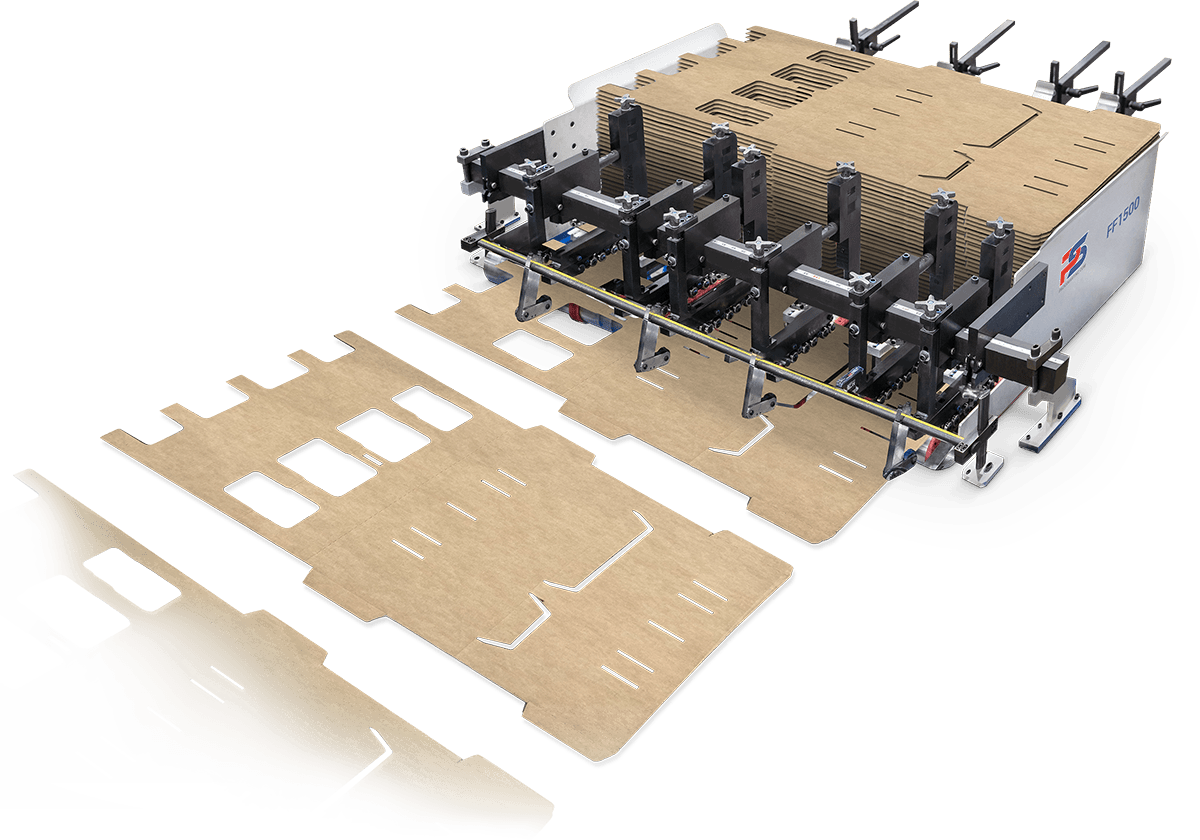

Primary Friction Feeder

The FF Series Friction Feeder can handle the lightest paper and is equally at home when dealing with heavy stock materials when called upon.

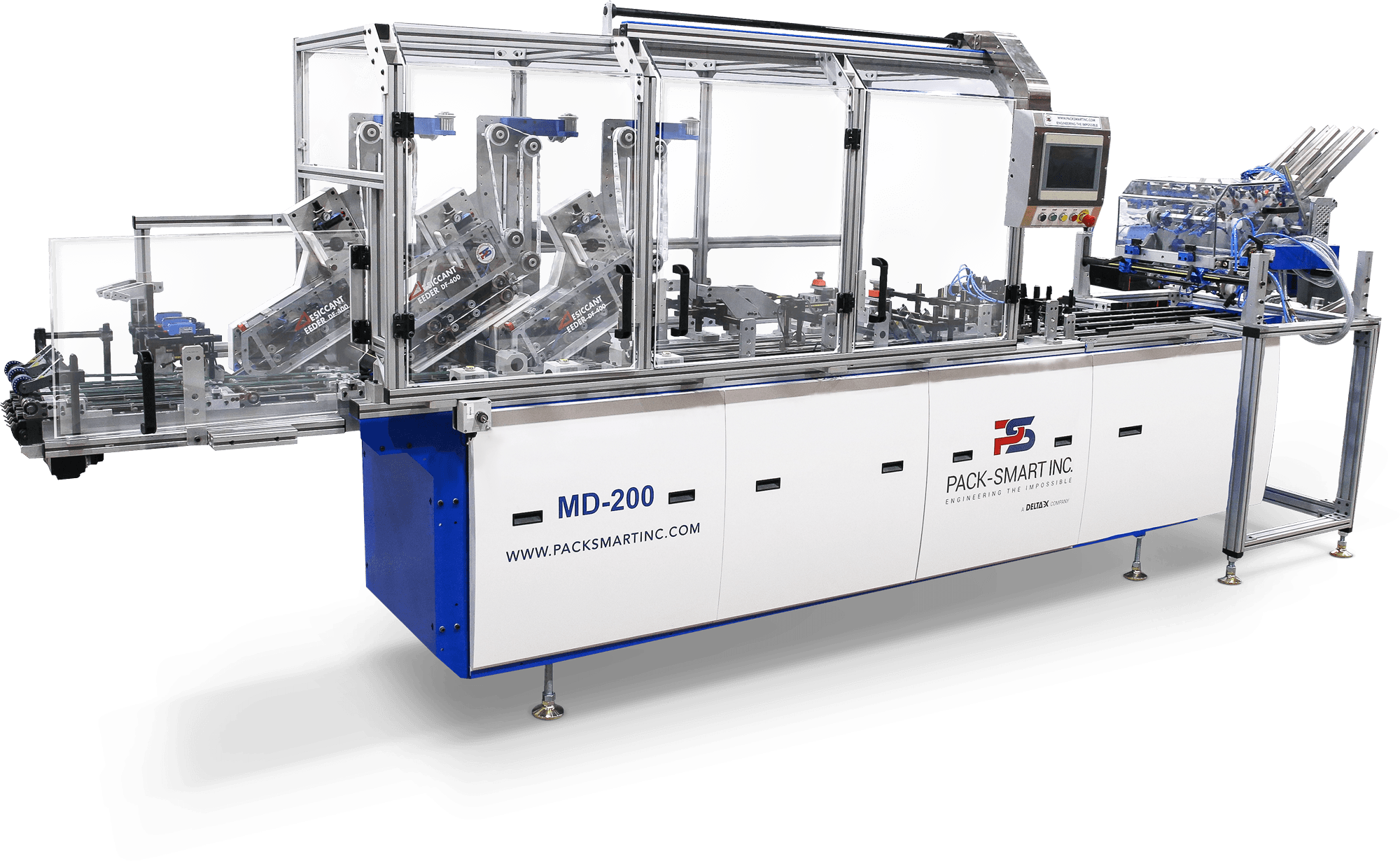

Elevate your medical kit production with the MD-200, a multi-stream system engineered for high efficiency and precision in assembling and packaging medical-grade antigen test kits.

The MD-200 streamlines the final assembly of medical kits through its advanced multi-lane capabilities. Each production lane meticulously adds components, folds carriers, applies DOD serialization, and securely guides kits into wrapping modules, enhancing throughput and precision.

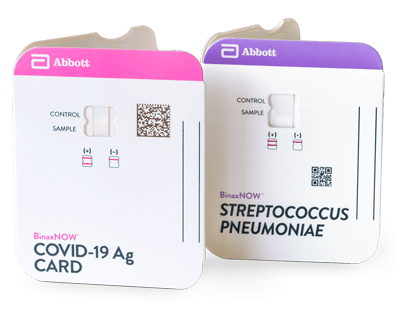

Medical Kits

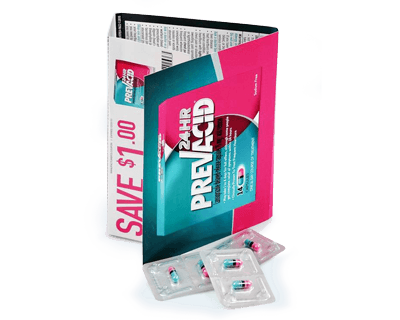

Pharmaceutical Products

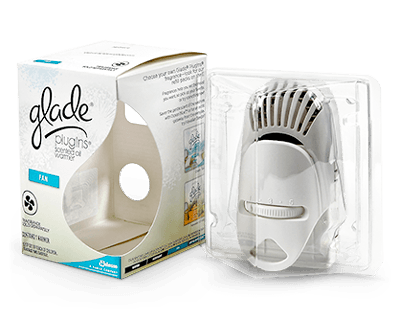

Fast Moving Consumer Goods

The MD-200 Metal Detector plays a crucial role in the quality assurance process by integrating seamlessly into the production line to detect metallic contaminants. Products pass through the detector, where high-sensitivity sensors scan for any metal fragments. Upon detection, the system signals the rejection mechanism, promptly removing the contaminated product from the line.

The MD-200 leverages Delta-X software for real-time control and end-to-end reporting, ensuring precision in medical kit assembly. Its servo-driven mechanisms enhance placement accuracy and speed, while its seamless integration with high-speed DOD printing meets stringent regulatory demands, significantly boosting throughput with minimal downtime.

The FF Series Friction Feeder can handle the lightest paper and is equally at home when dealing with heavy stock materials when called upon.

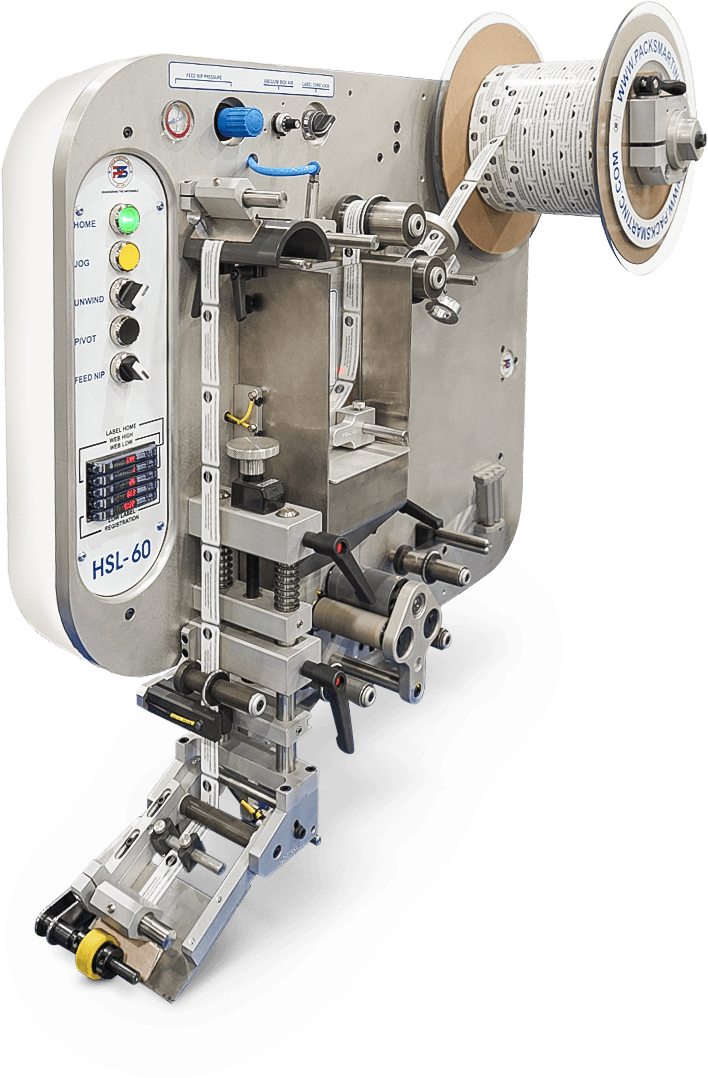

The HSL-60 is a highly versatile module that applies pressure sensitive labels at high speeds and accuracy for the most demanding precision-critical applications.