About Us

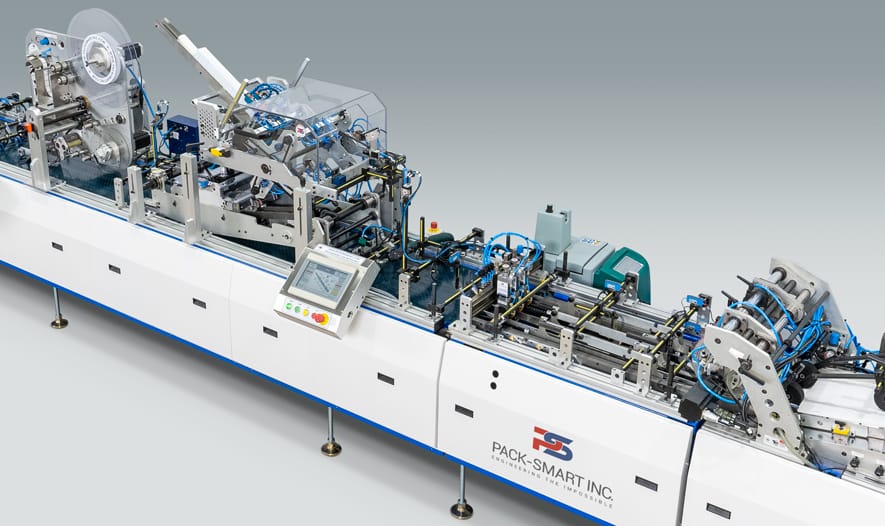

Pack-Smart Inc. is an industry leader in innovative and performance-driven solutions for industrial and digital automation, printing, finishing and packaging.

2000+

Solutions Deployed

From simple specialty finishing to fully integrated assembly, personalization and packaging lines.

90+

New Products Launched

Supporting customers through the product design process, we are ear-heading the release of new products on the market.

29

Countries Worldwide

Our solutions are deployed and utilized in all four corners of the world, but designed and built in Canada.

26

Years in Business

We build solutions to solve current problems and allow customers to be future ready, staying relevant through the decades.

Pack-Smart Inc. specializes in designing, engineering, and manufacturing configurable end-to-end automation packaging solutions.

Focus areas include intelligent and premium packaging, print finishing, product assembly, personalization, traceability, and consumer engagement with expertise in Currency, Secure Payment, ID, Telco, Specialty Print Finishing Solutions, Active & Intelligent Packaging Technologies, Cosmetics, Healthcare & OTC Packaging.

The company aims to deliver complete automation with in-line solutions that achieve traceability with 0%-defect manufacturing, and pride themselves on their packaging efficiency, product integrity, safe transport, business consulting, and product presentation.

Pack-Smart Advantages

Technology-Driven Excellence

Our blend of mechanical engineering, AI, machine learning, and motion controls powers configurable, in-line solutions tailored to match product and material variations automatically.

Global Impact

Trusted by brand owners and industry leaders across a range of sectors, our automation systems have revolutionized production lines worldwide.

Future-Ready Solutions

Whether it’s specialty finishing or fully integrated personalization and packaging lines, our equipment is designed to solve current challenges while enabling customers to stay ahead in a fast-changing world.

Our Vision

Our Three Step Vision is key to our technology development approach. Our aim is to develop technologies accurately, meaning that we must look toward the future in order to anticipate and generate a vision of our customers’ coming needs. We plan our technology development over a three-tiered timeline:

Step 1

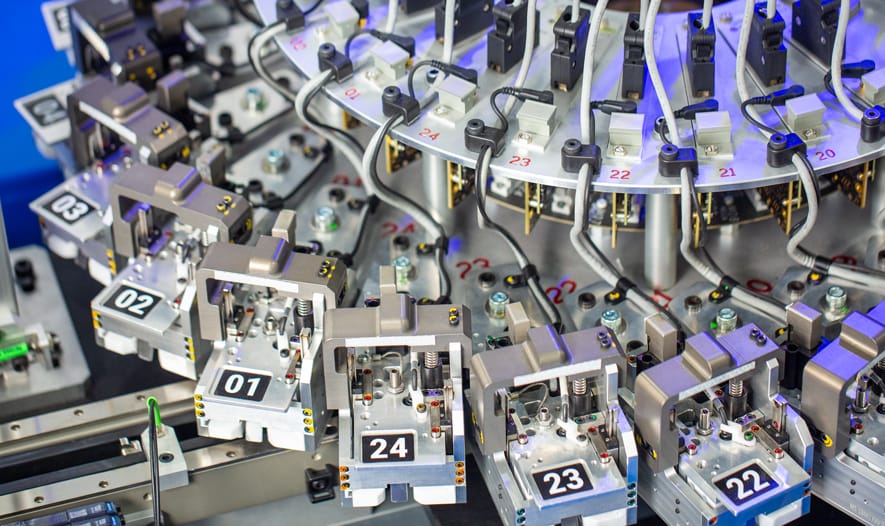

Pack-Smart technologies that are currently available ‘off-the-shelf.’ Proven technologies will be incorporated into new products, such as the Planetary, Rotary Pick and Place, while some current systems will be modified to incorporate them. This will ensure that current products remain market leaders in every aspect of performance, dependability and lowest-possible cost of ownership.

Step 2

Technologies currently in development and are due to be commercially available within 5 years.

Step 3

Technologies target future generations of products within a 10-year window. These are in the tactical emerging phase or are yet unproven, but will ensure that Pack-Smart is prepared for future marketplace progress by focusing extensive research on the technology requirements of future Pack-Smart product generations.

Our Values

Values are the foundations of our business. They reflect the culture, the state of mind, the way in which our business is conducted—both vis-à-vis our customers and our partners, and within the teams.

We are convinced that the more a company is attached to its values, the more its activity performs.

Entrepreneurial Spirit

Pack-Smart is all about embracing entrepreneurial spirit and collaborative creativity—we thrive in high-energy environment that allows us to march through challenges with swift solutions. We work in small teams that, much like our products, are agile, efficient, and innovative, with no compromise on performance or reliability.

Collaborative Creativity

At Pack-Smart Inc., collaborative creativity is the lifeblood of our innovation, where cross-functional teams of engineers, AI experts, and product developers converge to transform complex challenges into pioneering solutions. Our culture thrives on the synergy of diverse expertise, empowering every member to contribute to a dynamic brainstorming process. This collective intelligence approach not only fosters groundbreaking ideas but also ensures that our solutions are finely tuned to the evolving needs of our clients, embodying our commitment to driving progress through unity and shared vision.

Setting New Standards

We are driven by efforts that contribute to setting new standards and are passionate about our future in the digital print and packaging world. The jumps are high, the pace is fast, the work is stimulating, the structure is limited, and innovation is the norm.

Innovation is the Norm

We operate in a state of perpetual innovation, where the status quo is continuously challenged, and the boundaries of technology are expanded daily. Our commitment to pioneering new frontiers is evident in every project, with our team’s relentless pursuit of excellence and efficiency. By embedding innovation into our DNA, we ensure that each solution we deliver is not just a step ahead of the curve but also a catalyst for industry-wide transformation, setting new benchmarks for performance, quality, and sustainability.

Sustainability

Our goal at Pack-Smart Inc. is the long-term, responsible management of our environment through reduced energy consumption, increased energy distribution and improved process efficiencies. We accomplish this by constantly reviewing four main areas of production.

Raw Materials

The raw materials that we use are handpicked, high-quality, and low-mass, as reduced mass leads to reduced energy consumption. Pack-Smart uses the same type of high-grade aluminium that is used today in the aerospace industry.

Lean MFG

Pack-Smart follows strict lean manufacturing practices to constantly develop new and better process improvements. Some of these improvements have led to low-energy servo motors, regenerative power supplies, and planetary gearboxes that can improve the efficiency of your equipment by 50–80%.

Electronics and Controls

At Pack-Smart, we invest heavily in new technologies to keep improving our products every day. Using our Virtual Machine Platform 10 (VMP10), we can build and test new systems virtually, resulting in a faster time to market. The MVP10 can also be used to further improve energy distribution, gather accurate error reporting on systems and all products passing through them, and optimize air consumption and system management.

Energy Management in Pack-Smart Facilities

We aim to minimize unnecessary waste and reduce energy consumption through good management practices, such as our facility’s utilization of over 200 solar panels.

Innovation

In lean economic times, it can be easy for companies to waver in their commitment to innovation. Packaging improvements that hit the market today can take two or three years to demonstrate their profitability and unleash the power of a new or newly differentiated product.

At Pack-Smart, we are committed to measurably and immediately improving the success of our customers, and our infrastructure is based on a set of principles proven to facilitate efficient, leading-edge innovation.

Be a True Believer

Leading packaging professionals believe that innovative packaging is good for companies as well as society at large and want to provide consumers with quality goods that retain their integrity, shelf life, and other important characteristics. They take it upon themselves to constantly research the marketplace to identify growth opportunities. This is a practice not just for top management, but for packaging R&D groups as well.

Empower Engineers

Packaging engineers can get bogged down in day-to-day details. Don’t be afraid to empower engineers and provide them with packaging-specific data to help navigate the challenge. The process is more than just using packaging to develop a solution. Consumer behaviours, wants, and needs will inform the best strategy, so engineers need the right data to justify the solutions they offer.

Break Down Walls

You don’t need X-ray spectacles to see that information shouldn’t be hidden behind departmental barriers or organizational “walls.” It’s important to share consumer insights with all teams and personnel that could contribute to the improvement of packaging platforms and formats.

Work Hard to Work Together

It’s especially critical to ensure that marketing and technical teams work together to prevent tensions from arising. Engineers and technical R&D professionals may suspect that marketing doesn’t thoroughly understand issues of technical capability, while marketing pros may feel that tech teams are obstructing positive momentum.

Define the Common Goal

The key is for all departments to understand that each has a vital role to play in packaging improvements, and that everyone has the same end goal. Packaging innovation design doesn’t happen in a vacuum.

Systematically Anticipate the Future

Innovators don’t rely on the retailer to tell them what consumers want. They continually research new package ideas to meet present and future needs. To consistently meet tomorrow’s needs, innovators maintain a continuous, sustainable pipeline of innovation, planning by two, three, four, or more years. Leading innovators also keep multiple teams working on different timelines. As one team works on plans for the coming year, another works on plans further in the future.

Plan for the Good and the Bad

Planning affords organizational agility. To meet the changing needs of the marketplace, companies must remain flexible—from business processes to packaging line designs and layouts.

We Work with World Class Brands

Pack-Smart customers consist of brand owners and service industry leaders across Pharmaceutical,

Personal Care, Payment, E-Commerce and FMCG markets.