Rotary Pick and Place Series

Consistently feed, insert, attach, and batch delicate materials and oddly shaped products at 30,000 PPH, with vacuum pick & place motion and ±0.02″ placement accuracy.

Inline card to carrier affixing, booklet tipping, 4-corner secure folding/gluing, and DOD personalization.

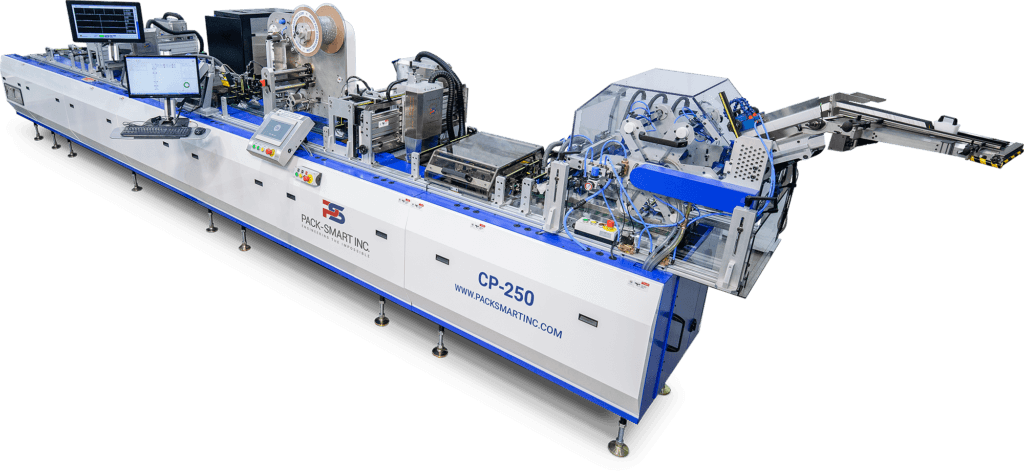

With speeds up to 30,000 PPH, it is ideal for all your closed, secure, and open loop needs. By combining advanced features, uncompromising quality, top throughput, reliable reporting, and an operator-friendly interface, the CP2500-1 can achieve any goal.

Open Loop Cards

Closed Loop Cards

Payment Cards

High-Speed Performance

Integrated Verification Systems

Comprehensive Software & Hardware Platform

Versatile Card Handling

Modular & Adaptable Design

The process flow for the CP-250 Duplex Card Personalization System is designed to ensure efficient, high-speed, and precise personalization of cards. This system integrates each step, from initial card feeding to final quality inspection, guaranteeing accurate and secure card personalization with seamless operation.

The CP-250 Duplex Card Personalization System incorporates advanced technologies to enhance performance and reliability. Key technologies include high-resolution duplex printing for detailed personalization, precision encoding systems for secure data management and automated quality control mechanisms to maintain high standards of card production.

Consistently feed, insert, attach, and batch delicate materials and oddly shaped products at 30,000 PPH, with vacuum pick & place motion and ±0.02″ placement accuracy.

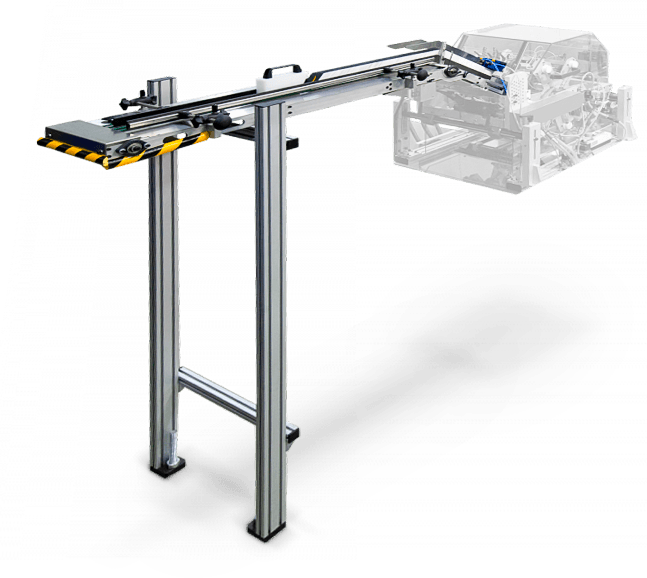

Maximize productivity with the AL Series Powered Autoloader. Designed to extend loading capacities and reduce manual reloading for high-speed applications, ensuring continuous operation and efficiency.

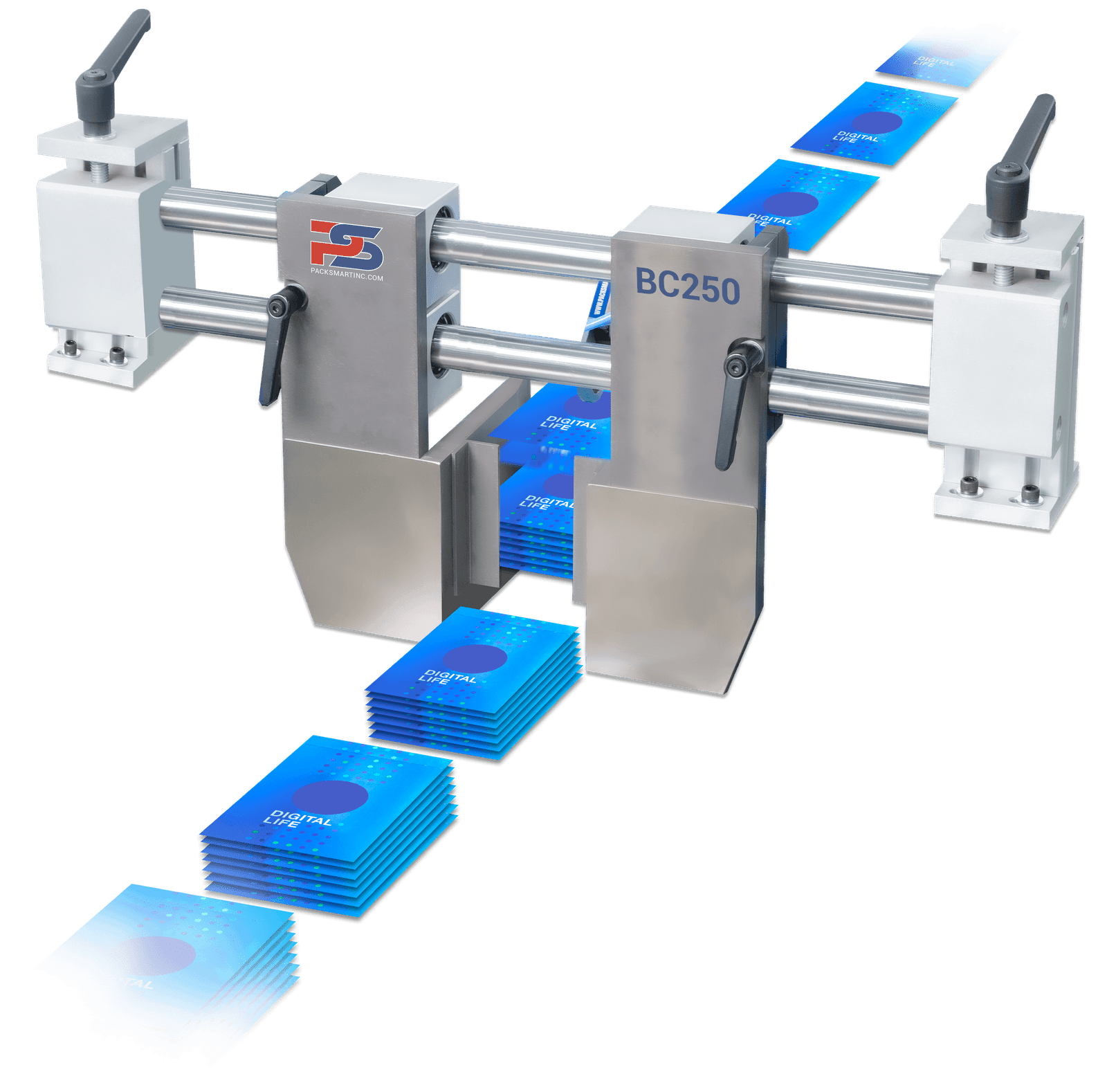

Efficiently batch single products into precise groups with Pack-Smart’s BC Series, designed for a wide range of materials and applications.

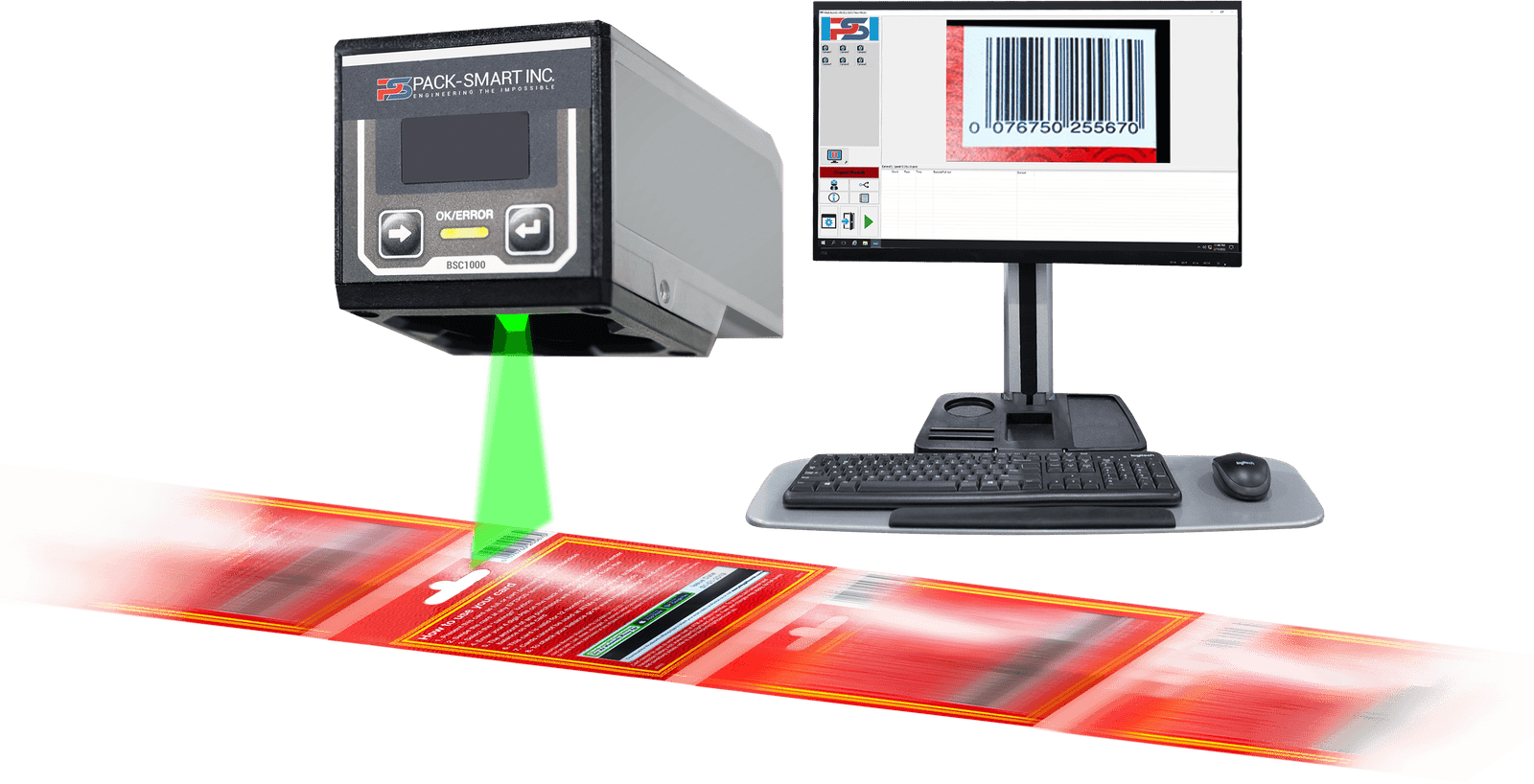

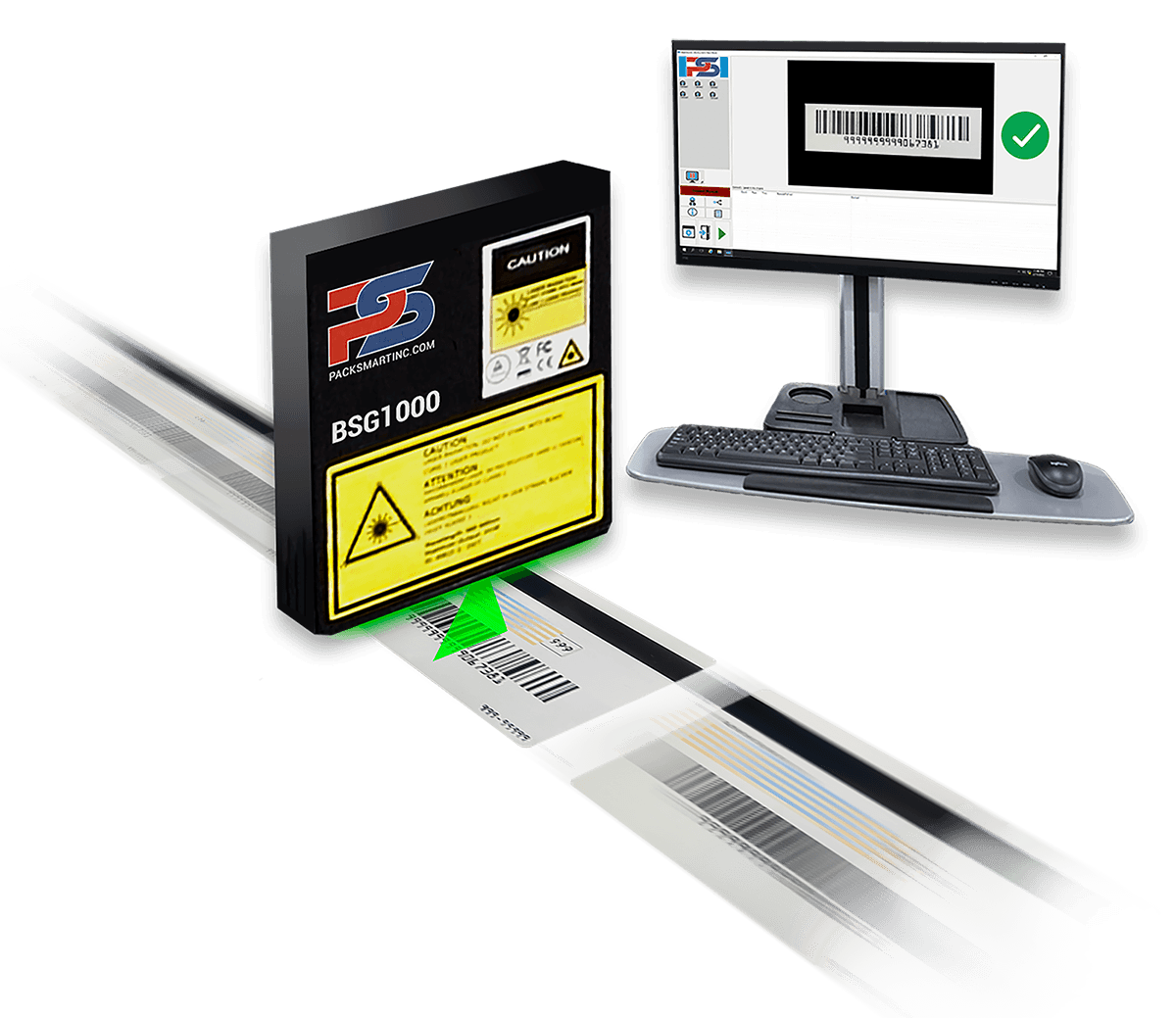

A user-friendly, fully packaged CCD reader, offering easy integration and several configurations to meet a variety of needs.

The BSG-1000 Barcode Scanning and Grading module is designed to ensure that all your barcoded products meet ISO standards for quality.

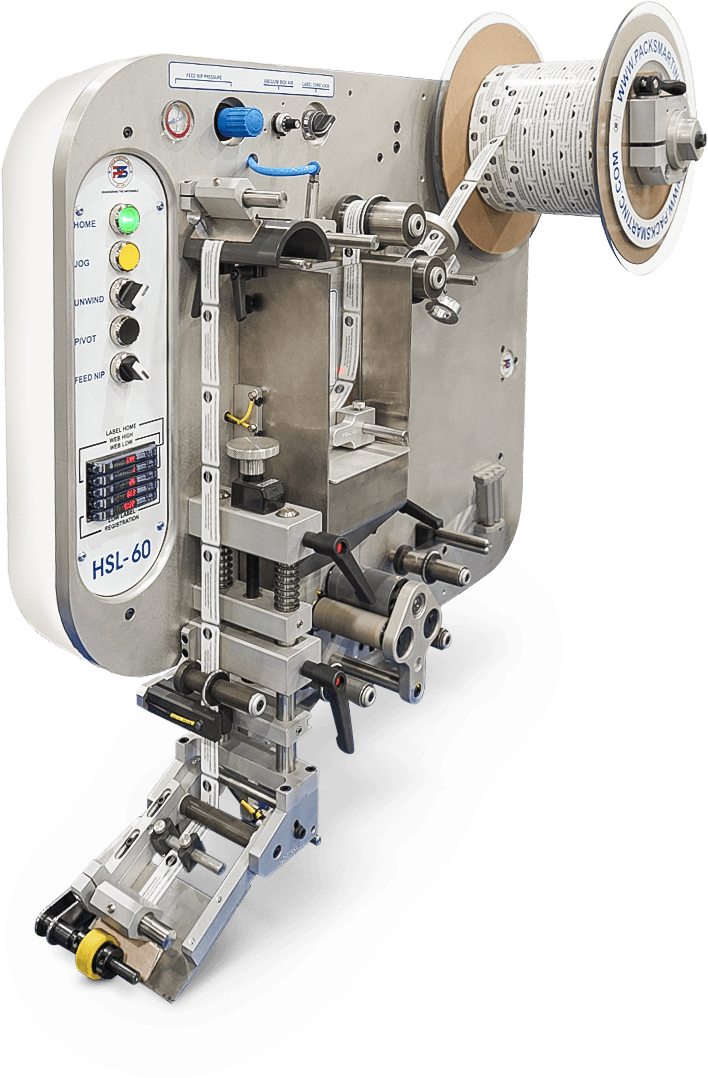

The HSL-60 is a highly versatile module that applies pressure sensitive labels at high speeds and accuracy for the most demanding precision-critical applications.

Smart Jet uses industry leading head technology to deliver UV Cured 600 DPI DOD Ink onto any surface.

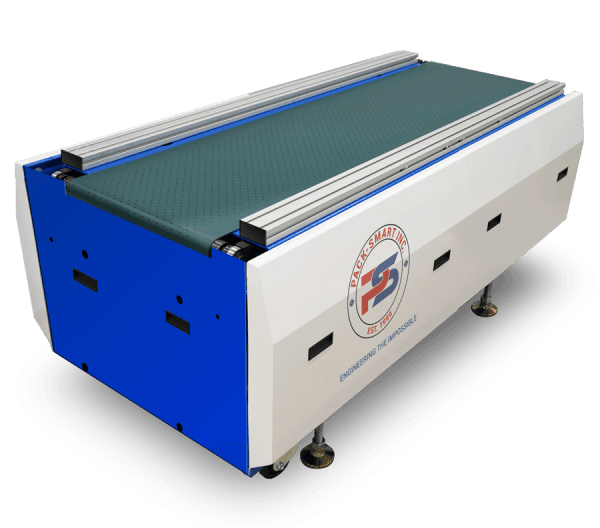

High torque servo driven vacuum transport conveys products at accurate speeds and controls product placement with 8 selectable vacuum zones.

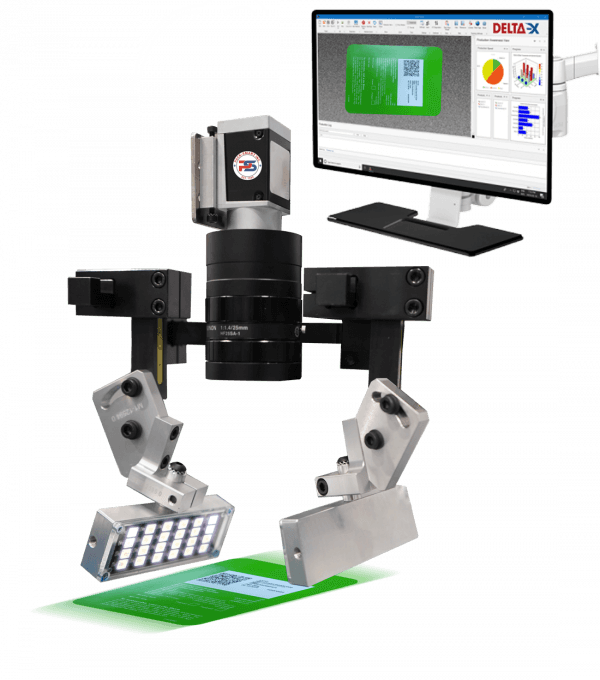

The VSC-1000 Vision System offers state-of-the-art vision scanning and real-time image processing, ideal for high-speed production environments.