Rotary Pick and Place Series

Consistently feed, insert, attach, and batch delicate materials and oddly shaped products at 30,000 PPH, with vacuum pick & place motion and ±0.02″ placement accuracy.

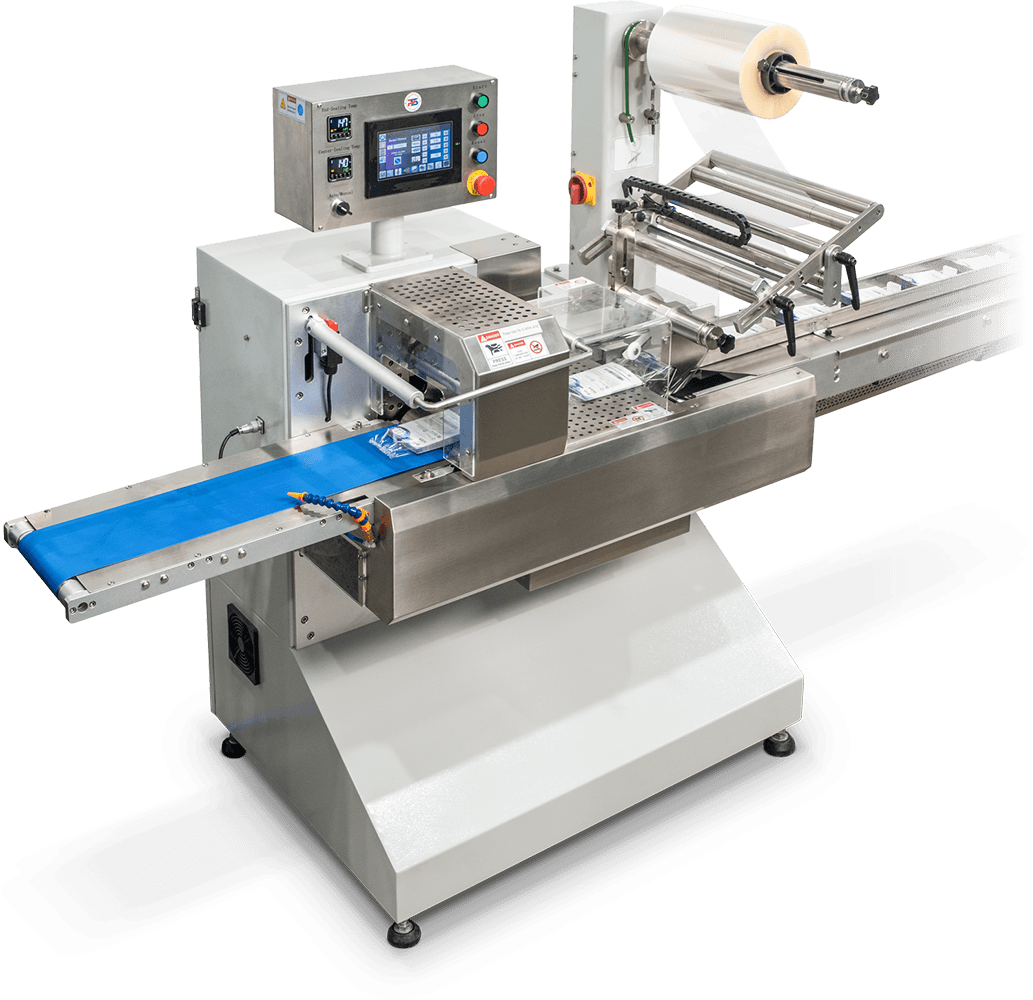

Maximize efficiency with the BA-250, a fully automated pack-out fulfillment system designed for wrapping, inline batching, bundling, and labeling, enhancing throughput up to 2,000 bundles per hour.

The BA-250 Pack-Out Fulfillment System is Pack-Smart’s state-of-the-art solution for inline batching, wrapping, and aggregate labeling, delivering up to 2,000 finished bundles per hour with precision and reliability.

This advanced system seamlessly integrates key functions, including batching, wrapping, scanning, weighing, and quality assurance. Each bundle, case, and pallet is labeled with pinpoint accuracy, streamlining workflow efficiency and ensuring end-to-end traceability for high-demand production environments.

The BA-250 exemplifies streamlined operational excellence, featuring a process flow that optimizes speed and precision. From material handling to the final inspection, each stage of the process is meticulously engineered to enhance productivity and ensure the highest quality output.

The BA-250 integrates a suite of cutting-edge technologies that elevate its operational capabilities. It incorporates advanced sensors for real-time monitoring, precision actuators for accurate material handling, and sophisticated software for seamless automation.

These technologies work in harmony to ensure the BA-250 delivers exceptional performance, making it a robust solution for industries seeking to leverage technological advancements for improved efficiency and quality.

Consistently feed, insert, attach, and batch delicate materials and oddly shaped products at 30,000 PPH, with vacuum pick & place motion and ±0.02″ placement accuracy.

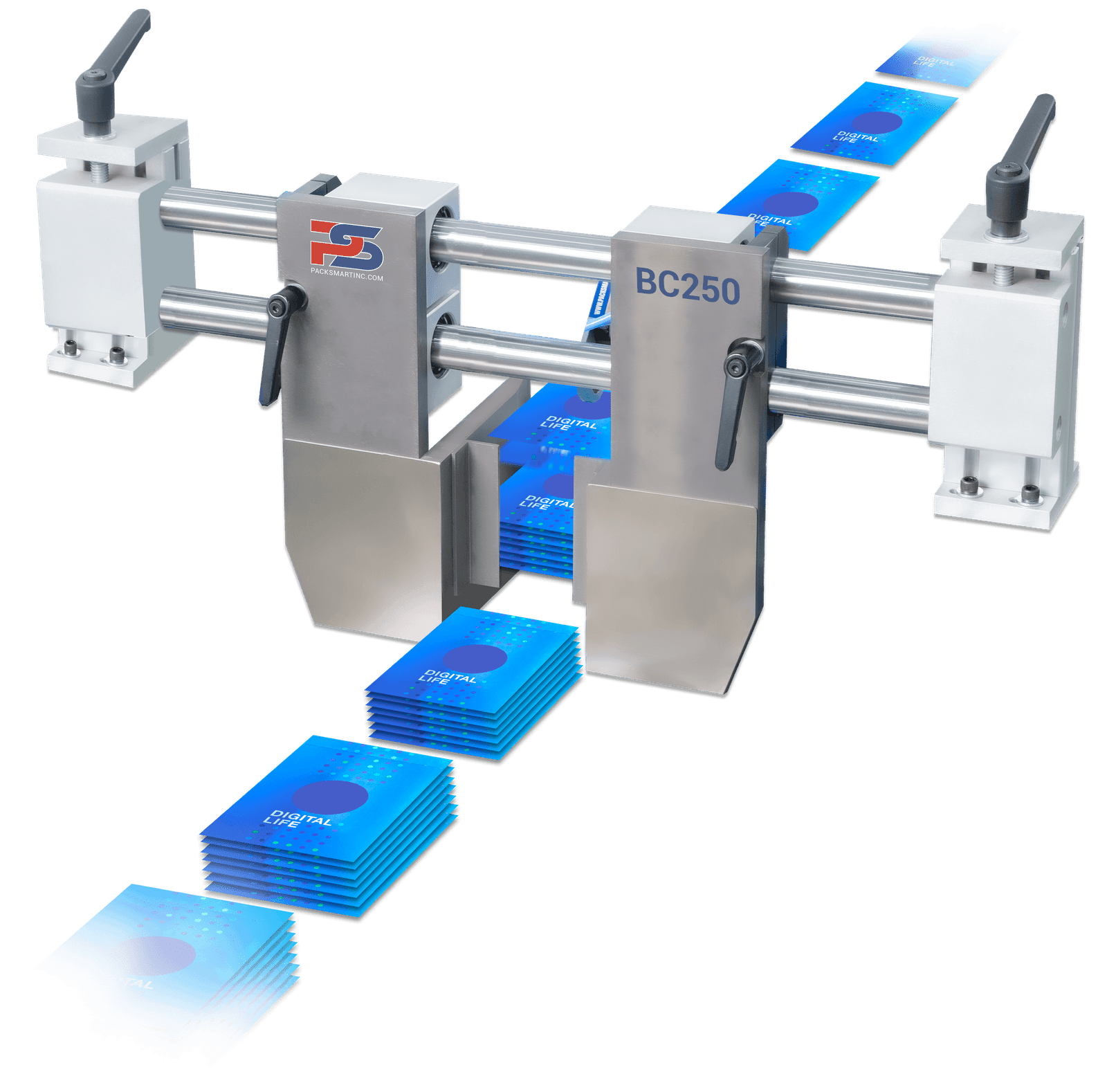

Efficiently batch single products into precise groups with Pack-Smart’s BC Series, designed for a wide range of materials and applications.

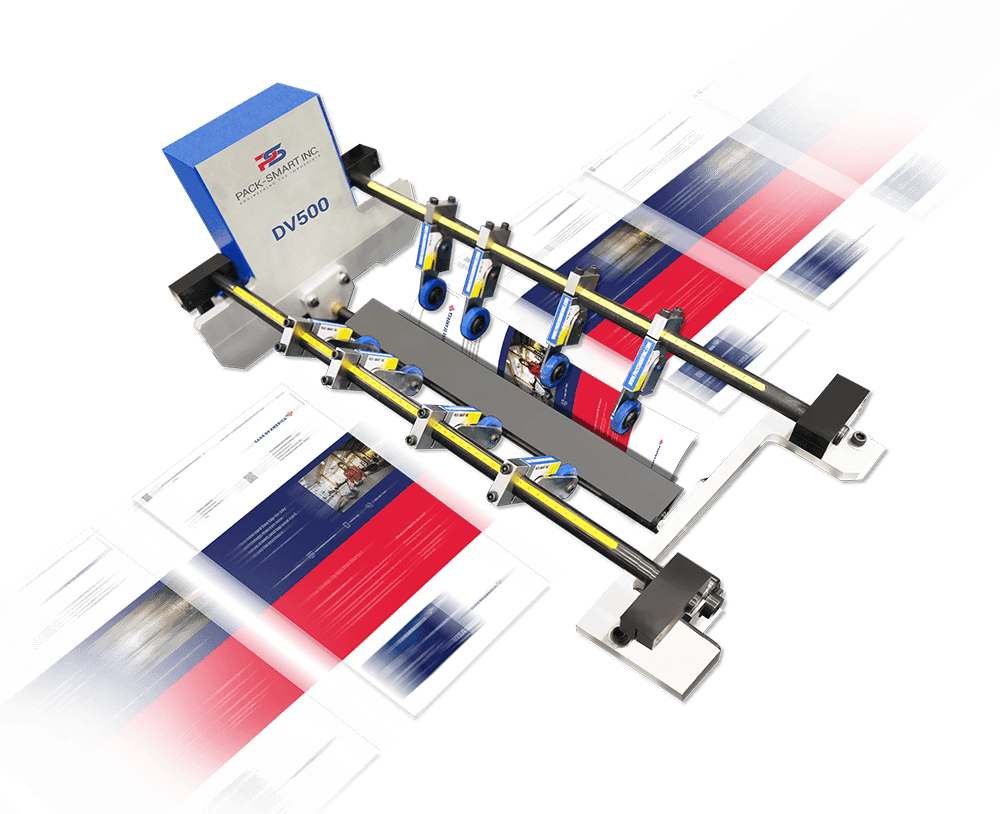

Elevate efficiency with the DZ Series Zoned Divert, designed for precise sorting and high-capacity handling in demanding industrial environments.

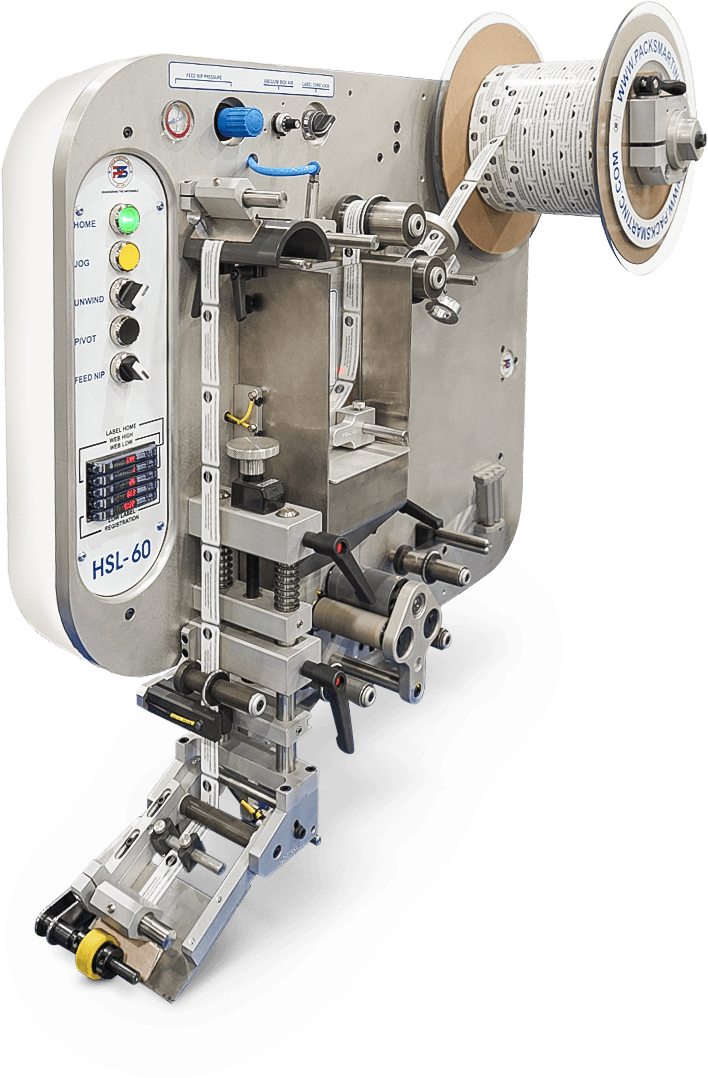

The HSL-60 is a highly versatile module that applies pressure sensitive labels at high speeds and accuracy for the most demanding precision-critical applications.

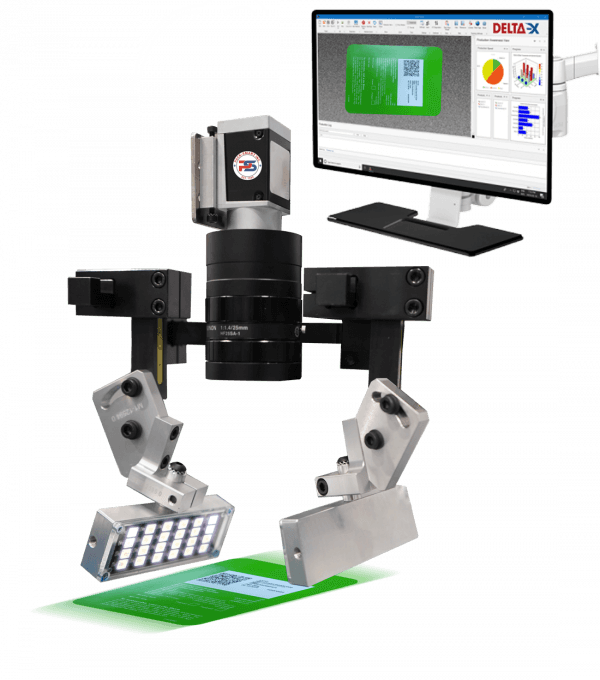

The VSC-1000 Vision System offers state-of-the-art vision scanning and real-time image processing, ideal for high-speed production environments.