Rotary Pick and Place Series

Consistently feed, insert, attach, and batch delicate materials and oddly shaped products at 30,000 PPH, with vacuum pick & place motion and ±0.02″ placement accuracy.

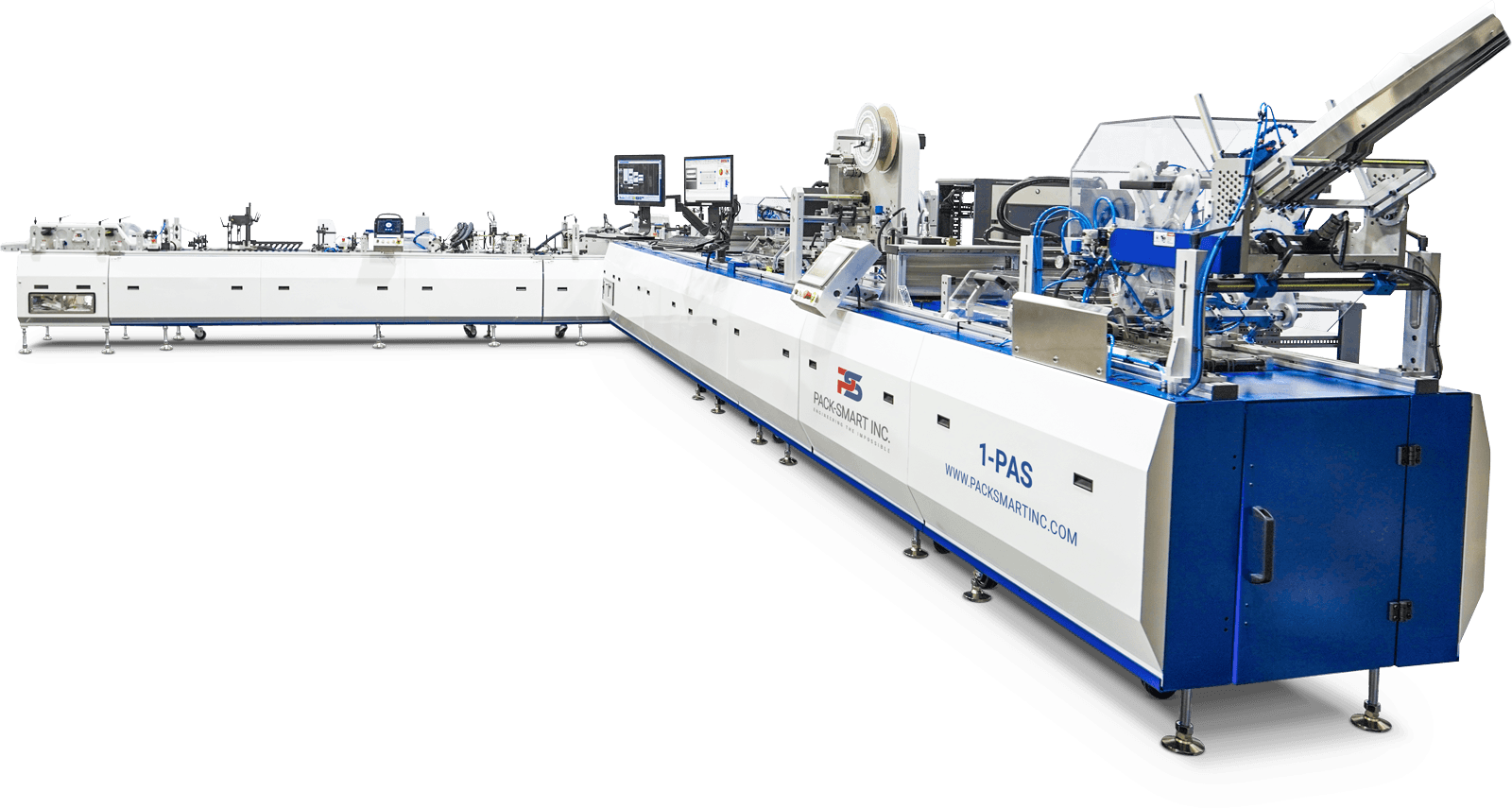

World’s first inline solution for secure open and closed loop card production without compromising quality and lowest cost per piece. High volume personalization, affixing, and tamper evident packaging with end-to-end encrypted reporting.

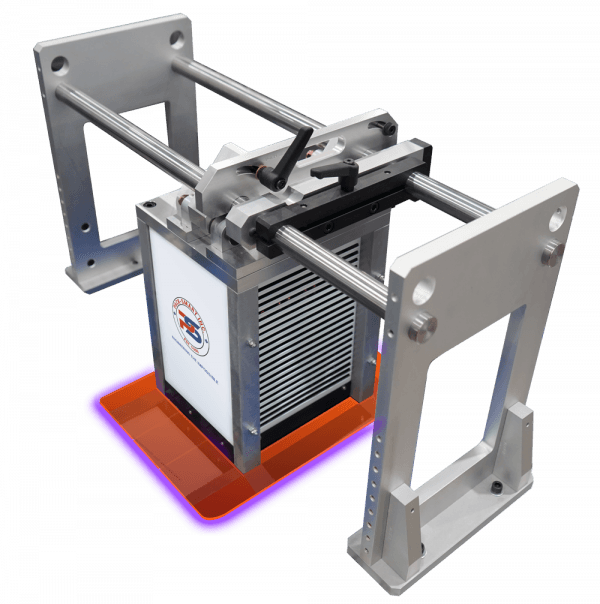

Revolutionize your secure card packaging with the industry-leading 1-PAS system. Designed for 100% tamper-proof results, it features advanced continuous compression technology that drastically reduces seal times to just half a second.

This innovation delivers unparalleled efficiency, achieving up to 10 times the throughput of traditional heat seal processes. Whether you’re producing financial cards, SIM cards, or ID cards, the 1-PAS ensures reliability, precision, and speed, making it the ultimate choice for high-volume inline secure card production.

Our customers consist of brand owners and industry leaders that continually come to us to overcome new complex engineering, manufacturing and distribution challenges. Find out more about the value and innovation we offer in each of these specific market segments.

General

Data Integrity

Batching

Data Mapping & Integration

Product Registration

Producing 100% tamper-proof packaging has never been easier. With continuous compression technology, the seal time is reduced to a half second allowing for 10 times the throughput compared to current heat seal processes. Governed by Delta-X software, 1-PAS allows real-time control of production data while mitigating quality assurance risks with End-to-End Reporting.

Consistently feed, insert, attach, and batch delicate materials and oddly shaped products at 30,000 PPH, with vacuum pick & place motion and ±0.02″ placement accuracy.

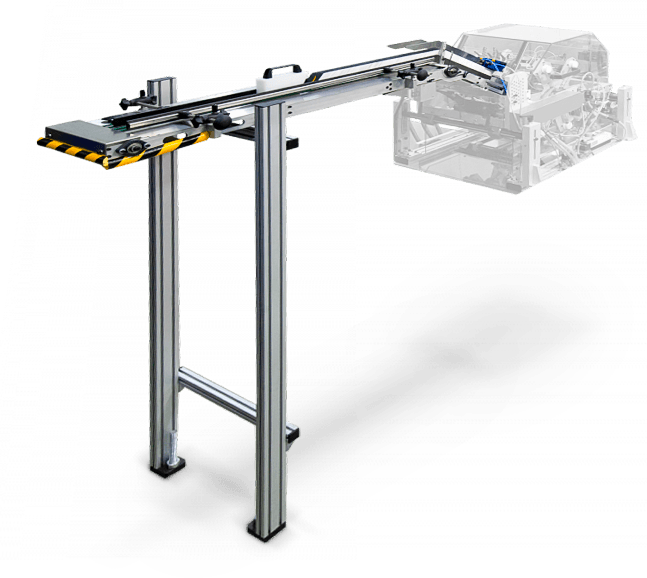

Maximize productivity with the AL Series Powered Autoloader. Designed to extend loading capacities and reduce manual reloading for high-speed applications, ensuring continuous operation and efficiency.

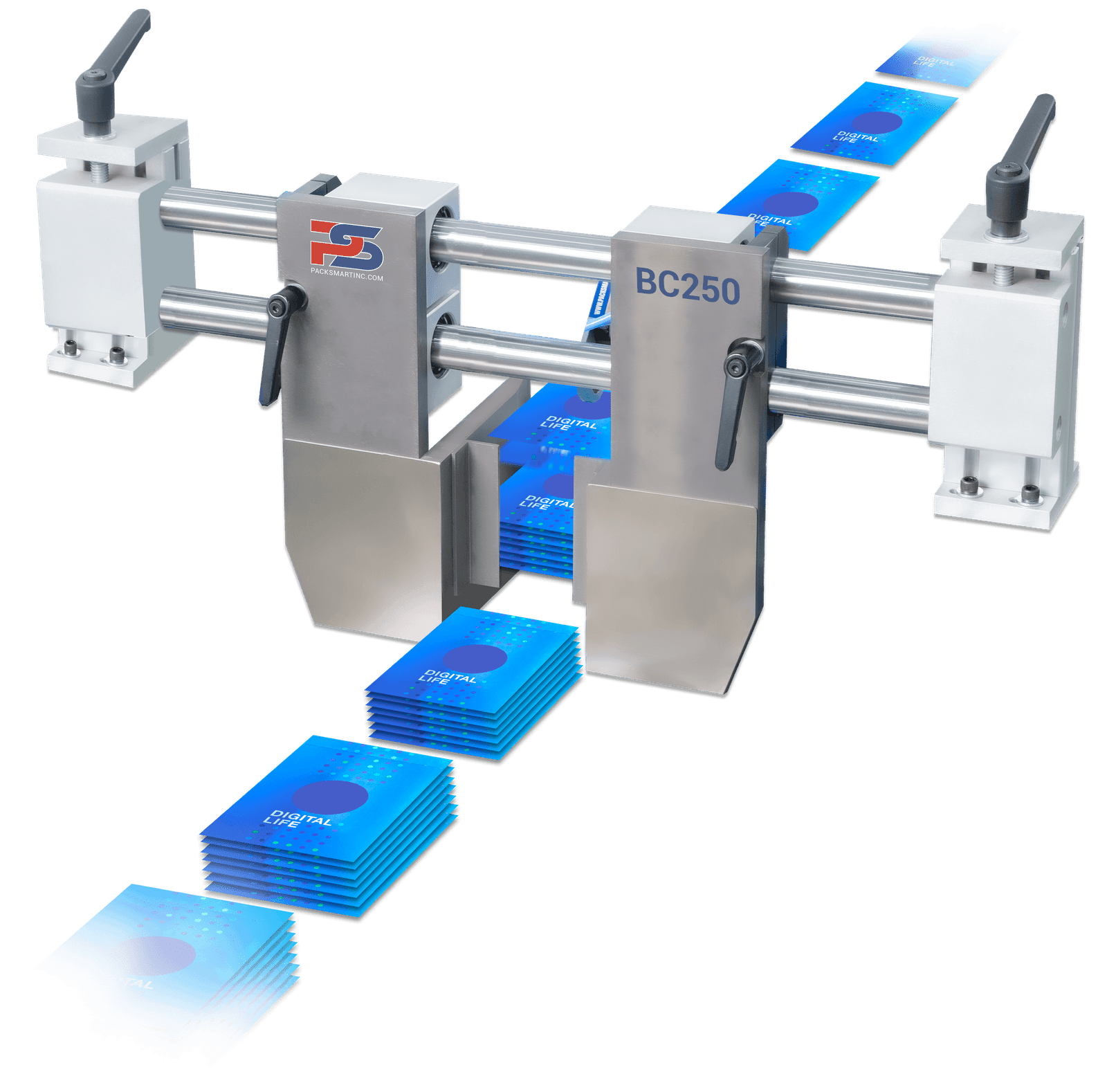

Efficiently batch single products into precise groups with Pack-Smart’s BC Series, designed for a wide range of materials and applications.

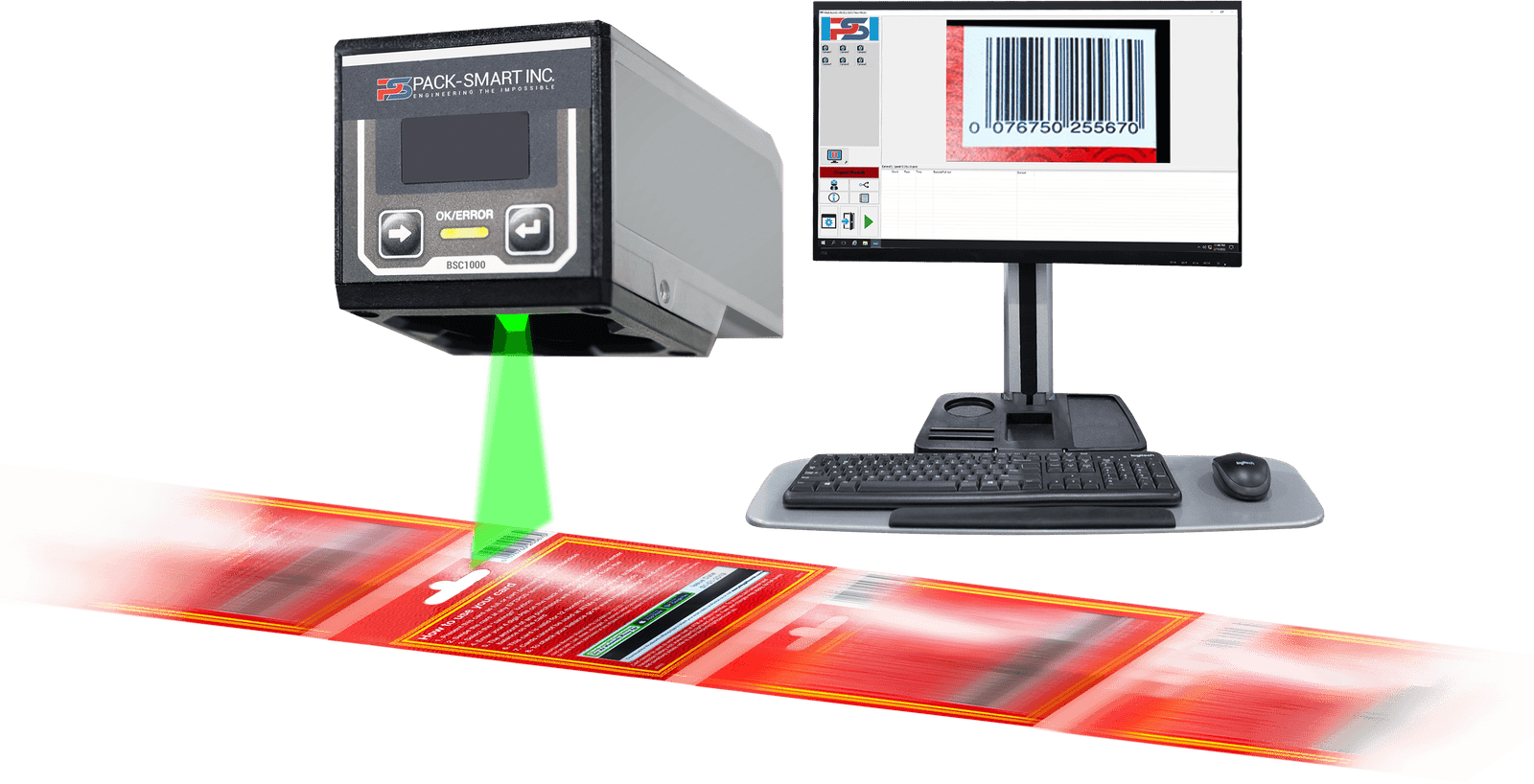

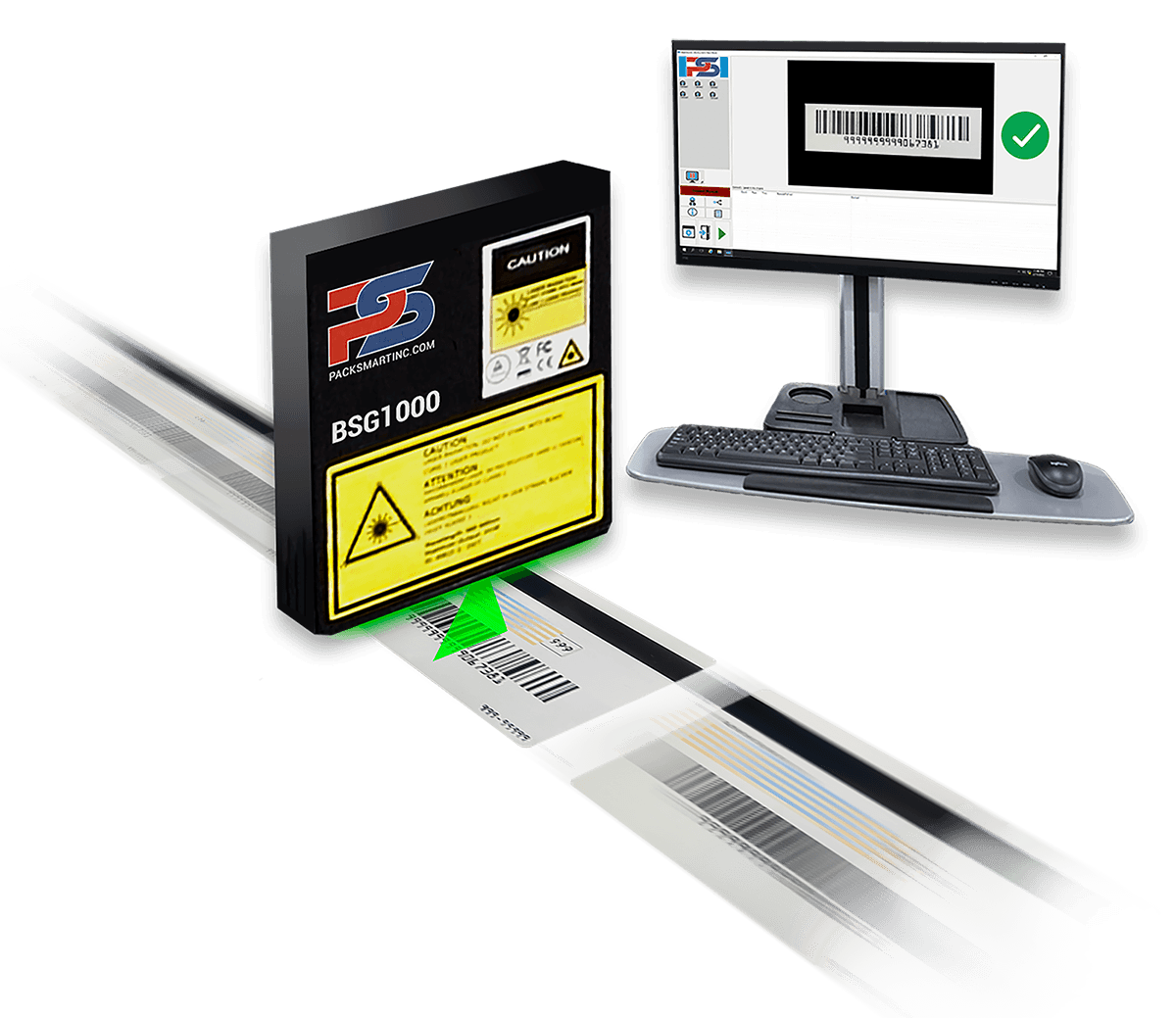

A user-friendly, fully packaged CCD reader, offering easy integration and several configurations to meet a variety of needs.

The BSG-1000 Barcode Scanning and Grading module is designed to ensure that all your barcoded products meet ISO standards for quality.

The CEG-1 Cold Glue System is engineered for high-precision, tamper-proof adhesive applications.

Smart Jet uses industry leading head technology to deliver UV Cured 600 DPI DOD Ink onto any surface.

The UVL-7550 integrates high-power LED UV lamps for superior, high-speed, single-pass drying and curing applications. Offering an eco-friendly solution with significantly reduced power consumption compared to traditional systems.

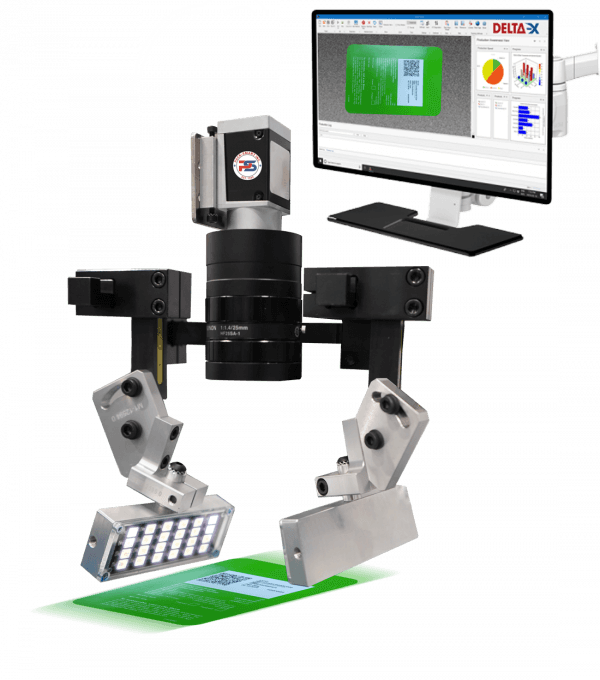

The VSC-1000 Vision System offers state-of-the-art vision scanning and real-time image processing, ideal for high-speed production environments.