Blog

Connected Packaging on the Rise: Bridging the Gap Between Consumers, Brands, and the Future of Smart Packaging

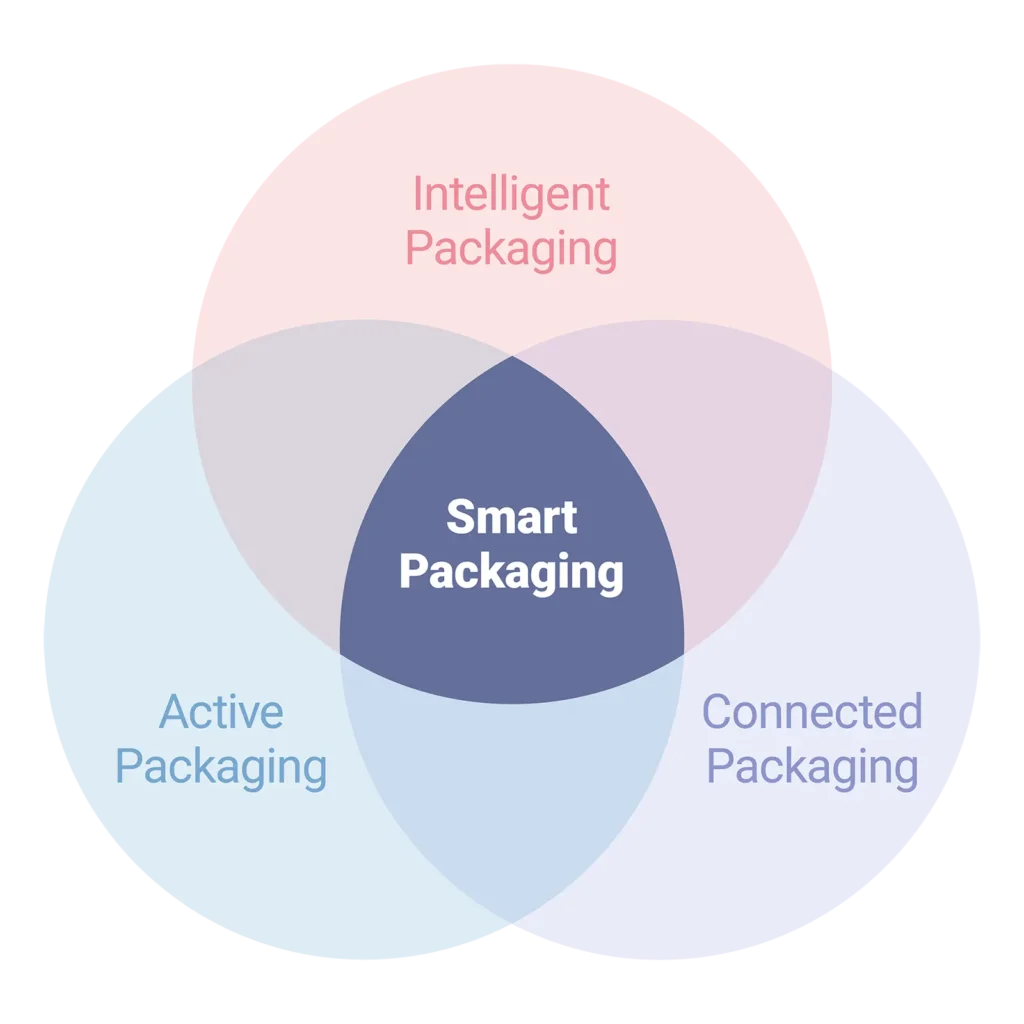

The world of connected packaging is undergoing a transformative revolution. No longer limited to simply protecting or presenting a product, packaging has become a dynamic interface that connects brands with their consumers, enhances product quality, and ensures supply chain transparency. This evolution is driven by smart packaging, an umbrella term that integrates three key innovations: connected packaging, active packaging, and intelligent packaging solutions.

At the heart of this transformation is the need for businesses to adapt to rapidly changing consumer expectations and regulatory landscapes. Shoppers demand more transparency, authenticity, and sustainability than ever before. Simultaneously, brands seek ways to enhance engagement, reduce waste, and ensure product safety. Enter smart packaging—solutions that meet these demands and redefine the relationship between the physical and digital worlds.

This blog explores the rise and benefits of connected packaging, the growing demand for its digital-first interactions, and how it integrates seamlessly with active and intelligent packaging. Together, these technologies form a comprehensive approach to shaping the future of packaging, offering unparalleled opportunities for innovation and impact.

What is Smart Packaging?

Smart packaging refers to advanced systems that enhance product functionality, consumer interaction, and supply chain transparency. It encompasses three core categories:

- Connected Packaging: Links the physical packaging to digital experiences.

- Active Packaging: Interacts with the product to extend shelf life and maintain quality.

- Intelligent Packaging: Embeds sensors to monitor product conditions and provide actionable insights.

These technologies often overlap, creating powerful, multifunctional solutions that meet the growing demands of consumers, brands, and regulators.

Connected Packaging: A Gateway to Digital Interaction

Connected packaging is designed to create a seamless bridge between the physical and digital worlds. It uses technologies like QR codes, NFC tags, RFID chips, and even augmented reality (AR) to enhance the consumer experience and gather valuable insights.

Key Features:

- Two-Way Communication: Brands can interact directly with consumers, fostering loyalty and trust.

- Real-Time Data Tracking: Connected packaging solutions enables supply chain transparency, allowing brands to track products from production to purchase.

- Enhanced Consumer Engagement: Offers features like tutorials, rewards programs, or exclusive content.

- Authentication Tools: Protects brands by allowing consumers to verify product authenticity.

Examples:

- A beverage bottle with a QR code linking to recipes and promotions.

- Pharmaceutical packaging that provides dosage instructions through an NFC-enabled device.

- Apparel with RFID tags enable personalized recommendations in-store.

Connected packaging solutions are particularly valuable in fostering brand loyalty by providing unique experiences and enabling traceability to address the growing consumer demand for transparency.

Active Packaging: Extending Shelf Life and Ensuring Quality

Active packaging interacts directly with the product it contains to maintain or enhance its quality. Unlike connected packaging, which focuses on digital interaction, active packaging operates within the physical realm.

Key Features:

- Oxygen Absorbers: Protect food items by reducing oxygen exposure and extending shelf life.

- Moisture Regulators: Maintain product freshness by controlling humidity levels.

- Light-Filtering Materials: Protect sensitive products like beverages and pharmaceuticals from UV degradation.

Examples:

- Fresh produce packaging with ethylene absorbers to slow ripening.

- Meat trays are designed to inhibit bacterial growth by absorbing oxygen.

- The film wraps release preservatives to maintain freshness during shipping.

Active packaging plays a crucial role in reducing food waste, enhancing safety, and preserving the quality of sensitive goods, making it a staple in industries like food, beverage, and healthcare.

Intelligent Packaging: Real-Time Insights for Products and Supply Chains

Intelligent packaging takes packaging functionality to the next level by embedding sensors and leveraging data analytics to monitor and report product conditions. It combines the physical capabilities of active packaging with the connectivity of connected packaging to deliver real-time insights.

Key Features:

- Environmental Monitoring: Tracks conditions like temperature, humidity, and light exposure.

- Predictive Analytics: Uses data to forecast product performance and shelf life.

- Interactive Consumer Features: Provides dynamic updates about product quality or authenticity.

Examples:

- Pharmaceutical blister packs that notify users of missed doses.

- Wine bottles with sensors that monitor storage conditions and quality.

- Logistics packages with GPS tracking to ensure proper handling during transport.

Intelligent packaging offers unparalleled visibility into product performance, helping brands identify inefficiencies, reduce waste, and enhance consumer confidence.

How These Packaging Categories Combine to Define Smart Packaging

While connected, active, and intelligent packaging has distinct functionalities, their integration under the smart packaging umbrella creates versatile, robust solutions. These overlaps address complex consumer demands and regulatory requirements.

Connected + Active Packaging:

- Interactive labels that also regulate moisture or absorb oxygen.

- QR codes linking to tutorials on how active packaging enhances product quality.

Active + Intelligent Packaging:

- Temperature-sensitive smart films that notify retailers of improper storage.

- Packaging that adjusts its properties based on real-time environmental data.

Connected + Intelligent Packaging:

- NFC-enabled tags that track temperature and share product quality updates with consumers.

- Serialized codes allow users to verify authenticity while brands monitor supply chain conditions.

Together, these technologies redefine packaging as a multifaceted interaction, safety, and data-driven decision-making tool.

The Pack-Smart Inc. Advantage

Smart packaging solutions require a seamless blend of advanced software and cutting-edge packaging automation technologies. At Pack-Smart Inc., we deliver a one-stop turnkey solution, combining our Delta-X platform with a suite of hardware innovations designed to meet the highest standards of precision, efficiency, and flexibility. Together, they enable end-to-end solutions for connected, active, and intelligent packaging.

Delta-X Platform

The Delta-X platform remains at the heart of our smart packaging solutions, delivering:

- End-to-End Visibility: Ensure transparency across every stage of the production and distribution process.

- Track and Trace: Ensure authenticity and supply chain integrity with real-time tracking.

- Interactive Engagement: Enable dynamic consumer experiences through QR codes, NFC tags, and serialized identifiers.

- Regulatory Compliance: Meet global standards with precision and efficiency.

- Predictive Insights: Optimize supply chains and identify risks with real-time data analytics.

HSL-60 High-Speed Labeller: Setting New Standards for Precision

The HSL-60 High-Speed Labeller ensures accurate application of labels equipped with RFID tags and NFC-enabled identifiers. Operating at speeds of up to 25,000 products per hour, it supports traceability and digital interaction, making it a cornerstone for connected packaging solutions. Watch the HSL-60 Labeller in Action

SJ Series Inkjet Printers: Variable Printing at High Speeds

Our SJ Series Inkjet Printers deliver unparalleled precision for connected and intelligent packaging. Designed for high-resolution variable data printing, they integrate seamlessly with serialized QR codes, barcodes, and other unique identifiers—essential for creating traceable, interactive packaging. Watch the SJ Series DOD Inkjet in Action

Pick and Place Technologies: Versatility and Accuracy

The RP Series Rotary Pick and Place andRPP Series Reciprocating Pick and Place technologies provide high-speed, precise placement of active components like oxygen absorbers and intricate packaging elements. These systems support active and intelligent packaging, maintaining product integrity while delivering scalable solutions. Watch the Pick and Place in Action

Friction Feeders: Precision Feeding for Seamless Integration

Our SF Series Secondary Friction Feeder and FF Series Friction Feeder excel in handling materials with precision. These feeders ensure the accurate placement of inserts, labels, and active components, while seamlessly integrating serialized QR codes and RFID tags to support traceability and supply chain transparency at scale. Watch the Friction Feeder in Action

With over two decades of expertise, Pack-Smart Inc. delivers tailored solutions that combine these technologies into unified systems, setting the standard for innovation in the packaging industry.

The Rising Demand for Smart Packaging

As consumer expectations evolve, smart packaging is becoming essential. Here’s why:

- Transparency: Today’s consumers demand to know where their products come from and how they were made.

- Sustainability: Smart packaging supports eco-friendly practices by reducing waste and promoting recycling.

- Safety: Real-time monitoring ensures products are stored, handled, and delivered under optimal conditions.

- Engagement: Interactive features enhance the customer experience, building loyalty and trust.

Smart packaging represents not just the future but the present of the packaging industry. Brands that invest in these solutions now will lead the market in the years to come.

Conclusion

Smart packaging, driven by innovations in connected, active, and intelligent technologies, is transforming the role of packaging in today’s market. From enhancing consumer engagement to ensuring product safety and sustainability, it offers a range of solutions that meet modern demands.

At Pack-Smart Inc., we’re committed to helping brands harness the full potential of smart packaging. Our Delta-X platform delivers cutting-edge solutions that drive efficiency, transparency, and trust across industries.

Are you ready to embrace the future of packaging? Let’s build it together.

Recent Posts

- Combating Gift Card Fraud: How to Ensure Compliance and Consumer Trust Amid Maryland’s SB760 Bill

- Digitization of Packaging: How Delta-X™ Transforms Customer Engagement and Operational Efficiency

- From Plastic to Paper: Key Drivers for Sustainable Gift Cards

- Pack-Smart Inc. Announces JCOP Pay Readiness for its 1-PAS Platform, Setting New Standards in Secure Card Personalization