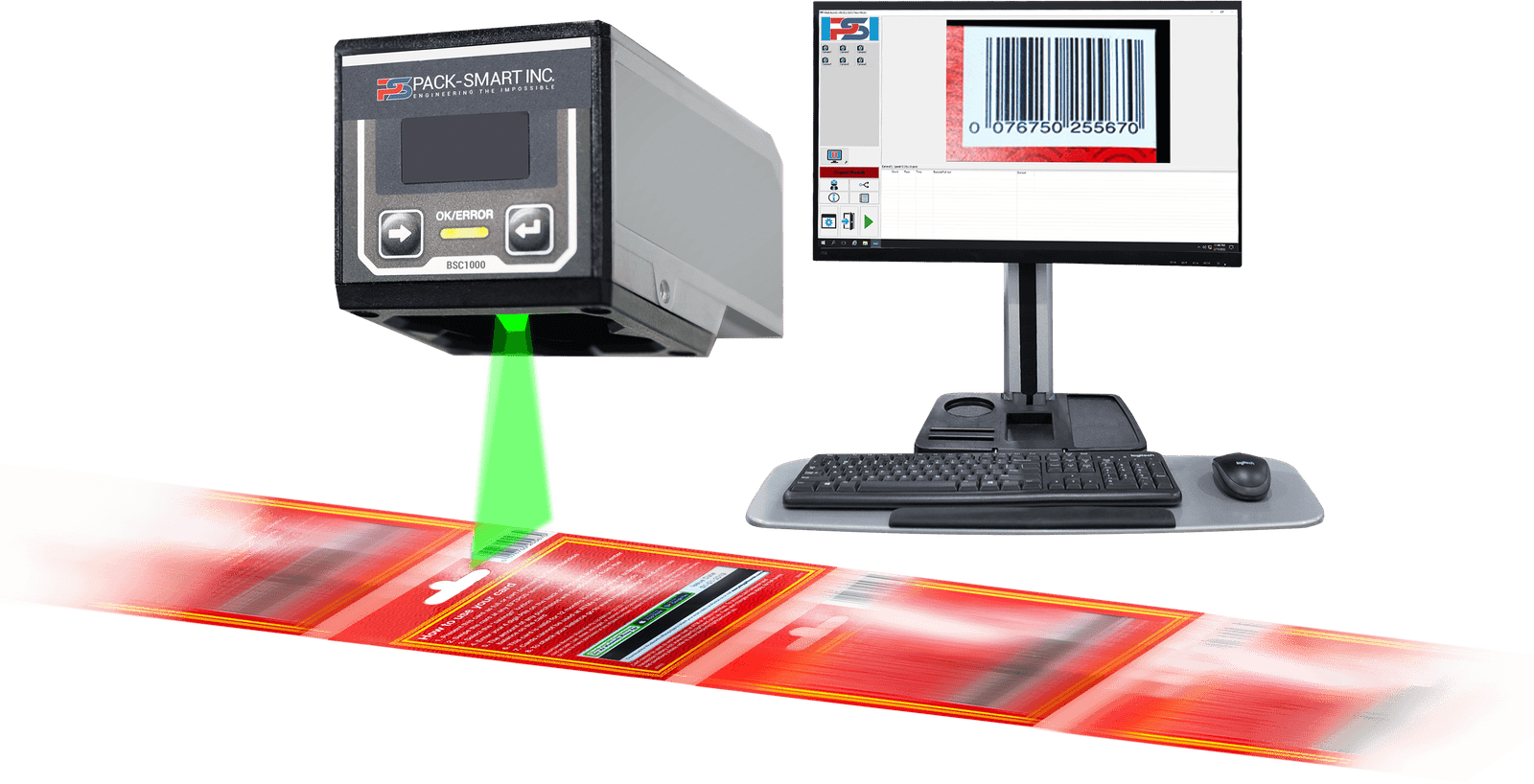

Barcode and Data Reading

A user-friendly, fully packaged CCD reader, offering easy integration and several configurations to meet a variety of needs.

Precision Secure Document Inspection System at Production Speeds — Automated Quality Assurance and NFC Validation for Zero-Defect Manufacturing.

The HyperVision 3500 sets a new industry benchmark in automated secure document inspection. Engineered specifically for secure credential manufacturing, including passports, national IDs, financial cards, and currency substrates, this advanced vision inspection platform combines 8K ultra-high-resolution optical systems, real-time embedded NFC/RFID chip validation, and fully integrated traceability.

Manufacturers gain unmatched quality control, compliance assurance, and productivity — achieving precision that manual inspection and current systems cannot match.

Passports and Laminations

Government-Issued IDs and Secure Credentials

Currency and Banknote

The HyperVision 3500 automates every critical step in secure document inspection, providing unparalleled accuracy, reliability, and traceability from initial loading through to final sorting and labeling.

The HyperVision 3500 incorporates advanced, integrated technologies designed to deliver unmatched precision, secure document inspection, comprehensive real-time traceability, automated defect detection, and NFC/RFID validation — ensuring 100% zero-defect compliance and optimal production efficiency.

A user-friendly, fully packaged CCD reader, offering easy integration and several configurations to meet a variety of needs.

Smart Jet uses industry leading head technology to deliver UV Cured 600 DPI DOD Ink onto any surface.

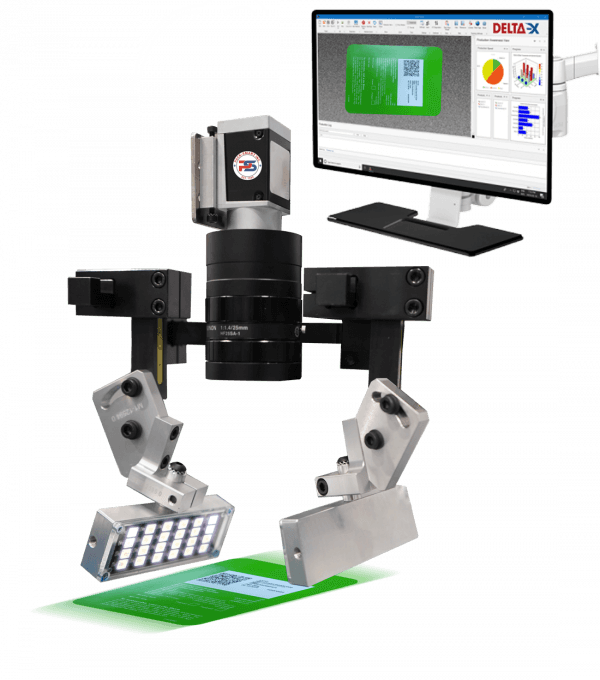

The VSC-1000 Vision System offers state-of-the-art vision scanning and real-time image processing, ideal for high-speed production environments.

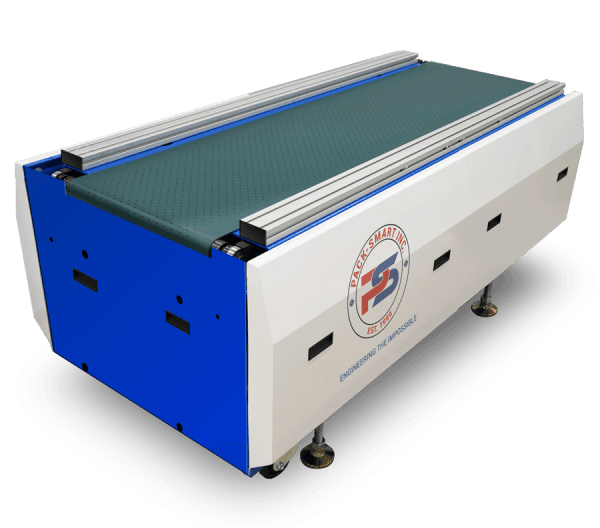

High torque servo driven vacuum transport conveys products at accurate speeds and controls product placement with 8 selectable vacuum zones.