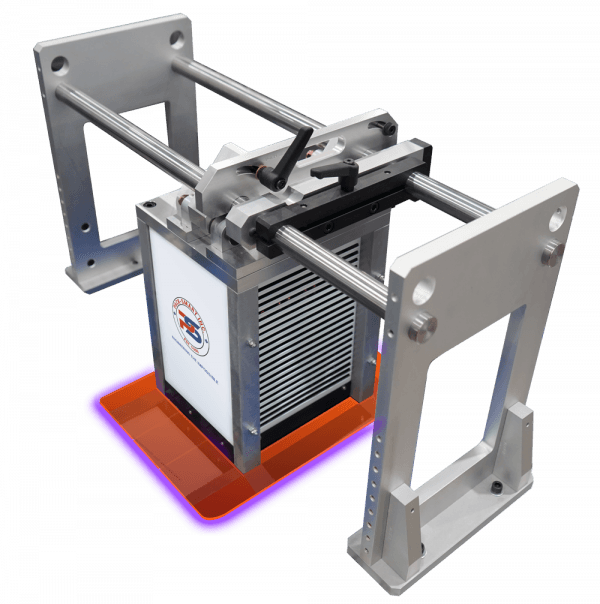

The UVL-7550 integrates high-power LED UV lamps for superior, high-speed, single-pass drying and curing applications. Offering an eco-friendly solution with significantly reduced power consumption compared to traditional systems.

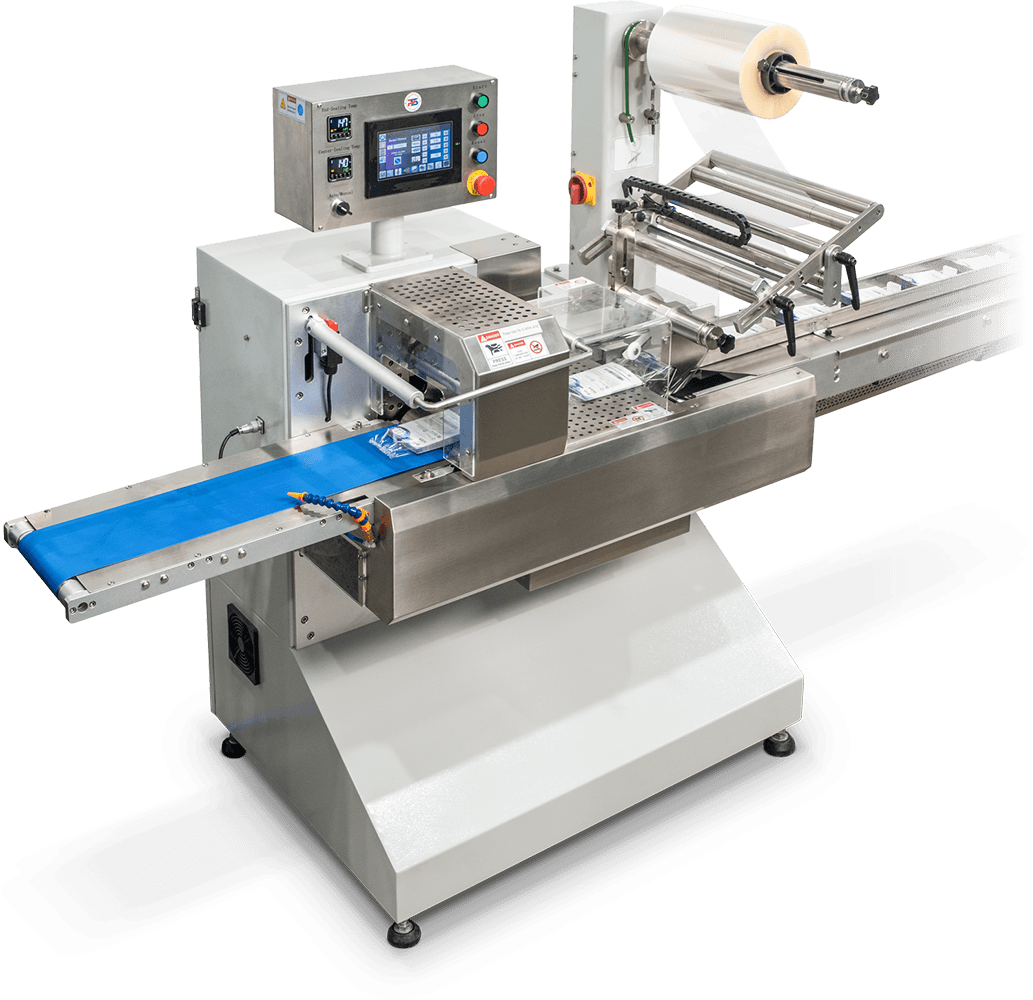

Maximize efficiency with the BA-250, a fully automated pack-out fulfillment system designed for wrapping, inline batching, bundling, and labeling, enhancing throughput up to 2,000 bundles per hour.

The BA-250 Pack-Out Fulfillment System is Pack-Smart’s state-of-the-art solution for inline batching, wrapping, and aggregate labeling, delivering up to 2,000 finished bundles per hour with precision and reliability.

This advanced system seamlessly integrates key functions, including batching, wrapping, scanning, weighing, and quality assurance. Each bundle, case, and pallet is labeled with pinpoint accuracy, streamlining workflow efficiency and ensuring end-to-end traceability for high-demand production environments.

The BA-250 exemplifies streamlined operational excellence, featuring a process flow that optimizes speed and precision. From material handling to the final inspection, each stage of the process is meticulously engineered to enhance productivity and ensure the highest quality output.

The BA-250 integrates a suite of cutting-edge technologies that elevate its operational capabilities. It incorporates advanced sensors for real-time monitoring, precision actuators for accurate material handling, and sophisticated software for seamless automation.

These technologies work in harmony to ensure the BA-250 delivers exceptional performance, making it a robust solution for industries seeking to leverage technological advancements for improved efficiency and quality.

Consistently feed, insert, attach, and batch delicate materials and oddly shaped products at 30,000 PPH, with vacuum pick & place motion and ±0.02″ placement accuracy.

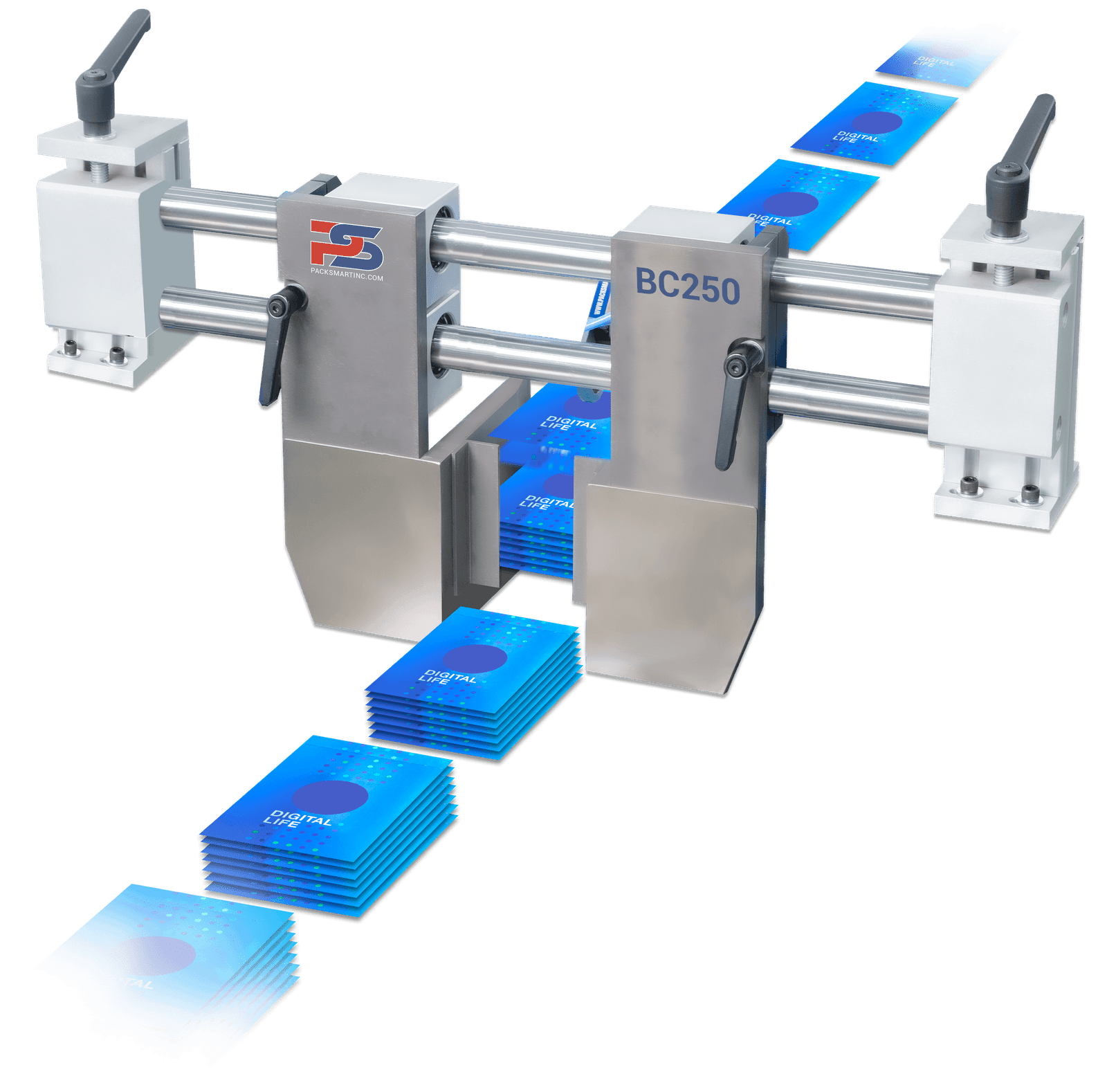

Efficiently batch single products into precise groups with Pack-Smart’s BC Series, designed for a wide range of materials and applications.

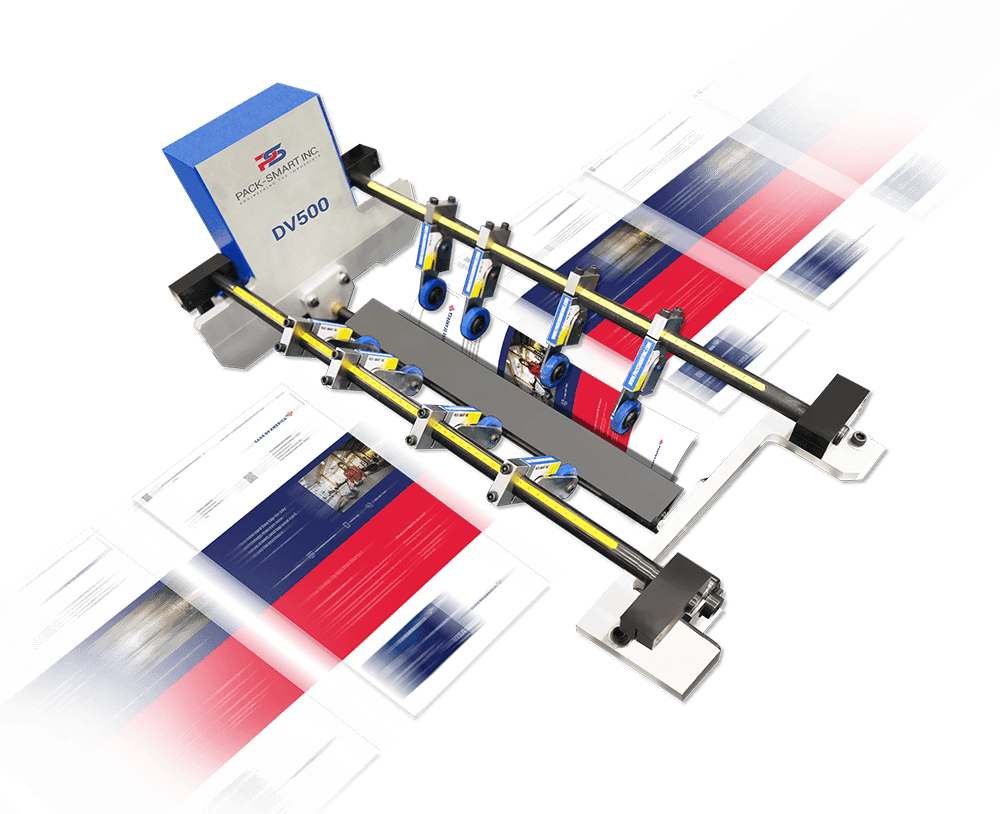

Elevate efficiency with the DZ Series Zoned Divert, designed for precise sorting and high-capacity handling in demanding industrial environments.

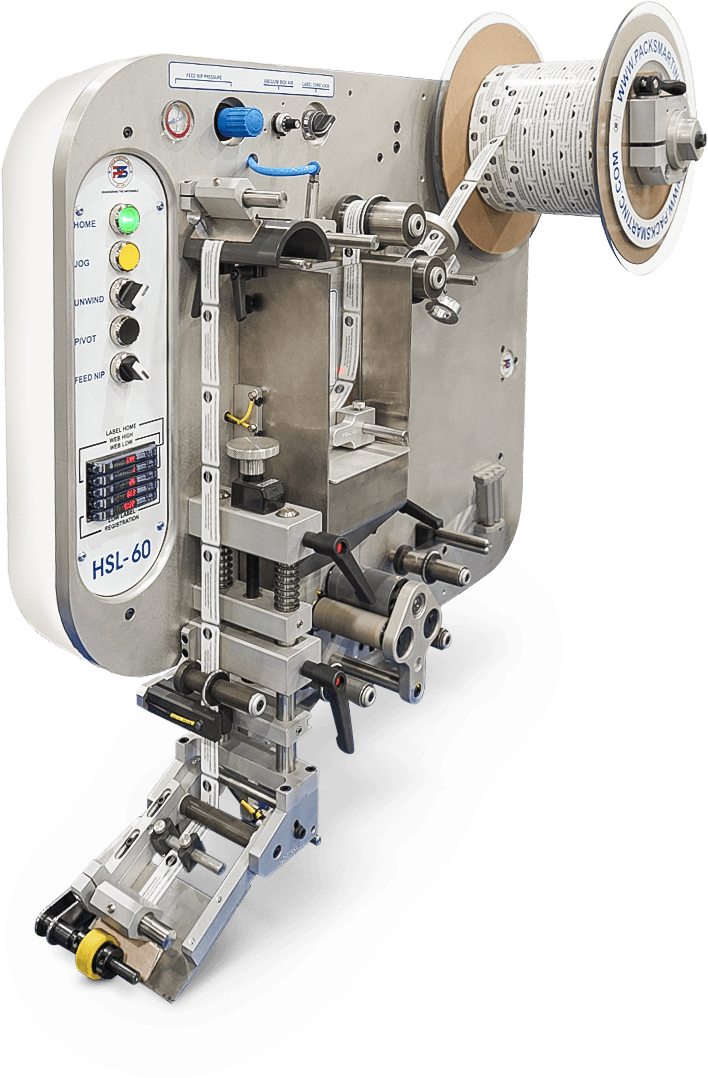

The HSL-60 is a highly versatile module that applies pressure sensitive labels at high speeds and accuracy for the most demanding precision-critical applications.

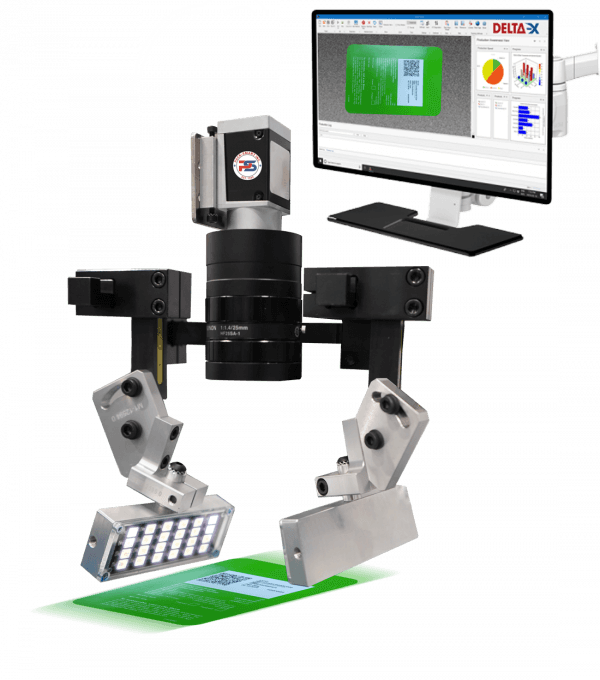

The VSC-1000 Vision System offers state-of-the-art vision scanning and real-time image processing, ideal for high-speed production environments.