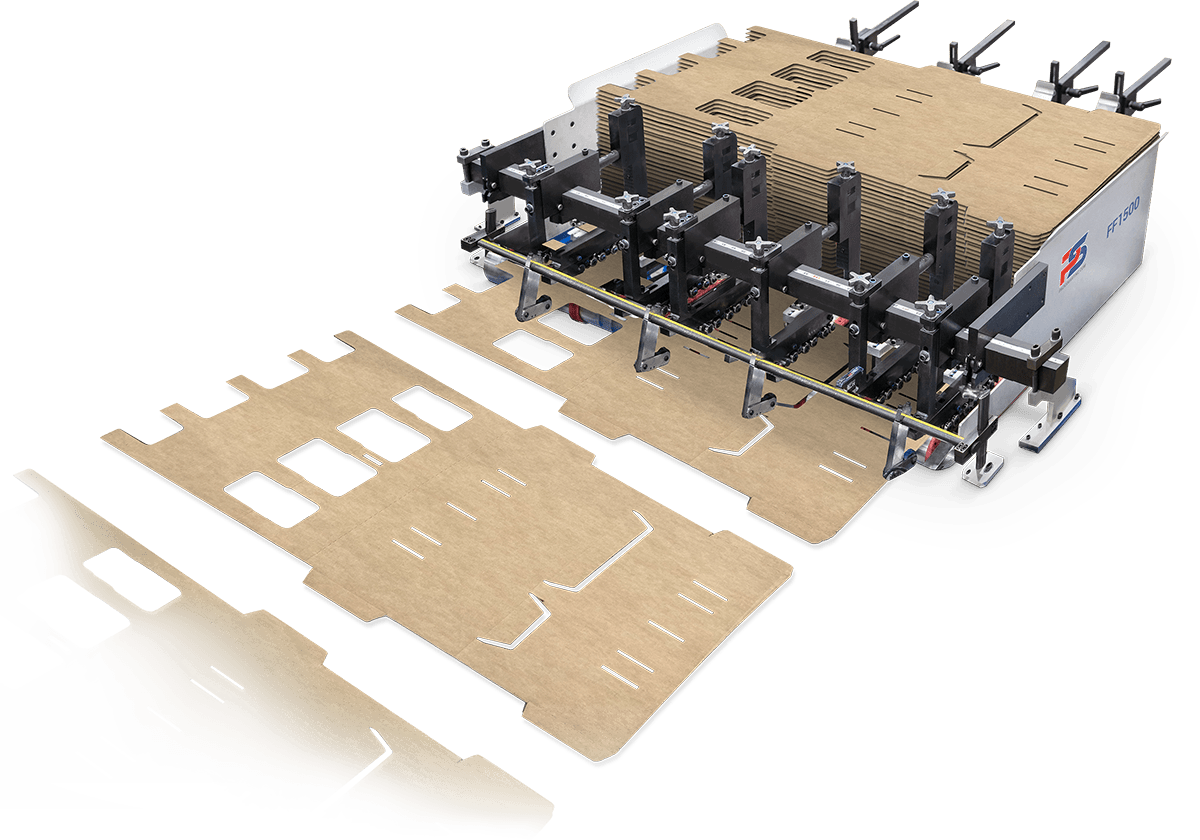

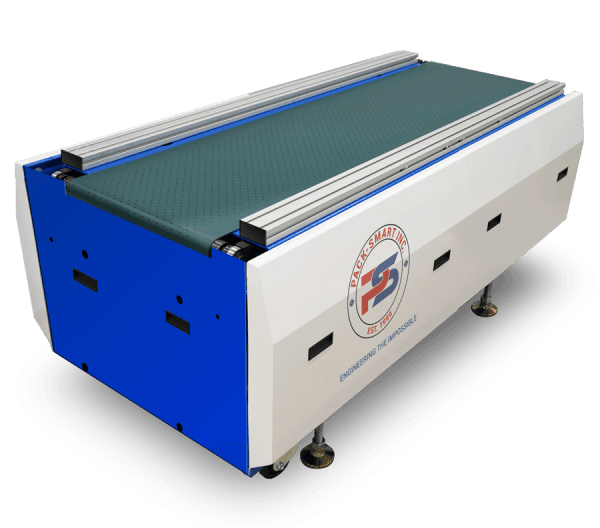

Primary Friction Feeder

The FF Series Friction Feeder can handle the lightest paper and is equally at home when dealing with heavy stock materials when called upon.

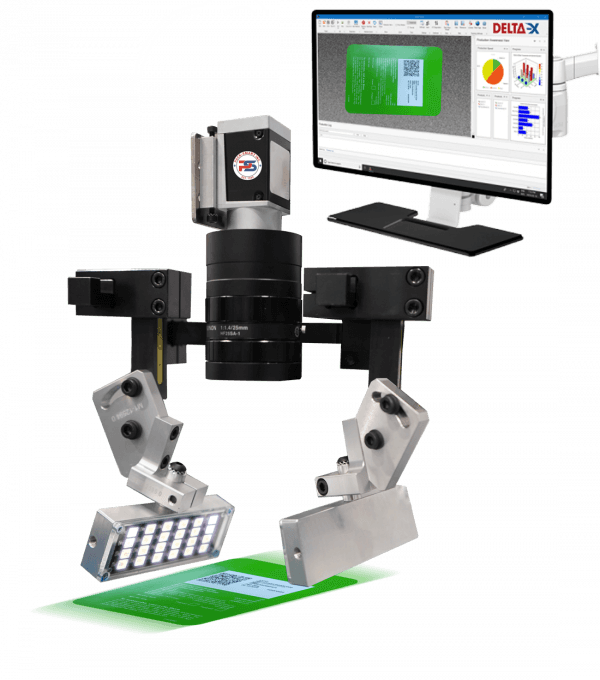

Elevate your production quality with the CC-500, a cutting-edge defect detection system designed to ensure flawless carton output through comprehensive inspection.

The CC-500 delivers unparalleled defect detection for cartons by integrating advanced imaging and processing technology to inspect a variety of materials at speeds up to 150 meters per minute.

This system is adept at identifying a wide range of print defects and substrate inconsistencies, ensuring that only perfect cartons reach your customers.

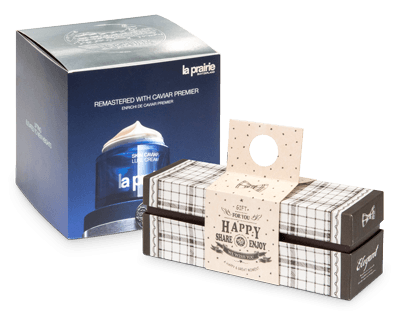

Folding Cartons

Paper & Corrugated Material

The CC-500 Compact Carton Former revolutionizes the way retail-ready packaging is produced by integrating a seamless process flow that ensures efficiency and consistency.

The

The FF Series Friction Feeder can handle the lightest paper and is equally at home when dealing with heavy stock materials when called upon.

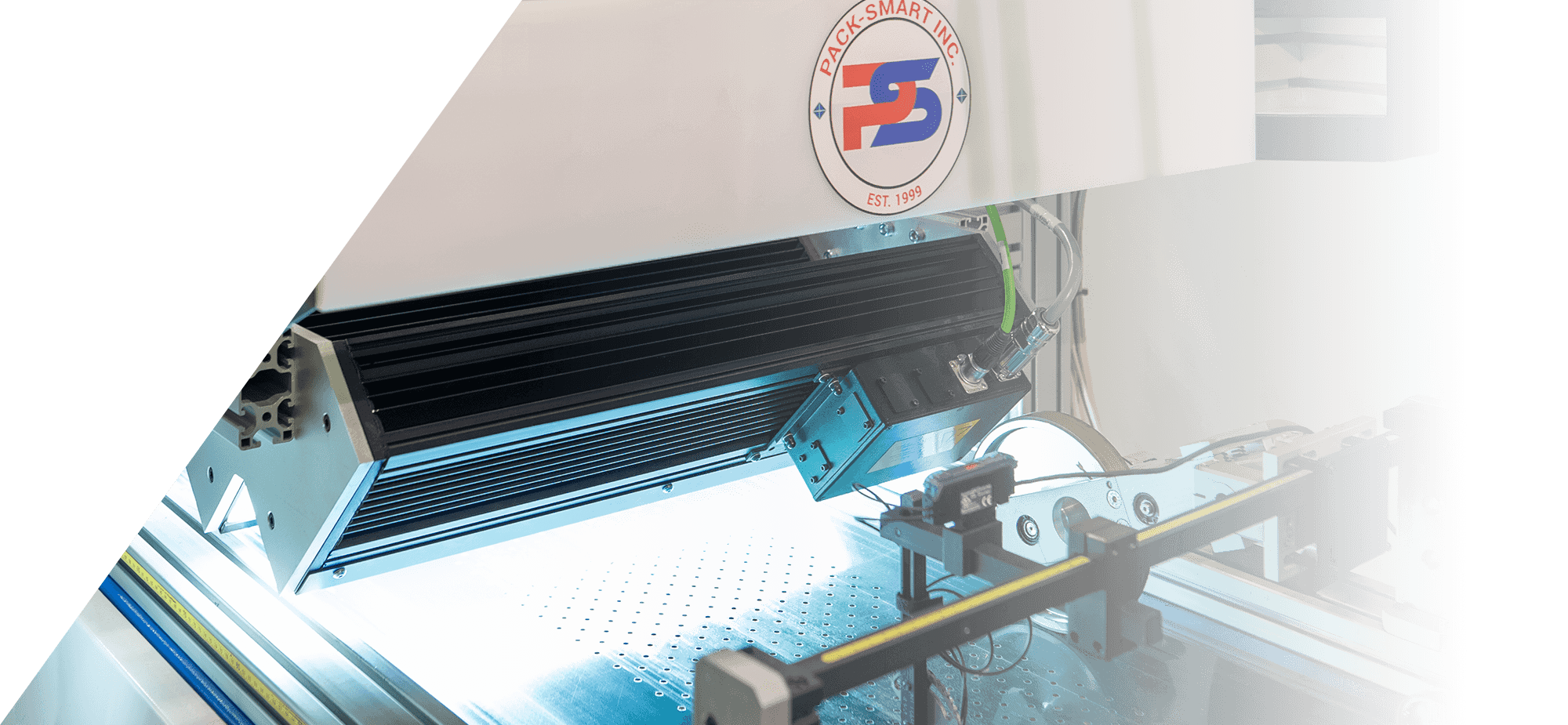

The VSC-1000 Vision System offers state-of-the-art vision scanning and real-time image processing, ideal for high-speed production environments.

High torque servo driven vacuum transport conveys products at accurate speeds and controls product placement with 8 selectable vacuum zones.