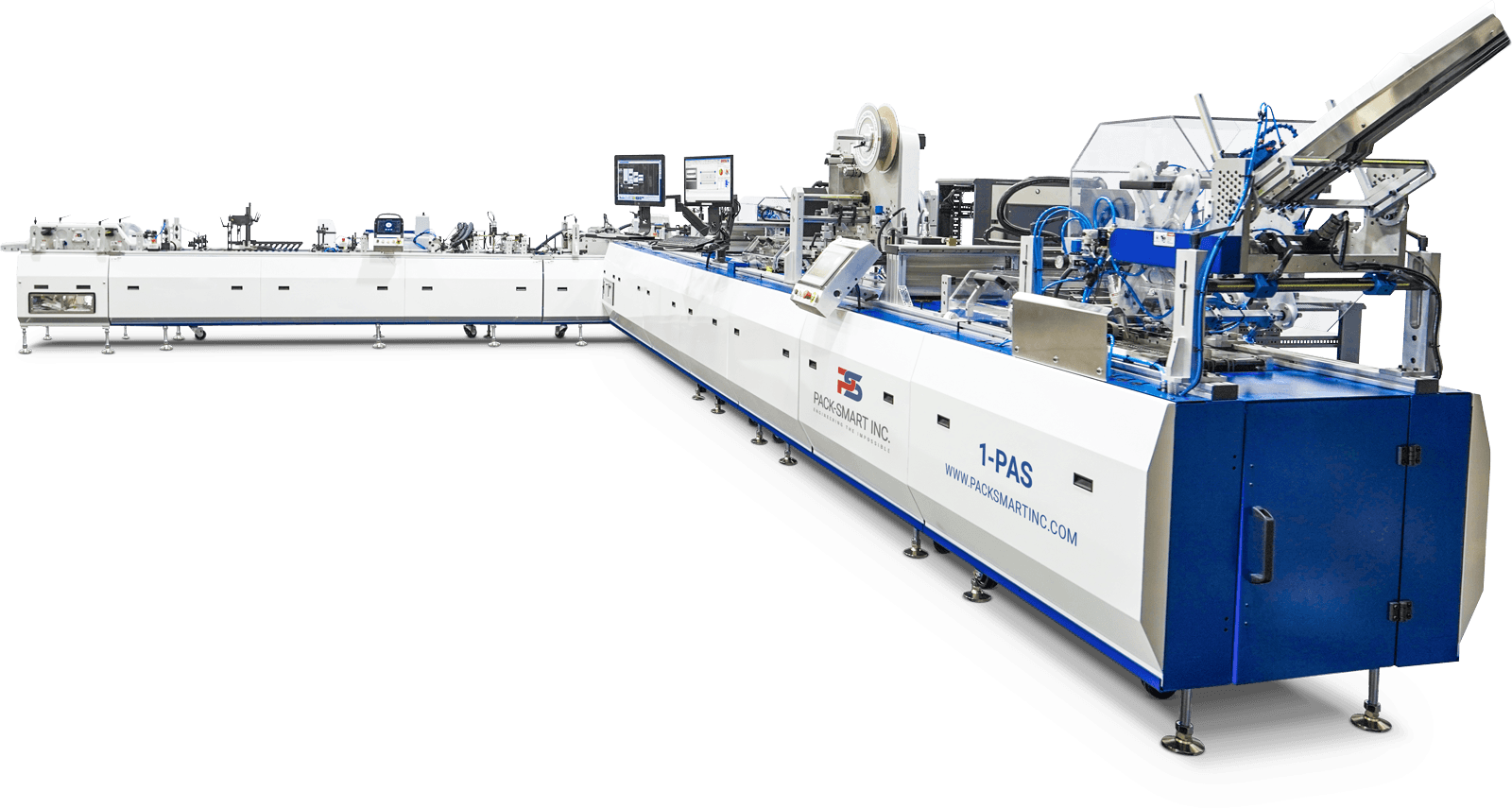

Card to Bundle in One Pass

World’s first inline solution for high volume personalization, affixing, packaging and pack-out of secure open and closed loop cards at 20,000 PPH.

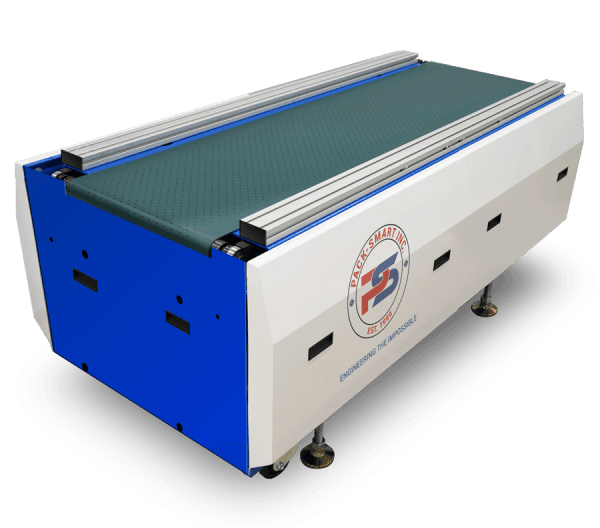

Revolutionize your production line with the DZ Series, High-Speed Zoned Divert Gate, crafted for precise, high-capacity product sorting and handling.

The DZ Series Zoned Divert Gate module redefines efficiency and accuracy in high-volume production settings. It features strategically placed zone-specific divert gates that allow for precise control and routing of products according to specific operational requirements.

This advanced system is equipped with state-of-the-art sensors and programmable logic controllers, enabling customizable operation and real-time adjustments to meet diverse production demands.

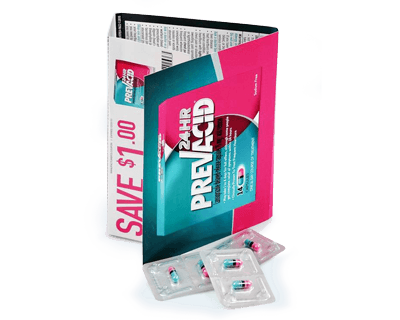

Pharmaceutical

eCommerce

Food and Beverage

Models catered to different operational scales, from small to large-sized products.

DV-250

250 mm gate width

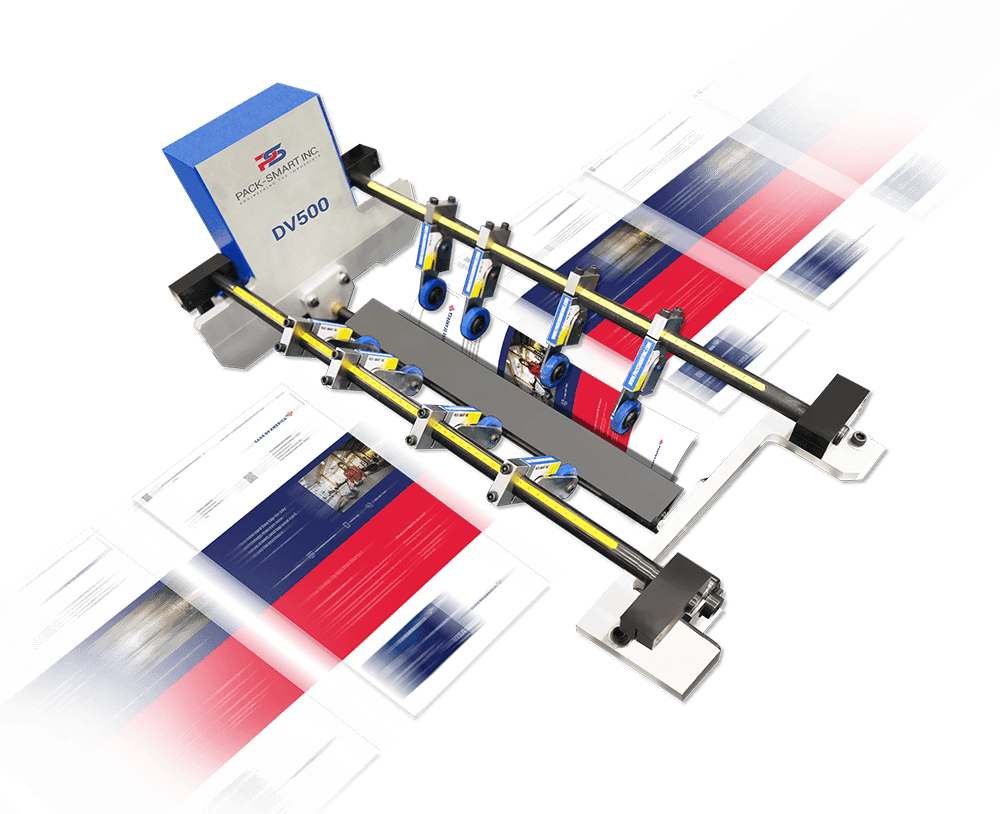

DV-500

500 mm gate width

This technology is used in the following automated systems.

World’s first inline solution for high volume personalization, affixing, packaging and pack-out of secure open and closed loop cards at 20,000 PPH.

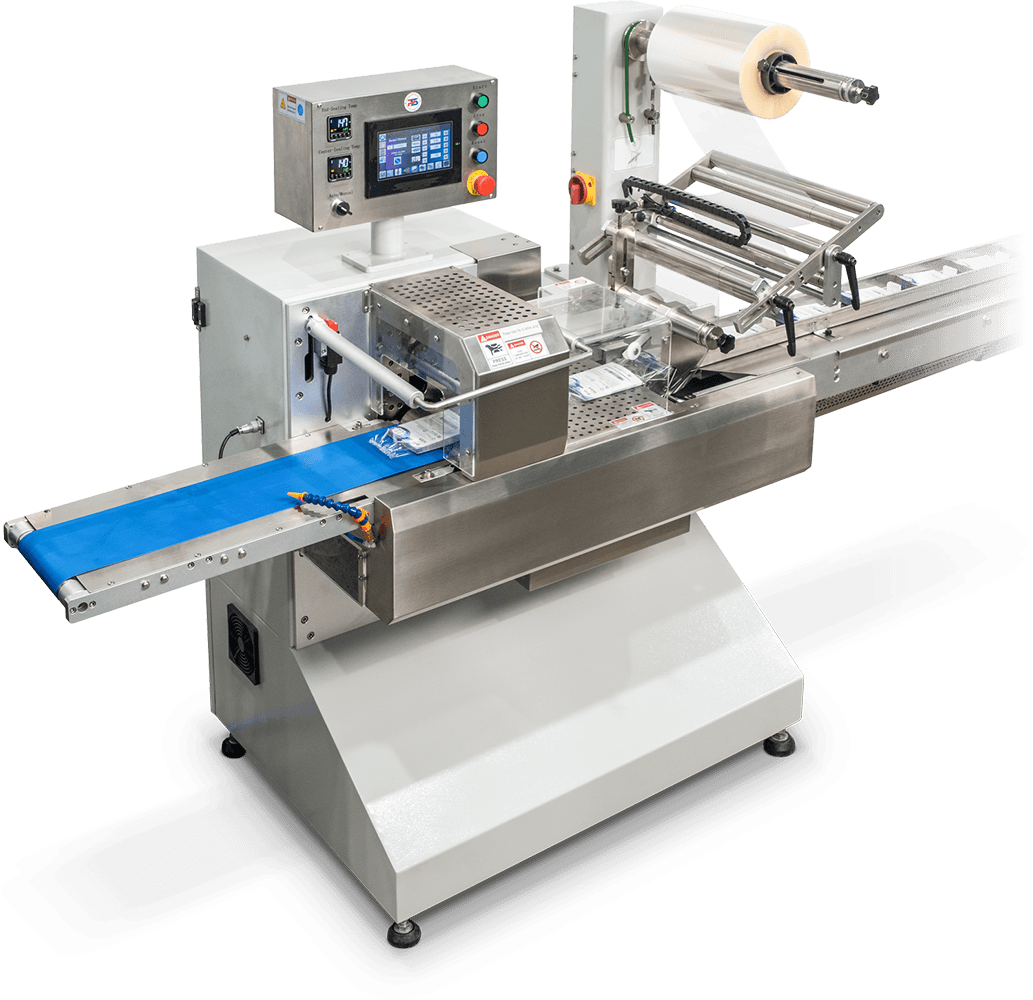

Discover the BA-250 Automated Pack-Out System, a high-speed solution for packaging fulfillment.

Engineered to meet the rigorous demands of EMV chip card encoding, this system combines advanced encoding capabilities with high-speed processing to deliver unparalleled efficiency.

Related modules are available for inline applications.

High torque servo driven vacuum transport conveys products at accurate speeds and controls product placement with 8 selectable vacuum zones.

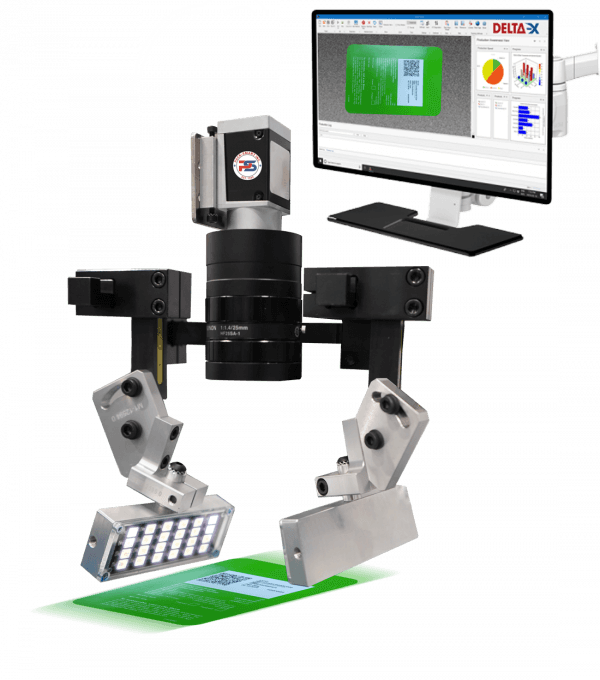

The VSC-1000 Vision System offers state-of-the-art vision scanning and real-time image processing, ideal for high-speed production environments.

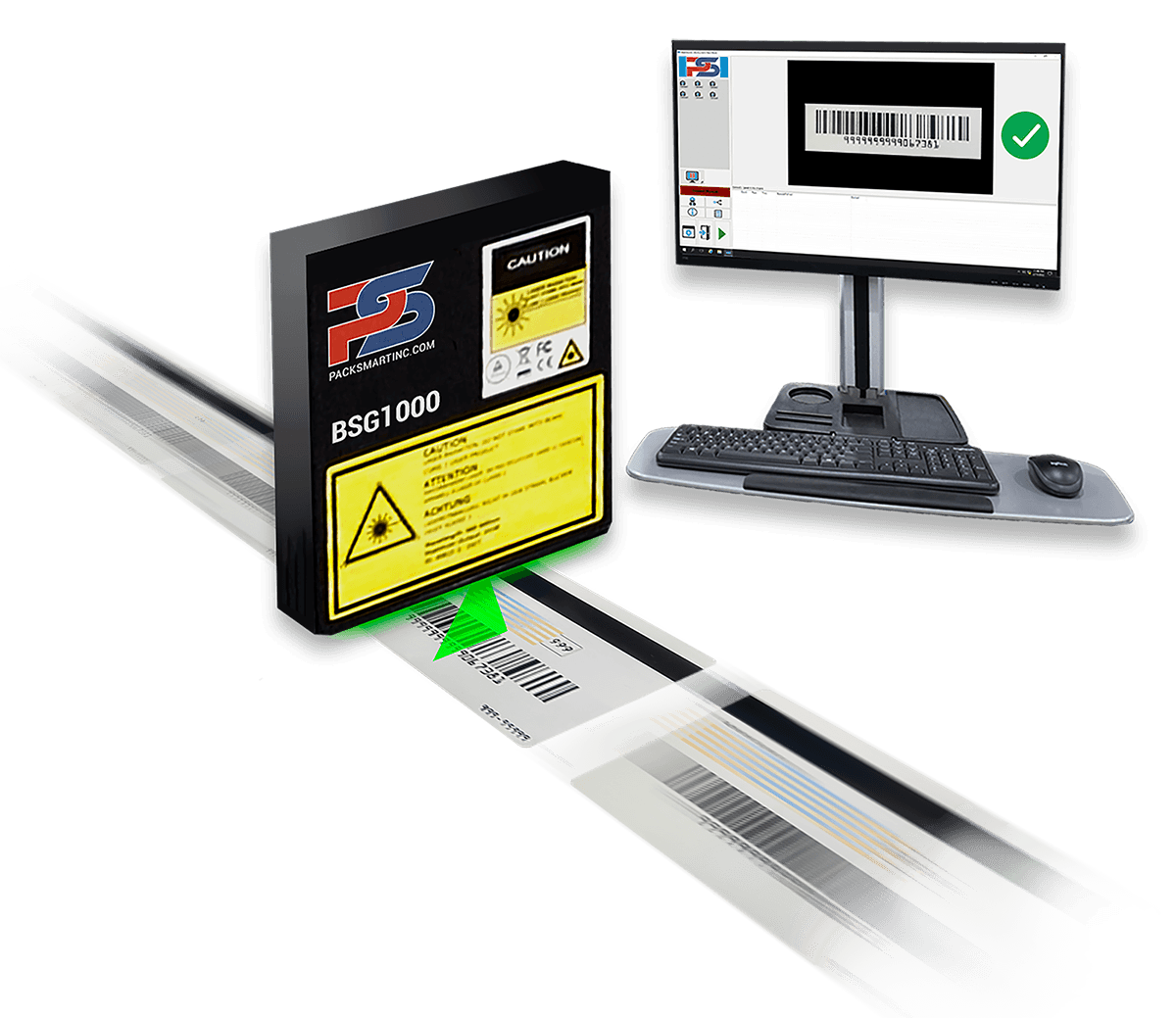

The BSG-1000 Barcode Scanning and Grading module is designed to ensure that all your barcoded products meet ISO standards for quality.