Card to Bundle in One Pass

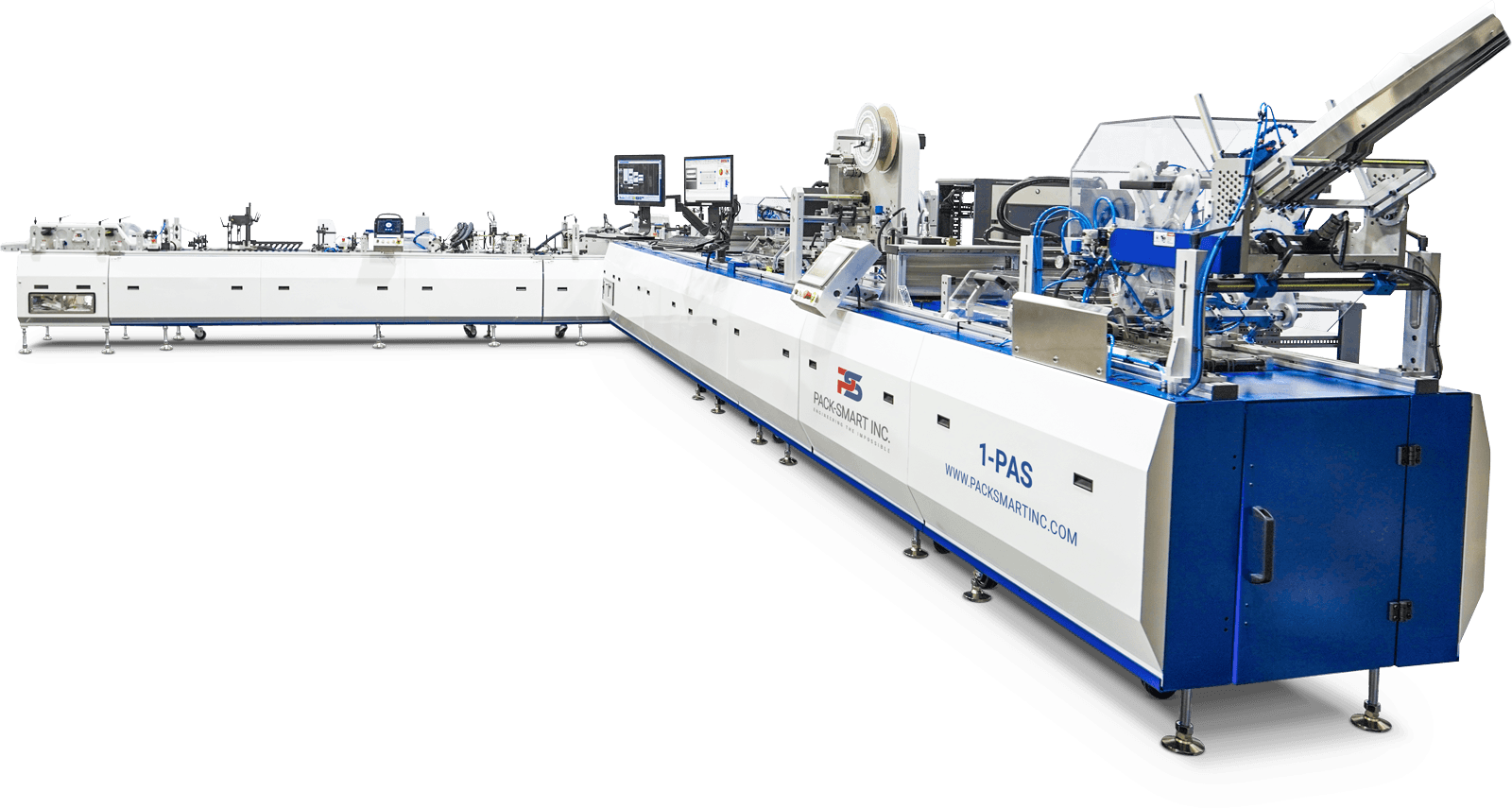

World’s first inline solution for high volume personalization, affixing, packaging and pack-out of secure open and closed loop cards at 20,000 PPH.

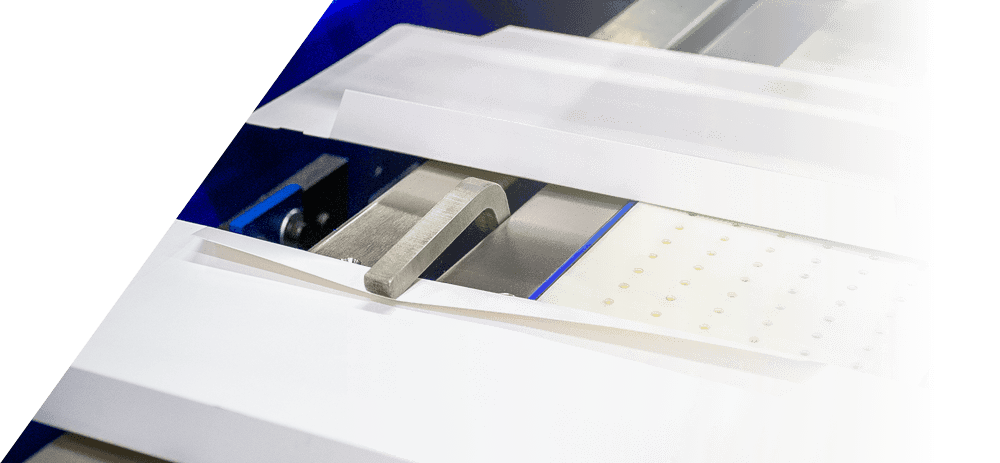

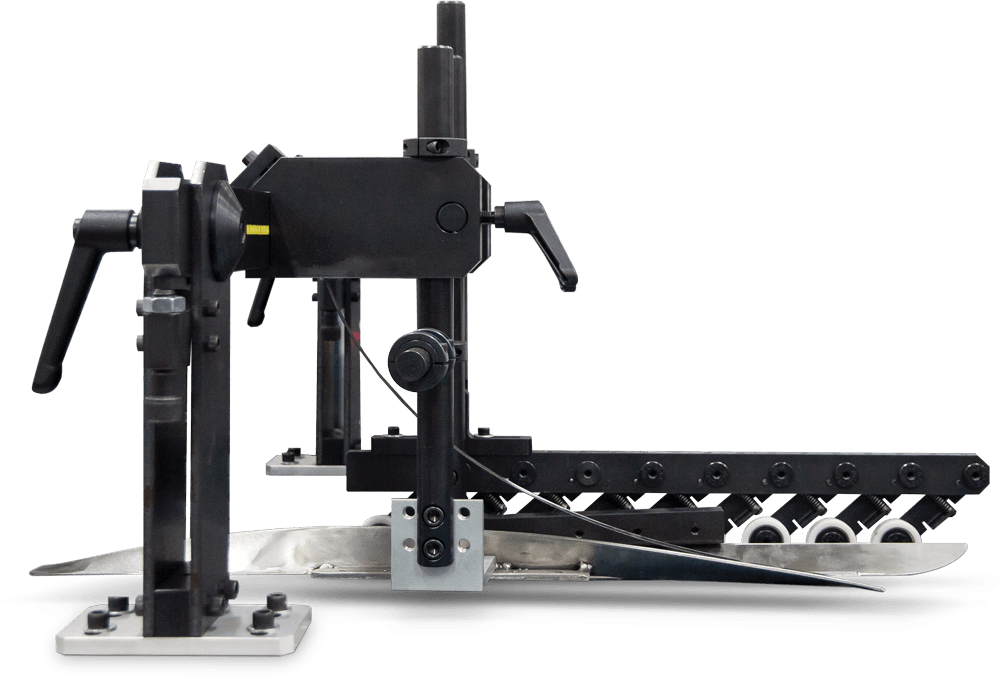

The BF-100 Back Fold module is engineered for high-speed precise folding of a wide range of products.

The BF-100 Back Fold Module combines state-of-the-art technology with practical design to enhance production line capabilities.

Equipped with a digital servo controller and an ultra-lightweight alloy folding attachment, the BF-100 delivers unmatched productivity for four and six-corner folding tasks.

Its compact design integrates seamlessly with existing systems, offering a small footprint that fits various industrial settings.

Membership & Loyalty

eCommerce

Retail

Tailored configurations from small to large products, ensuring a perfect fit for every production requirement.

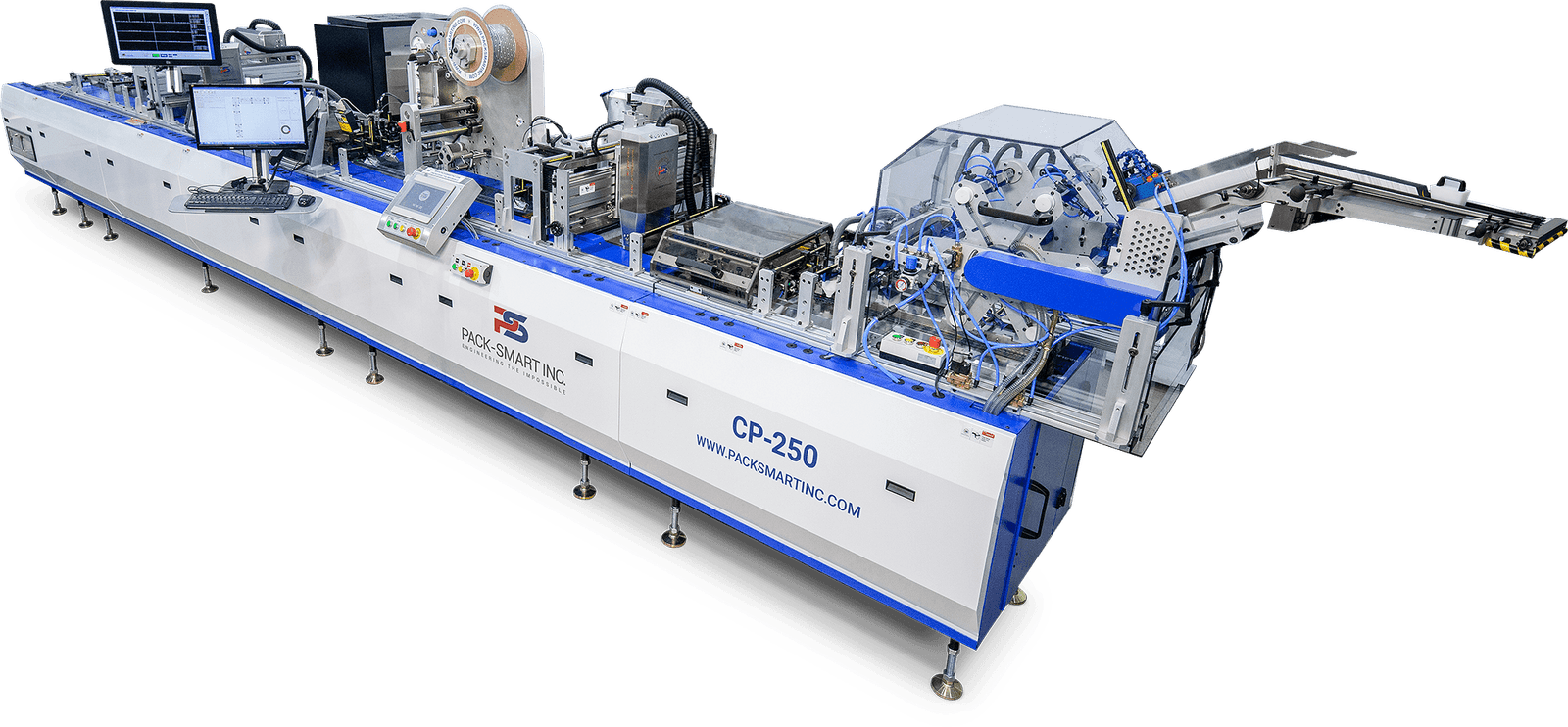

This technology is used in the following automated systems.

World’s first inline solution for high volume personalization, affixing, packaging and pack-out of secure open and closed loop cards at 20,000 PPH.

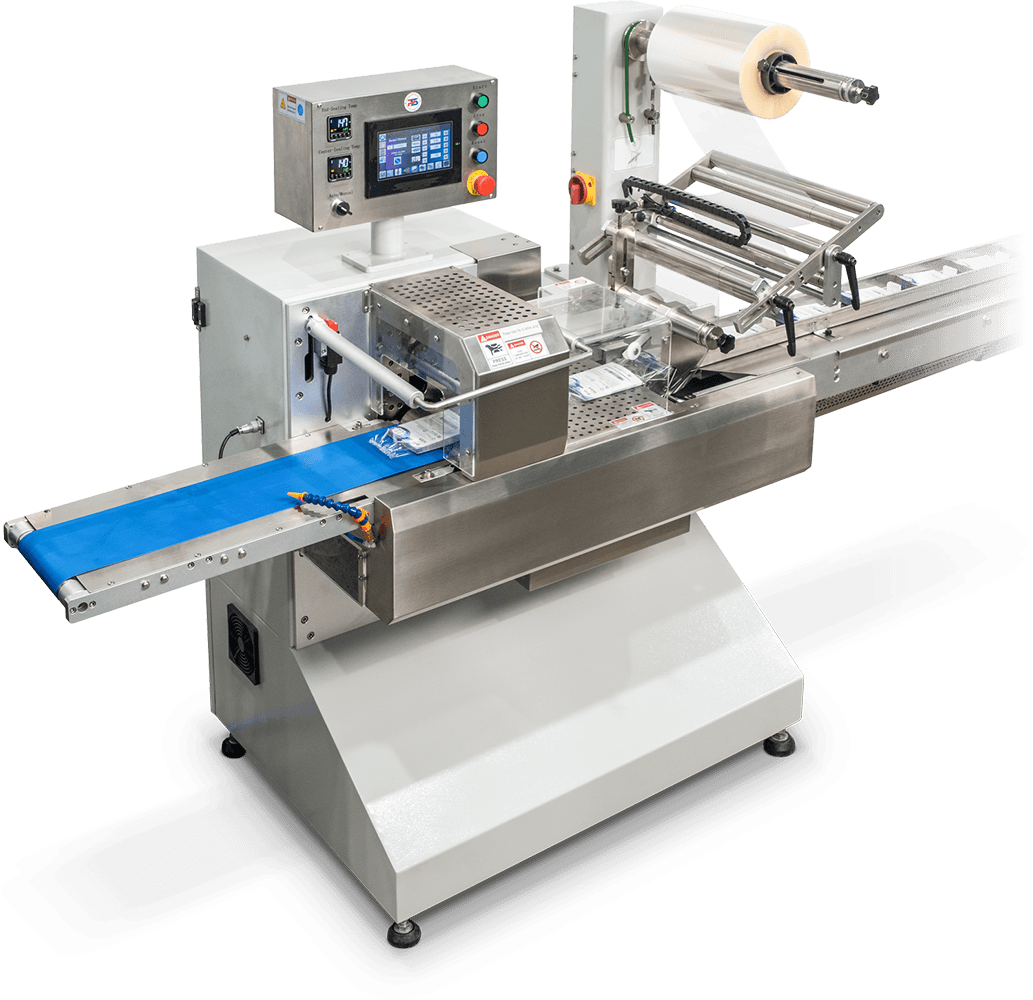

Discover the BA-250 Automated Pack-Out System, a high-speed solution for packaging fulfillment.

With speeds up to 30,000 PPH, it is ideal for all your closed, secure, and open loop needs.

Related modules are available for inline applications.

Streamline your production with the MFF-120 Front Fold Module, designed for high-speed, precise folding of various products at right angles.

The PF50-90 Plow Fold Module integrates seamlessly into production lines, offering both left and right folding configurations.