High-Speed Label Applicator

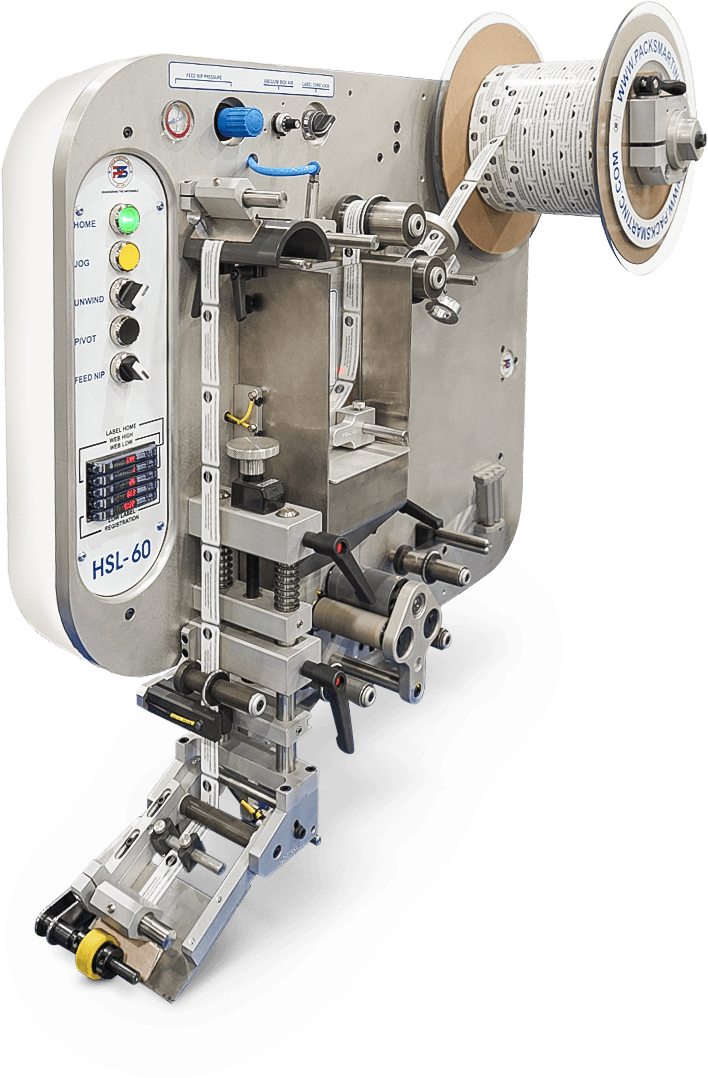

The HSL-60 is a highly versatile module that applies pressure sensitive labels at high speeds and accuracy for the most demanding precision-critical applications.

This system is equipped with sophisticated sensors and control systems that adjust parameters in real time to suit varying material specifications and environmental conditions.

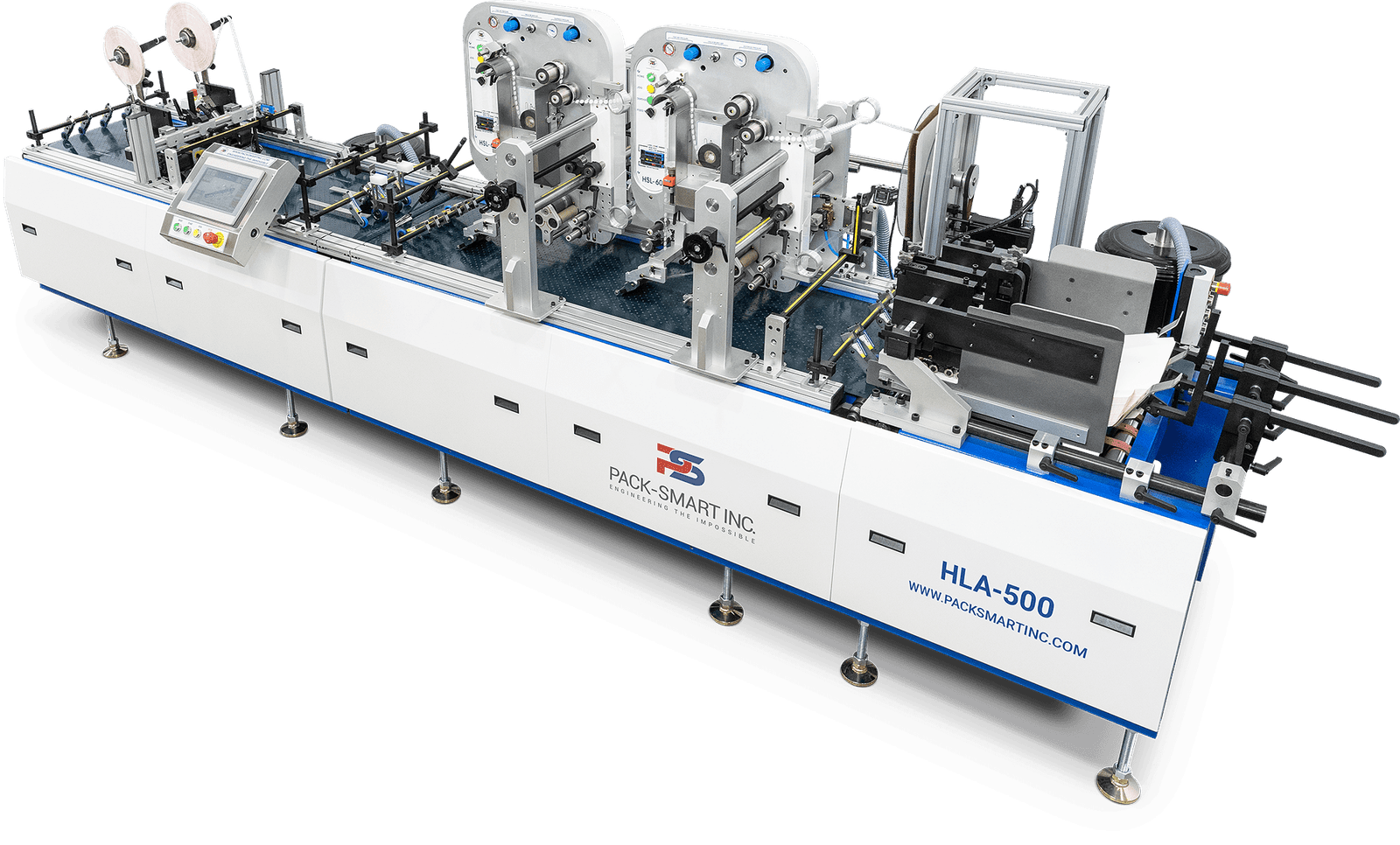

Pack-Smart’s HLA-500 system is the fastest solution for accurate velcro label and hi/low tack tape application at speeds up to 15,000 products per hour. Because of a modular system approach, HLA-500 is ideally suited to simultaneously carry out other in-line processes such as folding and gluing, creasing, tipping, Braille embossing inspection and digital imaging.

The system comes with your choice of delivery options, shingled, in batches, or bridging modules, for seamless integration with third-party equipment for downstream processes.

High-Value Cartons

Specialty Packaging

The process flow for the HLA-500 High-Speed Label Application System is engineered to maximize efficiency and precision. This system seamlessly integrates each step of the labeling process, from initial product feeding to final quality inspection, ensuring high-speed, accurate label application with minimal downtime.

The HLA-500 High-Speed Label Application System incorporates state-of-the-art technologies designed to enhance performance and reliability. Key technologies include a brushless servo drive for precise control, vacuum tensioned web for stable label handling, and advanced fiber-optic sensors for accurate positioning and operation monitoring.

The HSL-60 is a highly versatile module that applies pressure sensitive labels at high speeds and accuracy for the most demanding precision-critical applications.

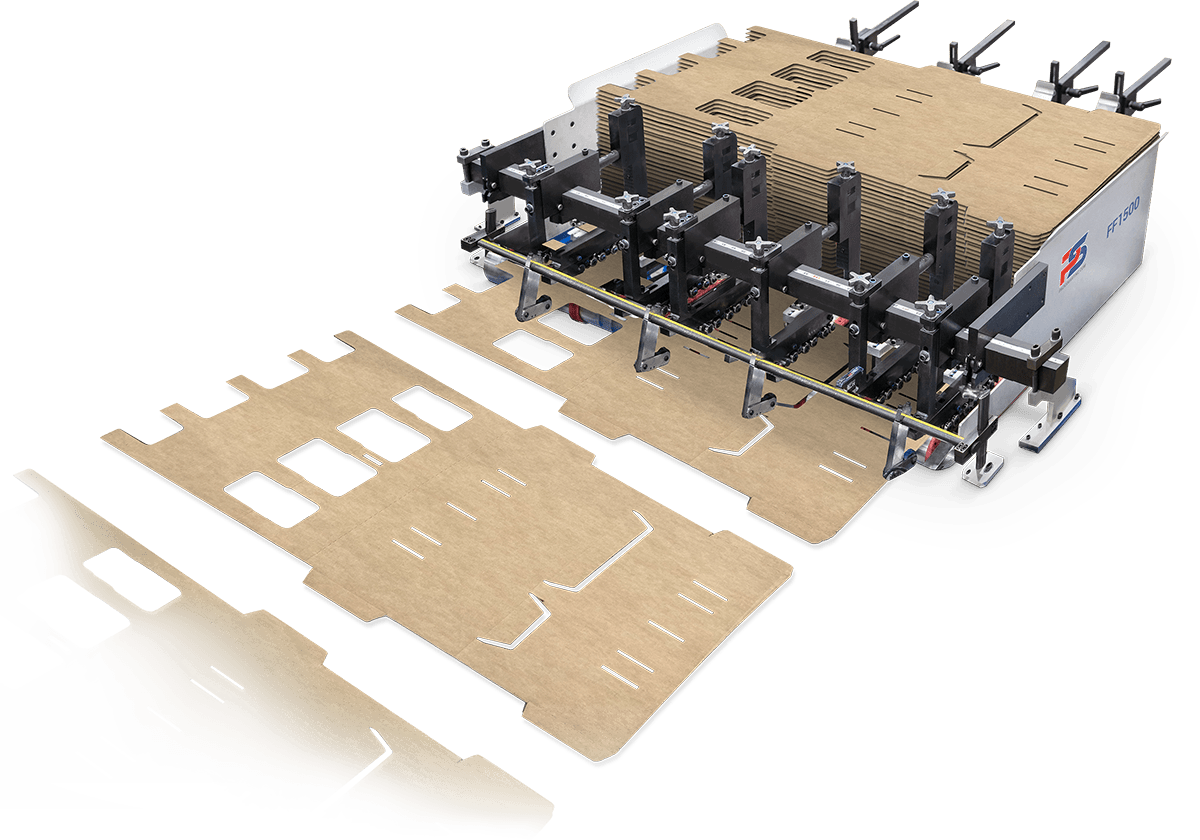

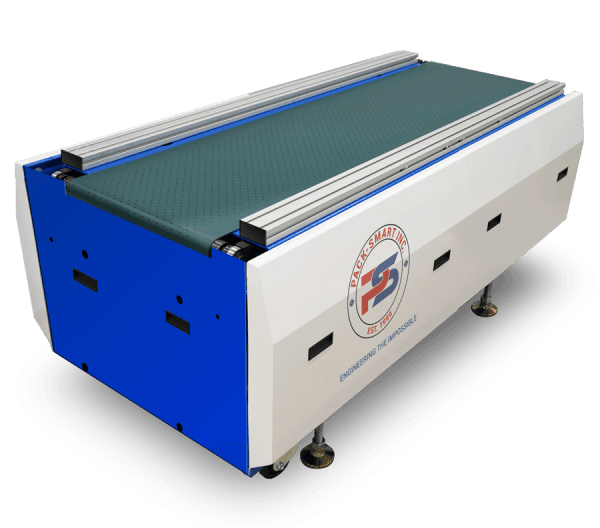

The FF Series Friction Feeder can handle the lightest paper and is equally at home when dealing with heavy stock materials when called upon.

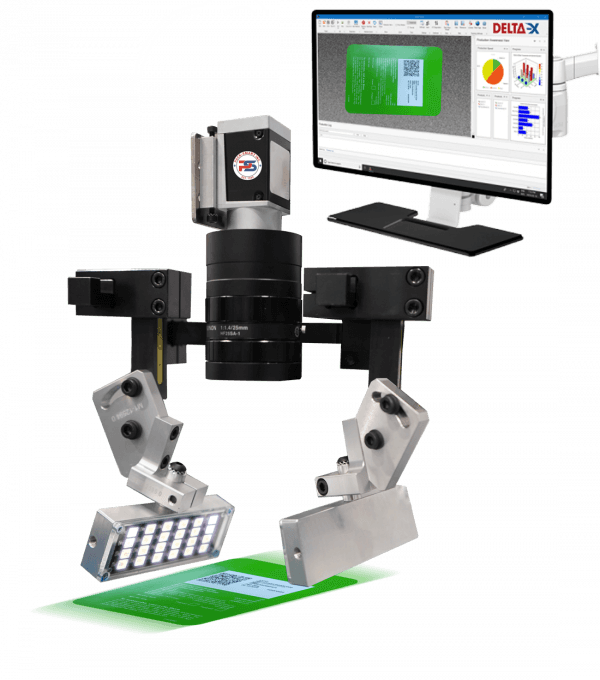

The VSC-1000 Vision System offers state-of-the-art vision scanning and real-time image processing, ideal for high-speed production environments.

High torque servo driven vacuum transport conveys products at accurate speeds and controls product placement with 8 selectable vacuum zones.