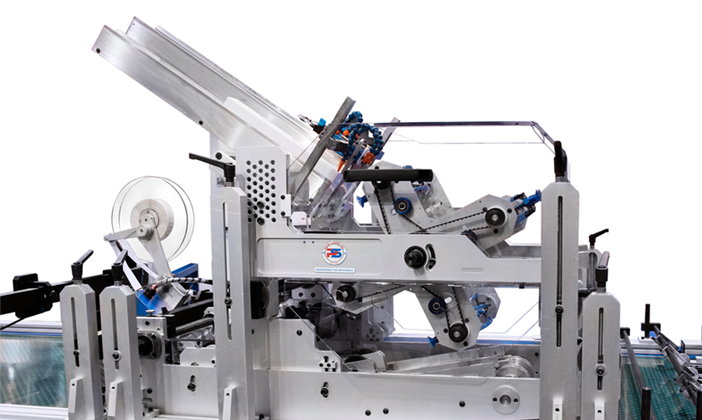

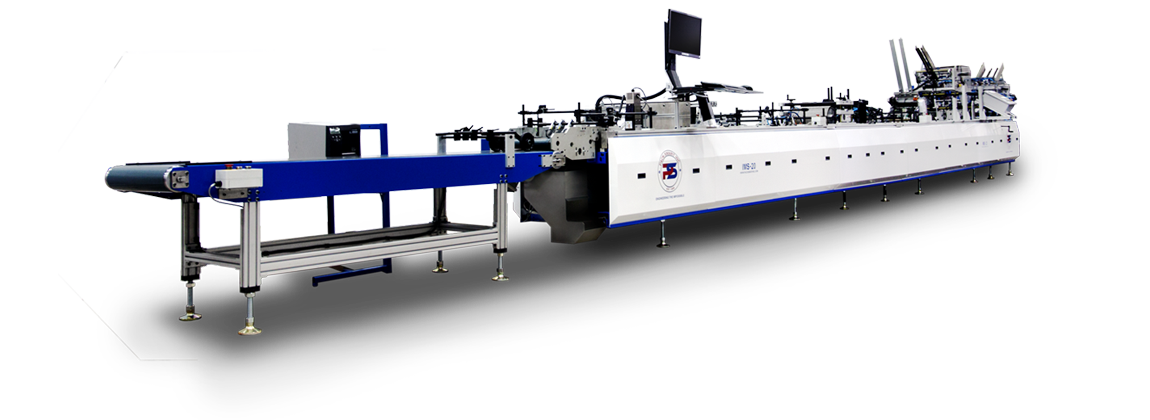

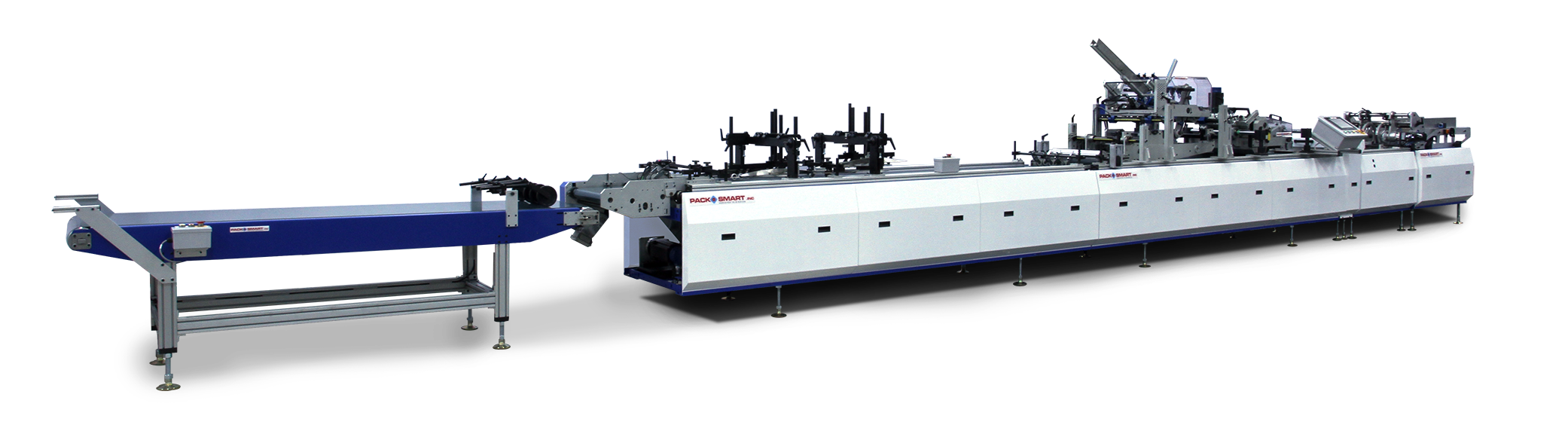

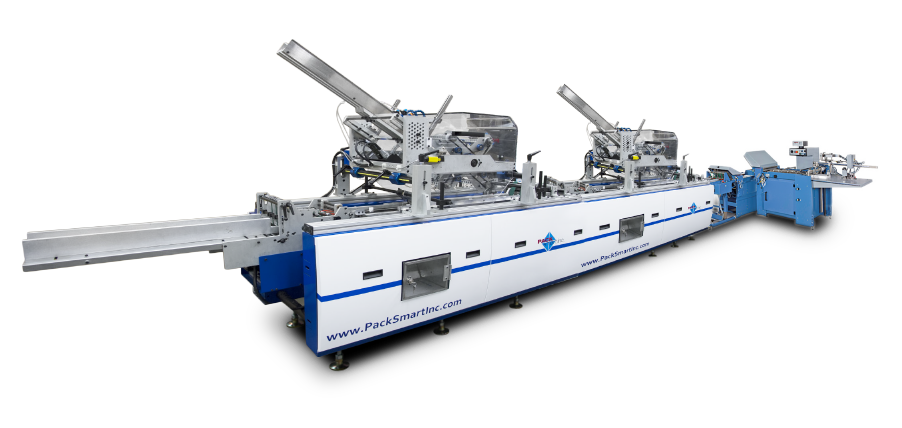

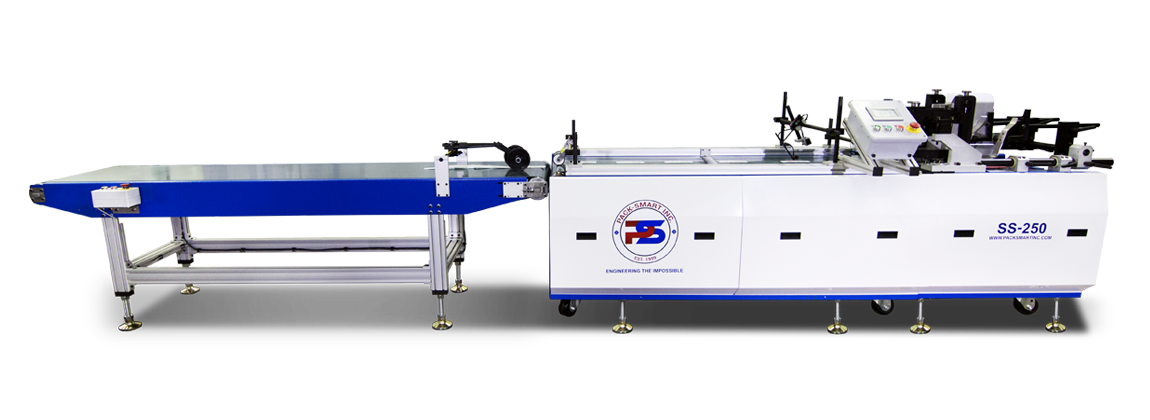

CP2500-1 Card Personalization System

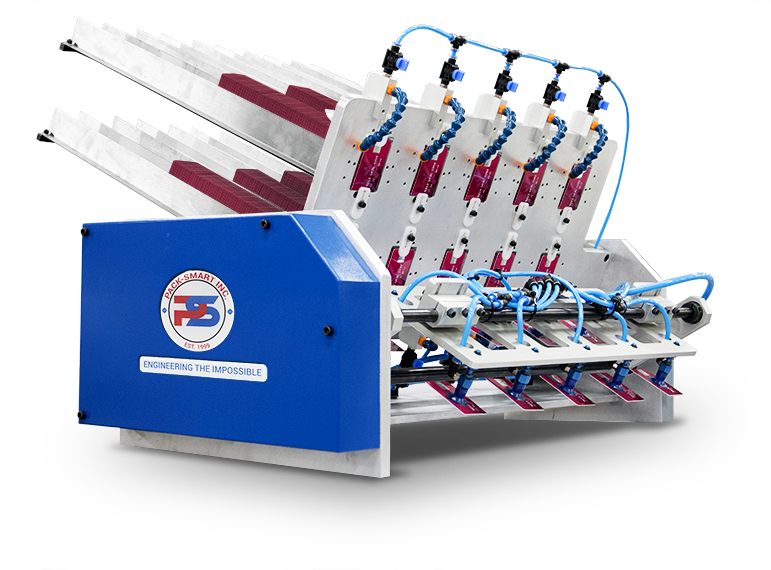

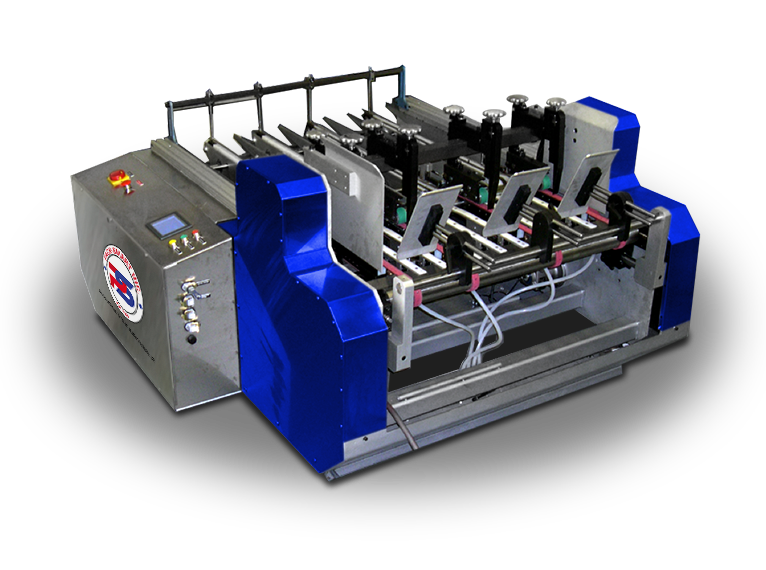

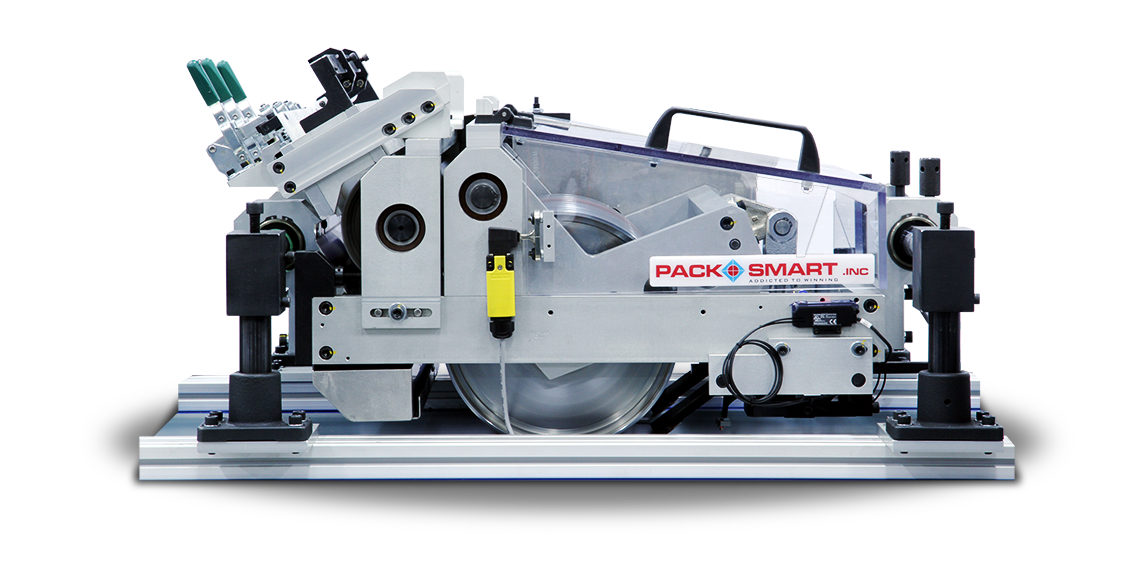

The CP2500-1 from Pack-Smart Inc. is the industry’s most robust and flexible card personalization solution. With speeds up to 30,000 PPH, it is ideal for all your closed, secure, and open loop needs. By combining advanced features, uncompromising quality, top throughput, reliable reporting, and an operator-friendly interface, the CP2500-1 can achieve any goals. The CP2500-1 features a high-speed pick and place feeding system. This system allows for excellent handling of a diverse number of card formats; CR80s, M6 hang tags, and many custom shaped cards. It’s no surprise that it is the preferred choice of global leaders with complex and unique projects, substrates, shapes, and inline processes. The CP2500-1 runs on Pack-Smart Inc.’s virtual machine software/hardware platform, backed up by a rugged fiber-optic network and customizable report compliance interface.

Multiple components, inserting, packaging and component personalization, full data capturing, tracking, reporting & modular design is at the core of all Pack-Smart systems. This building block approach to design allows our customers to tailor their system to their specific needs at any point in time. Prior to purchase, or after owning a system for several years, Pack-Smart is ready to help integrate additional features into your production line. Whether it be the personalization of cards, carriers, or both, we can offer that inline in a single system pass. At Pack-Smart we work with our customers every step of the way and provide continuing support long after the Pack-Smart system has been delivered to your facility.

Speed

Speeds up to 30,000 UPH. Optimize your process with our end-to-end solutions, including batching, wrapping, and labeling bundles.

Versatility

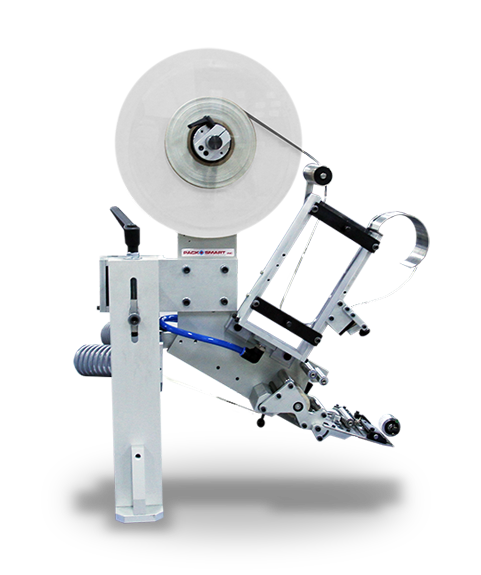

Personalization features include various magstripe label affixing, 1D and 2D barcode printing, and scratch-off label application.

Quality

With integrated verification systems your product is tracked throughout the production process. All errors are diverted, and remakes are initiated, guaranteeing a 100% verified product is delivered.

Our solutions have 3x the accuracy when compared to the next closest competitor and we don’t sacrifice on speed.

Our solutions have 3x the accuracy when compared to the next closest competitor and we don’t sacrifice on speed. Our overall equipment effectiveness(OEE) is above world class. No competitor even comes close to matching our capabilities.

Our overall equipment effectiveness(OEE) is above world class. No competitor even comes close to matching our capabilities. Our commitment to speed, accuracy, and efficiency allows us to consistently produce brand changing product volumes.

Our commitment to speed, accuracy, and efficiency allows us to consistently produce brand changing product volumes.