Rotary Pick and Place Series

Consistently feed, insert, attach, and batch delicate materials and oddly shaped products at 30,000 PPH, with vacuum pick & place motion and ±0.02″ placement accuracy.

Combine folding, gluing, affixing, personalization, and sorting in a single pass.

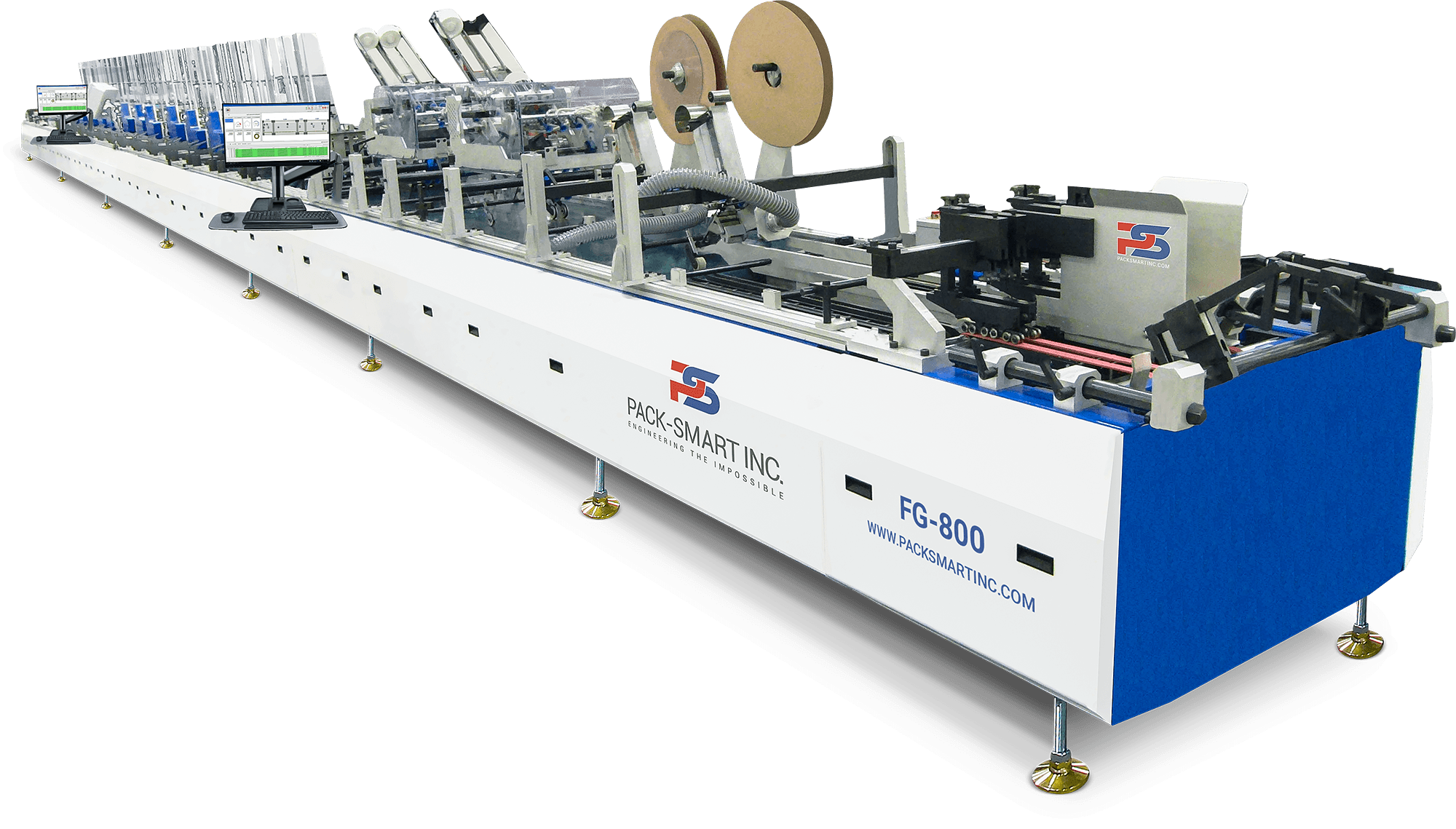

The FG-800 is designed to give the tools and flexibility needed to explore new manufacturing opportunities in the folding carton and specialty finishing world. The alignment of cartons is handled by a state-of-the-art registration module, which employs innovative servo technology making setups swift and effortless.

High Value Carton

Auto-Erect Cartons

The process flow for the FG-800 Rigid Window Affixing System is designed to ensure precise, secure, and efficient production of folding cartons. This system integrates each step, from initial material feeding and registration to final gluing and finishing, ensuring high-speed, accurate application with robust security measures.

The FG-800 Rigid Window Affixing System incorporates advanced technologies to enhance its performance and reliability. Key technologies include high-speed friction feeders, precision affixing mechanisms, advanced folding modules, and real-time data management systems. These technologies work together to ensure consistent, high-quality production of folding cartons.

Consistently feed, insert, attach, and batch delicate materials and oddly shaped products at 30,000 PPH, with vacuum pick & place motion and ±0.02″ placement accuracy.

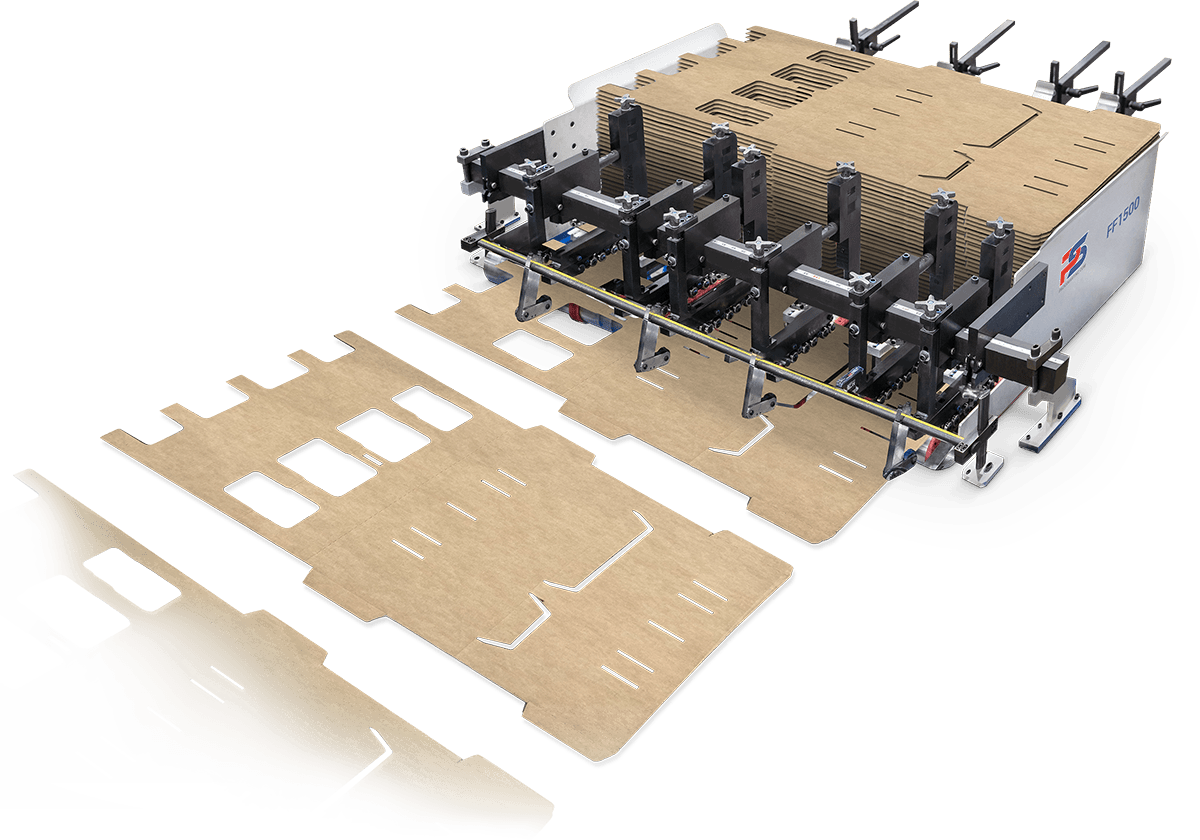

The FF Series Friction Feeder can handle the lightest paper and is equally at home when dealing with heavy stock materials when called upon.

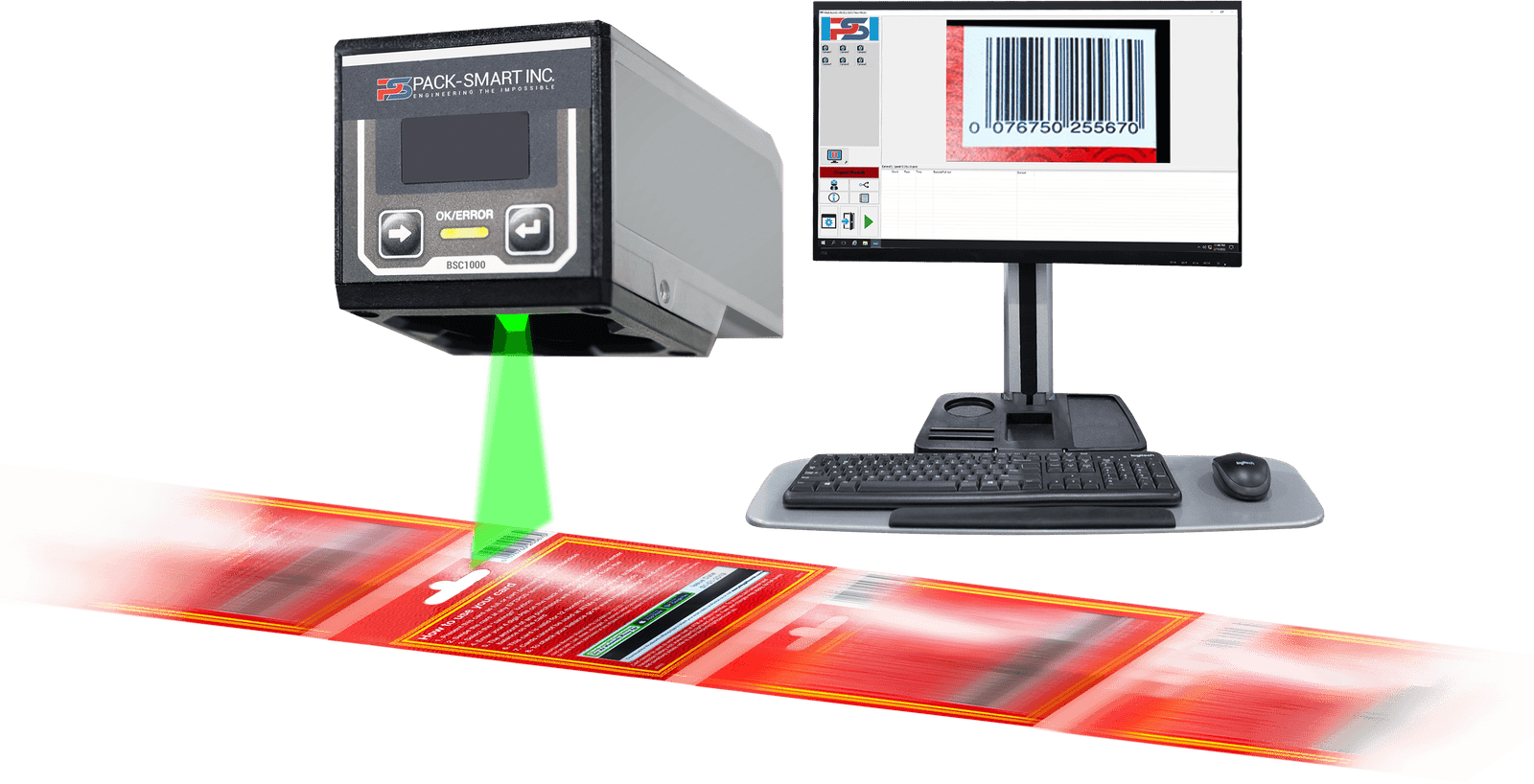

A user-friendly, fully packaged CCD reader, offering easy integration and several configurations to meet a variety of needs.

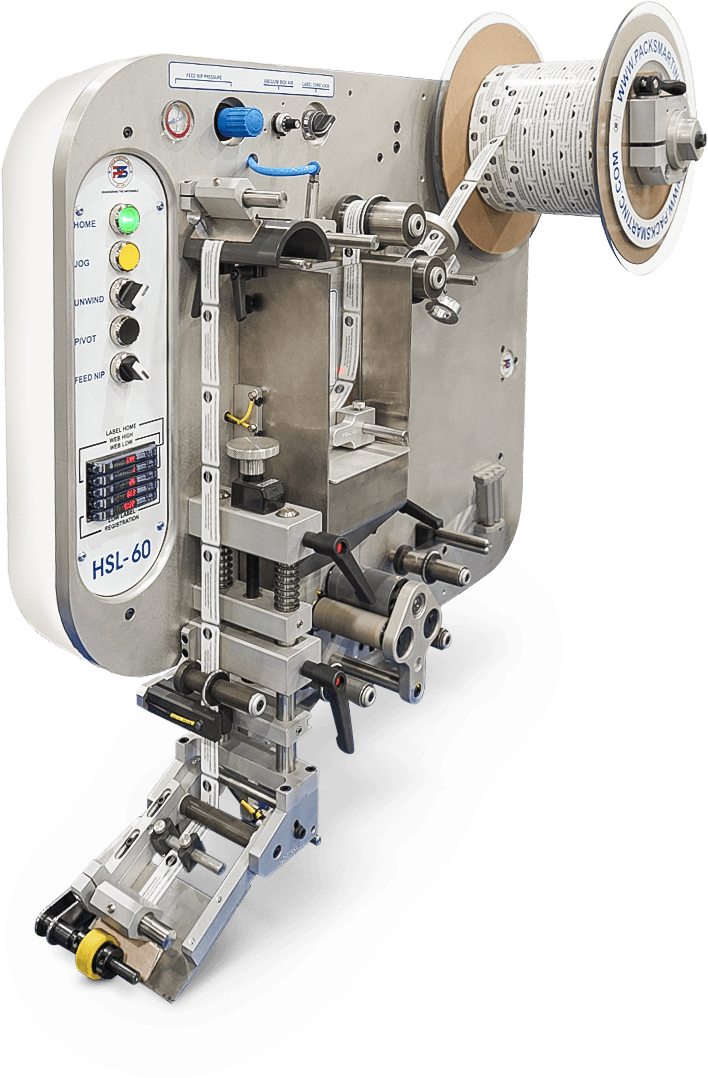

The HSL-60 is a highly versatile module that applies pressure sensitive labels at high speeds and accuracy for the most demanding precision-critical applications.

Reaching up to 600 products per minute, the SF Series is a perfect choice for handling light paper to heavy stock material.